Automatic lubricating powder recovery device

An automatic recycling and lubricating powder technology, which is applied in workpiece surface treatment equipment, metal rolling, manufacturing tools, etc., can solve the problems of endangering the health of operators, flying lubricating dust, polluting the working environment, etc., and achieves low processing cost and clean operation The effect of the environment and operation is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

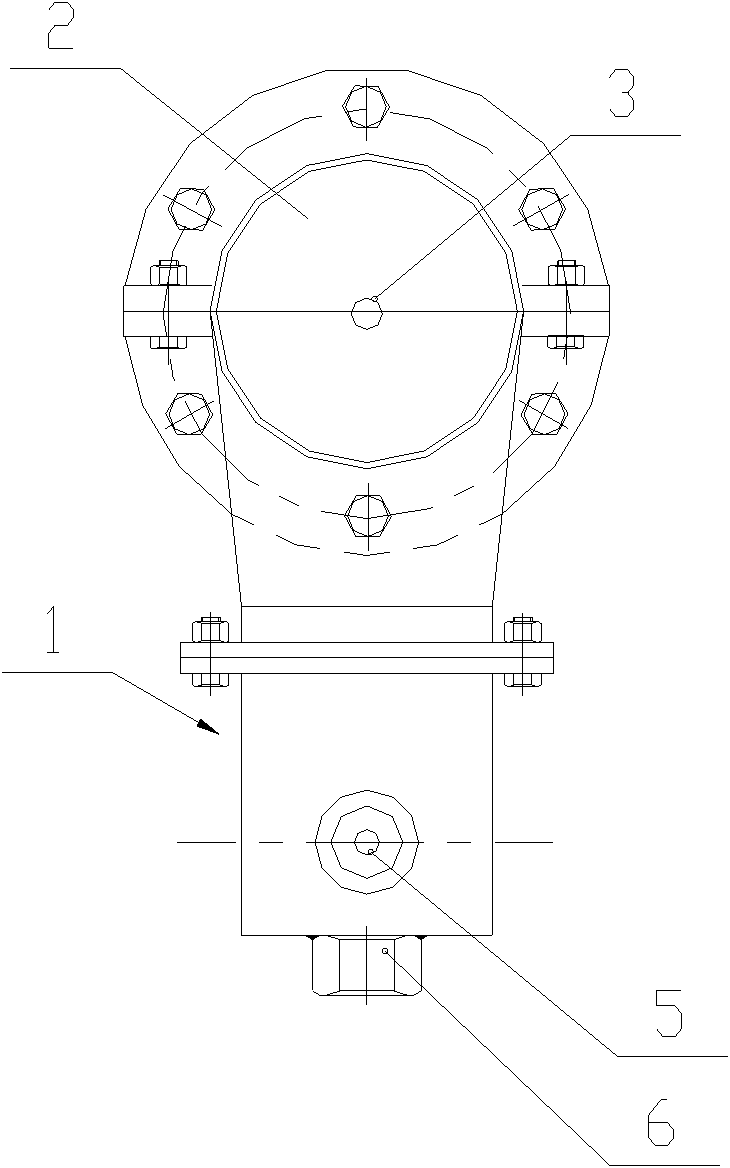

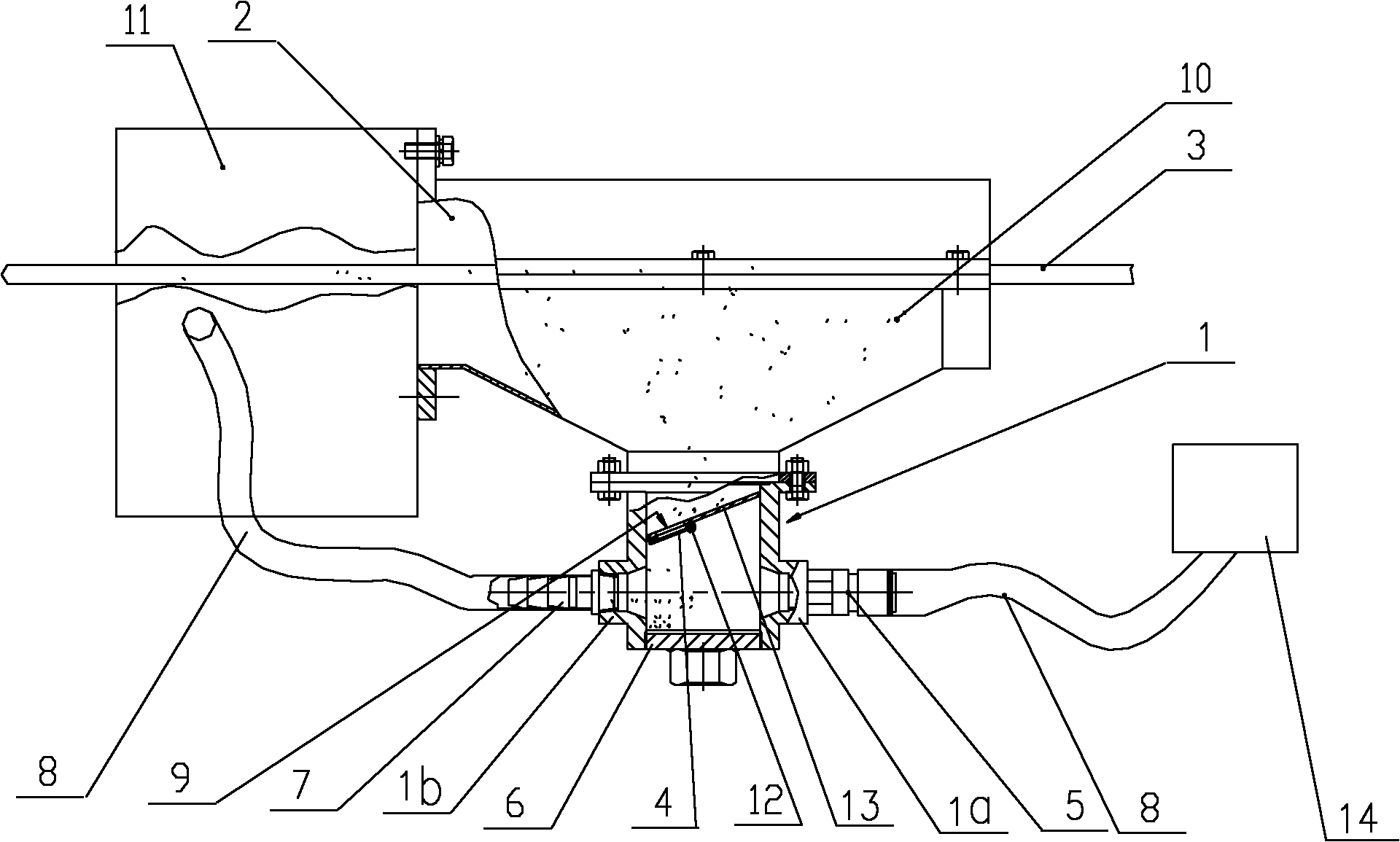

[0012] figure 1 Is the main view of the present invention; figure 2 Yes figure 1 Right side view.

[0013] The invention discloses a lubricating powder automatic recovery device. The lubricating powder automatic recovery device includes: a lubricating powder recovery cylinder 2, a valve body 1, a valve flap 4; both ends of the lubricating powder recovery cylinder 2 are respectively provided with steel bars 3 passing through The bottom of the lubricating powder recovery cylinder 2 is connected to the upper end of the valve body 1; the upper part of the inner side of the valve body 1 is provided with a powder discharge hole 9 that communicates the lubrication powder recovery cylinder 2 and a valve disc 4 that switches the powder discharge hole 9. The lower part of the inner side is provided with an air inlet 1 a and a powder discharge port 1 b, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com