Prefabricated double-skin wall structure of prefabricated superimposed assembly type pipe gallery and seam structure

A prefabricated and pipe gallery technology, applied in structural elements, underwater structures, building structures, etc., can solve the problems of operation and maintenance loss, local stress concentration, high fraud of underground comprehensive pipe gallery, and improve crack resistance Permeability, improve mechanical performance, improve the effect of bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments, and the purpose and effect of the present invention will become clearer. It should be understood that the specific embodiments described here are only used to explain the present invention and are not intended to limit the present invention.

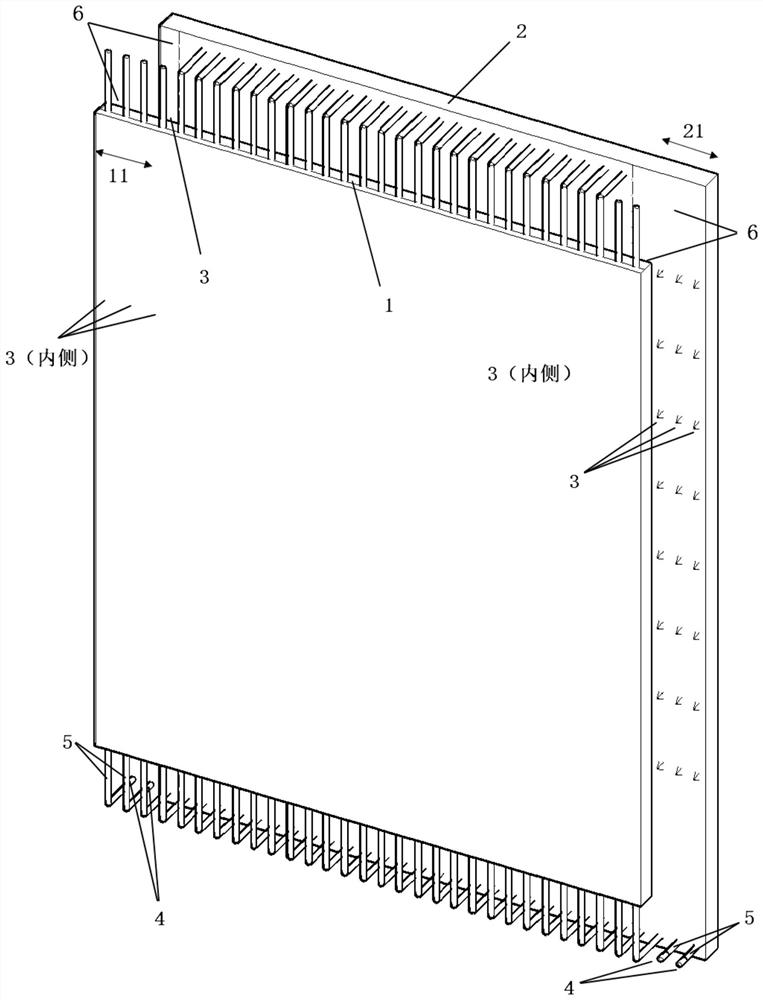

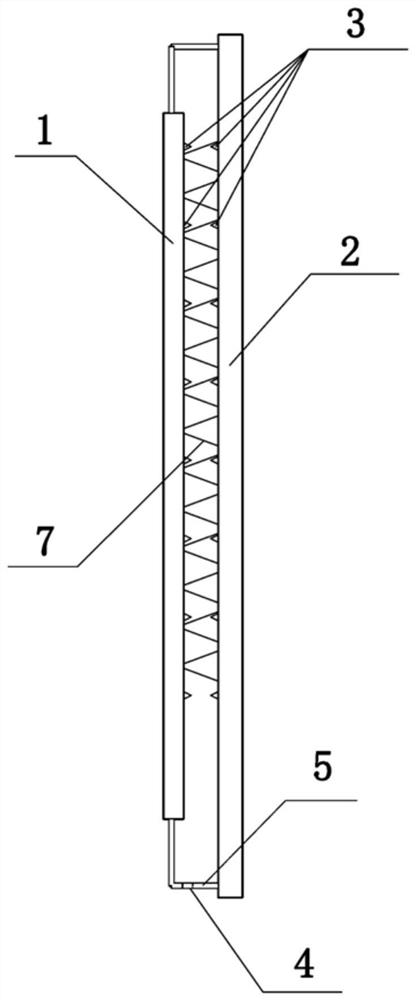

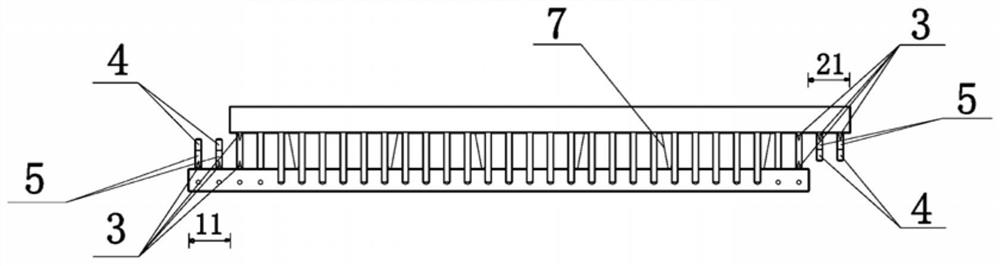

[0030] Such as Figure 1~3 and Figure 5 As shown, the prefabricated double-skin wall structure of the prefabricated composite pipe gallery of the present invention is based on the general prefabricated composite pipe gallery double-skin wall structure, and the concrete part of the double-skin wall prefabricated slab, the inner edge of the slab The steel bars in the length direction of the gallery section are translated and staggered along the length direction of the pipe gallery section, and the prefabricated inner panel 1 and the prefabricated outer panel 2 are simultaneously translated in opposite direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com