Purifying treatment method and system for cuttings-carrying slurry of bentonite

A technology of mud purification and treatment method, which is applied in earthwork drilling, wellbore/well components, flushing wellbore, etc. It can solve the problems of large amount of filter aid, low efficiency and low treatment efficiency, etc., and achieve reduction of transportation resistance and Energy consumption, control of performance indicators, and the effect of saving pulping materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific implementation modes in conjunction with the accompanying drawings.

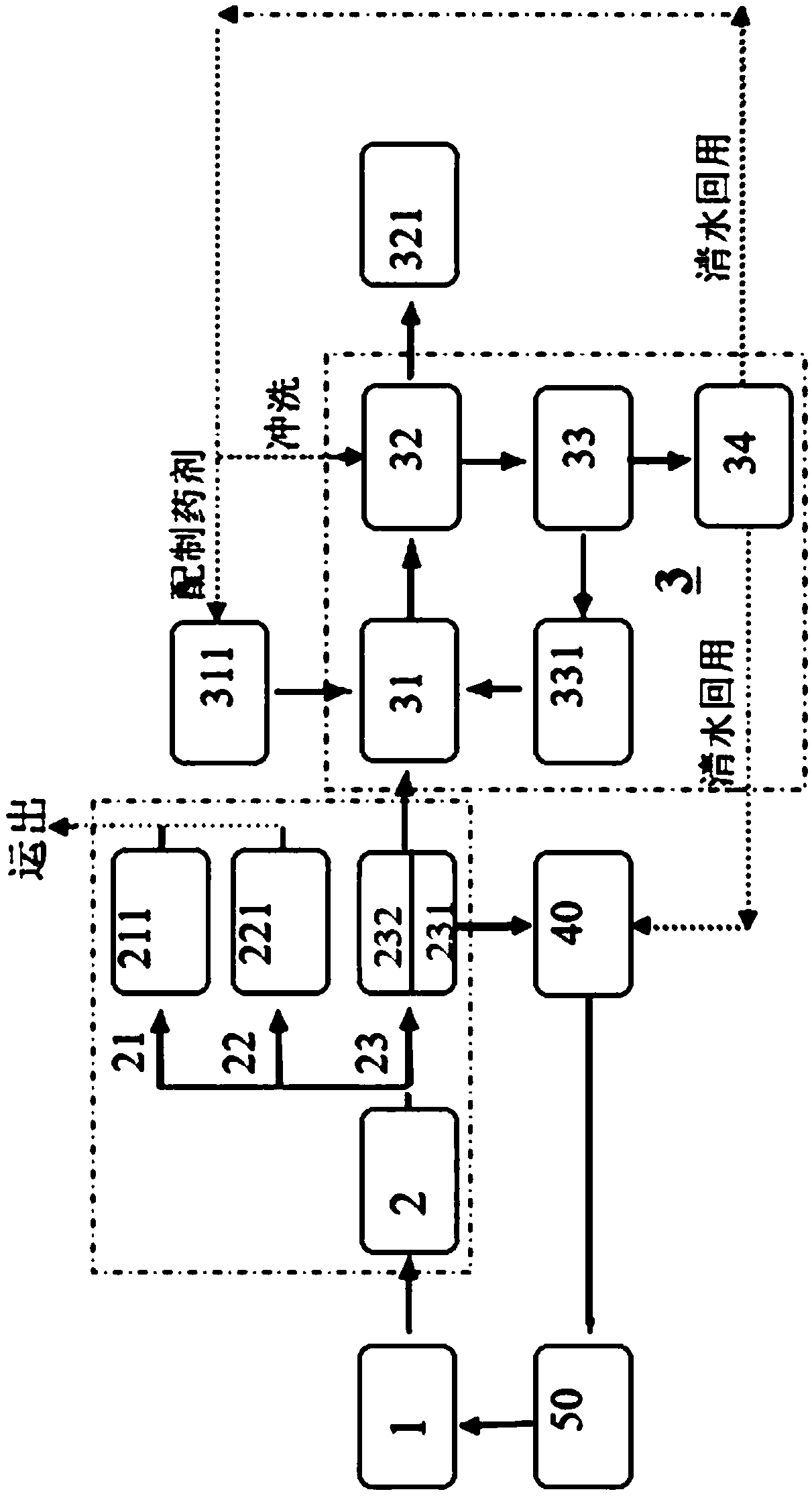

[0044] Such as figure 1 As shown, it is a flow chart of a preferred embodiment of the bentonite rock-carrying mud purification treatment system of the present invention, which mainly includes two parts: a mud-water separation system 2 and a purification and recovery system 3 for muddy water bodies. As shown in the figure, after the mud 2 prepared by the pulping system is used by mud equipment 50 such as shield machines, the rock-carrying mud 1 is treated by the mud-water separation system 2, and then enters the purification and recovery system 3 of muddy water. The purification and recovery system 3 for muddy water includes a mixing tank 31 , a filter press 32 , a sedimentation tank 33 , and a clear water tank 34 . The mud-water separation system 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com