Preparation method of high bonding type salt storage asphalt pavement material

A kind of asphalt pavement and combined technology, which is applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems of expensive slow-release complex salt filler and low bonding strength of base asphalt materials, so as to improve the bonding performance and mechanical strength, Excellent structural performance and the effect of improving bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

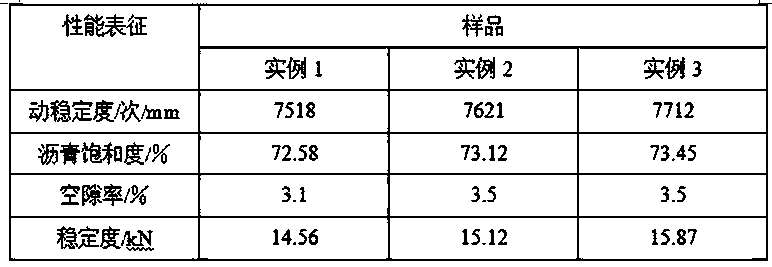

Examples

Embodiment Construction

[0019] Take the severe saline-alkali soil with a pH of 9.5 and dry it, collect the dry matter and ball mill it, collect the ball mill powder and put it in a crucible, put the crucible in a muffle furnace, heat up to 1650-1700°C at 10°C / min, keep warm and melt After 25 to 30 minutes, collect the molten liquid and draw it, control the diameter of the molten drawing to 0.5 to 0.8 mm, collect the drawn fiber and place it at 650 to 700 ° C for annealing treatment for 3 to 5 hours, and then let it stand to cool to room temperature to obtain the matrix salt storage Fiber; count parts by weight, weigh 5-10 parts of polydimethylsiloxane, 45-50 parts of N, N-dimethylformamide, and 10-16 parts of matrix salt-storing fiber and place them in a mortar , grind and disperse and collect the mixed slurry, dry the mixed slurry at 130-140°C for 3-5 hours, obtain the dried product and grind it, and pass through a 200-mesh sieve to obtain modified fiber particles; according to the mass ratio of 1:10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com