Down coal face goaf water dredging structure and dredging method thereof

A technology for dredging structures and working faces, applied in drainage, mining equipment, mining equipment, etc., can solve problems such as damage to electromechanical equipment and facilities, hidden dangers that cannot be treated, and accidents, so as to improve production efficiency and quality standardization. Eliminate hidden dangers in production safety and reduce the effect of dredging projects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

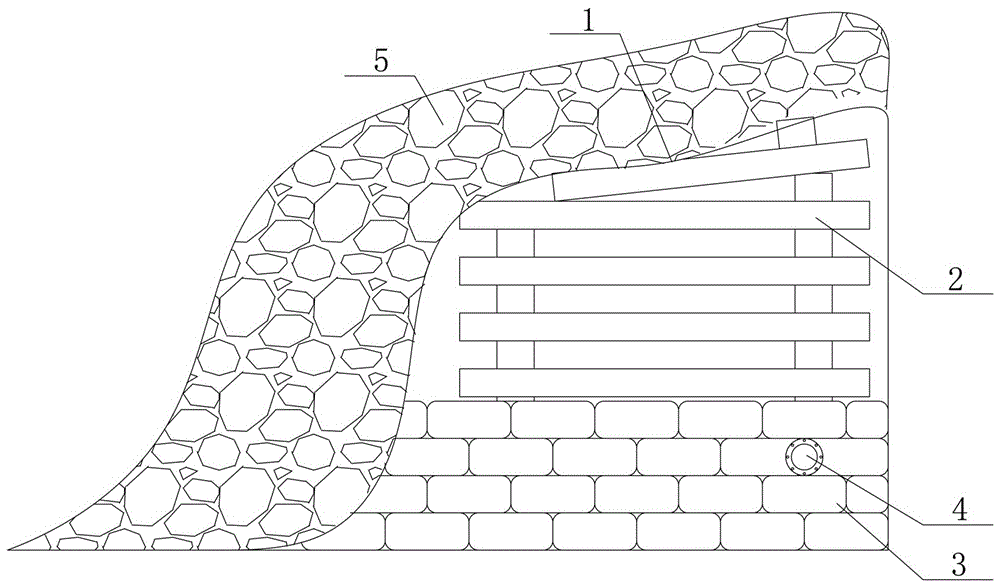

[0032] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] refer to figure 1 , a method for dredging old empty water in the down mining face described in this specific embodiment, comprising the following steps:

[0034] 1. The lower corner of the working face is hung with a net to protect the roof

[0035] All the roofs within 10m from the lower end of the working face are hung with double-layer fish scale nets for false roofs, and the nets are warp and weft nets woven with 8# iron wires. The stubble between the net and the net is not less than 10cm, and the mesh is connected with 14# iron wire every 200mm, and the binding is firm to form a unified whole. As the working face advances, the fish scale net is gradually thrown into the old empty area. After the roof gangue collapses, it no longer freely fills the gob area, and is enveloped by the mesh to achieve the effect of roof protection and pocket gan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com