Synchronous ring for synchronizer and method for manufacturing synchronous ring

A manufacturing method and technology for synchronizing rings, which are applied in the manufacture of tools, clutches, mechanical drive clutches, etc., can solve the problems of insufficient kinetic friction coefficient, poor bonding reliability, and low material utilization rate, and achieve low cost, machining-free, material High utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

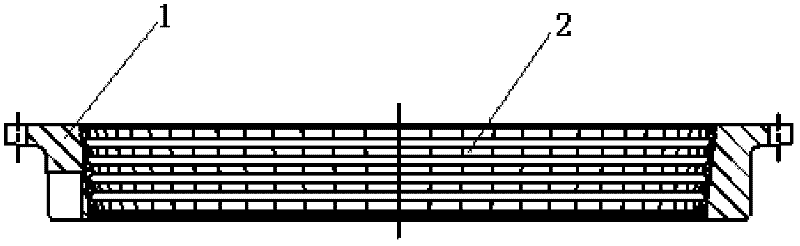

[0029] Embodiment 1: A synchronous ring for a synchronizer is provided, including a synchronous ring base 1 , and a friction plate 2 is provided inside the synchronous ring base 1 , and the friction plate 2 is composed of a soft base layer 21 and a friction layer 22 . By replacing the existing hard friction layer structure with the combined structure of the soft base layer 21 and the friction layer 22, the anti-overload performance of the synchronous ring is improved. The surface of the friction layer 22 is provided with an oil discharge groove 3 . The thickness of the friction plate 2 is 0.5mm˜1mm.

[0030] A method for manufacturing a synchronizer ring for a synchronizer, comprising the following steps:

[0031] (1) Mix artificial graphite and friction additive with resin powder evenly to make a friction layer mixture, wherein the mass ratio of artificial graphite is 45% to 63%, the mass ratio of friction additive is 25% to 42%, and the resin powder The mass ratio of the f...

Embodiment 2

[0036] Embodiment 2: A synchronous ring for a synchronizer is provided, including a synchronous ring base 1 , and a friction plate 2 is provided inside the synchronous ring base 1 , and the friction plate 2 is composed of a soft base layer 21 and a friction layer 22 . By replacing the existing hard friction layer structure with the combined structure of the soft base layer 21 and the friction layer 22, the anti-overload performance of the synchronous ring is improved. The surface of the friction layer 22 is provided with an oil discharge groove 3 . The thickness of the friction plate 2 is 0.5mm˜1mm.

[0037] A method for manufacturing a synchronizer ring for a synchronizer, comprising the following steps:

[0038] (1) Mix artificial graphite and friction additive with resin powder evenly to make a friction layer mixture, wherein the mass ratio of artificial graphite is 45% to 63%, the mass ratio of friction additive is 25% to 42%, and the resin powder The mass ratio of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com