Low-temperature-resistant rubber, preparation method thereof and air spring end cover applying low-temperature-resistant rubber

A technology of low temperature resistance and rubber, which is applied in the direction of springs, springs/shock absorbers, mechanical equipment, etc. It can solve the problems of poor dispersion of cold resistance agents and poor low temperature resistance of rubber, and achieve uniform low temperature resistance and crosslinking Strength, friction reduction, likelihood reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

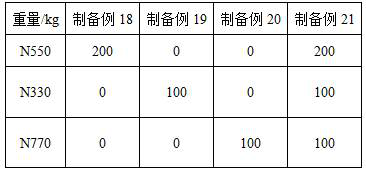

Examples

preparation example 1-6

[0048] Weigh EVA emulsion, layered kaolin, stearic acid and pentaerythritol stearate respectively, and the specific quality is shown in Table 1. First, layered kaolin and EVA emulsion are stirred and mixed, impregnated, filtered, and solids are retained, dried, and obtained Primary product: Stir and mix the primary product, stearic acid and pentaerythritol stearate to prepare Dispersant 1-6.

[0049] Table 1 preparation example 1-6 dispersant composition

[0050]

[0051] Restorative preparation example

preparation example 7

[0053] Take 2kg of zinc dimethacrylate as low-temperature restoration agent 1.

preparation example 8-10

[0055] Weigh zinc dimethacrylate, epoxy resin and silicone rubber respectively, see Table 2 for the specific quality, first stir and mix zinc dimethacrylate and epoxy resin to form a microsphere structure of zinc dimethacrylate-epoxy resin , and then mix the microsphere structure with silicone rubber to prepare low-temperature repair agent 2-4.

[0056] Table 2 Preparation Example 8-10 Low Temperature Restoration Agent Composition

[0057]

[0058] Vulcanizing agent preparation example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com