Compressor connecting rod

A compressor and connecting rod technology, applied in the field of powder metallurgy, can solve problems such as abnormal parts matching or lubrication, abnormal compressor operation, and infiltration of coolant, etc., achieving less processing volume, scientific and reasonable material composition ratio, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

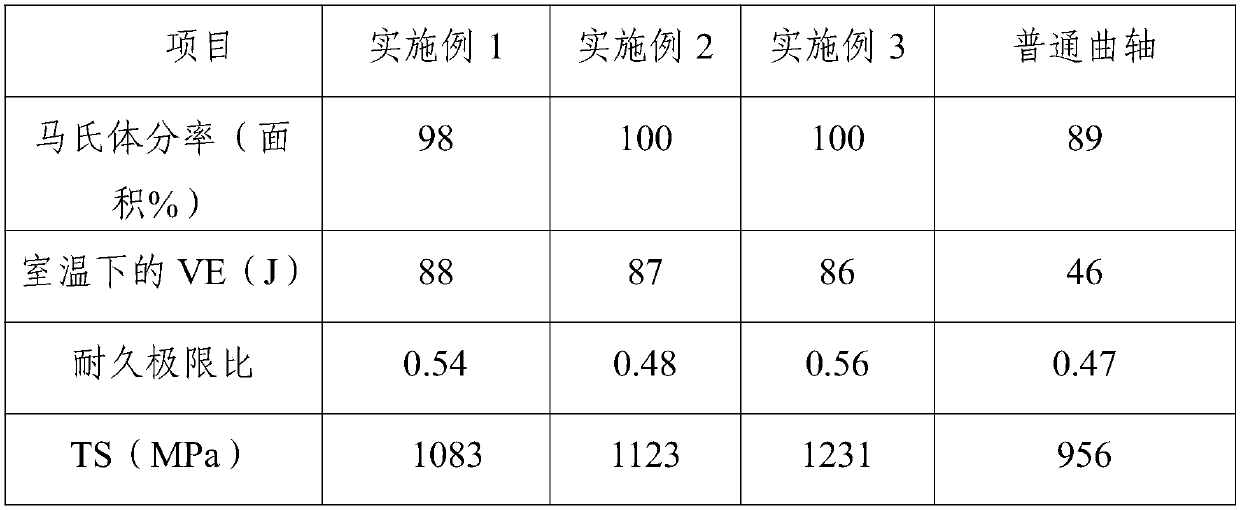

Examples

Embodiment 1

[0017] A compressor connecting rod, which comprises the following raw materials weighed by weight: 1-1.6 wt% of silicon, 0-4 wt% of copper, 0.8-2.0 wt% of magnesium, 0.1-0.3% of iron, and 0-2.1 wt% of tin , Magnet powder 1-1.6wt%, magnesium nitride 1-2wt%, carbon powder 0.8-0.2wt%, titanium dioxide 0.1-0.7wt%, titanium powder 0.5-0.8, tantalum nitride 1-2wt%, niobium powder 0.03- 0.05wt%, Al is the balance.

Embodiment 2

[0019] A compressor connecting rod, which comprises the following raw materials weighed by weight: 1-1.6 wt% of silicon, 0-4 wt% of copper, 0.8-2.0 wt% of magnesium, 0.1-0.3% of iron, and 0-2.1 wt% of tin , Magnet powder 1-1.6wt%, magnesium nitride 1-2wt%, carbon powder 0.8-0.2wt%, titanium dioxide 0.1-0.7wt%, titanium powder 0.5-0.8, tantalum nitride 1-2wt%, niobium powder 0.03- 0.05wt%, Al is the balance.

[0020] Preferably, the manufacturing method of the compressor connecting rod is:

[0021] (1) Mix and stir iron, magnet powder, copper, magnesium, niobium powder, and tin at 80-100°C for 60-80 minutes, and add 0.8-2.0% lubricant for mixing,

[0022] (2) Then heat to 60-130°C, then add magnesium nitride, carbon powder, and titanium dioxide powder, cool to 100-120°C, put it into a mold, press it into a billet, and then cool it naturally to room temperature. The pressing pressure is 100-100°C. 200MPa, pressing pressure 150-600MPa, forming density 2.30-2.60g / cm3;

[0023] ...

Embodiment 3

[0027] A compressor connecting rod, which comprises the following raw materials weighed by weight: 1-1.6 wt% of silicon, 0-4 wt% of copper, 0.8-2.0 wt% of magnesium, 0.1-0.3% of iron, and 0-2.1 wt% of tin , Magnet powder 1-1.6wt%, magnesium nitride 1-2wt%, carbon powder 0.8-0.2wt%, titanium dioxide 0.1-0.7wt%, titanium powder 0.5-0.8, tantalum nitride 1-2wt%, niobium powder 0.03- 0.05wt%, Al is the balance.

[0028] Preferably, the manufacturing method of the compressor connecting rod is:

[0029] (1) Mix and stir iron, magnet powder, copper, magnesium, niobium powder, and tin at 80-100°C for 60-80 minutes, and add 0.8-2.0% lubricant for mixing,

[0030] (2) Then heat to 60-130°C, then add magnesium nitride, carbon powder, and titanium dioxide powder, cool to 100-120°C, put it into a mold, press it into a billet, and then cool it naturally to room temperature. The pressing pressure is 100-100°C. 200MPa, pressing pressure 150-600MPa, forming density 2.30-2.60g / cm3;

[0031] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com