Device capable of reducing water recirculation rate of supporting beam in heating furnace effectively

A technology for supporting beams and heating furnaces, applied in lighting and heating equipment, furnaces, furnace cooling and other directions, can solve the problems of high investment costs, increased power consumption, large operating costs, etc., to reduce operating energy consumption, ensure cooling effect, The effect of eliminating hidden dangers in production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

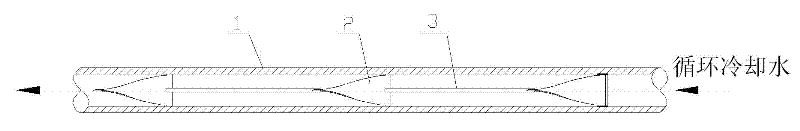

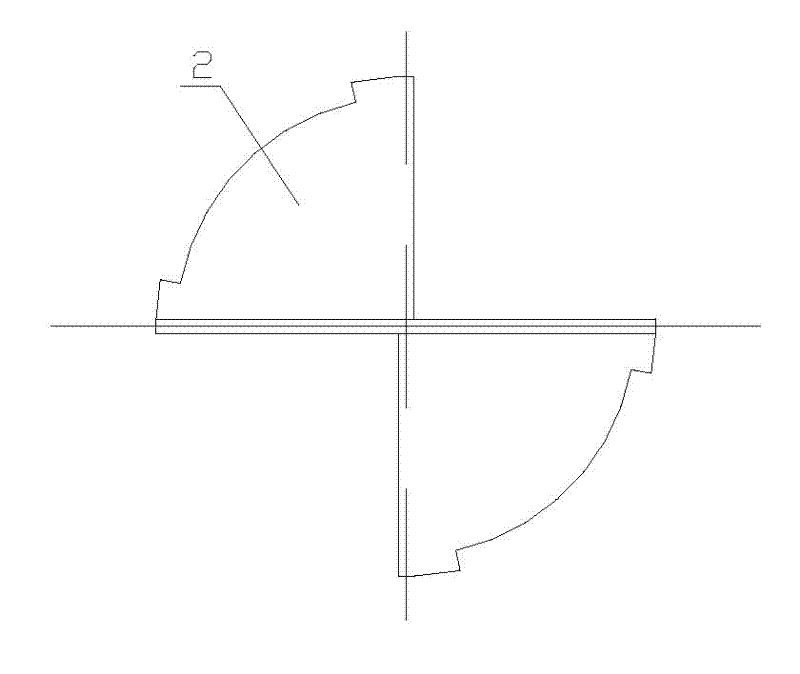

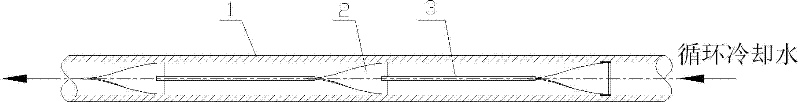

[0011] Such as figure 1 and figure 2 As shown, the device for effectively reducing the circulating water of the support beam in the heating furnace includes a cooling water pipe 1 in the support beam, at least three spiral spoilers 2 and several connecting rods 3, and the spiral spoiler 2 passes through the The plurality of connecting rods 3 are sequentially connected and arranged in the cooling water pipe 1 of the support beam, and the first spiral spoiler along the water flow direction of the cooling water pipe 1 in the support beam is fixedly connected with the inner wall of the cooling water pipe 1 . The spiral spoiler 2 can be formed by helically bending a steel plate.

[0012] In order to achieve a better water flow spiral effect, the spiral angle of the spiral spoiler 2 is 45-180 degrees, and the length of the spiral spoiler 2 is 100mm-400mm. The distance between each spiral spoiler 2 is 300-3000mm.

[0013] To facilitate the manufacture of the device, the spiral sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com