Blowout prevention and dust prevention device

A dust-proof device and anti-blowout technology, which is applied in dust-proof, safety devices, fire prevention, etc., can solve the problems of general effect and temperature generated by the drill bit, and achieve the effect of improving work efficiency, high work efficiency and wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

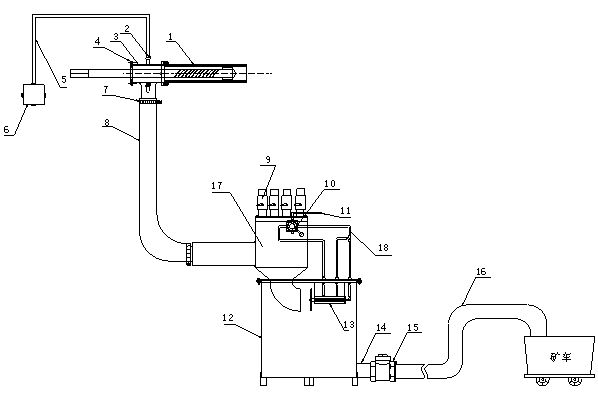

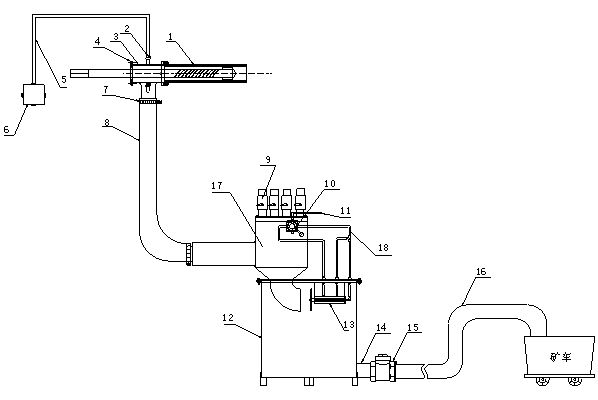

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0015] The spray-proof and dust-proof device of the present invention is mainly composed of a spray system, a wind pressure system, a pre-embedded pipe 1, a spray head 2, a dust cover 3 and an air slag separator. The embedded pipe 1 is arranged in the drilling entrance, and the outer end surface of the embedded pipe 1 is connected with a dustproof cover 3. The outer end of the dustproof cover 3 is provided with a dustproof plate 4 with a drill hole in the middle, and The upper part is provided with a spray head 2 connected to the spray system; the spray system includes a four-way valve 6 connected to the water pipe, a high-pressure rubber hose 5 connected to the four-way valve 6, and the high-pressure rubber hose 5 is connected to the spray head 2; the lower part of the dust cover 3 An air slag separator connected to the conduit 8 is provided, and fixed ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com