Electric spark deposition preparation method of self-lubricating coating containing tantalum oxide

A self-lubricating coating and electric spark deposition technology, which is applied in the field of EDM deposition to achieve the effects of excellent anti-friction and wear resistance, improved mechanical properties, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

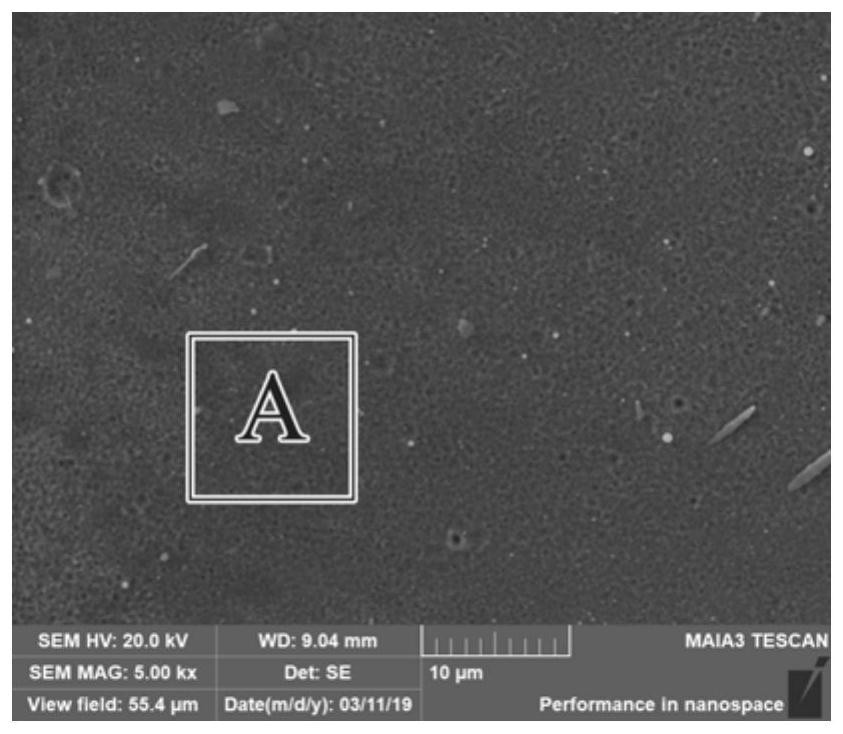

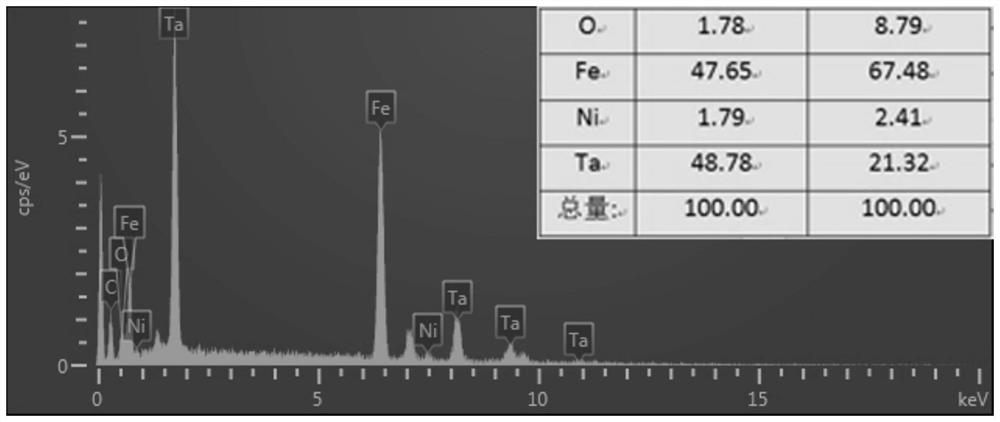

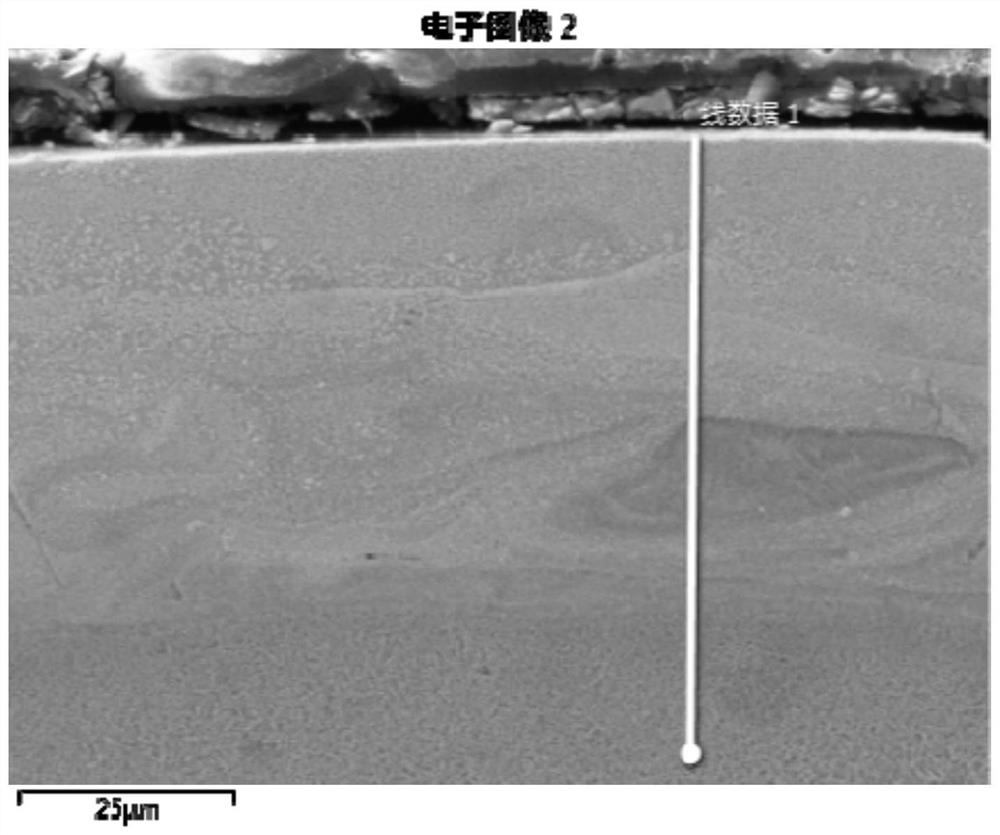

[0037] In this embodiment, the base material is CrNi3MoVA steel, the electrode is pure tantalum, and the preparation steps of the tantalum self-lubricating coating are as follows:

[0038] (1) Firstly, the substrate material is polished step by step according to 240#, 400#, 600#, and 800# sandpaper to remove the oxide film on the surface of the substrate, and then polish it with an abrasive paste with a particle size of 2.5 μm, and then perform ultrasonic cleaning with acetone for 10 minutes to remove surface oil;

[0039] (2) First process the pure tantalum electrode into a columnar shape of Φ4mm×50mm, and grind it step by step according to 240#, 400#, 600#, 800# sandpaper to remove the oxide film on the surface of the substrate, and then use the abrasive paste with a particle size of 2.5μm Polishing, followed by ultrasonic cleaning with acetone for 10 minutes to remove surface oil;

[0040] (3) EDM deposition was carried out under argon protection. The specific process para...

Embodiment 2

[0050] In this embodiment, No. 45 steel is used as the base material, pure tantalum is used as the electrode, and the preparation steps of the self-lubricating coating are as follows:

[0051] (1) Firstly, the substrate material is polished step by step according to 240#, 400#, 600#, 800# sandpaper to remove the oxide film on the surface of the substrate, then polish it with a grinding paste with a particle size of 2.5 μm, and then perform ultrasonic cleaning with acetone for 8 minutes to remove surface oil;

[0052] (2) First process the pure tantalum electrode into a columnar shape of Φ3mm×50mm, and grind it step by step according to 240#, 400#, 600#, 800# sandpaper to remove the oxide film on the surface of the substrate, and then use the abrasive paste with a particle size of 2.5μm Polishing, followed by ultrasonic cleaning with acetone for 8 minutes to remove surface oil;

[0053] (3) EDM deposition is carried out under the protection of argon gas. The specific process p...

Embodiment 3

[0057] In this embodiment, the base material is Q235 steel, the electrode is pure tantalum, and the self-lubricating coating preparation steps are as follows:

[0058] (1) Firstly, the substrate material is polished step by step according to 240#, 400#, 600#, 800# sandpaper to remove the oxide film on the surface of the substrate, then polish it with an abrasive paste with a particle size of 2.5 μm, and then perform ultrasonic cleaning with acetone for 9 minutes to remove surface oil;

[0059] (2) First process the pure tantalum electrode into a Φ5mm×40mm column, and grind it step by step according to 240#, 400#, 600#, 800# sandpaper to remove the oxide film on the surface of the substrate, and then use the abrasive paste with a particle size of 2.5μm Polishing, followed by ultrasonic cleaning with acetone for 9 minutes to remove surface oil;

[0060] (3) EDM deposition was carried out under argon protection. The specific process parameters were: output power 1200W, output vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com