Production method of powder metallurgy high-silicon aluminum alloy compressor piston

A technology of high-silicon aluminum alloys and manufacturing methods, which can be applied to other manufacturing equipment/tools, turbines, engine components, etc., can solve problems such as inability to take into account shapes, not suitable for mass production, and complicated processes, so as to reduce production costs and material The effect of scientific and reasonable component distribution and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

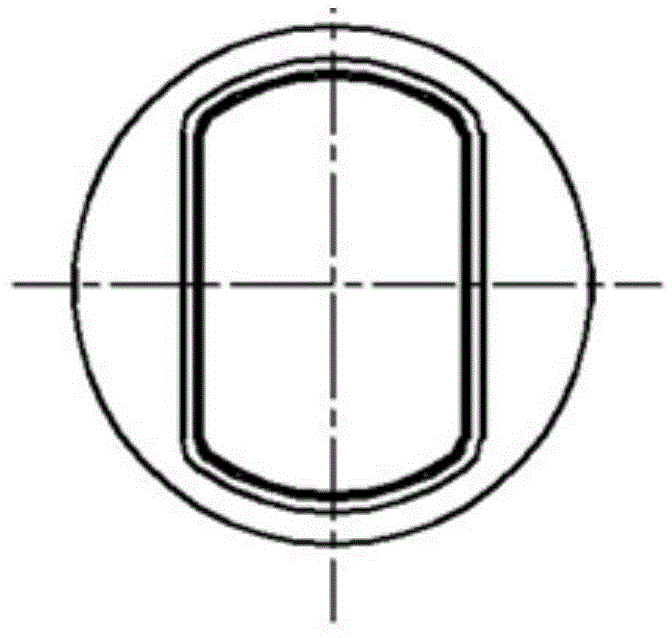

Image

Examples

Embodiment 1

[0034] 1. Mixing: The chemical composition of the piston is: Al-14%Si-2.5%Cu-1%Mg (mass fraction), and the ingredients are 48.8% 100-mesh aluminum powder (such as figure 2 shown), 50% of 100 mesh Al-28%Si-5%Cu-2%Mg alloy powder (such as image 3 shown), add 1.2% organic wax as a lubricant.

[0035] 2. Forming: Mold the mixed powder at room temperature, the pressing pressure is 450MPa, and the forming density is 2.40g / cm 3 .

[0036] 3. Dewaxing: Rapidly heat the green body to 420°C and keep it warm for 30 minutes. The protective atmosphere is pure nitrogen, the nitrogen dew point is ≤-30°C, and the residual carbon content after dewaxing is ≤0.05%.

[0037] 4. Sintering: heat the dewaxed product to 550°C, keep it warm for 30 minutes, the protective atmosphere is pure nitrogen, the dew point of nitrogen is ≤ -45°C, and the sintering density is 2.60g / cm 3 .

[0038] 5. Heat treatment: solid solution temperature 510°C, heat preservation 110min, artificial aging temperature 15...

Embodiment 2

[0047] 1. Mixing: The chemical composition of the piston is: Al-28%Si-2%Mg (mass fraction), 98.5% 100 mesh Al-28%Si-2%Mg (mass fraction) alloy powder, 1.5% amide Wax acts as a lubricant.

[0048]2. Forming: Mold the mixed powder at room temperature, the pressing pressure is 450MPa, and the forming density is 2.40g / cm 3 .

[0049] 3. Dewaxing: The green body is rapidly heated to 420°C and held for 30 minutes, the protective atmosphere is pure nitrogen, the nitrogen dew point is ≤ -30°C, and the residual carbon content after dewaxing is ≤0.05%.

[0050] 4. Sintering: Heat the dewaxed product to 585°C, keep it warm for 30 minutes, the protective atmosphere is pure nitrogen, the nitrogen dew point is ≤ -45°C, and the sintering density is 2.50g / cm 3 .

[0051] 5. Shaping: Squeeze and deform the sintered piston in a shaping mold to correct the deformation caused by sintering, the deformation amount is 0.5-5%, and improve the size and shape tolerance of the piston.

[0052] 6. Ma...

Embodiment 3

[0058] 1. Mixing: The chemical composition of the piston is: Al-32%Si-2%Cu-1%Mg (mass fraction), the ingredients are 64% of 100 mesh Al-50% Si alloy powder, 2% of 200 mesh Al - 50% Mg alloy powder, 2% 200-mesh copper powder, the balance 200-mesh aluminum powder, 1.0% amide wax is added to the alloy powder as a lubricant.

[0059] 2. Forming: Heat the mixed powder and female mold to 100°C for forming, the pressing pressure is 600MPa, and the forming density is 2.30g / cm 3 .

[0060] 3. Dewaxing-sintering: Heat the green body rapidly to 420°C, keep it warm for 30 minutes, then raise the temperature to 550°C, keep it warm for 30 minutes, to achieve one-time dewaxing-sintering, the protective atmosphere is pure nitrogen, nitrogen dew point ≤ -45°C, sintering The density is 2.60g / cm 3 .

[0061] 5. Heat treatment: solid solution temperature 490°C, heat preservation 90min, artificial aging temperature 160°C, time 8 hours.

[0062] 6. Shaping: Squeeze and deform the sintered pisto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com