Method for improving wear resistance of polymer material by composite filling

A technology of polymer materials and wear resistance, which is applied in the field of polymer composite materials, can solve the problems of grinding metal surface oxidation, friction and wear reduction, etc., and achieve the effects of improving friction and wear resistance, improving performance, and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 A method for composite filling to improve the wear resistance of polymer materials. The method refers to that polytetrafluoroethylene, cleaned carbon fiber, aramid fiber, and graphite powder are fully dried according to the material drying parameters, and then press The volume fraction is 75:10:10:5 and dry polytetrafluoroethylene, carbon fiber, aramid fiber and graphite powder are mixed, and the polytetrafluoroethylene-based composite material is obtained by cold pressing and sintering. Among them, the process parameters of cold-press sintering are cold-press mixed powder at 10-40MPa for 10-60min, and then transfer to the sintering furnace for 1-4h at 300-400°C.

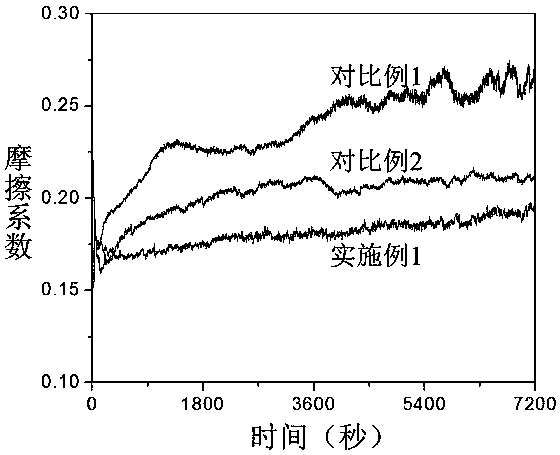

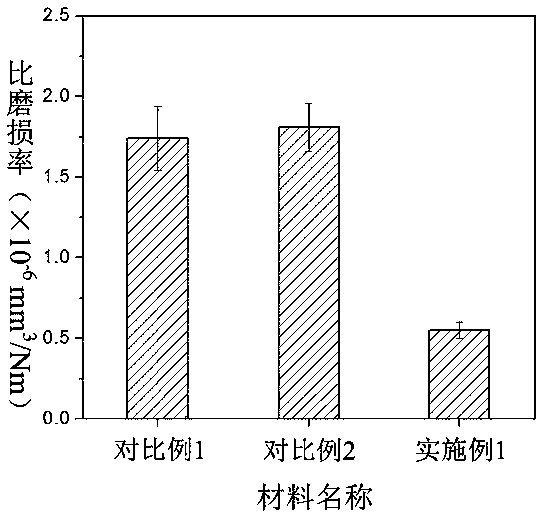

[0029] The resulting PTFE-based composite material was cut into 4×4×12mm 3 The sample used for the test was installed on a TRM1000 pin-on-disk friction tester from Wazau, Germany for tribological tests. Test conditions: the load is 3MPa, the line speed is 0.5m / s, and the test time is 2h. From ...

Embodiment 2

[0031] Embodiment 2 A kind of composite filling improves the method for wear-resisting performance of polymer material, and this method refers to that polyoxymethylene pellets, cleaned glass fiber and carbon fiber, and graphite powder are fully dried according to the material drying parameters, and then press 60 : 10:20:10 volume ratio into a 185 ° C internal mixer for melting and banburying for 10 minutes to obtain a homogeneously mixed polyoxymethylene-based composite material. Then, the mixture after banburying was hot-pressed at 190°C with a flat vulcanizer under a pressure of 10MPa to obtain a modified polyoxymethylene-based material.

Embodiment 3

[0032] Embodiment 3 A kind of composite filling improves the method for wear-resisting performance of polymer material, and this method refers to first fully drying polyoxymethylene pellets, cleaned glass fiber and aramid fiber, molybdenum disulfide according to material drying parameters, and then According to the volume ratio of 60:20:10:10, it was added to a 185°C internal mixer for melting and banburying for 10 minutes to obtain a homogeneously mixed polyoxymethylene-based composite material. Then, the mixture after banburying was hot-pressed at 190°C with a flat vulcanizer under a pressure of 10MPa to obtain a modified polyoxymethylene-based material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com