Ag/BNNSs nano material modified epoxy resin composite coating layer

A technology of epoxy resin and composite coating, applied in epoxy resin coatings, coatings and other directions, can solve the problems of high brittleness, poor friction properties, etc., and achieve high bonding strength, low wear rate, and small friction coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

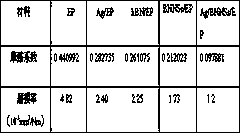

Embodiment 1

[0028] First add 75mL of deionized water, 2.84g of sodium hydroxide, 1.08g of potassium hydroxide, and 1g of hexagonal boron nitride powder (hBN) into a 100mL polytetrafluoroethylene reactor, ultrasonically disperse for 30 minutes, magnetically stir for 30 minutes, and seal Heated at 180°C for 2h, after the reaction was completed, cooled to room temperature, centrifuged, washed the product three times with deionized water and ethanol, and freeze-dried for 48 hours to obtain hexagonal boron nitride nanosheet powder (BNNSs); react in 100mL polytetrafluoroethylene Add 80mL of deionized water, 0.6g of silver nitrate, and 1.2g of polyvinylpyrrolidone K30 into the kettle in sequence, take 0.05g of the prepared hexagonal boron nitride nanosheet powder, disperse it by ultrasonic for 30 minutes, stir it magnetically for 30 minutes, and seal it at 180°C After heating for 18 hours, after the reaction was completed, cool to room temperature, centrifuge, wash the product with deionized wate...

Embodiment 2

[0033]First, add 75mL of deionized water, 2.80g of sodium hydroxide, 1.0g of potassium hydroxide, and 0.8g of hexagonal boron nitride powder into a 100mL polytetrafluoroethylene reactor, ultrasonically disperse for 30 minutes, magnetically stir for 30 minutes, and seal at 180°C Heating for 2 hours, after the reaction is complete, cool to room temperature, centrifuge, wash the product three times with deionized water and ethanol, and freeze-dry for 48 hours to obtain hexagonal boron nitride nanosheet powder; add 80 mL of Deionized water, 0.5g silver nitrate, 1.0g polyvinylpyrrolidone K30, take 0.05g of the prepared hexagonal boron nitride nanosheet powder, ultrasonically disperse for 30 minutes, magnetically stir for 30 minutes, seal and heat at 180°C for 18h, the reaction is complete Afterwards, cool to room temperature, centrifuge, wash the product with deionized water and ethanol three times each, and freeze-dry for 48 hours to obtain the silver / hexagonal boron nitride nanosh...

Embodiment 3

[0035] First, add 75mL of deionized water, 2.86g of sodium hydroxide, 1.2g of potassium hydroxide, and 0.9g of hexagonal boron nitride powder into a 100mL polytetrafluoroethylene reaction kettle, ultrasonically disperse for 30 minutes, magnetically stir for 30 minutes, and seal at 180°C Heating for 2 hours, after the reaction is complete, cool to room temperature, centrifuge, wash the product three times with deionized water and ethanol, and freeze-dry for 48 hours to obtain hexagonal boron nitride nanosheet powder; add 80 mL of Deionized water, 0.7g silver nitrate, 1.4g polyvinylpyrrolidone K30, take 0.05g of the prepared hexagonal boron nitride nanosheet powder, ultrasonically disperse for 30 minutes, magnetically stir for 30 minutes, seal and heat at 180°C for 18h, the reaction is complete Afterwards, cool to room temperature, centrifuge, wash the product with deionized water and ethanol three times each, and freeze-dry for 48 hours to obtain the silver / hexagonal boron nitri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com