Self-lubricating type epoxide resin material and preparation thereof

An epoxy resin and self-lubricating technology, which is applied in the preparation of microspheres, lubricating compositions, microcapsule preparations, etc., can solve the problem of reducing the friction coefficient and wear rate of epoxy resin, poor friction and wear performance of epoxy resin, and large proportion of fillers and other issues, to achieve low friction coefficient and wear rate, less environmental pollution, and improve the effect of anti-friction and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

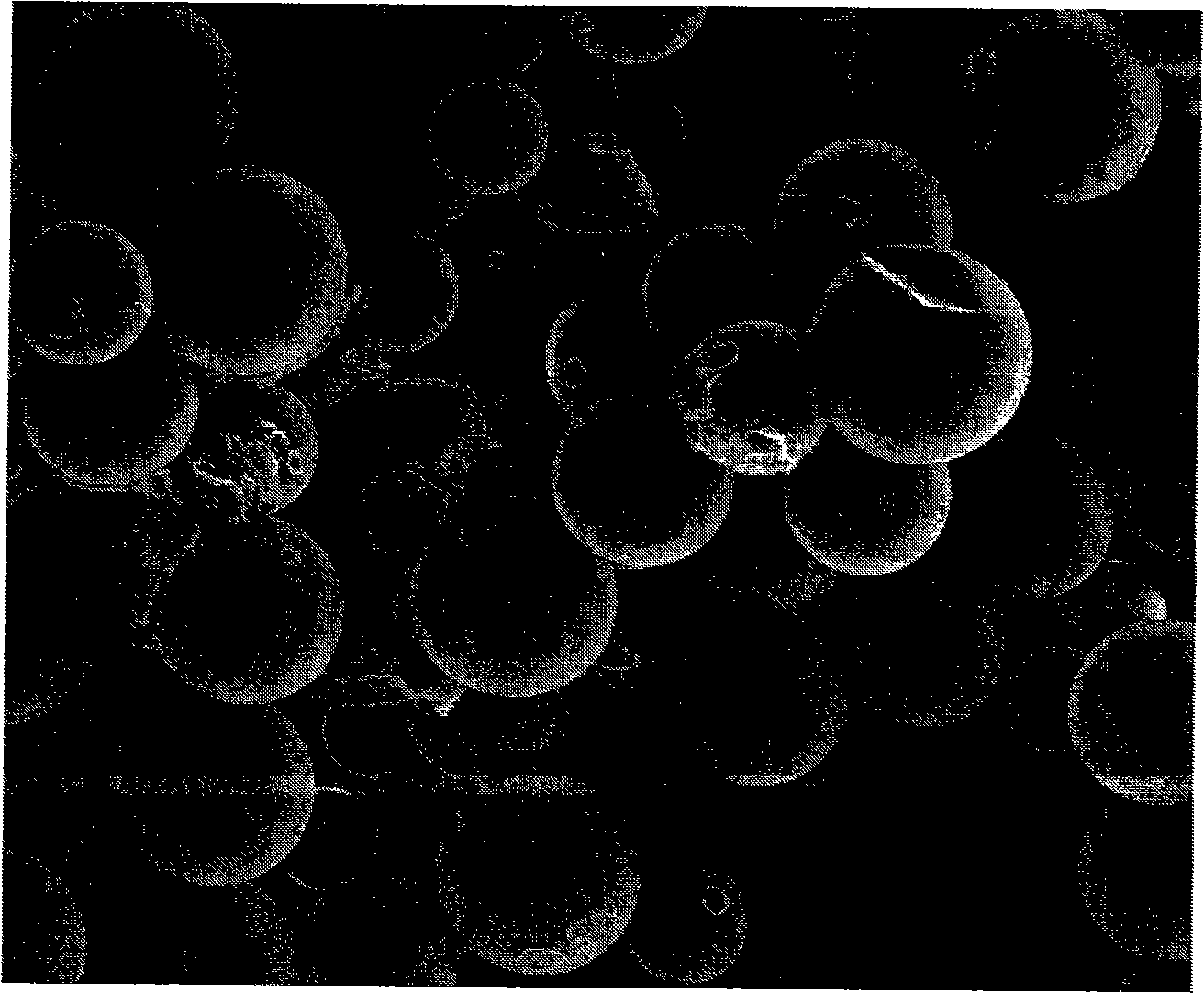

[0027] (1) Preparation of lubricating oil microcapsules: (a) weigh 2.0g SDBS, 2.0g PVA in a beaker containing 130ml, stir and dissolve, add 10.0g lubricating oil, stir and emulsify; (b) weigh 3.0g melamine, Measure 13.0ml of formaldehyde into a 500ml flask, add 40ml of water; (c) adjust the pH value to about 8.0 with 3% sodium hydroxide solution at 70°C, stir and dissolve for 5min; (d) add the prepared emulsion, 400rpm Stir and emulsify at 1 / min for 30 minutes; (e) adjust the pH value to about 4.0 with acetic acid, and stir for 3 hours; (f) stop the reaction, filter, and dry to obtain microcapsules, wherein the melamine-formaldehyde resin is the shell and the lubricating oil is the core.

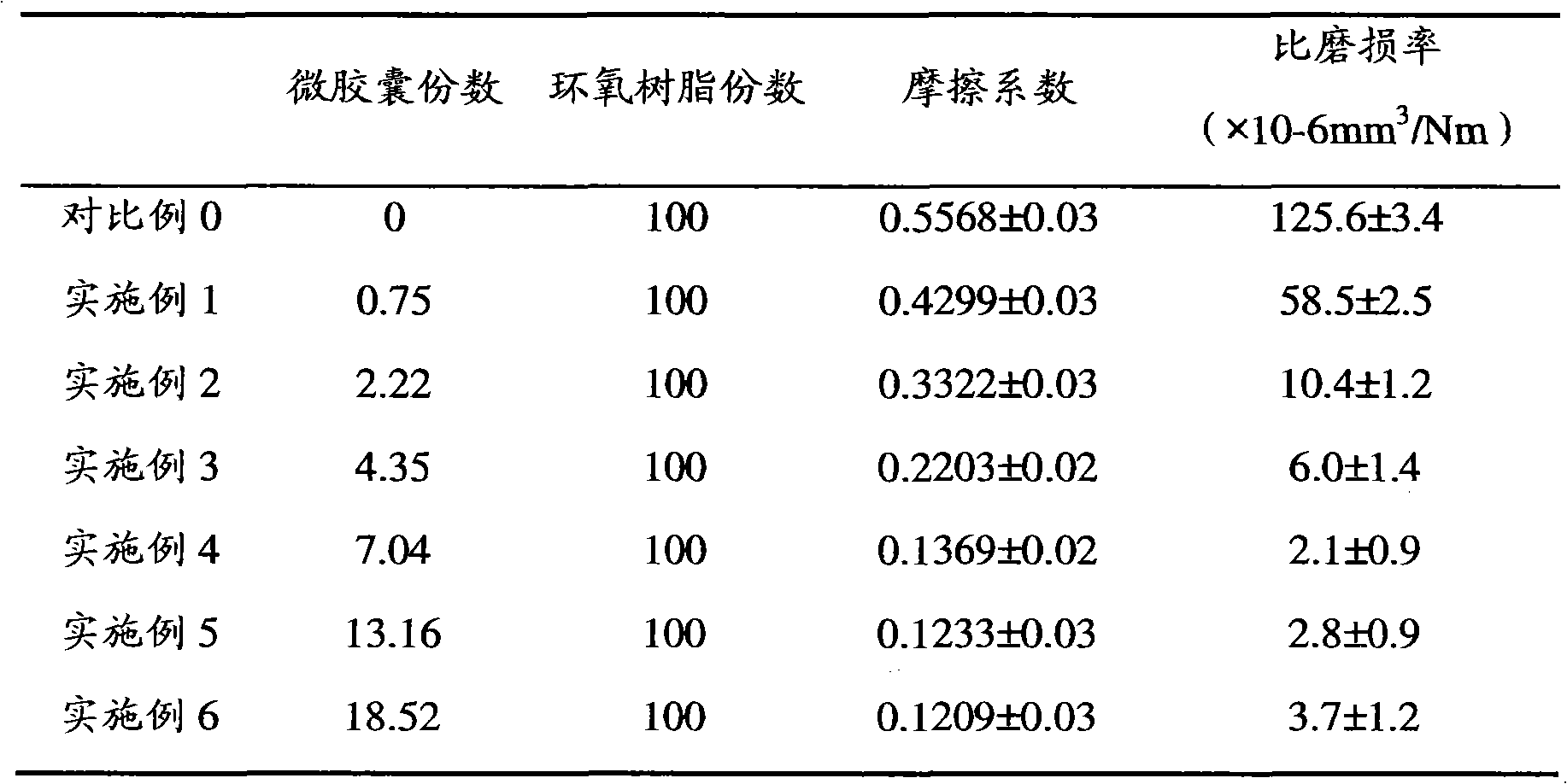

[0028] (2) Preparation of epoxy resin composite material: Add the dried lubricating oil microcapsules into epoxy resin E-51, stir under vacuum mechanically at 100°C for 1h, heat to 130°C and slowly add curing agent 4, 4'- Diaminodiphenylsulfone (DDS) (E51 / DDS weight ratio = 100 / 32), let it f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com