Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Realize quick change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

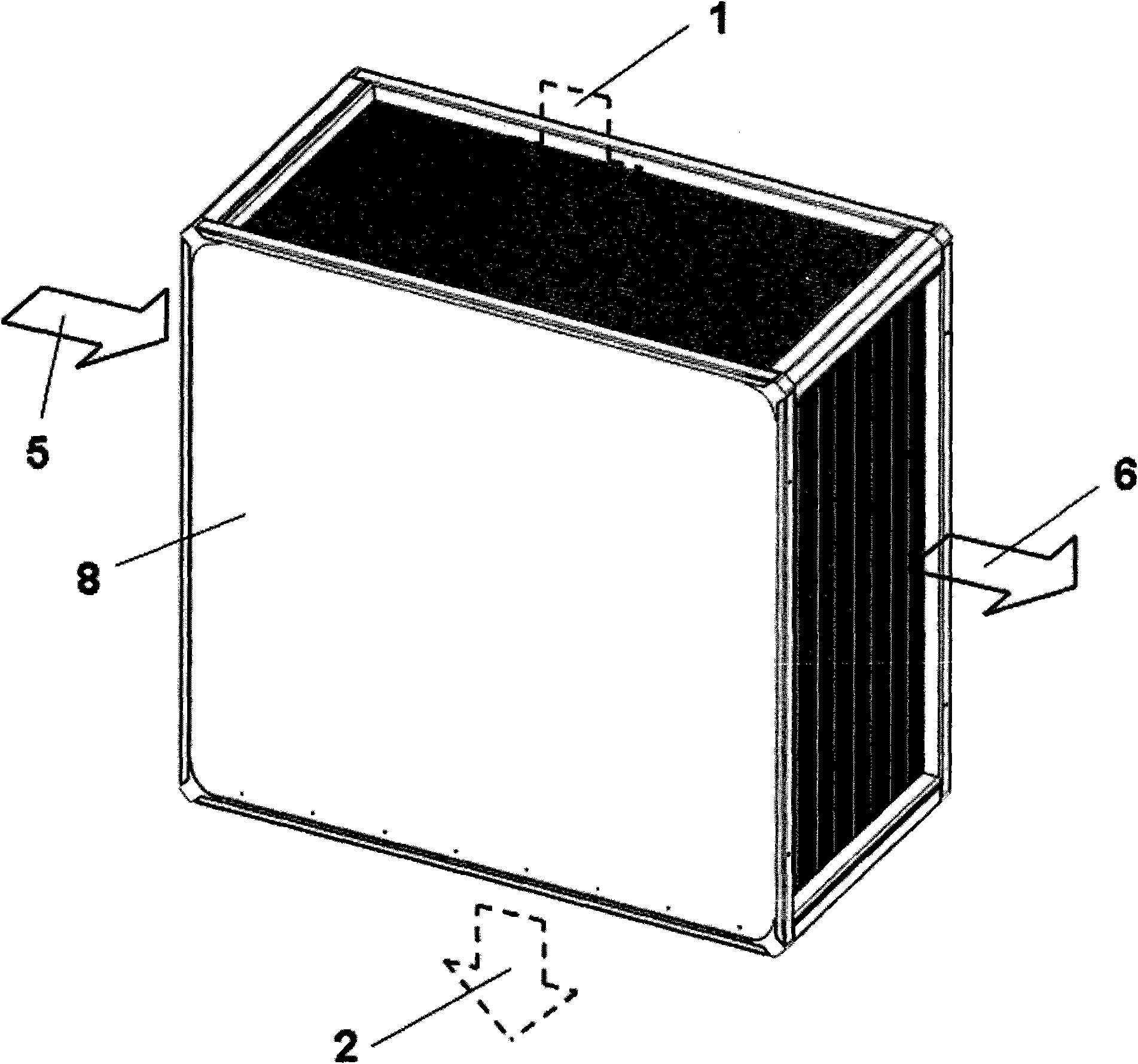

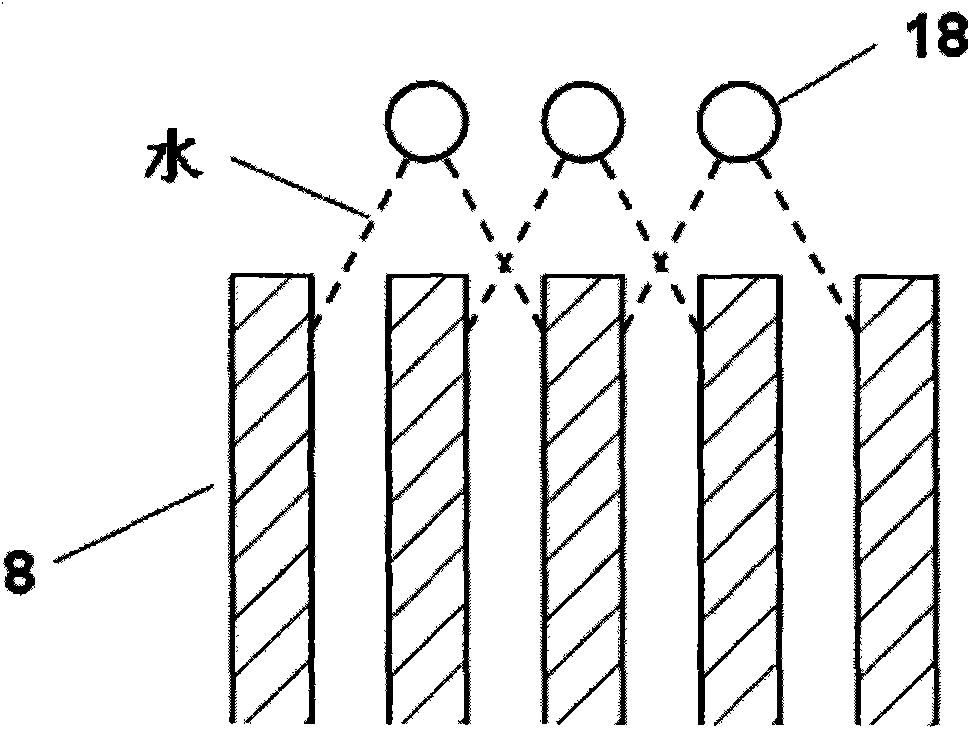

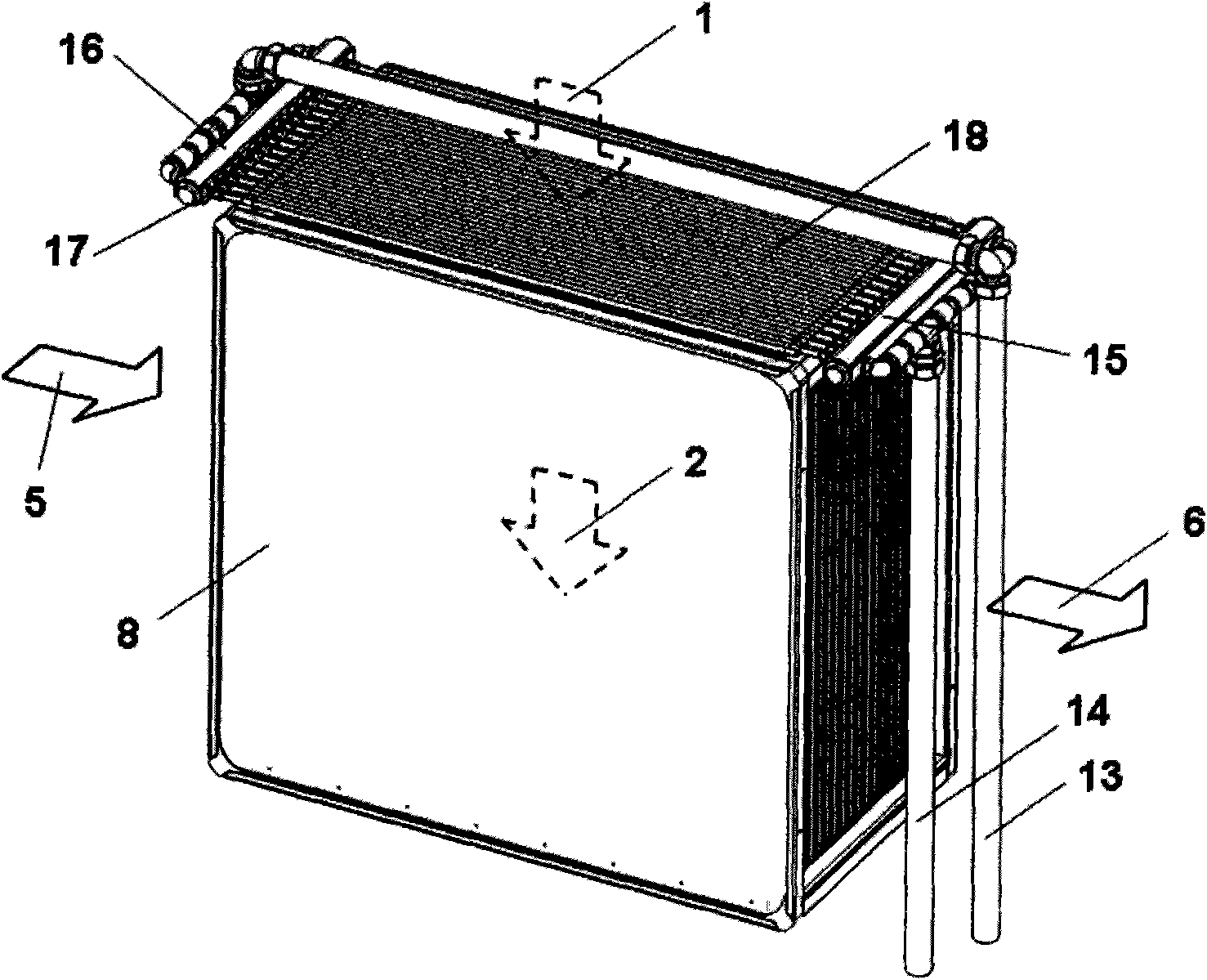

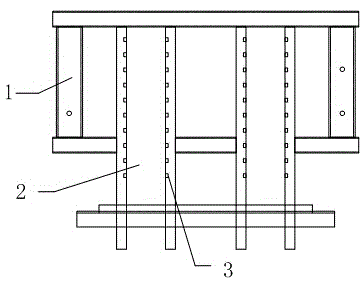

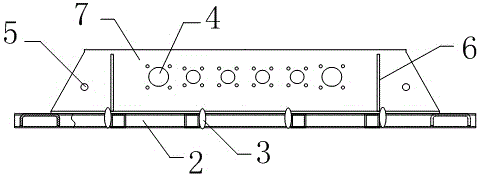

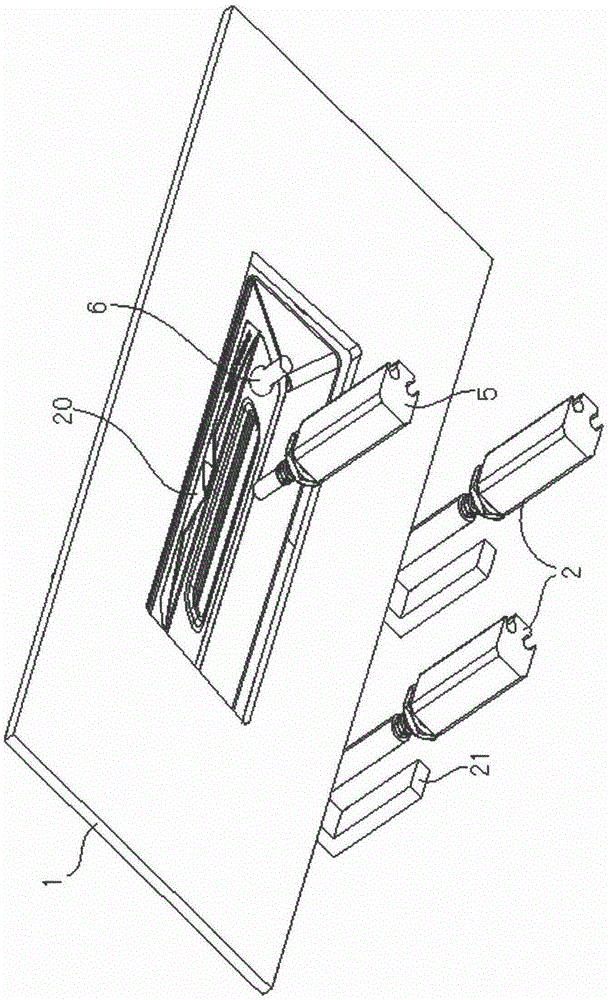

Spray water distribution system in plate-type indirect evaporative cooling system

InactiveCN102116512AAvoid corrosionImprove the protective effectTrickle coolersAir conditioning systemsEvaporationDistribution system

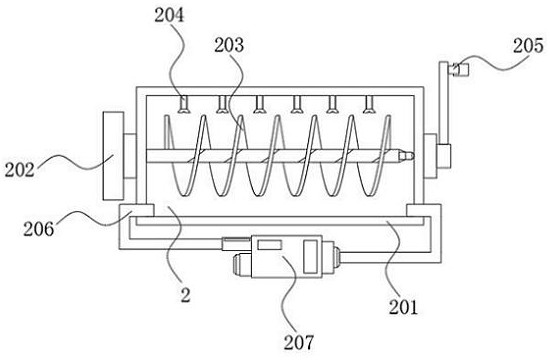

The invention relates to an air adjustment system by utilizing a plate-type air-air heat exchanger to indirectly evaporate and cool used in the heating ventilating and air conditioning field, in particular relates to a water system part of the system, and especially emphasizes an efficient and endurable spray water distribution subsystem in the water system. The water distribution rate improvement has vital function for improving the heat exchange efficiency and the refrigerating capacity. Meanwhile, the system has important function on sealing, corrosion prevention, scale prevention, blocking prevention, biohazard prevention and the endurable operation of the system in the water system in the opening environment. In the water distributor provided by the invention, a long and thin pipe consistent with the opening cross section of each evaporation channel is adopted as a water spray pipe which is provided with two rows of water spray holes; all the evaporation channels of the whole heat exchanger are fixedly sprayed correspondingly by a plurality of water spray pipe or a water spray pipe scanned by a track; evenly continuous water films are formed on each wall face of the heat exchanger; and the water distributing system is applied to the air-conditioner system of plate-type indirect water evaporation and cooling.

Owner:张洪

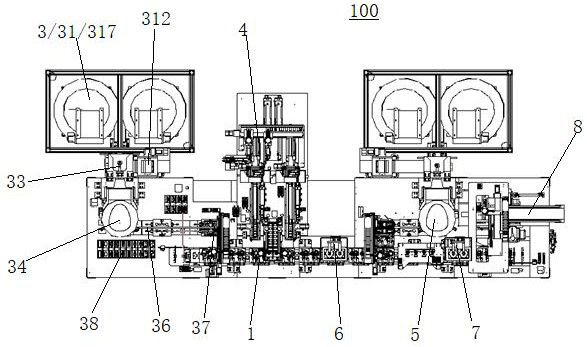

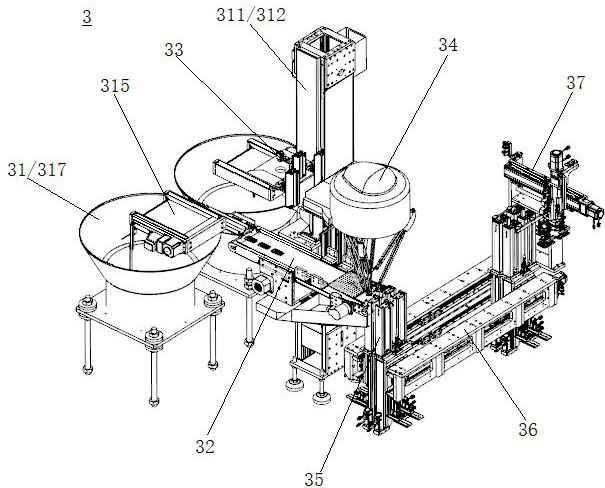

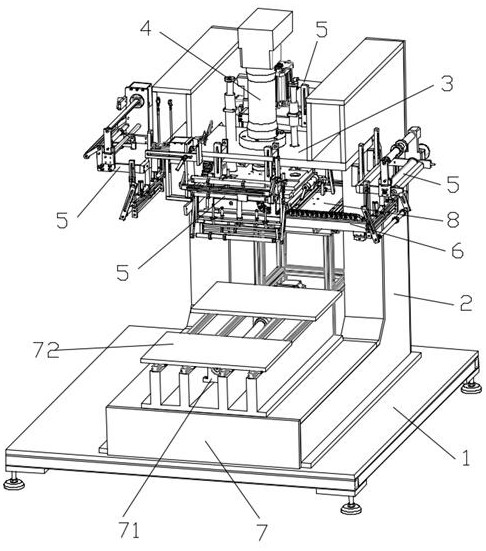

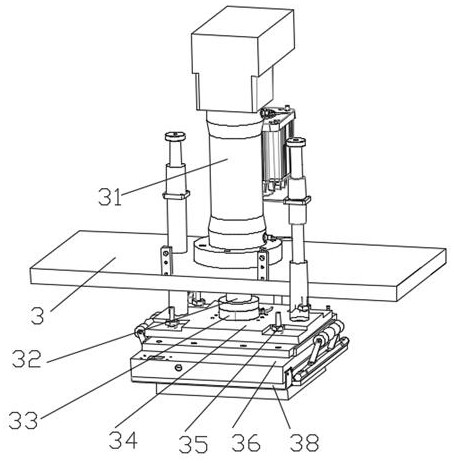

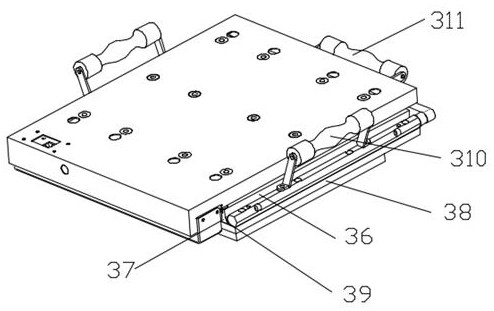

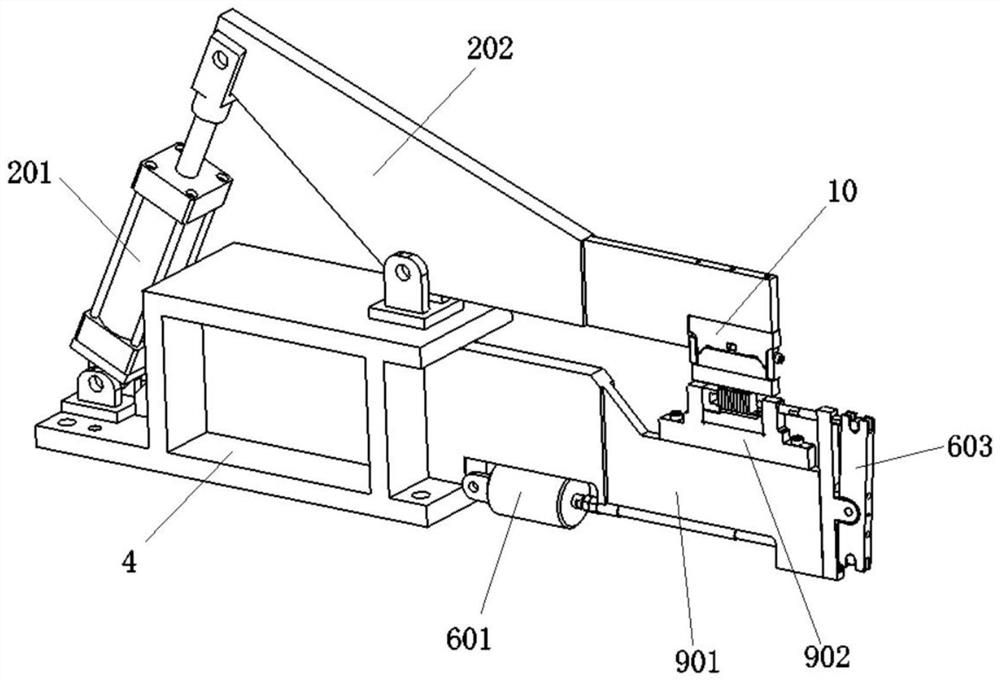

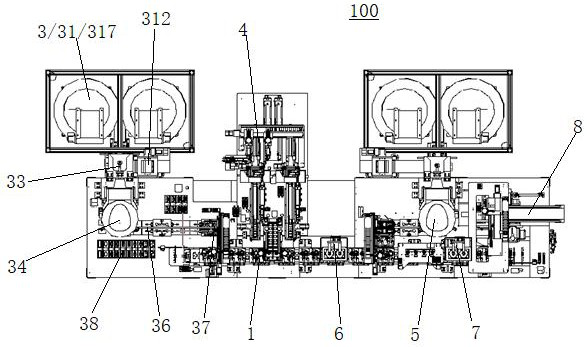

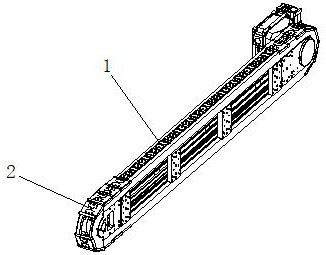

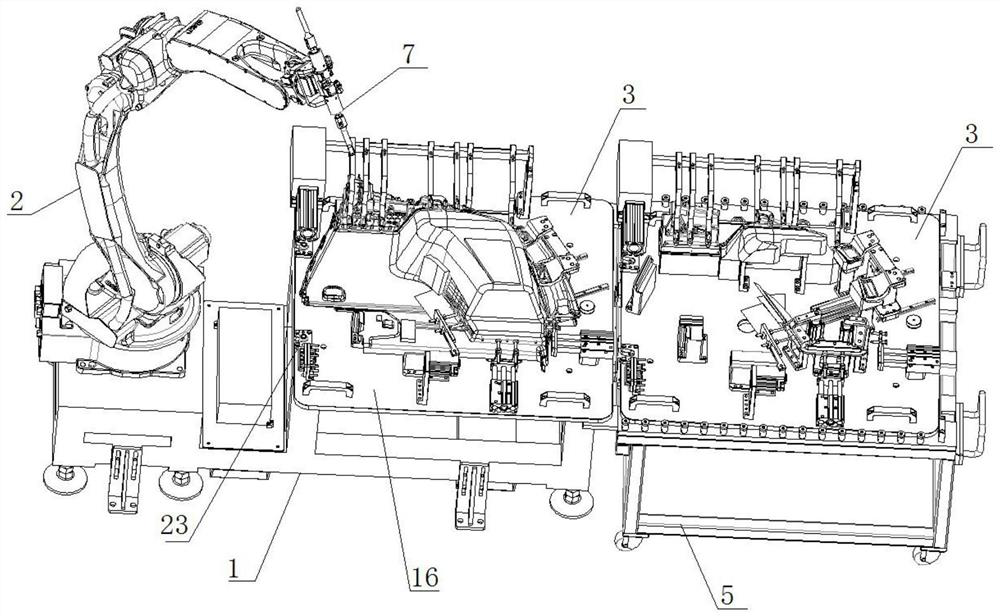

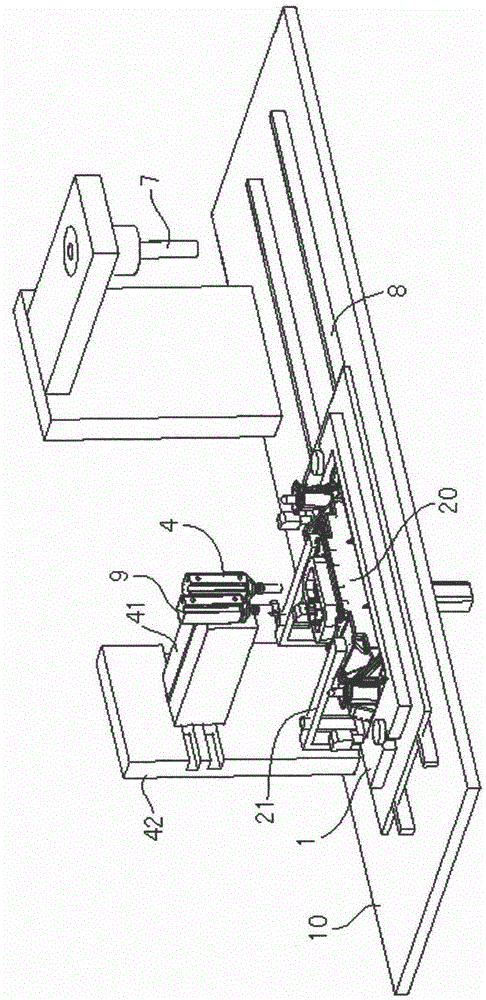

Automatic assembling production line compatible with medical kits of various models

ActiveCN112249699ARealize online automatic adjustmentRealize quick changeSortingMetal working apparatusProduction lineReagent strip

The invention discloses an automatic assembling production line compatible with medical kits of various models. The automatic assembling production line comprises a circulating conveying line body, aplurality of toolings that can be compatible with multiple different types of shells, and the toolings are arranged on the circulating conveying line body for cyclic utilization; a lower shell feeding, sorting and loading device; a reagent strip feeding, cutting and loading device; an upper shell feeding, sorting and loading device; and an unloading device; visual positioning units are arranged inthe lower shell feeding, sorting and loading device and the upper shell feeding, sorting and loading device, shells are screened and picked up into a shell clip through visual positioning screening in cooperation with a picking robot, and the shells are moved to a loading station through a transferring unit; and a shell clamping and loading unit is used for clamping the shells into the tooling toachieve loading. The automatic assembling production line provided by the invention can be compatible with various types of kits, and the universality of the production line is greatly improved.

Owner:KUNSHAN YITIAN AUTOMATION

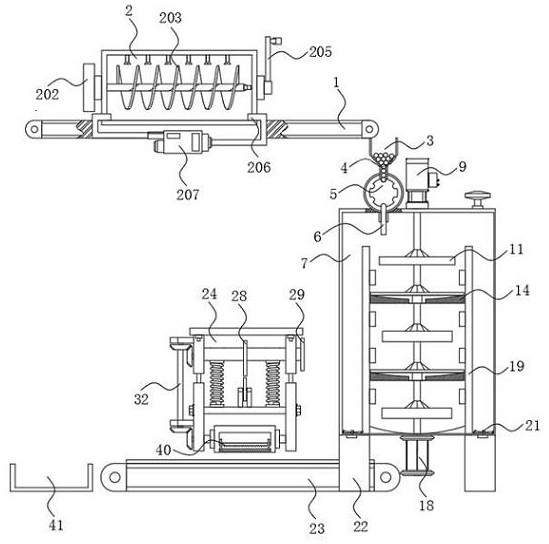

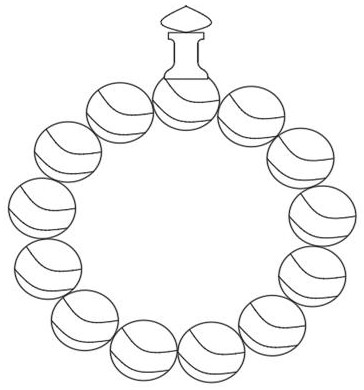

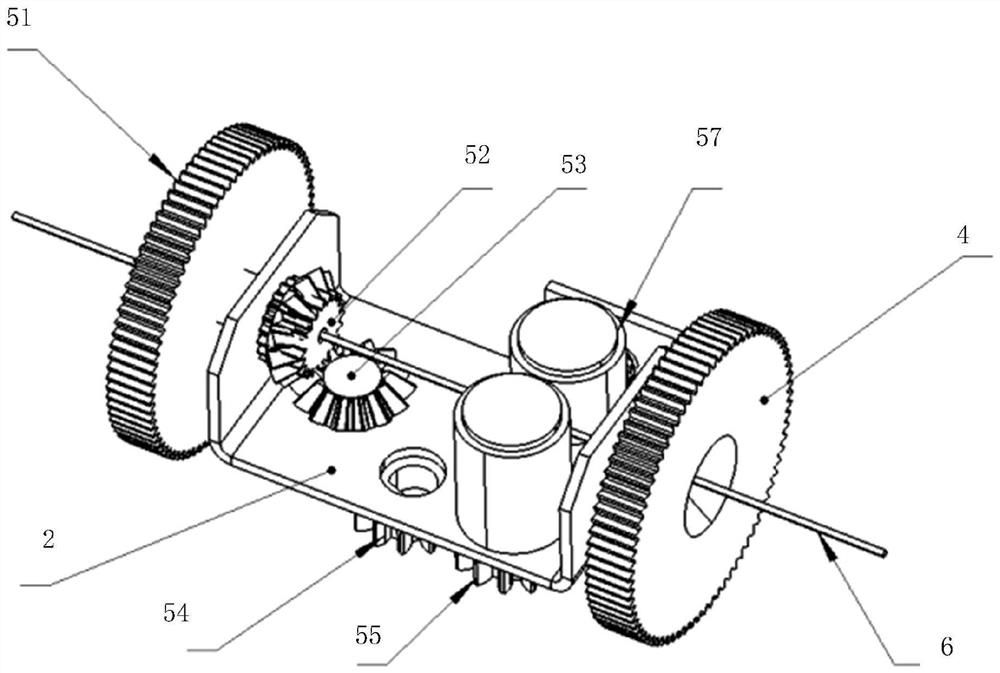

Production device with drying and polishing functions for processing Bodhi fruit hand strings

InactiveCN112264912AWith dry polishing functionQuick unloadingPolishing machinesDrying solid materials without heatSurface cleaningGear wheel

The invention discloses a production device with drying and polishing functions for processing Bodhi fruit hand strings, and relates to the technical field of jewelry processing. The production devicecomprises a first conveying belt, a surface cleaning mechanism, a disc type drying mechanism, a polishing and slurry coating mechanism and an abrasive paper quick-change mechanism, wherein the surface cleaning mechanism is arranged on one side of the top end of the first conveying belt. According to the production device with the drying and polishing functions for processing the Bodhi fruit handstrings, the polishing and slurry coating mechanism is arranged, so that the defect that existing hand string raw materials are mostly completed by manual auxiliary positioning in the background technology is perfectly overcome; the output stroke of a polishing roller is controlled through the intermittent contact stroke of the output end of a triangular cam and an idle wheel, the transverse stroke and the longitudinal stroke of the polishing and slurry coating mechanism are driven at the same time by using one power source, the transmission of a driving gear to a transmission gear is transmitted through a spline shaft, and the power output direction is changed through a direction changing gear; and a reset spring is arranged, so that rapid elastic reset of the polishing and slurry coatingmechanism is realized, and the applicability is very high.

Owner:东莞市帕特慕可科技有限公司

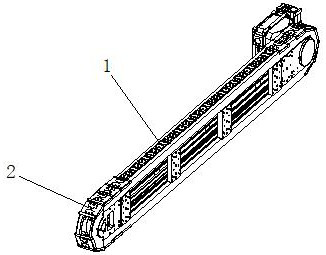

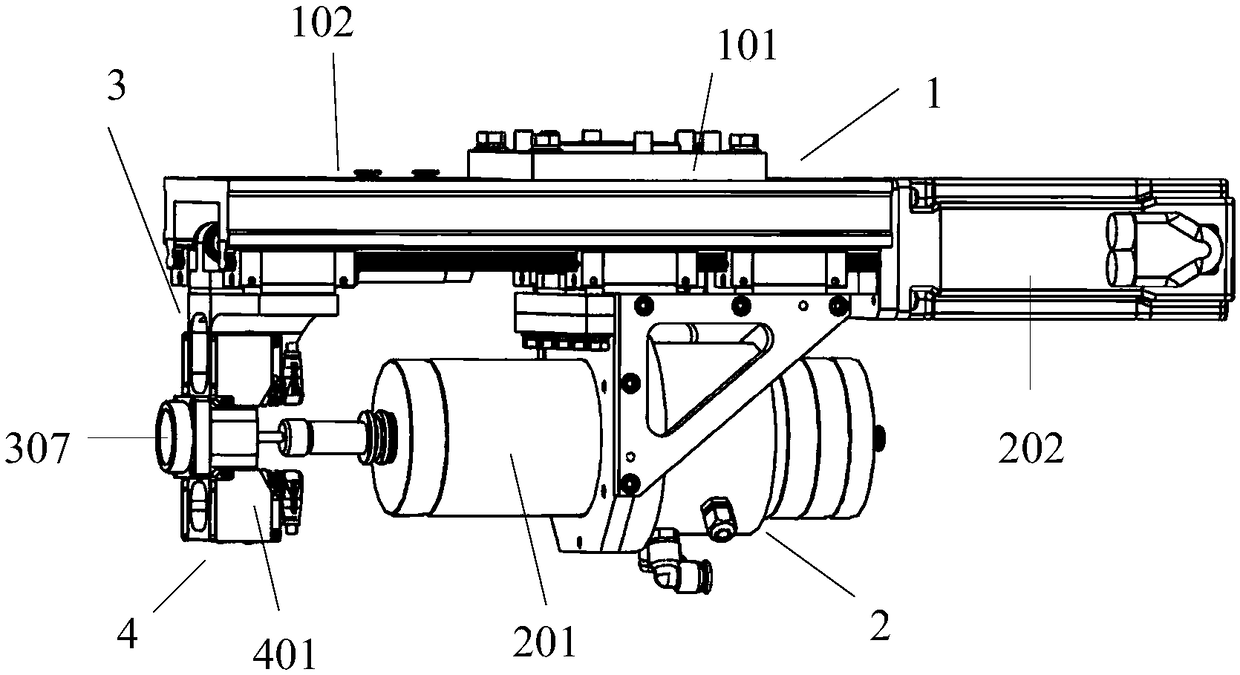

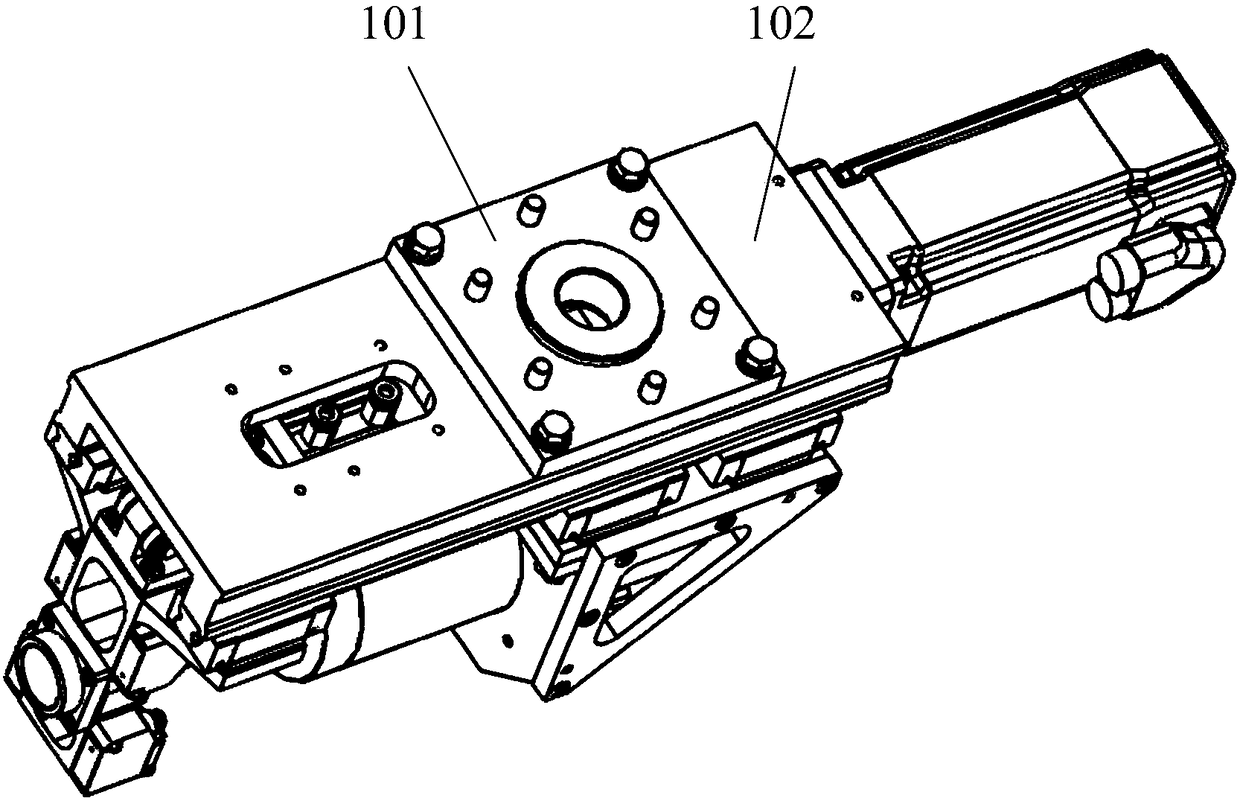

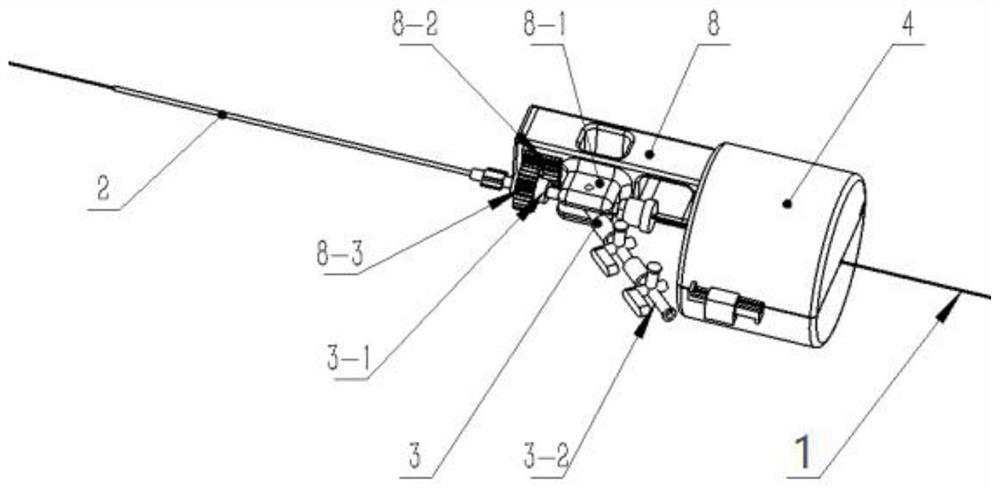

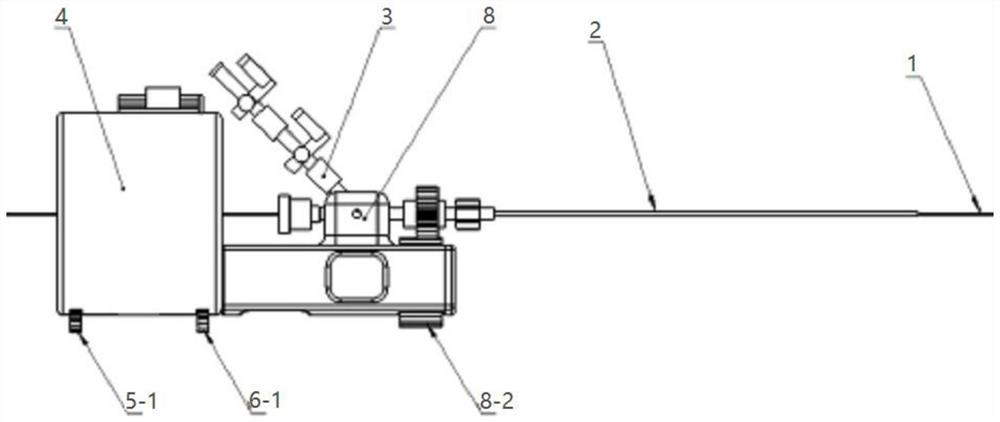

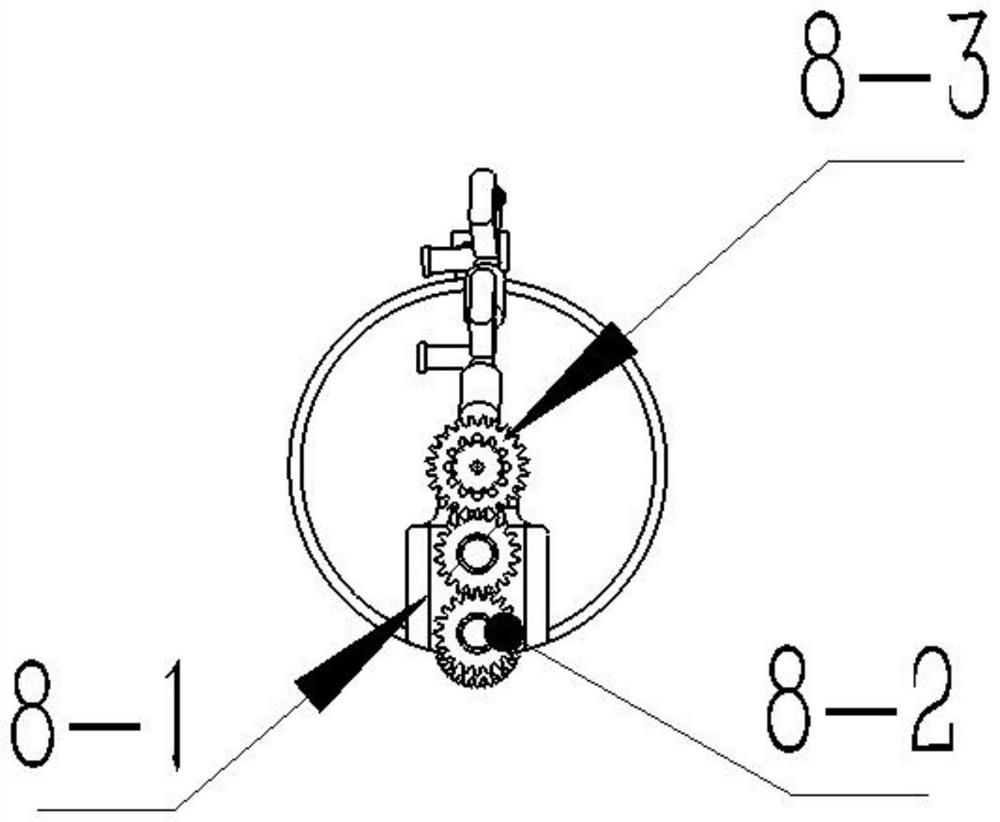

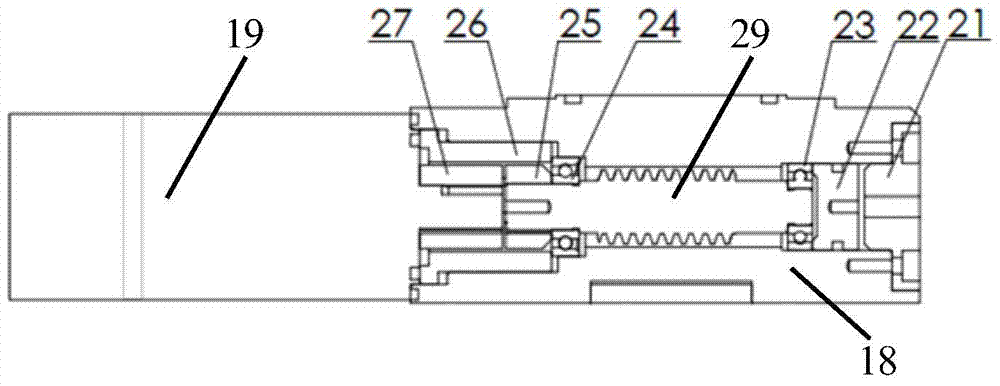

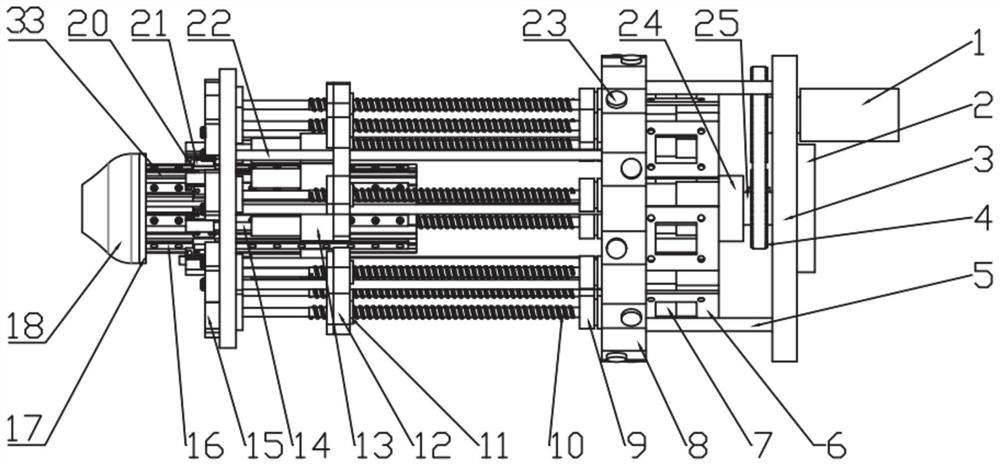

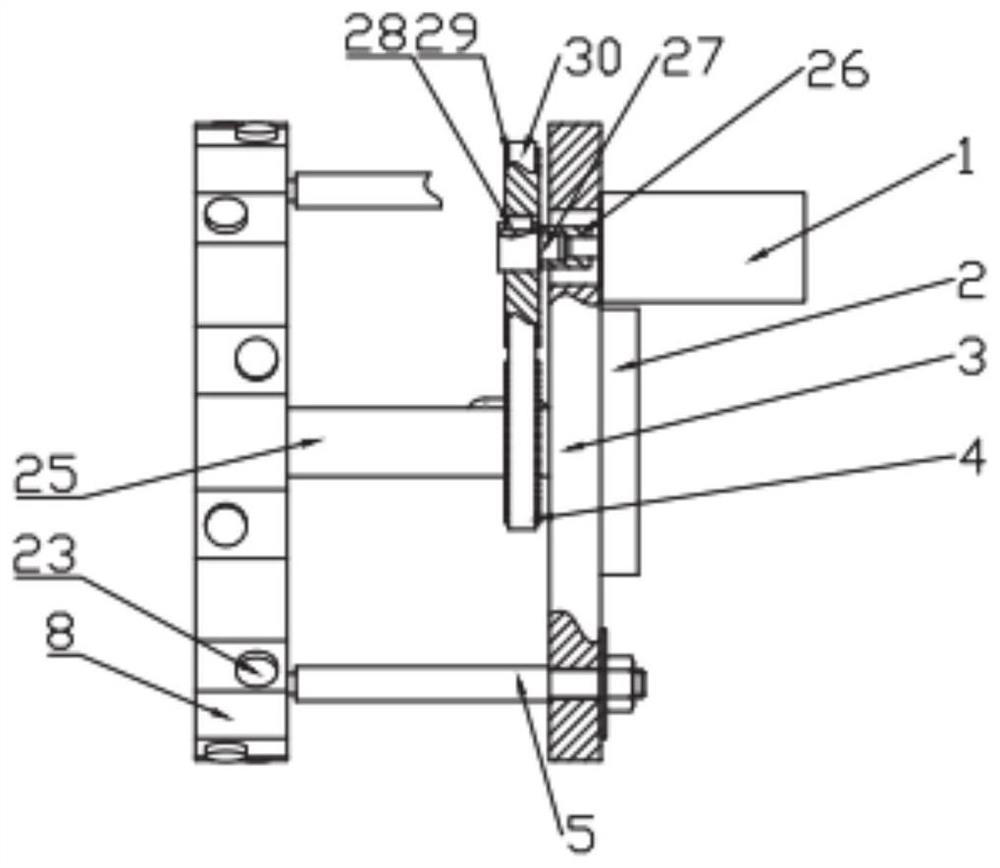

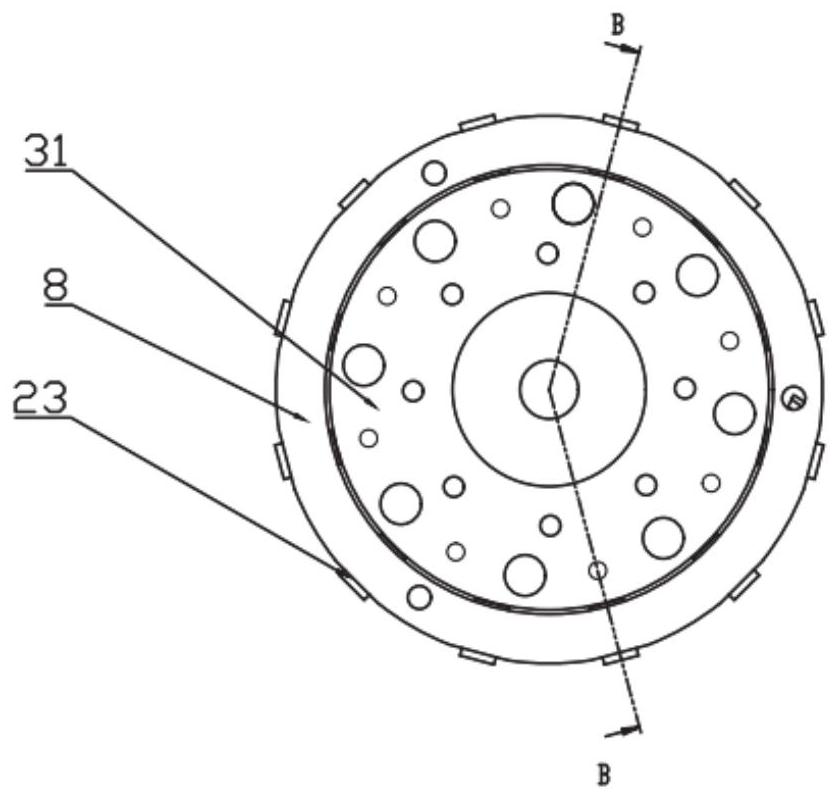

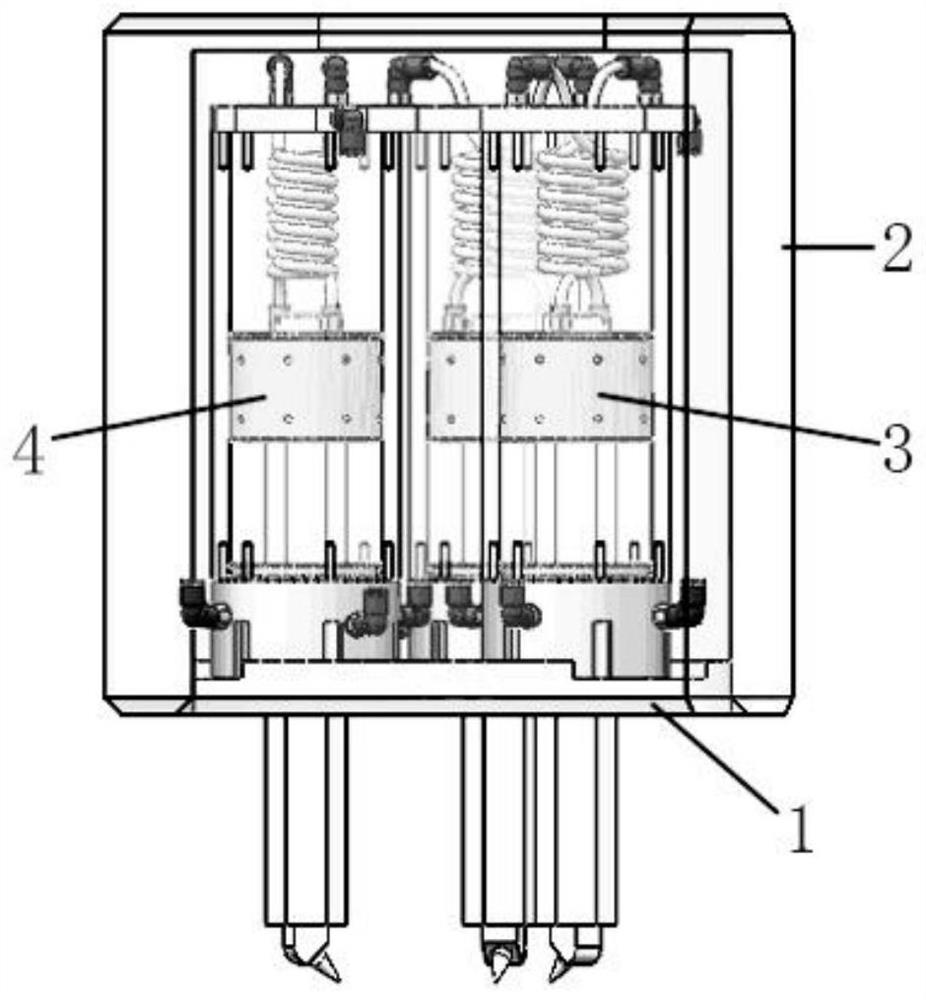

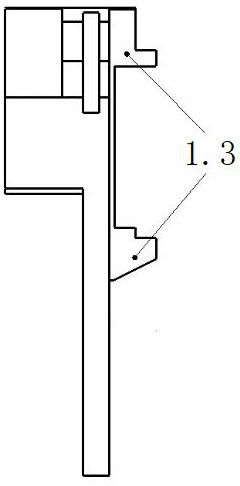

Linear driving device of surgical robot and surgical robot

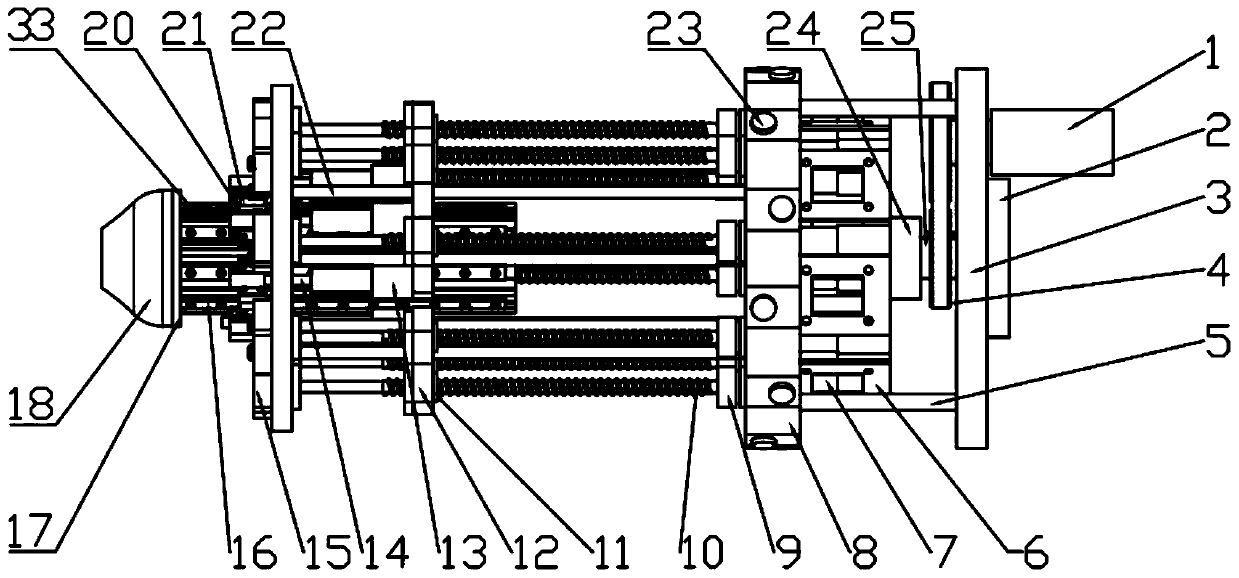

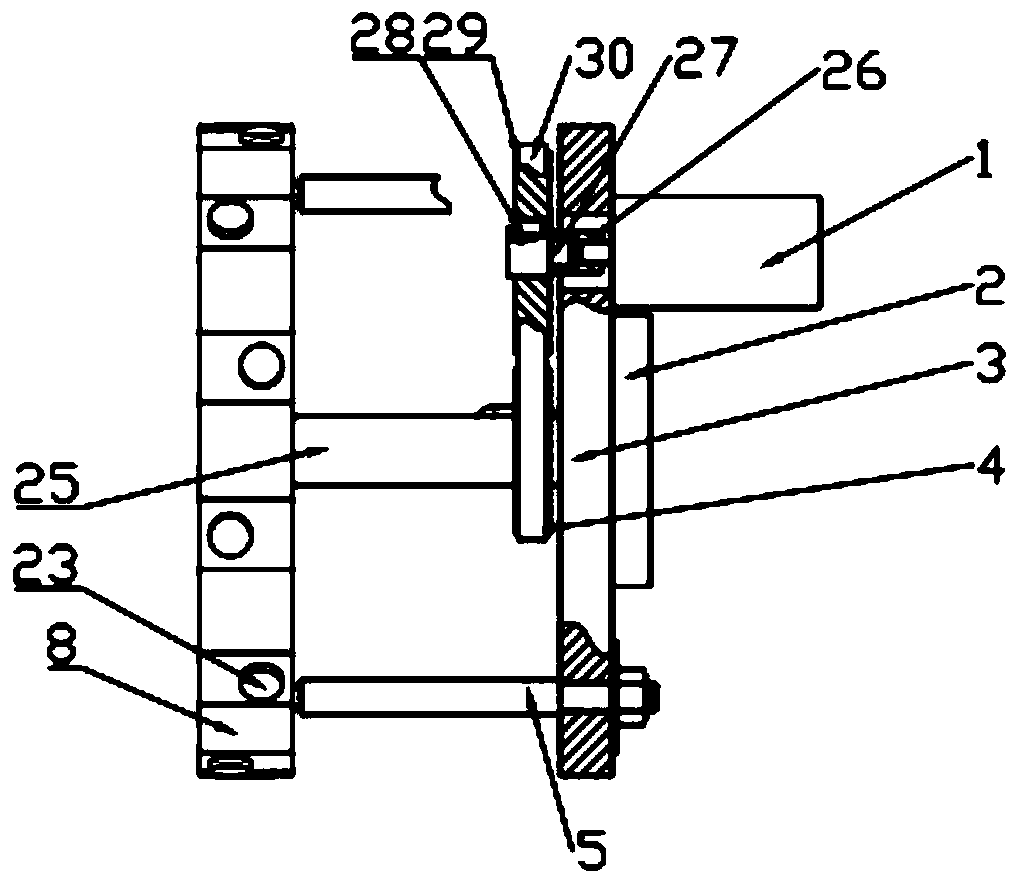

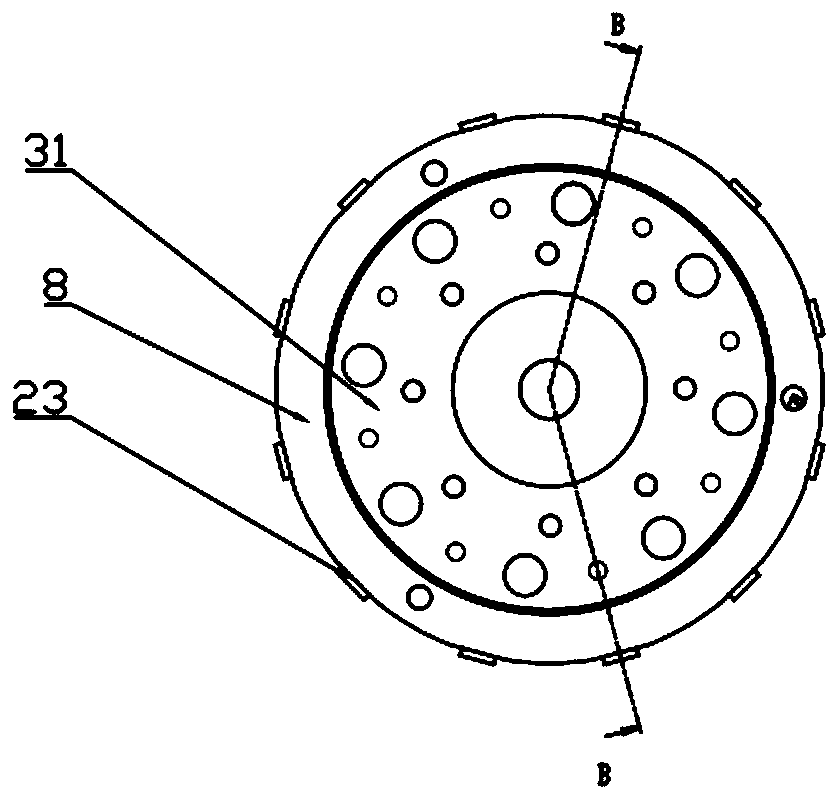

ActiveCN111529064ASimple structureSolve the entanglementSurgical manipulatorsSurgical robotsRobotic systemsLinear motion

The present invention discloses a linear driving device of a surgical robot and the surgical robot. A technical scheme is as follows: the linear driving device of the surgical robot comprises a rotational freedom degree module, a device driving module, a motion transmission module and a quick change module, the rotational freedom degree module is connected with device driving module, an output endof the device driving module is connected with the motion transmission module, and an output end of the motion transmission module is connected with the quick change module. A rotation motion of thedevice driving module is changed into a linear motion through the motion transmission module and transmitted to the quick change module, so that quick changes are realized. The linear driving device of the surgical robot can better realize the quick changes of different end actuators. The linear driving device of the surgical robot has universality, can realize a modularized use of a surgical robot system, and reduces use cost.

Owner:SHANDONG UNIV

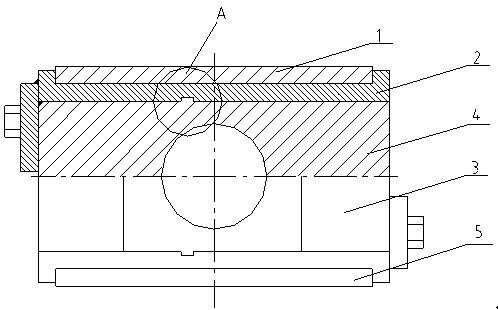

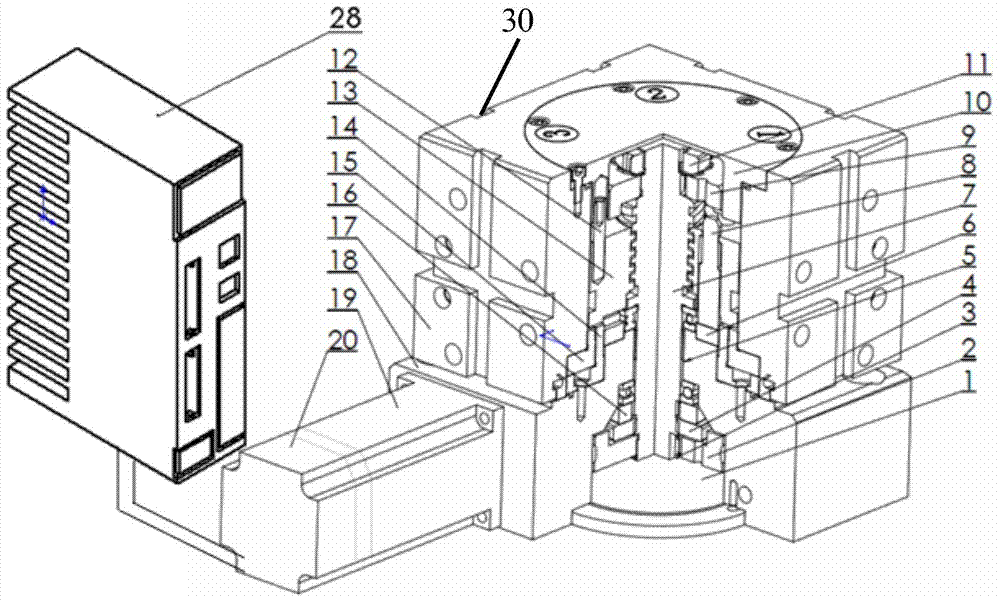

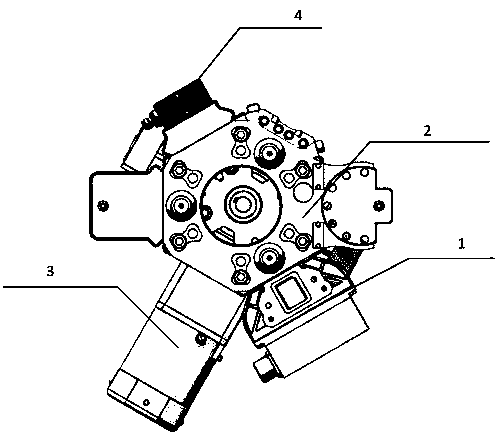

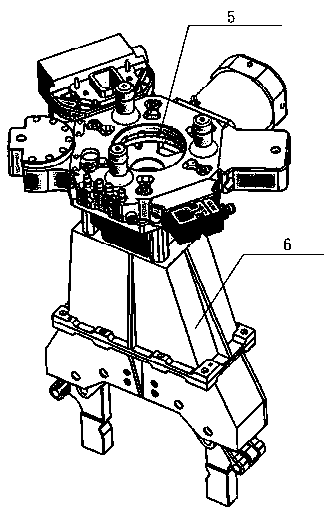

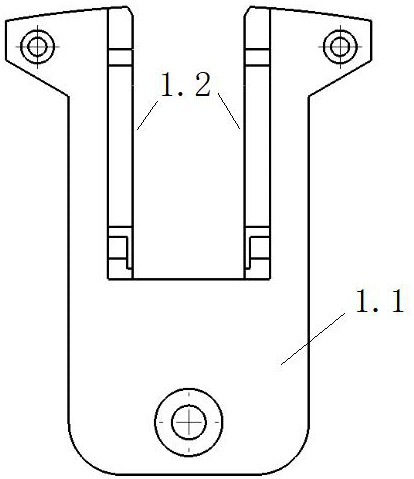

Compact hole-forming end executer for shared guide rails of electric spindle and pressure foot

InactiveCN108081281ARealize quick changeReduce downtime preparation timeGripping headsComputer moduleEngineering

The invention discloses a compact hole-forming end executer for shared guide rails of an electric spindle and a pressure foot. The compact hole-forming end executer comprises an installation base, a hole-forming unit, a compression unit and a normal detection unit. A flange connection plate connected with a robot end is installed on the upper surface of an installation base, two parallel guide rails are erected on the end parts of the two sides of the lower surface of the installation base, and the central axes of the two guide rails are superposed with the central axis of the lower surface ofthe installation base. The hole-forming unit and the compression unit are arranged on the two guide rails in parallel in the central axis direction through slide blocks, and the normal detection unitis installed on the compression unit. Rapid switchover with regard to different part surface compression functions can be realized through rapidly changing a pressing sleeve. According to the compacthole-forming end executer disclosed by the invention, the electric spindle of a hole-forming module and the pressure foot of a pressure foot module share one set of guide rails, and one transmissiondevice is reduced, so that the weight of the end executer is greatly reduced.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

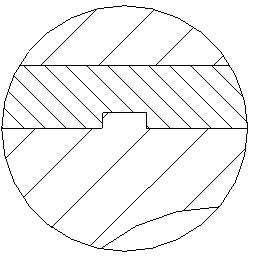

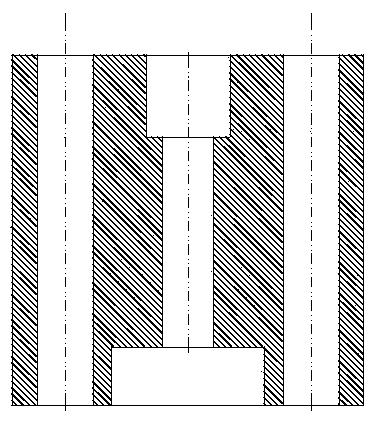

Main sliding block assembly of ring rolling mill

InactiveCN103521664AChange the installation methodEasy to assemble and disassembleMetal rollingRolling mill

The invention discloses a main sliding block assembly of a ring rolling mill. The main sliding block assembly comprises a transverse rack, machine body guide rails, a main sliding block, a wear-resisting copper plate I, a wear-resisting copper plate II and the like. The main sliding block assembly is characterized in that the main sliding block is connected with the wear-resisting copper plate I and the wear-resisting copper plate II through hook-headed plate brackets. The main sliding block assembly of the ring rolling mill has the advantages of changing the mounting mode of the wear-resisting copper plates on the main sliding block, being more convenient and faster to disassemble and assemble and simple and practical in structure, and improving work efficiency.

Owner:SHANDONG IRAETA HEAVY IND

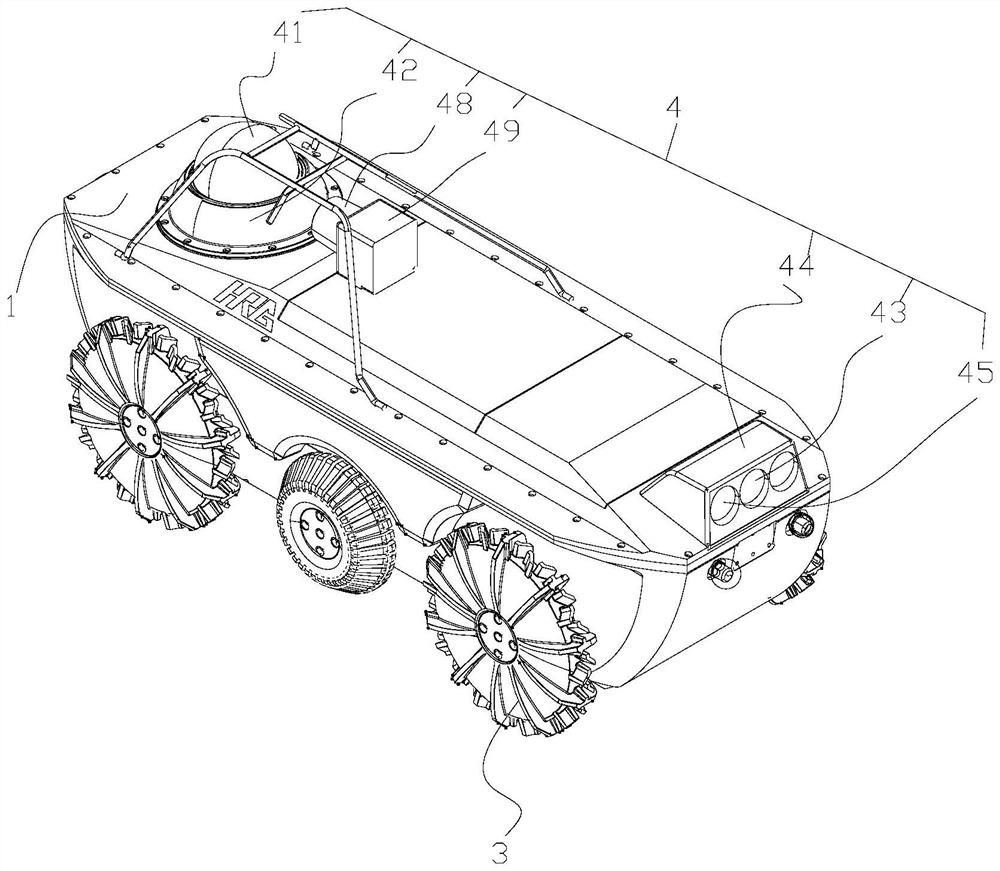

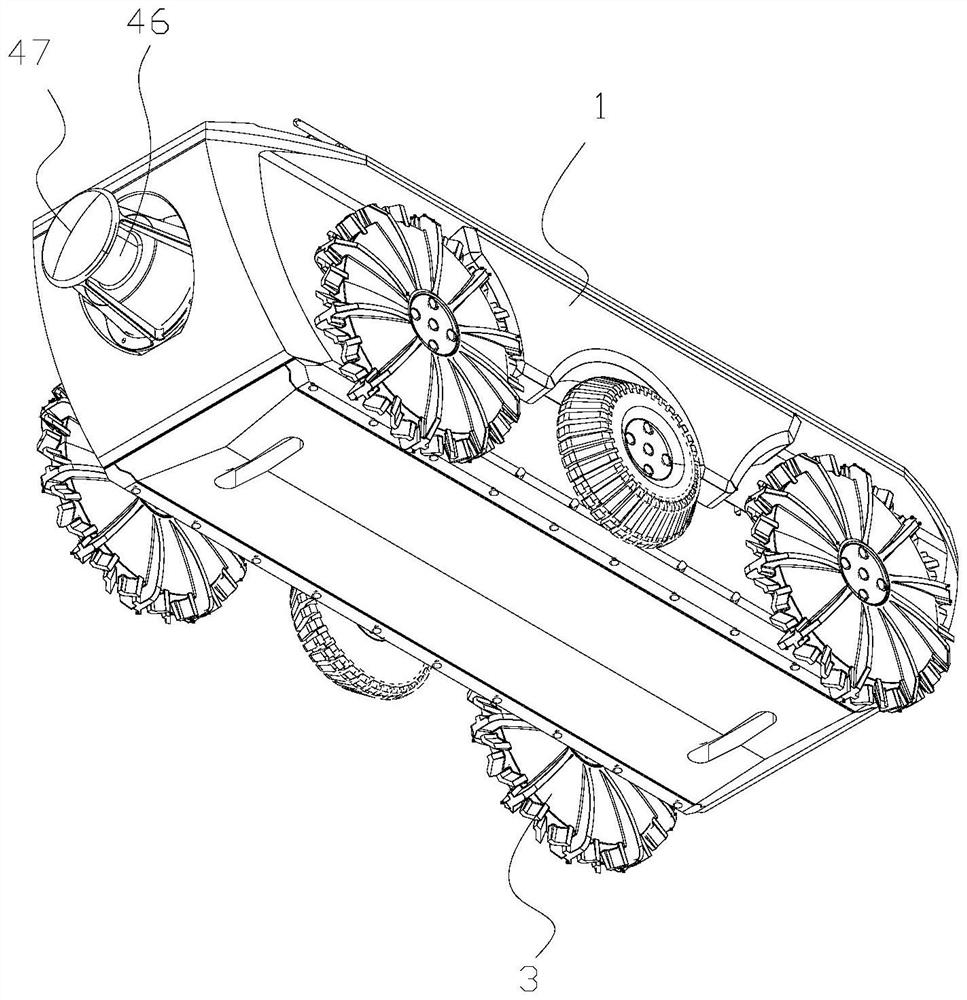

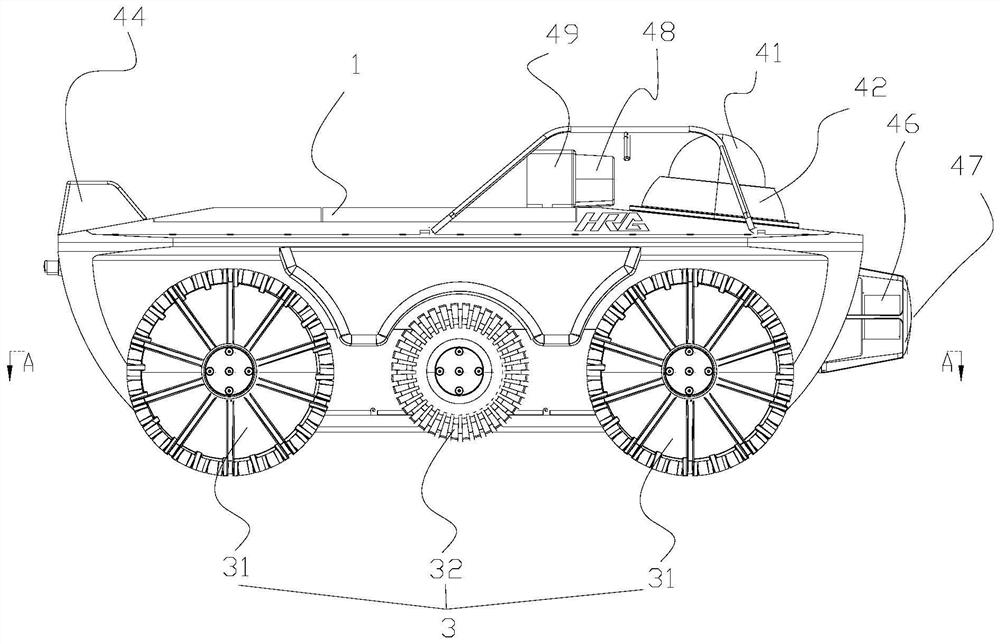

Pipeline detection robot

PendingCN114738598ASatisfy buoyancy requirementsLower center of gravityVehicular energy storagePigs/molesBalancing machineWater flow

The pipeline detection robot comprises a machine body assembly, a driving assembly, a wheel assembly, a detection assembly and a power source, the driving assembly and the power source are connected into the machine body assembly, the driving assembly is connected with the wheel assembly, and the detection assembly is connected with the outer surface of the machine body assembly; the driving assembly and the detection assembly are connected with the power supply; the machine body assembly comprises a first shell, a second shell and buoys, the first shell is connected with the second shell in a sealed mode, the buoys are connected with the two sides of the second shell, and the buoys are located above the wheel assembly; and the side part of the first shell or / and the second shell extends outwards to form a wing. The robot has the beneficial effects that the wings and the buoy are matched to form a water baffle, interference of water spray to the detection assembly is prevented, meanwhile, swing of the robot is balanced, and the horizontal posture is kept; the whole structure is light in weight, large in buoyancy and high in strength, and pipeline detection under the conditions of high water flow velocity and full water can be met.

Owner:HRG INT INST FOR RES & INNOVATION

Automobile grille thermoprinting machine

InactiveCN112644156AHot stamping effect is goodRealize quick changeRotary pressesPrinting press partsAdhesive beltStructural engineering

The invention discloses an automobile grille thermoprinting machine. The machine comprises a bottom frame, integrated thermoprinting frames are installed at the upper side of the bottom frame, a thermoprinting bottom plate is connected between the integrated thermoprinting frames, a thermoprinting device is installed at the middle side of the thermoprinting bottom plate, and thermoprinting foil tape winding and unwinding devices are installed at the two sides of the front side of the thermoprinting bottom plate respectively. Thermoprinting foil tape winding and unwinding devices are installed at the two sides of the left sides of the integrated thermoprinting frames correspondingly, and foil tape adhesive tape tearing mechanisms are installed on the thermoprinting foil tape winding and unwinding device at the left side of the thermoprinting bottom plate and the thermoprinting foil tape winding and unwinding devices at the front sides of the integrated thermoprinting frames correspondingly. The automobile grille thermoprinting machine has the beneficial effects that a thermoprinting machine servo press drives and is provided with a pressure sensor, and the thermoprinting effect is good; a thermoprinting feeding mechanism can be placed in the left-right direction and the front-back direction; and a thermoprinting silica gel plate on a thermoprinting machine heating plate is mounted on the heating plate in a drawing and inserting manner, so that the silica gel plate can be quickly replaced, and the working time is saved.

Owner:苏州汇取智能机械有限公司

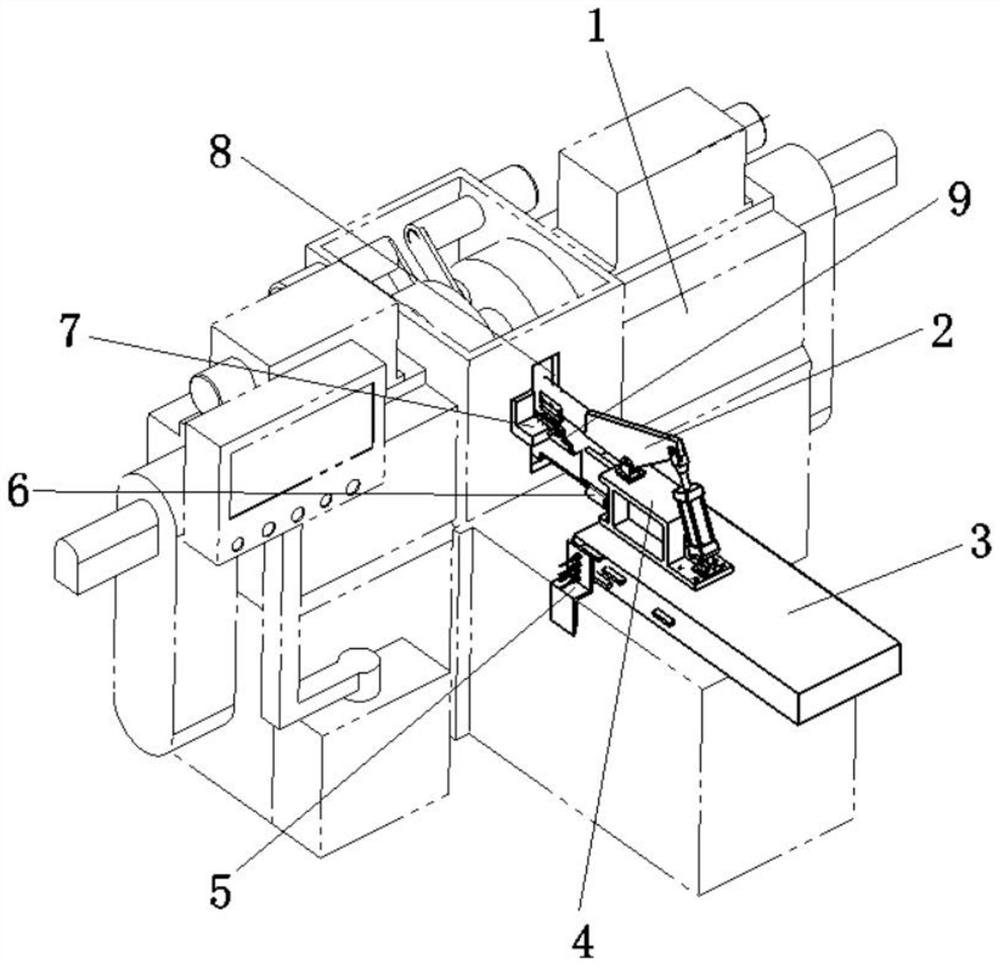

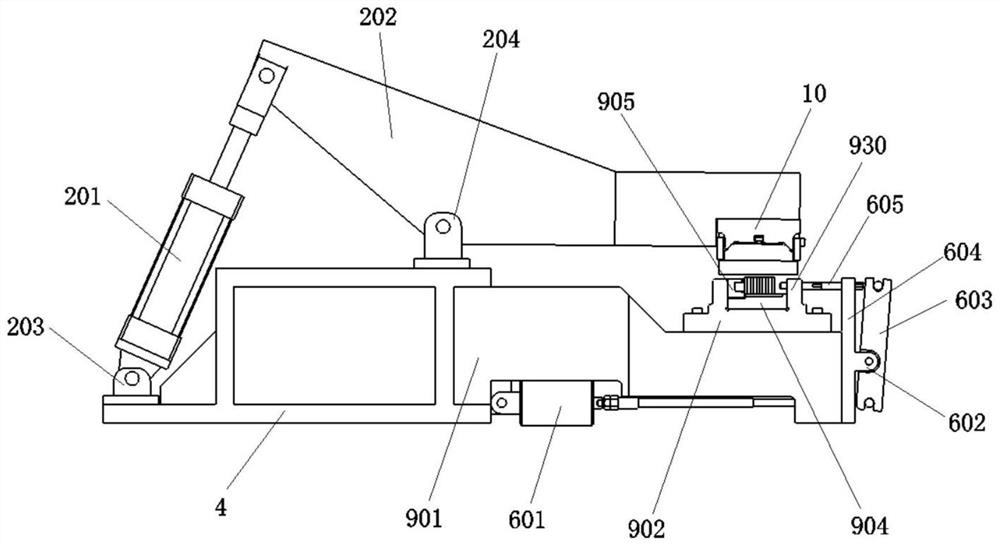

Tube and wire driving device of vascular intervention surgical robot

PendingCN114699172ASimplify the setup processRealize quick changeGuide wiresMechanical energy handlingLinear drivePhysical therapy

The invention relates to a tube and wire driving device of a vascular intervention surgical robot, and relates to the technical field of medical instruments. Comprising a guide wire driving device and a catheter driving device, and the guide wire driving device comprises a sterile isolation shell, a loading supporting mechanism, a rotary movement mechanism and a linear operation mechanism; the loading support mechanism, the rotary motion mechanism and the linear operation mechanism are all mounted in the sterile isolation shell; the linear running mechanism comprises a linear driving device, a transmission device and a long and straight consumable driving wheel set, the end, located on the outer side of the loading supporting mechanism, of the transmission device is in transmission connection with the linear driving device, and the end, located in the loading supporting mechanism, of the transmission device is in transmission connection with the long and straight consumable driving wheel set; the rotary movement mechanism is installed at the end, away from the linear driving device, of the loading supporting mechanism. The long-distance collaborative delivery of the catheter and the guide wire can be completed; the operability, the safety and the usability of the minimally invasive vascular interventional operation assisted by the robot are improved.

Owner:易度河北机器人科技有限公司

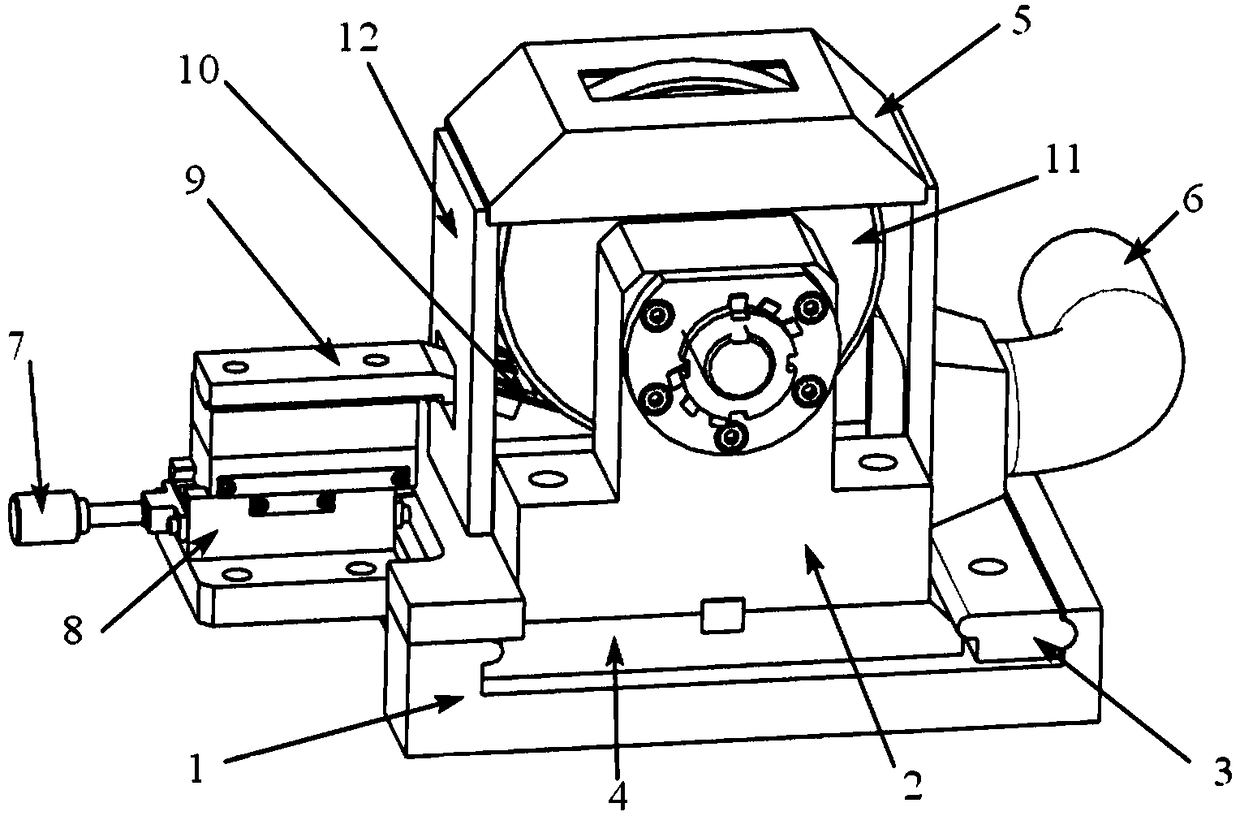

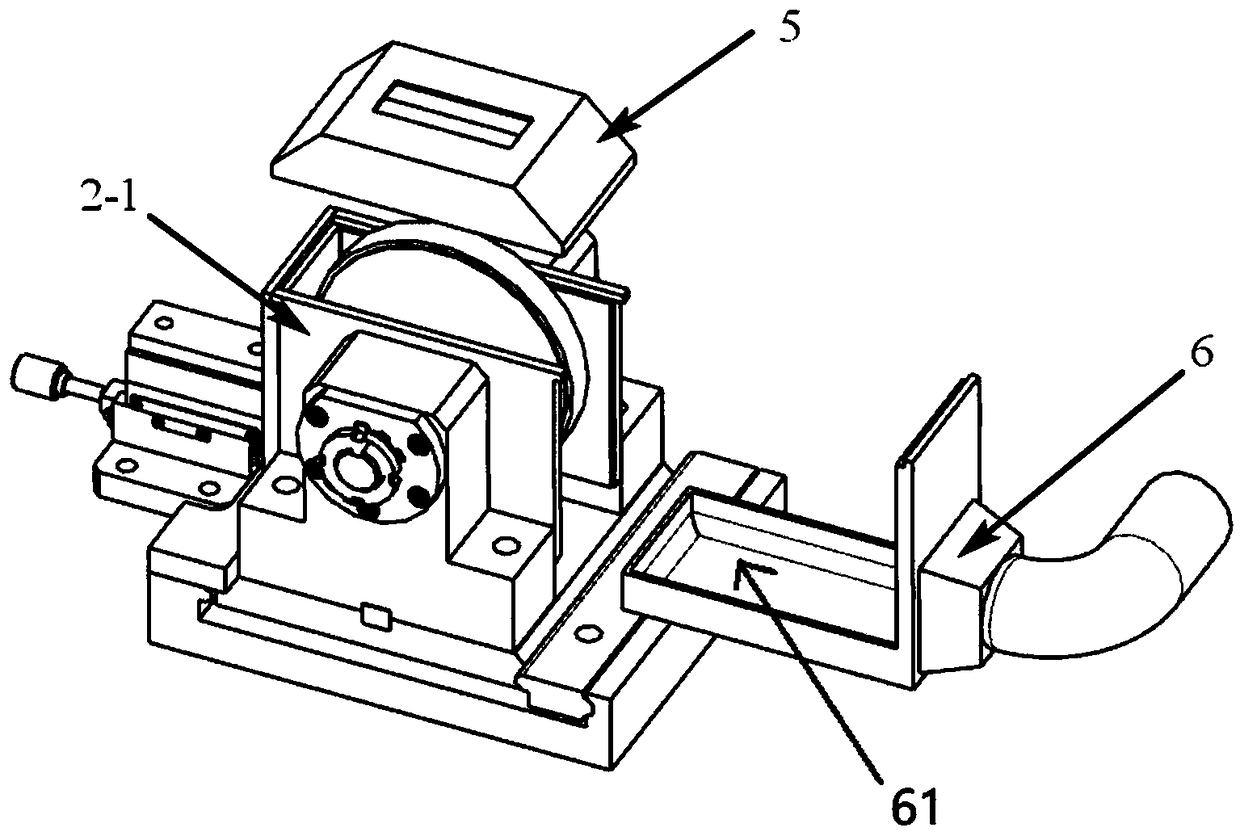

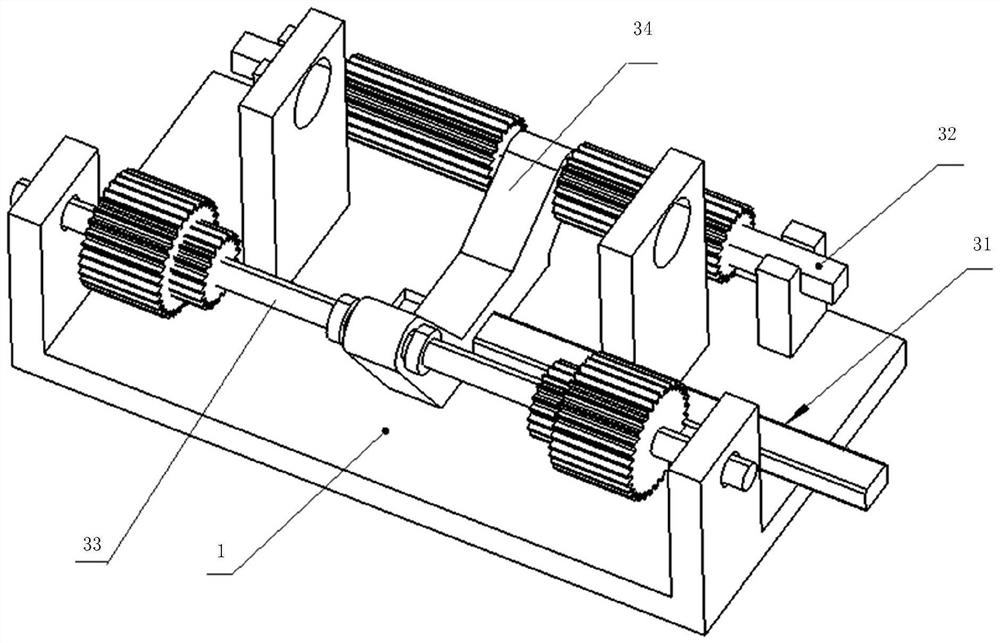

Reciprocating grinder automatic feeding and grinding clamp

PendingCN112658985APrevent looseningReduce adjustmentGrinding work supportsHydraulic cylinderStructural engineering

The invention discloses a reciprocating grinder automatic feeding and grinding clamp. The automatic feeding and grinding clamp comprises an existing reciprocating grinder, a hydraulic sliding table is installed at the position, close to a feeding port, of the reciprocating grinder, a supporting base is fixedly installed on the hydraulic sliding table, and a feeding device stretching into the feeding port is fixedly connected to the supporting base. A floating pressing mechanism and a jacking mechanism are installed at the top and the bottom of the feeding device respectively, and a side face positioning block is fixedly installed at the position, located at one side of the feeding device, of the feeding port. The floating pressing mechanism and the jacking mechanism are both driven by a hydraulic cylinder, it can be guaranteed that the pressing force is stable enough, and a slip sheet is prevented from loosening in the grinding process; and meanwhile, the floating pressing mechanism adopts a floating pressing manner, the clamp adjusting amount can be reduced during product remodeling, the clamp can be compatible with grinding of products of various types and sizes, and the universality is high.

Owner:XINAN TOOLS GUIZHOU PROV

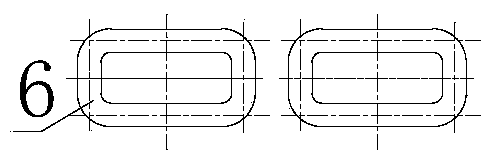

Ultrasonic roll welding anvil base with metal chip scraping and dust removing functions

InactiveCN109483039AConvenient position adjustmentDoes not affect positional accuracyNon-electric welding apparatusEngineeringBody positions

The invention discloses an ultrasonic roll welding anvil base with metal chip scraping and dust removing functions. The ultrasonic roll welding anvil base comprises a fixed base, a dovetail groove base plate positioned on the fixed base and slidingly connected with the fixed base, pressing plates positioned on two sides of the dovetail groove base plate, bearing bases positioned on the dovetail groove base plate, and an anvil base main body positioned between the bearing bases and mounted through bearings; a scraper module is arranged on one side of the base, and is slidingly connected with the base; a dustproof mechanism is arranged out of the anvil base main body; and the scraper module penetrates through the dustproof mechanism and approaches the anvil base main body. The ultrasonic roll welding anvil base is convenient to adjust the position to realize quick change, and can effectively scrape off metal chips to guarantee downward splashing of the scraped metal chips; and the dustproof mechanism and the scraper module are symmetrically arranged, so that the disassembly is convenient, the chips and dust can be effectively removed, and the welding quality is improved.

Owner:SBT ULTRASONIC TECH CO LTD

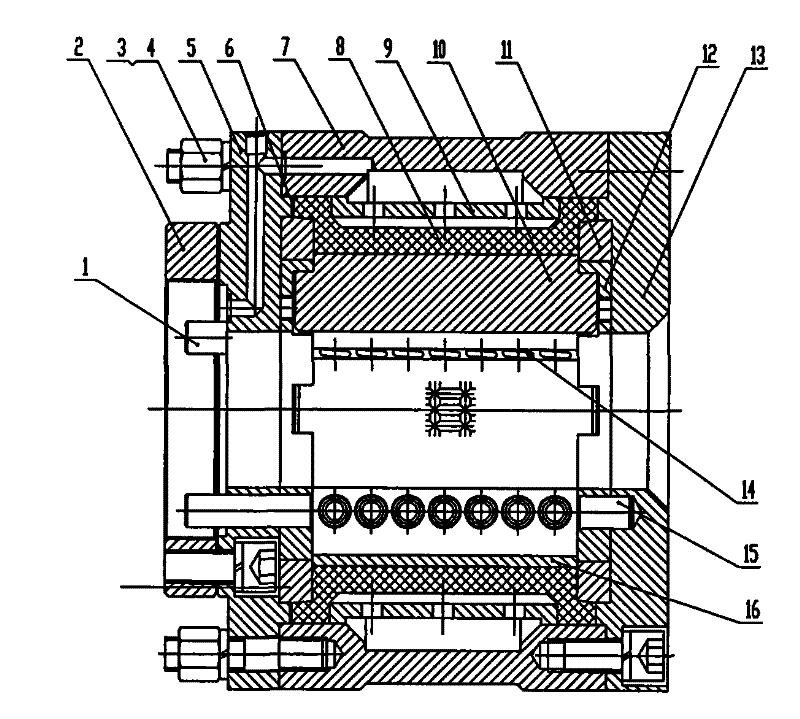

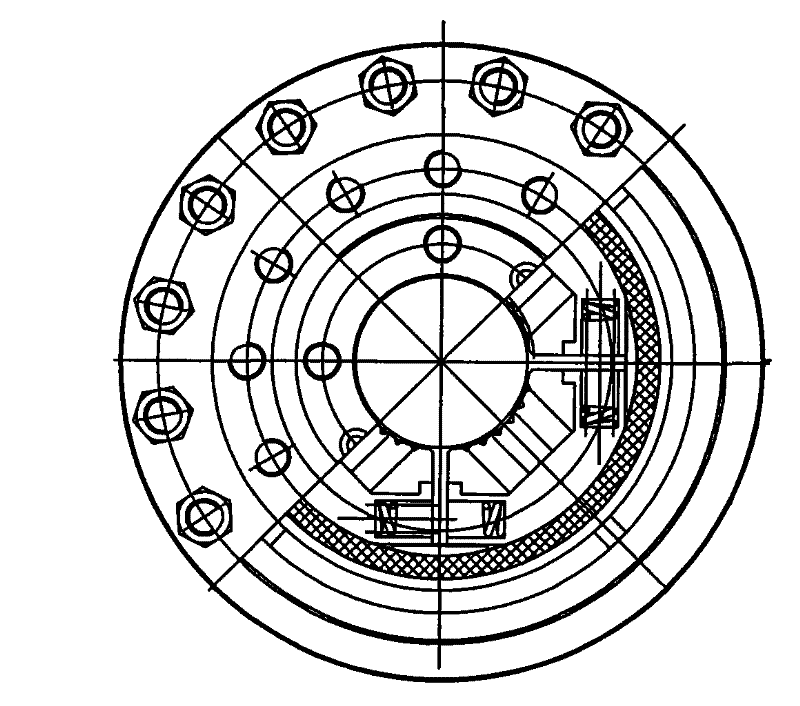

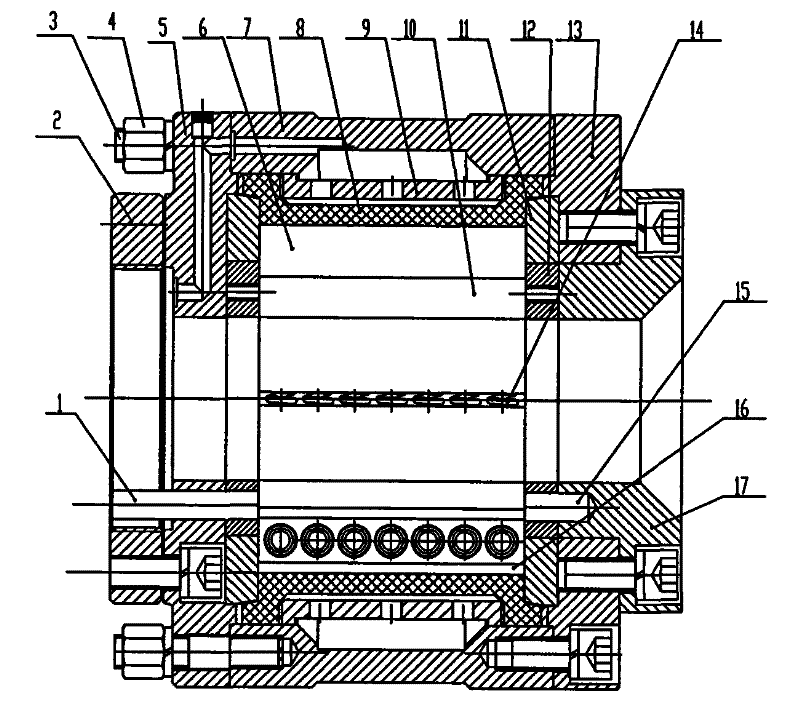

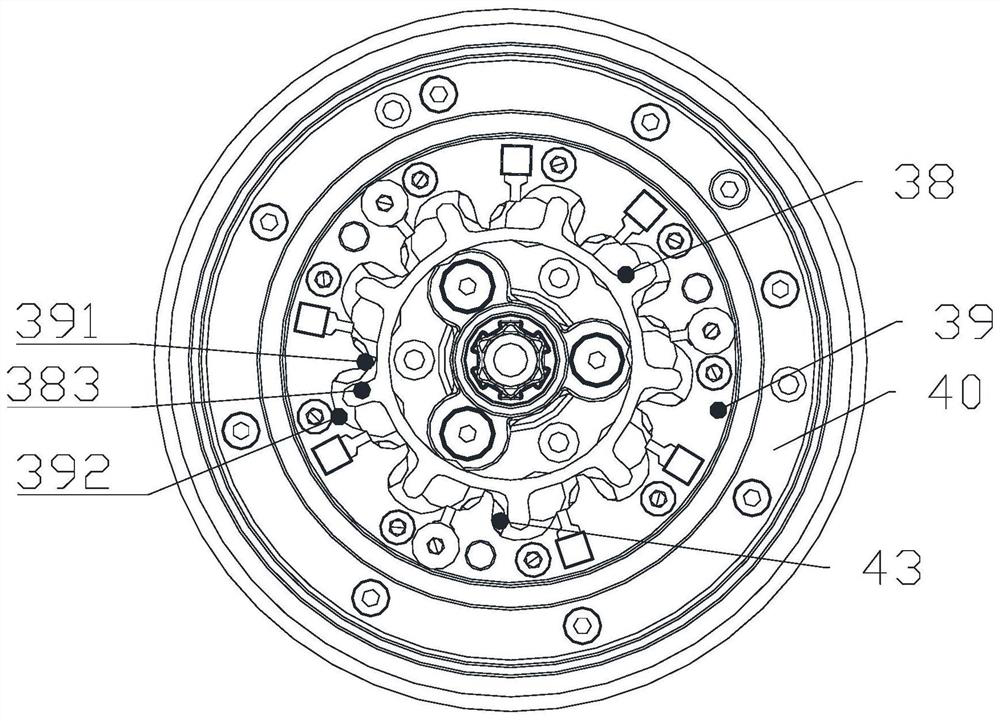

Quick-change slips hydraulic rubber cylinder chuck

ActiveCN101538989BSafe and reliable clamping workRealize quick changeDrilling rodsDrilling casingsAgricultural engineeringMoment of inertia

The invention relates to a chucking device, in particular to a quick-change slips hydraulic rubber cylinder chuck which adapts to a full hydraulic power head drill machine. When the slips of the prior hydraulic rubber cylinder chuck is replaced, a hydraulic slips disc needs to be integrally disassembled for reassembly, and under most conditions, the rubber cylinder is replaced simultaneously, so the service life of the rubber cylinder is manually shortened, and the production cost is increased. On the basis of the hydraulic rubber cylinder chuck, the quick-change slips hydraulic rubber cylinder chuck is additionally provided with the slips, a slips seat and an end press cover, and when the slips in different specification sizes is replaced, only the end press cover needs to be disassembled so as to pump out the slips from the slips seat. The hydraulic chuck does not need to be integrally disassembled so as to achieve the aim of quick change. The quick-change slips hydraulic rubber cylinder chuck has small outline dimension and low opening pressure, is beneficial to the pressure coordination between branch paths of a hydraulic system, improves the efficiency of the hydraulic systemand also has the advantages of safe and reliable chucking work of the hydraulic rubber cylinder chuck and small rotation inertia. When the quick-change slips hydraulic rubber cylinder chuck is matched with a hydraulic holder in the hydraulic system with the function of linkage, the quick-change slips hydraulic rubber cylinder chuck can guarantee the coordinated motion.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

A vertical electric servo tool holder and its use method

ActiveCN104816171BEfficient use ofRealize the purpose of economic and environmental protectionFeeding apparatusLarge fixed membersNumerical controlLocking mechanism

The invention relates to the field of numerical control tool holders, in particular to a vertical electric servo tool holder used by a numerical control lathe and a method for using the same. The vertical electric servo tool holder is equipped with a square knife table, a servo motor, a transmission mechanism, and a locking mechanism. The square knife table is located above the base. The square knife table has a keyway, and the keyway is connected with a quick-change tool holder mechanism; Above, the servo motor is connected to the worm through the motor coupling, bushing, and worm coupling. A servo motor encoder is installed at the end of the servo motor, and the servo motor is connected to the servo motor driver. The servo motor of the transmission mechanism is connected to the worm, and the worm meshes with the worm gear. The worm gear is connected with the screw sleeve, the transmission disc, and the transmission pin, and the movable toothed plate and the square knife table are connected with the transmission pin through the connecting plate; the locking mechanism drives the movable toothed plate to mesh with the upper toothed plate and the end faces of the lower toothed plate. The invention solves the problems of low reliability and high failure rate of the existing tool holder encoder due to the influence of the environment, and has compact structure and low failure rate.

Owner:SHENYANG MASCH TOOL CO LTD

Energy-saving cooking range

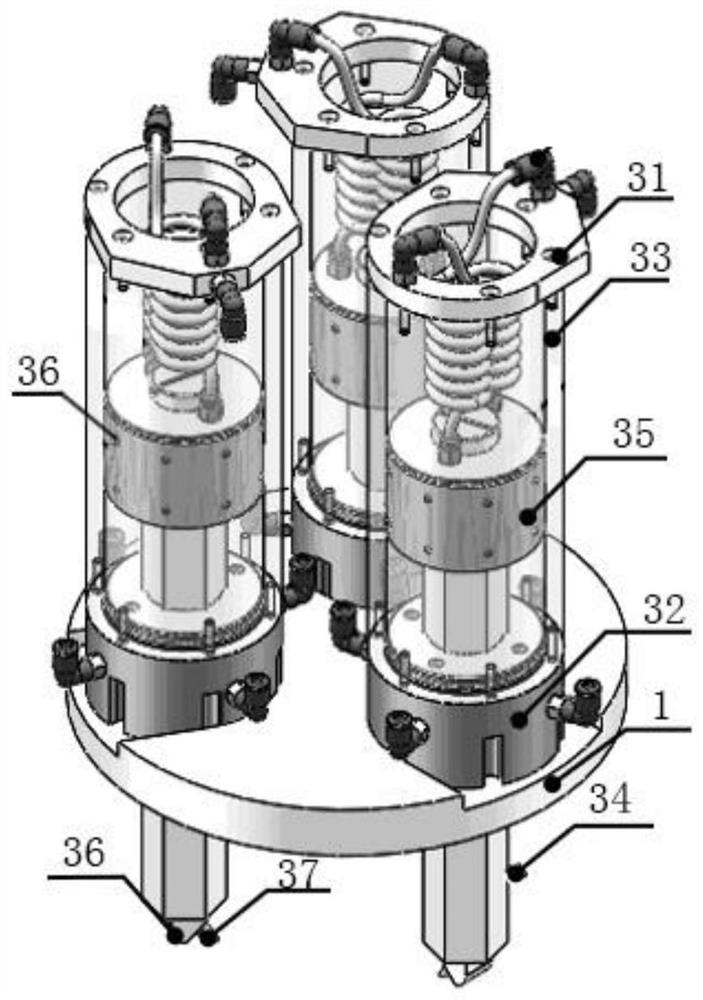

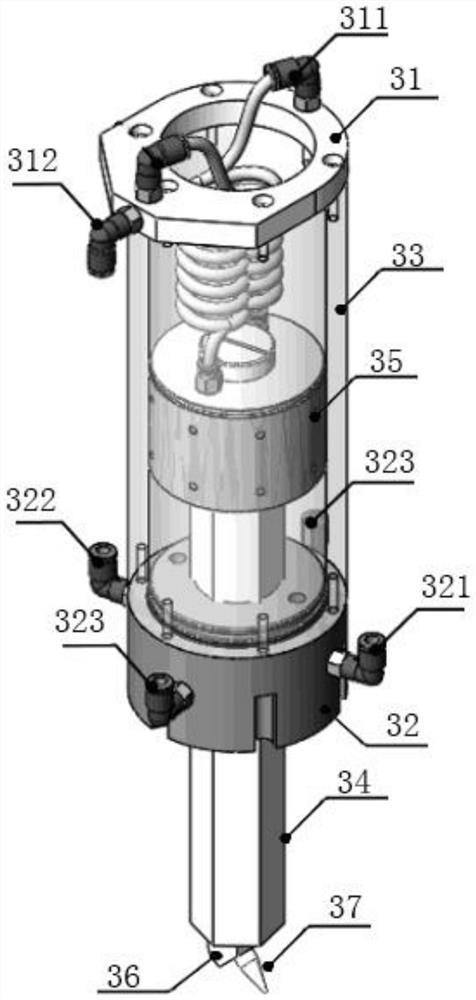

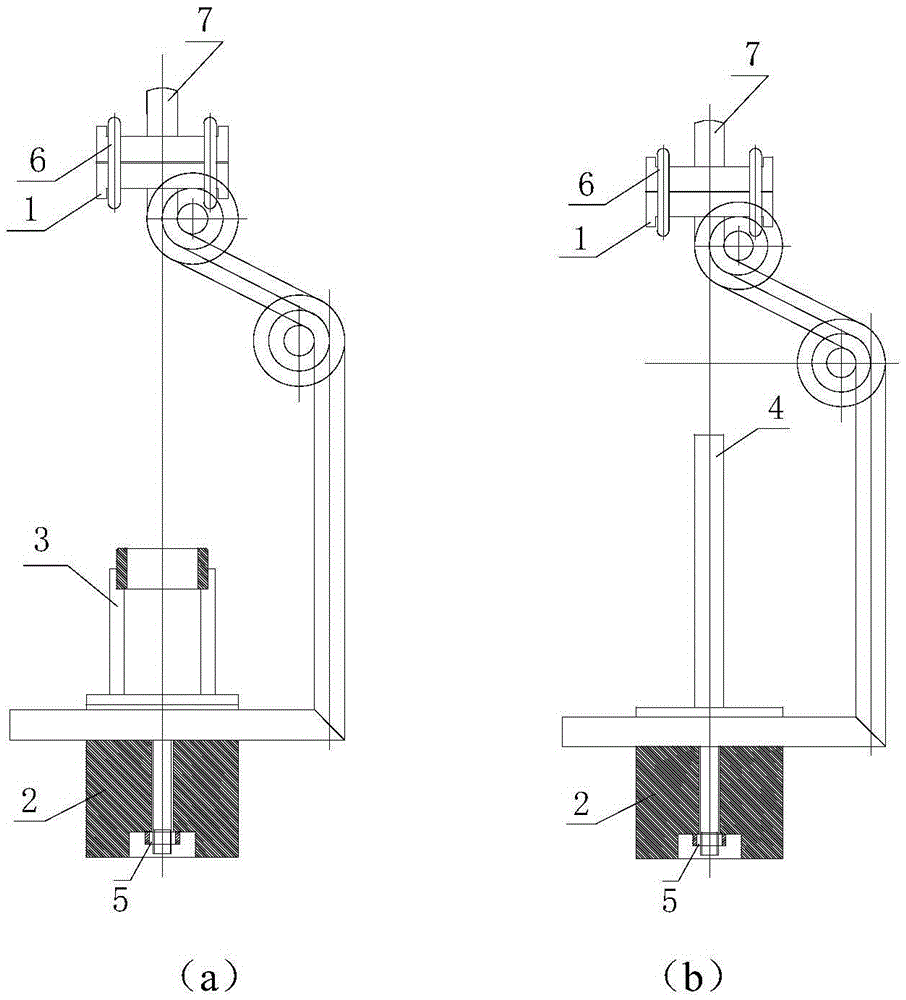

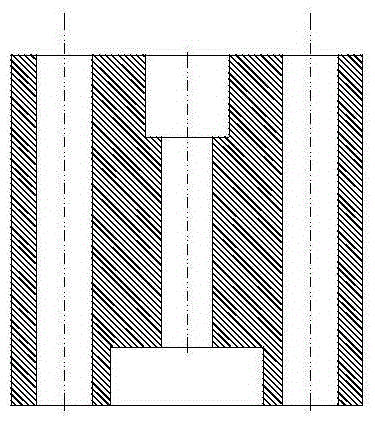

PendingCN109812846AThe installation position is accurateRealize quick changeWater heating stoves/rangesSteam generation plantsElectrical and Electronics engineeringWater tanks

The invention provides an energy-saving cooking range. The energy-saving cooking range comprises a coil base, a furnace body and a water tank; supporting plates are connected to the upper ends of internal furnace walls and external furnace walls; cavities formed among the internal furnace walls, the external furnace walls and the supporting plates are heating cavity; annular holes and through holes are formed in the supporting plates; the through holes are formed in the external sides of the annular holes; the annular holes are of structures which are big at the upper parts and small at the lower parts; connecting plates matched with the annular holes are arranged in the annular holes; coiled pipes surrounding a hearth are arranged in the heating cavities; the coiled pipes are arranged under the connecting plates; the upper ends of the coiled pipes communicate with the hearth through connecting pipes; the lower ends of the coiled pipes vertically arranged downwards to penetrate throughthe bottom of the coil base to extend outwards; a plurality of lifting rings sleeve the coiled pipes; connecting rods are arranged between the lifting rings and the connecting plates; and the coil base is arranged at the upper end of the furnace body. According to the energy-saving cooking range, by using the connecting plates to lift the coiled pipes, the accurate mounting positions of the coiled pipes are guaranteed; the coiled pipes can be detached to be quickly changed by directly taking out the connecting plates upwards when the coiled pipes need to be repaired or changed; the structureis simple; and the operation is convenient and fast.

Owner:JIANGSU SHENGONG STOVE CO LTD

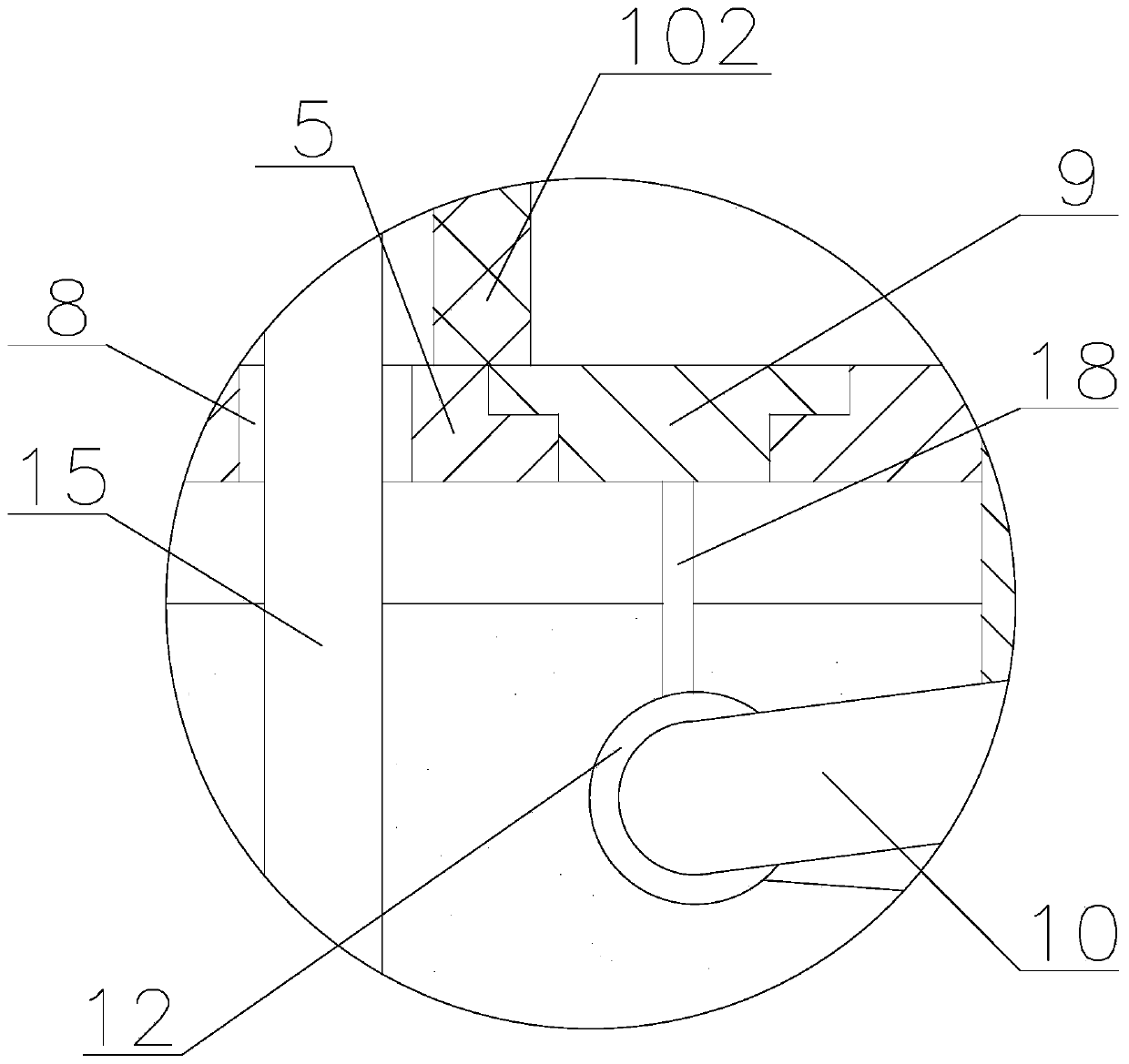

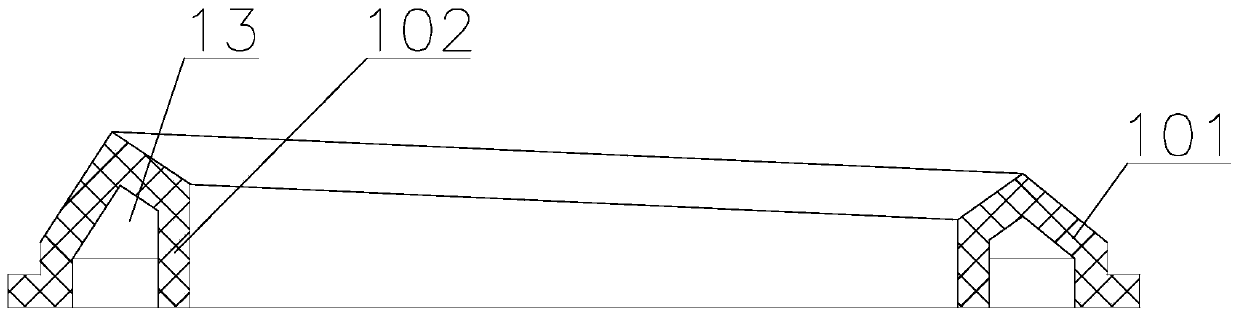

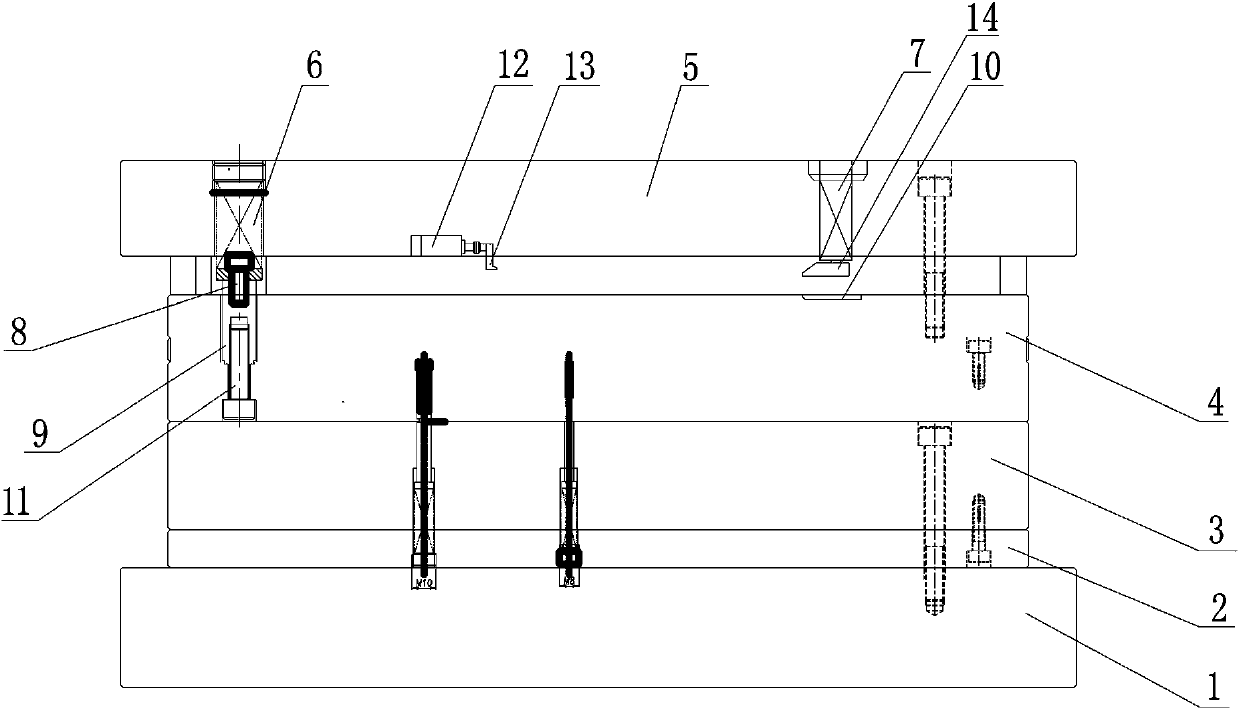

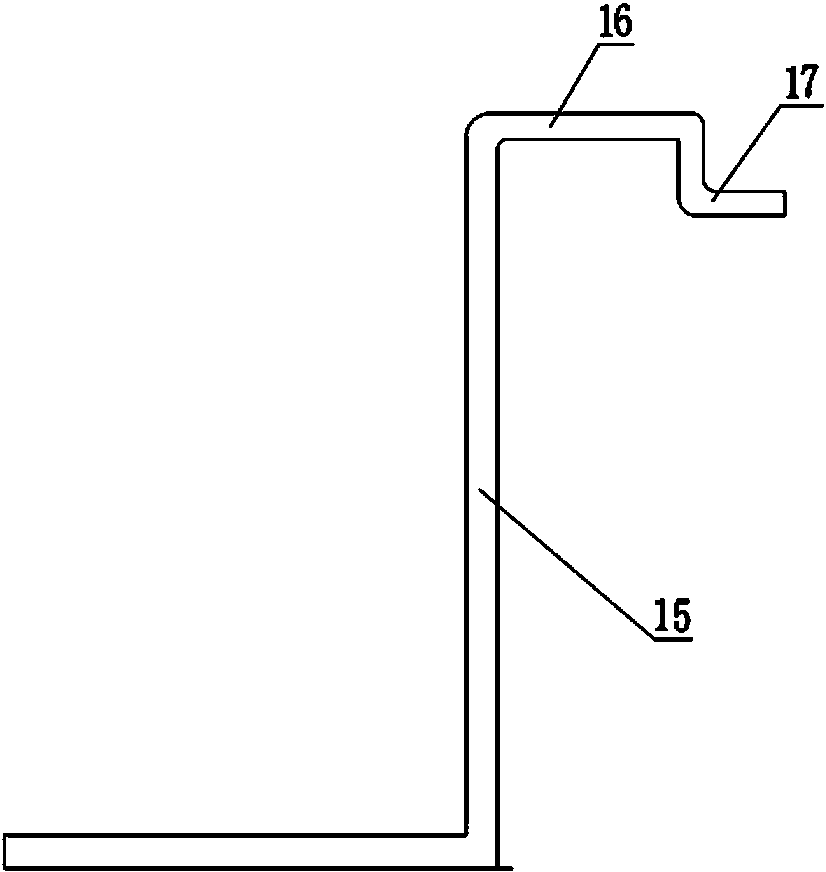

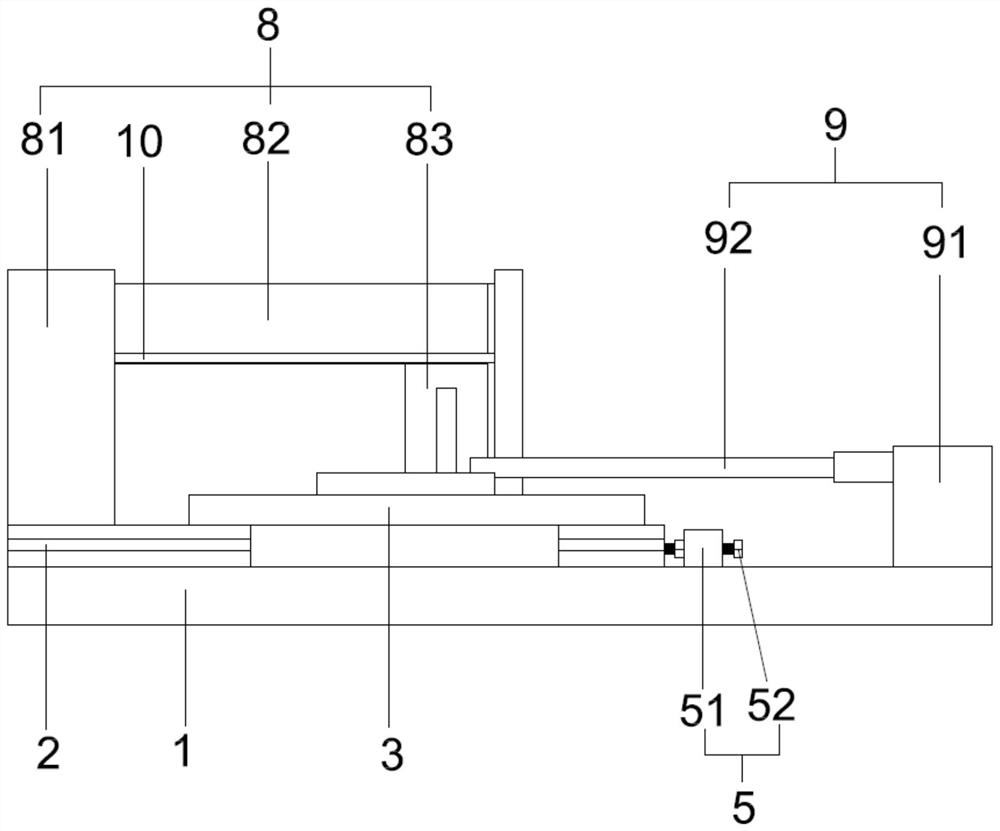

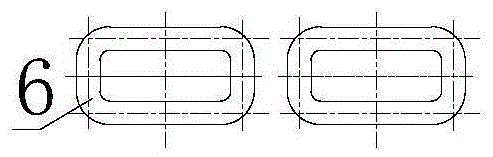

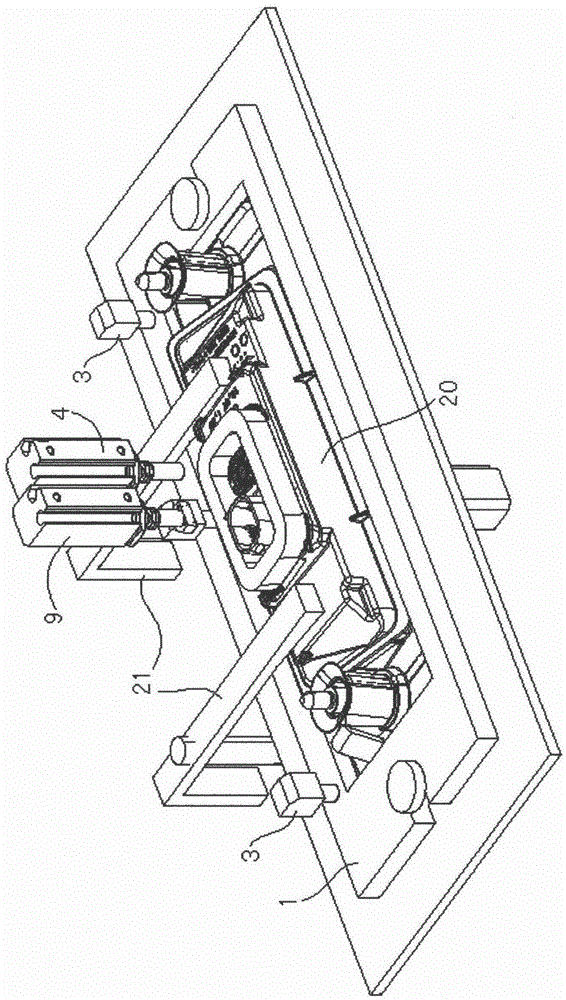

A precision progressive die for multi-bending forming

ActiveCN106180383BCompact structurePrecise bending angleShaping toolsMechanical engineeringSquare cavity

The invention discloses a precision progressive die with a multi-bending forming function. The precision progressive die comprises a base (1), a lower cushion plate (2), an upper cushion plate (3) and a female die body (4), wherein the lower cushion plate (2), the upper cushion plate (3) and the female die body (4) are arranged on the base (1) and sequentially connected from bottom to top. An upper support (5) is arranged above the female die body (4) and internally provided with a female die insert A (6) and a female die insert B (7). The lower end of the female die insert A (6) is connected with a pressing die body (8), and an ejector rod (11) located under the pressing die (8) is arranged in a square cavity (9). The lower end of the female die insert B (7) is connected with a wedge B (14), a circular bead is arranged on the left side of the wedge B (14), and the wedge B (14) is located over a cavity (10). An arc chamfer matched with the circular bead is arranged on the left side wall of the cavity (10). The precision progressive die has the beneficial effects that the structure is compact, the bending angle is precise, continuous bending is achieved, bending efficiency is improved, and the production output is increased.

Owner:CHENGDU HOMIN TECH

An automatic assembly line for medical kits compatible with various models

ActiveCN112249699BRealize online automatic adjustmentRealize quick changeSortingMetal working apparatusBiotechnologyProduction line

The invention discloses an automatic assembly line for medical kits compatible with various types, which includes a circular conveying line body; several tooling compatible with various types of shells, and the tooling is arranged on the circulating conveying line body Recycling on the bottom shell; a feeding and sorting device for the lower shell; a feeding and cutting device for reagent strips; a sorting and loading device for feeding the upper shell; and a feeding device for the lower shell; The material sorting and feeding device and the upper shell feeding sorting and feeding device are provided with a visual positioning unit, which uses visual positioning and screening, and cooperates with a picking robot to pick up the shell screening into a shell magazine, and It is moved to the loading station by a transfer unit, and clamped into the tooling by a shell clamping loading unit to realize loading. The invention is compatible with various types of test kits, which greatly improves the versatility of the production line.

Owner:KUNSHAN YITIAN AUTOMATION

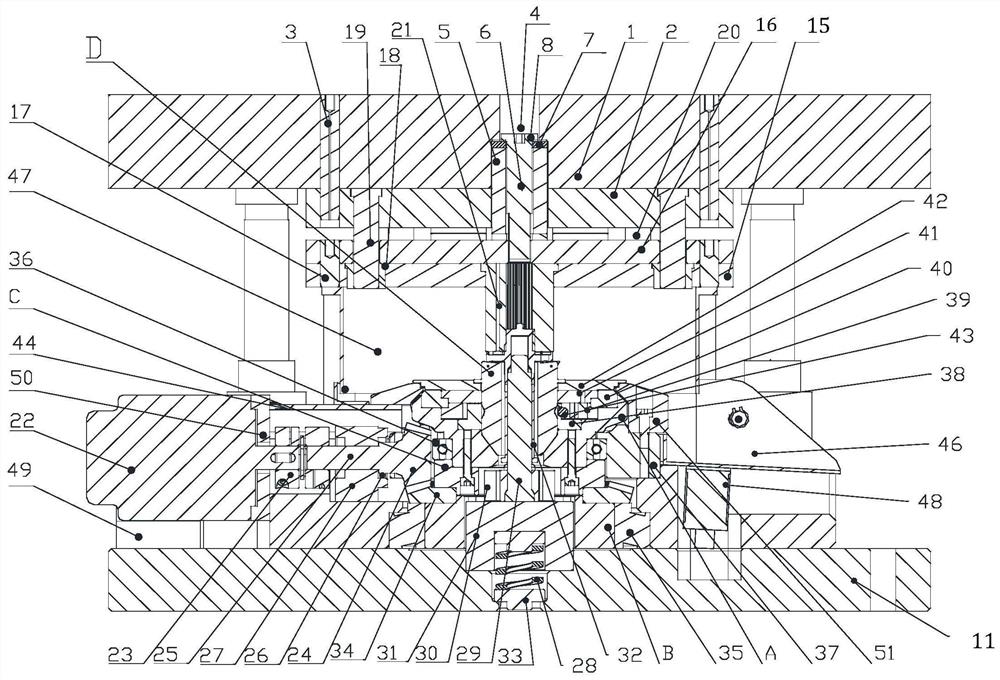

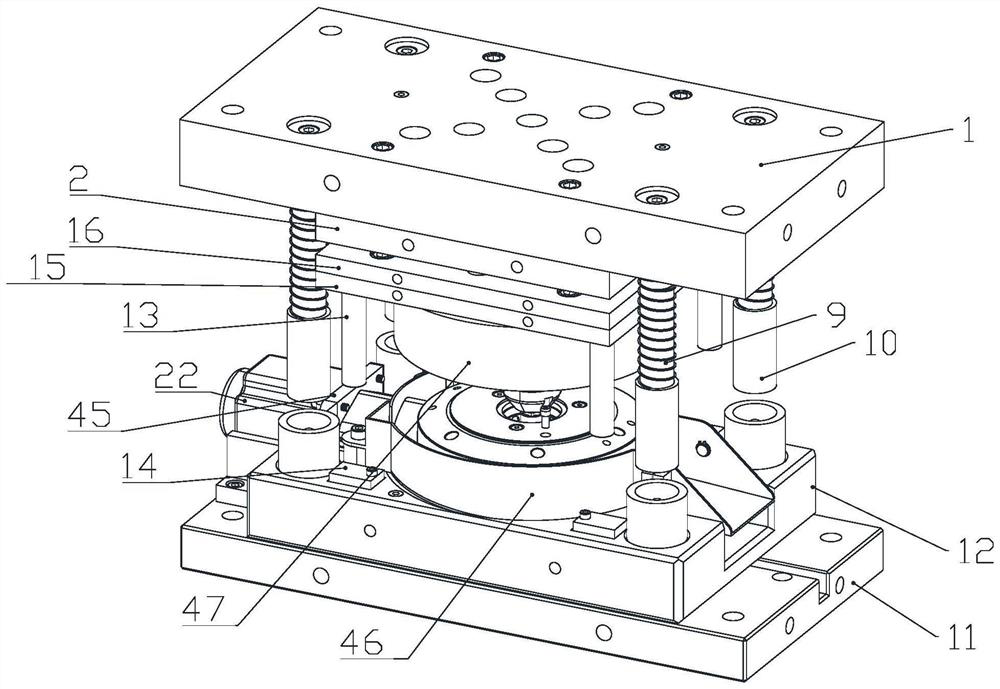

Mold base with function of deburring workpiece and method for deburring mold base

The present invention discloses a mold base with a workpiece burr removal function and a workpiece burr removal method, and belongs to the technical field of auxiliary cutting of a cold forming mold base. The mold base includes a mold base system, a material pressing system, and a cutting system; the cutting system includes a power part, a rotation part, a floating material part, and a cutter; theworkpiece is mounted in the mold base system and compressed and fixed by the material pressing system; the power part drives the rotation part to rotate; the cutter and the rotation part synchronously rotate around the workpiece; and the workpiece is cut by the cutter to remove the burr. In the mold base of the present invention, the whole machining device is arranged in a small mold base, and the cutter is locked by using a self-locking structure; the workpiece uses a floating material structure to achieve material floating and ejection; and a floating structure and a positioning structure are added to the material pressing part. By using the mold base and the method, in-mold machining, row cutting, handling, and other actions are achieved, and a main body is prevented from being activein a machining process, thereby improving safety performance, accelerating the installation and disassembly speed, and reducing the manufacturing cost of a single workpiece; merged production with a plurality of forming stations may be carried out to achieve automatic handling.

Owner:NANJING KANGNI PRECISION MECHANICS

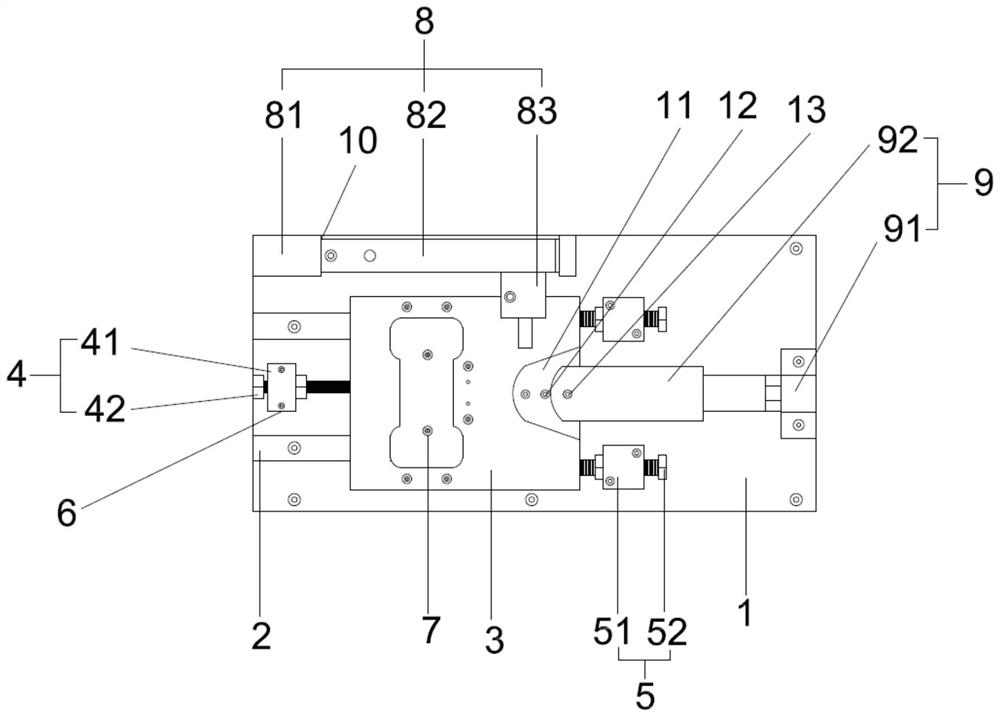

Quick-change tool structure capable of being adjusted to be assembled and inserted

PendingCN114670162ALow production costReduce riskWork benchesStructural engineeringMechanical engineering

The invention discloses an adjustable assembling and inserting quick-change tool structure, and belongs to the technical field of quick-change tools, the adjustable assembling and inserting quick-change tool structure comprises a base table, a tool fixing table, a front stroke adjusting and limiting structure and a plurality of rear stroke adjusting and limiting structures, the base table is provided with double guide rails, the tool fixing table is connected to the double guide rails, and the front stroke adjusting and limiting structure and the rear stroke adjusting and limiting structures are arranged on the base table. A mounting groove is formed in the base table, the front stroke adjusting and limiting structure and the rear stroke adjusting and limiting structure adjustably abut against the tool fixing table, a plurality of mounting holes are formed in the tool fixing table, and a tool is fixed to the tool fixing table through the mounting holes. According to the structure, quick change of different product tools is achieved, the manufacturing cost is saved, meanwhile, by arranging the front stroke adjusting and limiting structure and the rear stroke adjusting and limiting structure, the inserting tool profiling block is installed on the tool fixing table and limited, a fixed mold cannot be impacted, and the risk is reduced.

Owner:昆山伟理塑汽车部件有限公司

A battery fixing bracket

ActiveCN102785561BRealize quick changeEasy to disassembleElectric propulsion mountingEngineeringBattery pack

The invention relates to a battery fixed support which comprises a battery baseplate support assembly and is charaterized in that a battery guide component is distributed on the battery baseplate support assembly; the tail end of the battery guide component is provided with a battery suitcase lock component. Due to the design of an idler wheel, abrasion on a battery pack can be reduced, and replacement of the battery pack is convenient and efficient as well. As the battery suitcase lock component at the tail end of the battery guide component and a battery positioning hole are matched with each other, accurate positioning can be achieved, so that the battery can be in full contact with an external connecting terminal.

Owner:JIANGSU KAWEI AUTOMOBILE IND GRP CO LTD

A linear drive device for a surgical robot and the surgical robot

ActiveCN111529064BSimple structureSolve the entanglementSurgical manipulatorsSurgical robotsRobotic systemsLinear motion

The present invention discloses a linear driving device of a surgical robot and the surgical robot. A technical scheme is as follows: the linear driving device of the surgical robot comprises a rotational freedom degree module, a device driving module, a motion transmission module and a quick change module, the rotational freedom degree module is connected with device driving module, an output endof the device driving module is connected with the motion transmission module, and an output end of the motion transmission module is connected with the quick change module. A rotation motion of thedevice driving module is changed into a linear motion through the motion transmission module and transmitted to the quick change module, so that quick changes are realized. The linear driving device of the surgical robot can better realize the quick changes of different end actuators. The linear driving device of the surgical robot has universality, can realize a modularized use of a surgical robot system, and reduces use cost.

Owner:SHANDONG UNIV

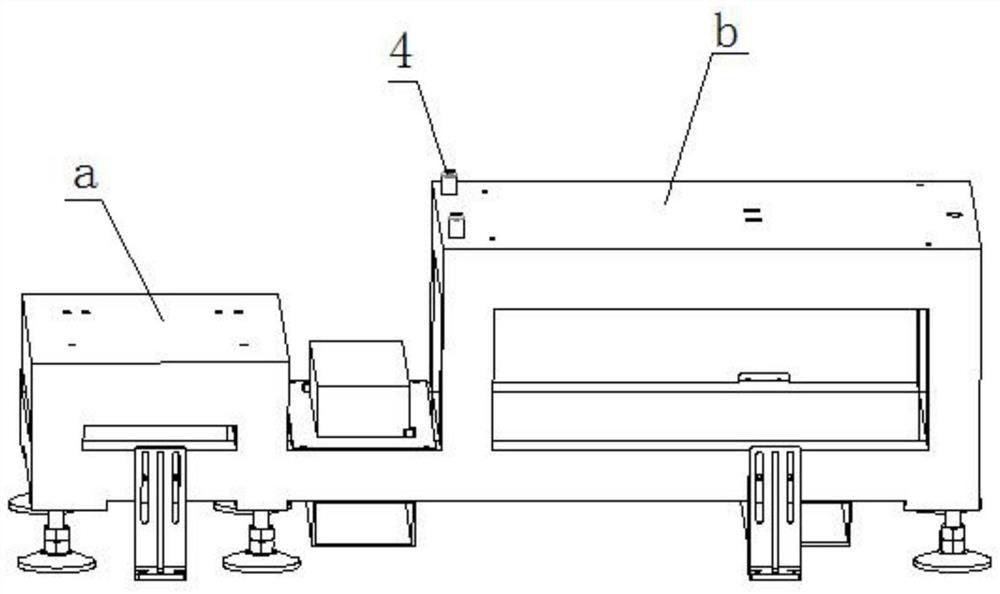

A Robotic Ultrasonic Welding Equipment for Automotive Interior Panels

The invention discloses a robot ultrasonic welding equipment for automotive interior panels, which is characterized in that it includes a support frame, a robot, and a welding fixture, and one end of the support frame is connected with a fixture transfer device, and the fixture transfer device is located at the The outer end of the second support platform, the end of the transfer device close to the support frame is provided with a connection limit block and a guide positioning block, the front end of the guide positioning block is wedge-shaped; the top of the frame is provided There is a second end positioning block corresponding to the first end positioning block. The beneficial effects of the present invention include: flexible welding, quick replacement of welded parts, faster production tempo, labor saving, and stable product quality.

Owner:必尚自动化技术(上海)有限公司

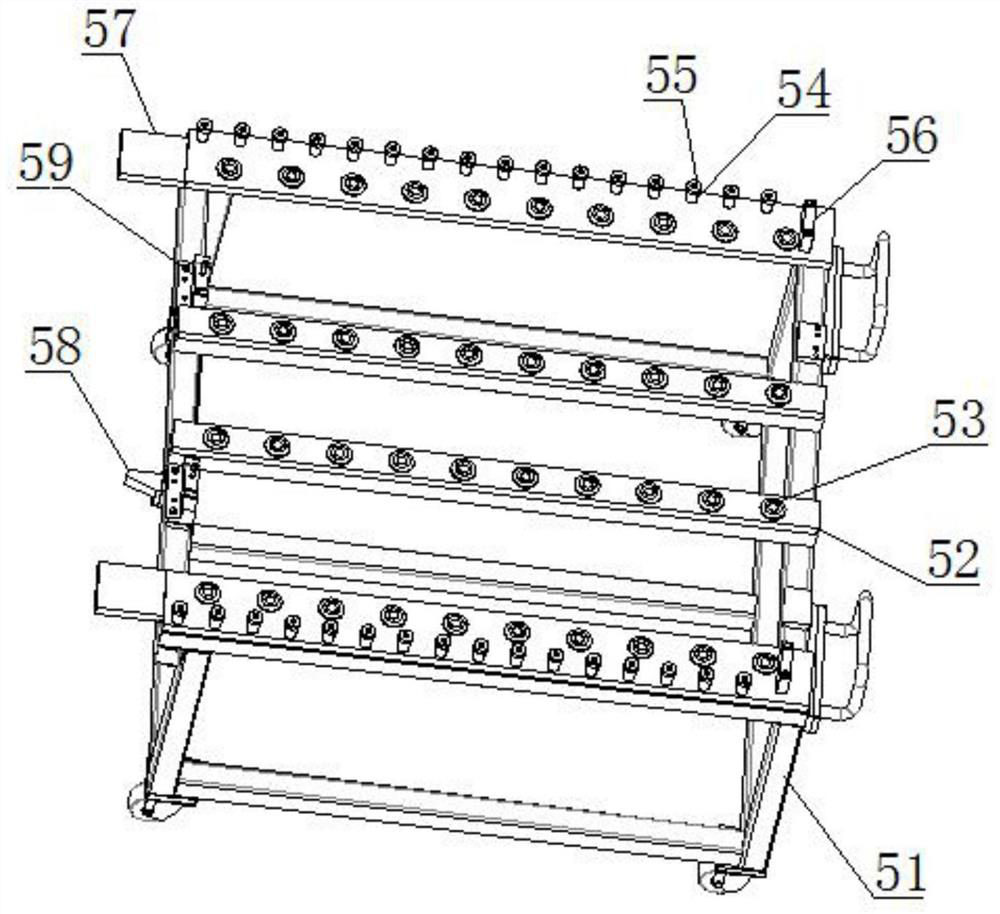

Gas nozzle quick change method and device for laser equipment

The invention discloses a rapid replacement method and device of gas nozzles of a laser device. The rapid replacement method and device of the gas nozzles of the laser device comprises a base plate and at least two paraxial rapid replacement gas nozzle assemblies arranged on the base plate. The work heights and the angles of the gas nozzles on all the paraxial rapid replacement gas nozzle assemblies are all different. Each paraxial rapid replacement gas nozzle assembly comprises an upper end cover, a lower end cover, a gas flotation cylinder body, a gas flotation piston rod, a gas flotation piston, a gas nozzle connector and a gas nozzle. According to the rapid replacement method of the gas nozzles of the laser device, by switching the paraxial rapid replacement gas nozzle assemblies at different positions to enter the work state, the purpose of rapid replacement of the gas nozzles is achieved. After the rapid replacement device of the gas nozzles is installed on the laser device, switching can be conducted between all the paraxial rapid replacement gas nozzle assemblies and between the paraxial rapid replacement gas nozzle assemblies and a coaxial gas nozzle, manual intervention is not needed, and then rapid, accurate and automatic replacement of the gas nozzles is achieved; besides, the angle and position consistency is effectively guaranteed during each replacement of the gas nozzles, the work stability is good, secondary adjustment is not needed, and the machining efficiency and quality are effectively improved.

Owner:SONGSHAN LAKE MATERIALS LAB +1

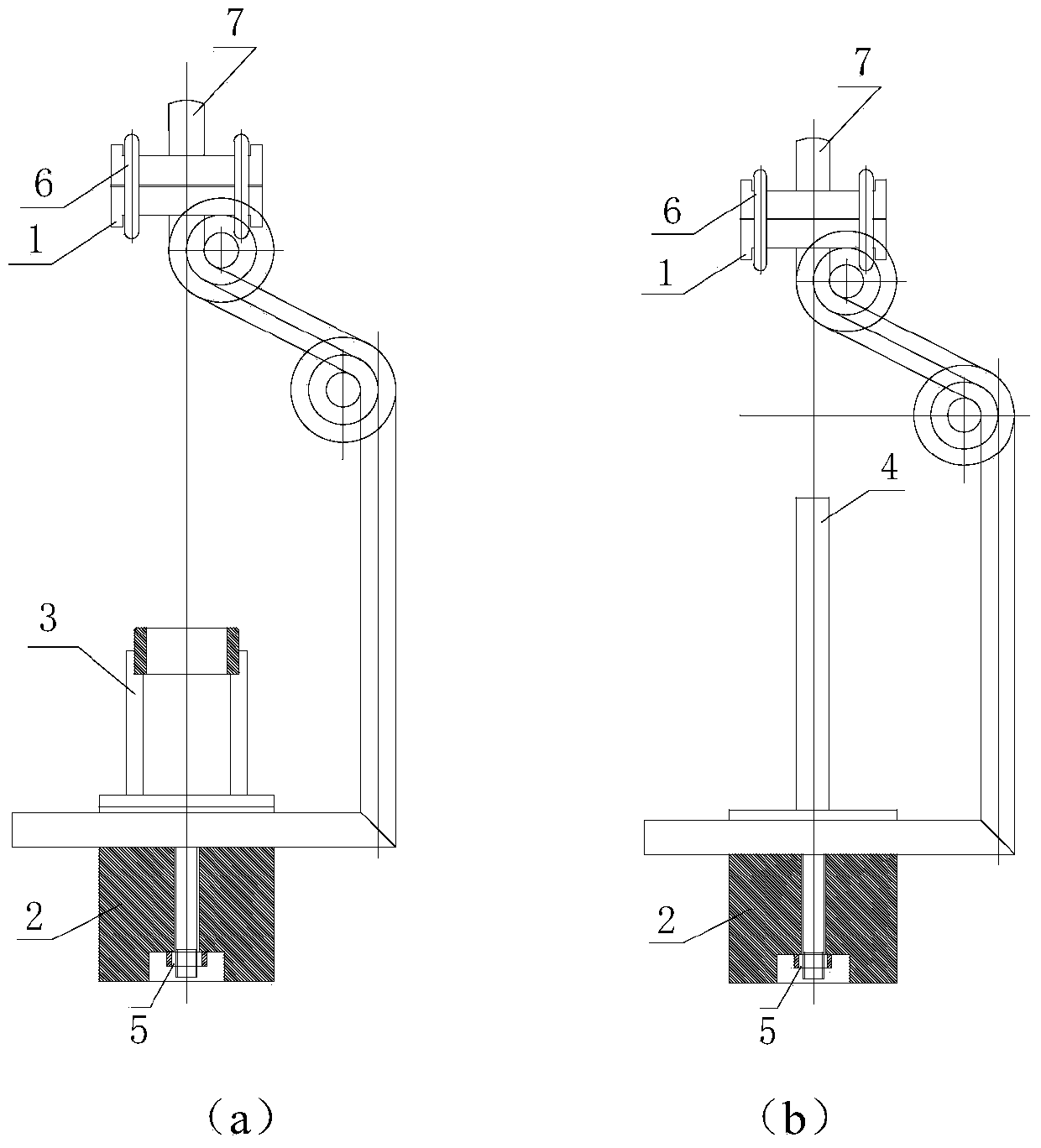

Catenary quick-changing rack of reinforced shot blasting machine

ActiveCN105538171AIncrease productivityReduce manual labor intensityAbrasive machine appurtenancesLoad-engaging elementsEngineeringMechanical engineering

The invention discloses a catenary quick-changing rack of a reinforced shot blasting machine. The catenary quick-changing rack comprises a bent neck body (1), a hammer (2) and a hanging ring (6), wherein the hanging ring (6) is used for connecting the top end of the bent neck body (1) with the equipment; the hammer (2) is fixed at the bottom end of the bent neck body (1); when in work, a through hole for fixing an axle tooth-type tool (3) or flat tooth-type tool (4) is formed in the hammer (2); and a shot blasting part is arranged on the axle tooth-type tool (3) or flat tooth-type tool (4). In the invention, according to the technological requirements of reinforced shot blasting, the part receives the same strength on the same peripheral tooth surface during reinforcement to realize hoisting; and in term of part loading and unloading, quick replacement of axle tooth-type parts and flat tooth-type parts is realized without increasing or reducing the labor intensity.

Owner:SHAANXI FAST GEAR CO

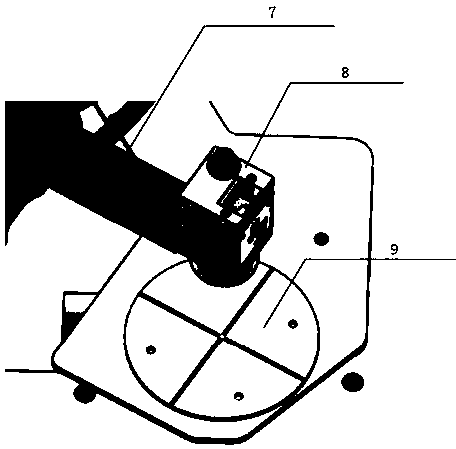

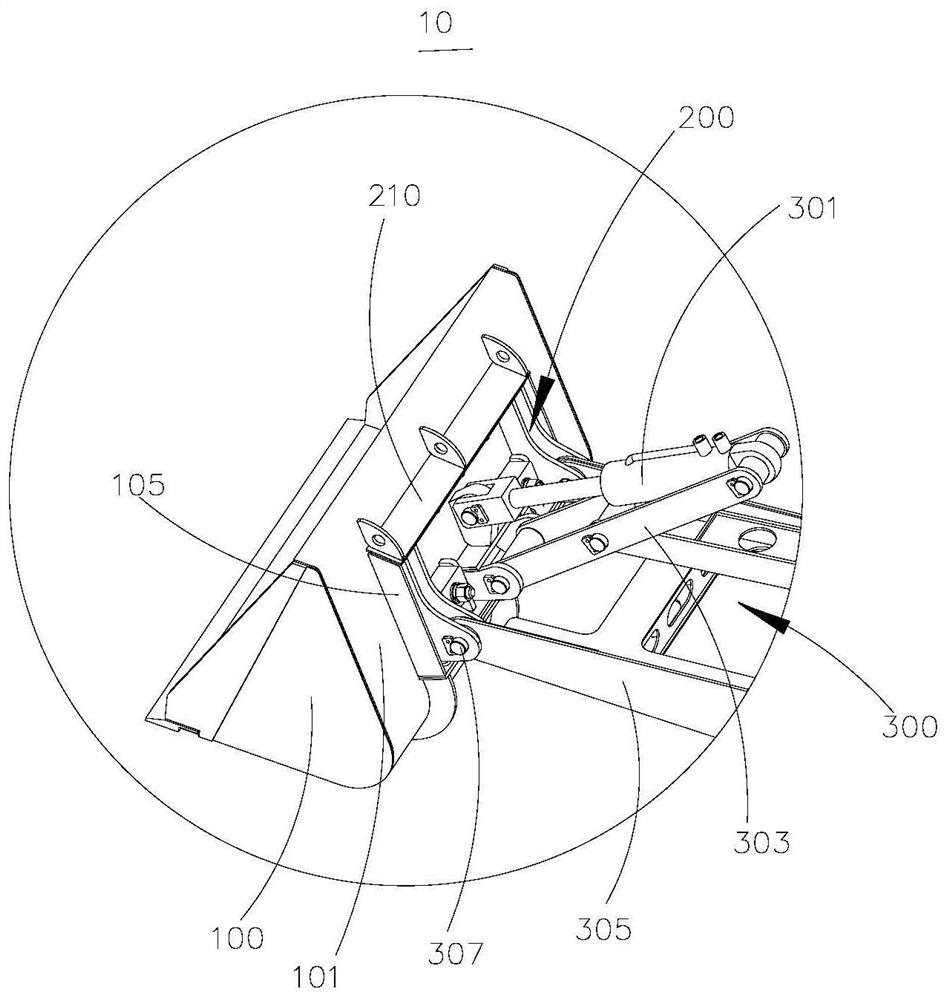

A tool quick change device and method for a power manipulator

ActiveCN106737795BDefects that change a single functionShorten quick change timeGripping headsVideo monitoringRobot hand

Owner:中国东方电气集团有限公司

Cigarette packaging production line

PendingCN112607091AAvoid deformationReduce the difficulty and cycle of assembly and debuggingPackaging cigaretteAluminium foilCardboard

The invention relates to a cigarette packaging production line. The cigarette packaging production line comprises an environment-friendly paper fixing and folding device, an aluminum-foil paper short edge fixing and folding device, an aluminum-foil paper synchronous conveying belt, an inner frame paper pneumatic clamping device, an aluminum alloy channel and a channel corner gearbox which are sequentially arranged from front to back, wherein the environment-friendly paper fixing and folding device comprises a second wheel die box, paper supporting protruding blocks and a working face; the paper supporting protruding blocks are arranged at the upper end and lower end of the outer edge of the working face of the second wheel die box; the aluminum-foil paper short edge fixing and folding device is installed on a transition channel plate between a second wheel and a third wheel; the aluminum-foil paper synchronous conveying belt comprises air suction paper guide plates, air suction holes, air suction grooves and air suction bases; the inner frame paper pneumatic clamping device comprises a cylinder body, tensioning blocks, a wheel core and springs; and the aluminum alloy channel comprises a high-level runway, a low-level runway, a descending runway and the channel corner gearbox. According to the cigarette packaging production line, the maintenance time is saved, and the production efficiency is improved.

Owner:上海浦东新区杨光机械厂 +1

Slave end driving device and method of interventional surgical robot

PendingCN114711970ASimplify the setup processRealize quick changeSurgical manipulatorsSurgical robotsLinear motionPhysical medicine and rehabilitation

The invention discloses a slave end driving device and method of an interventional surgical robot, which is applied to the technical field of medical equipment and comprises a base, a rotary table, a shifting fork part, a rotary driving part and a linear motion driving part, wherein the rotary table is mounted on the base, and the rotary driving part drives the rotary table to rotate; the shifting fork part is matched with the rotary driving part and the linear motion driving part at the same time, the motion speed of the rotary driving part and the motion speed of the linear motion driving part are adjusted through the working condition of the shifting fork part, and coordinated control is carried out. According to the slave end driving device of the interventional operation robot, the clamping process of long and straight consumables is simplified, and operation such as quick change of the long and straight consumables can be achieved through side-mounted sterile isolation, a quick change structure and a distance-adjustable device.

Owner:易度河北机器人科技有限公司

Soft touch switch detection device

ActiveCN103323227BRealize quick changeRealize detectionMachine part testingEngineeringPressure sensor

The invention discloses a soft-touch switch detection device. The soft-touch switch detection device comprises a working table, wherein a replaceable jig is connected to the working table, the jig and a pair of pressing plates driven by a locking cylinder are used for fixing a shell body of a soft-touch switch, a plurality of groups of reflecting photoelectric sensors are arranged on the jig and around the shell body of the soft-touch switch, a first pressure sensor and a power connector are arranged above the shell body of the soft-touch switch, and a second pressure sensor and a photosensitive sensor are arranged below the shell body of the soft-touch switch. According to the soft-touch switch detection device, a one-surface and two-pin positioning method is adopted by the jig, the jig is locked through a bolt, and fast replacement of different jigs is achieved; due to the fact that a sliding table structure is adopted by the first pressure sensor, detection of different products is achieved, and working efficiency is improved; a sliding rail structure is arranged between the detection device and a marking machine, a plurality of processes can be accomplished with one-time clamping, working efficiency is improved, an error trapping function is available for each detection step, a product is locked by the locking cylinder even when only one detection item is not qualified, and therefore detection omission of defective products is avoided.

Owner:SUZHOU INST OF INDAL TECH

A catenary type reinforced shot blasting machine quick-change hanger

ActiveCN105538171BIncrease productivityReduce manual labor intensityAbrasive machine appurtenancesLoad-engaging elementsEngineeringUltimate tensile strength

The invention discloses a catenary quick-changing rack of a reinforced shot blasting machine. The catenary quick-changing rack comprises a bent neck body (1), a hammer (2) and a hanging ring (6), wherein the hanging ring (6) is used for connecting the top end of the bent neck body (1) with the equipment; the hammer (2) is fixed at the bottom end of the bent neck body (1); when in work, a through hole for fixing an axle tooth-type tool (3) or flat tooth-type tool (4) is formed in the hammer (2); and a shot blasting part is arranged on the axle tooth-type tool (3) or flat tooth-type tool (4). In the invention, according to the technological requirements of reinforced shot blasting, the part receives the same strength on the same peripheral tooth surface during reinforcement to realize hoisting; and in term of part loading and unloading, quick replacement of axle tooth-type parts and flat tooth-type parts is realized without increasing or reducing the labor intensity.

Owner:SHAANXI FAST GEAR CO

Battery pack quick change locking device and vehicle

ActiveCN110001375BReduce volumeIncrease in sizeElectric propulsion mountingEngineeringMechanical engineering

Owner:ZHEJIANG JIZHI NEW ENERGY AUTOMOBILE TECH CO LTD +1

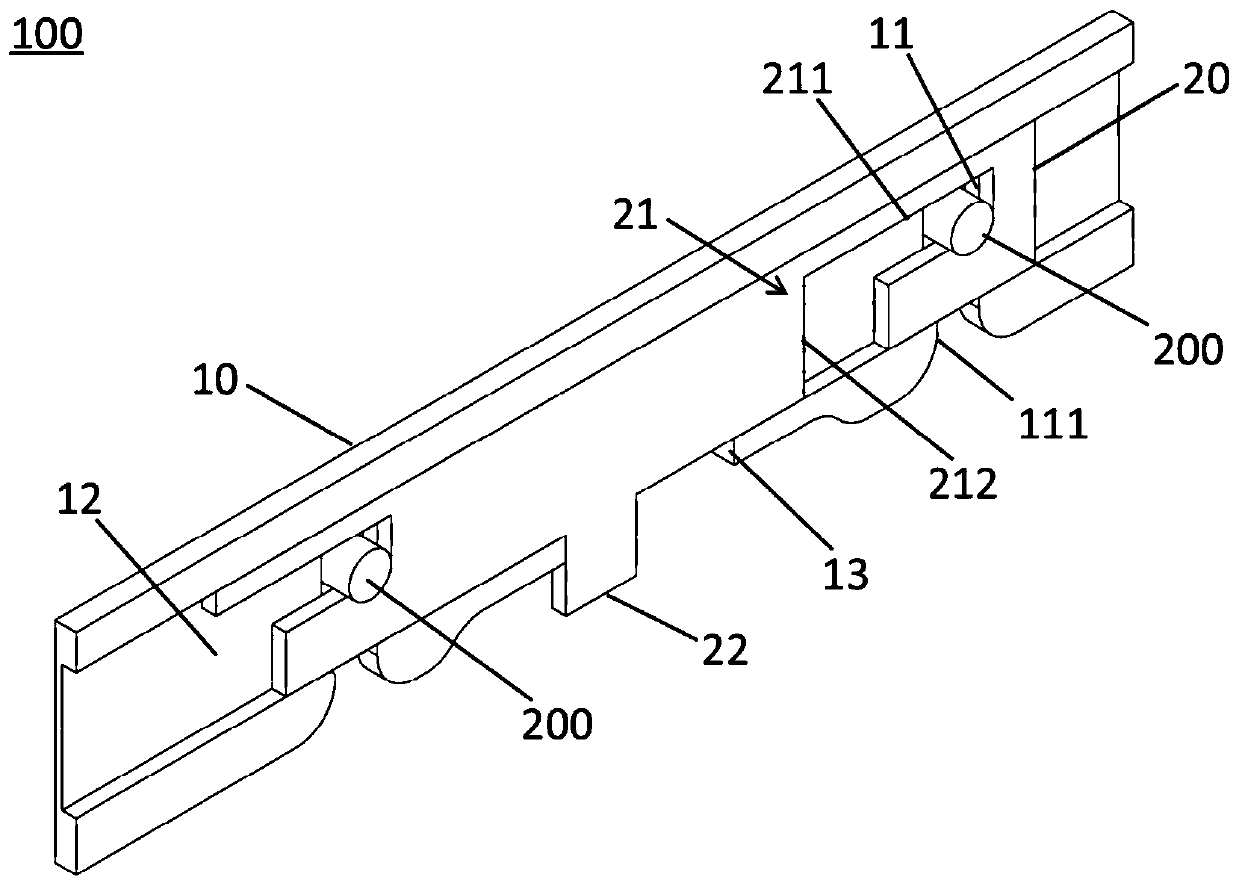

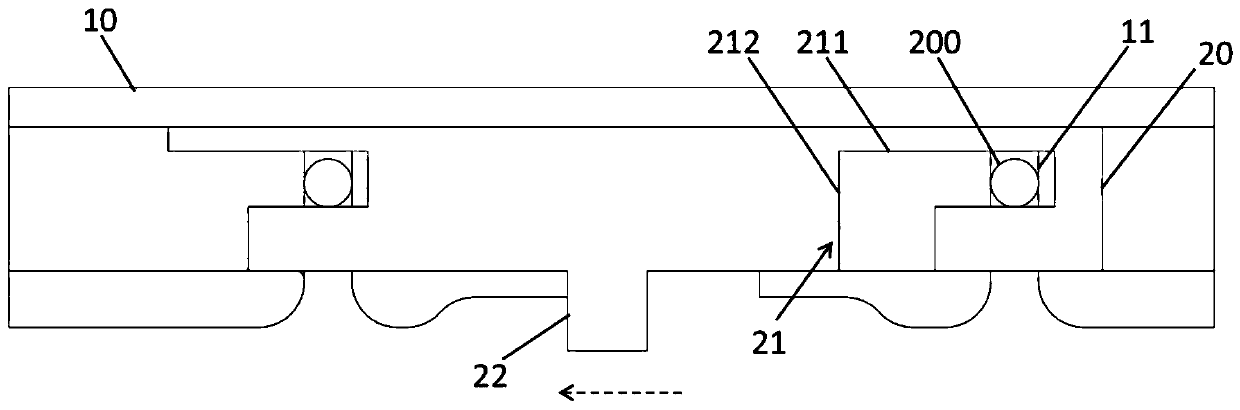

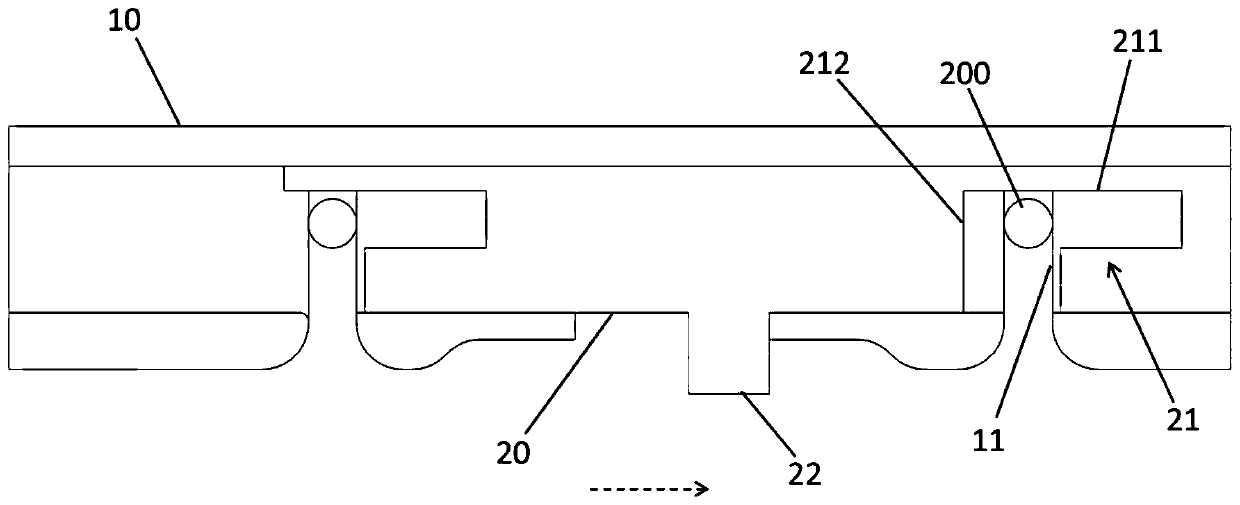

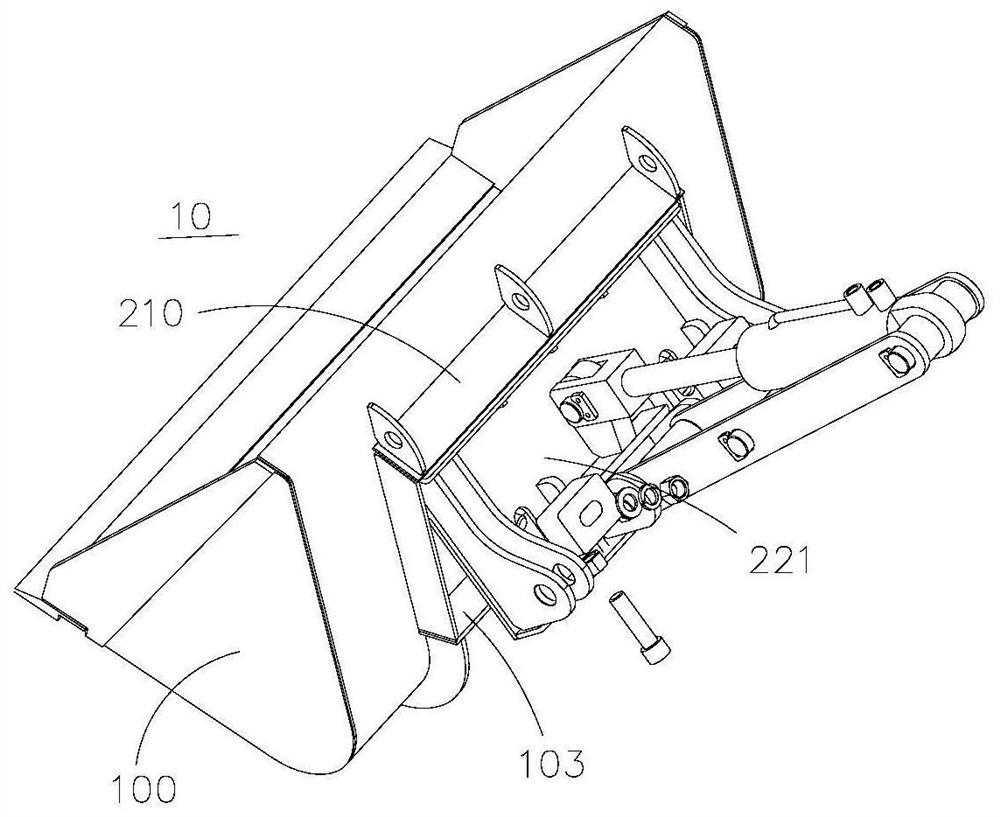

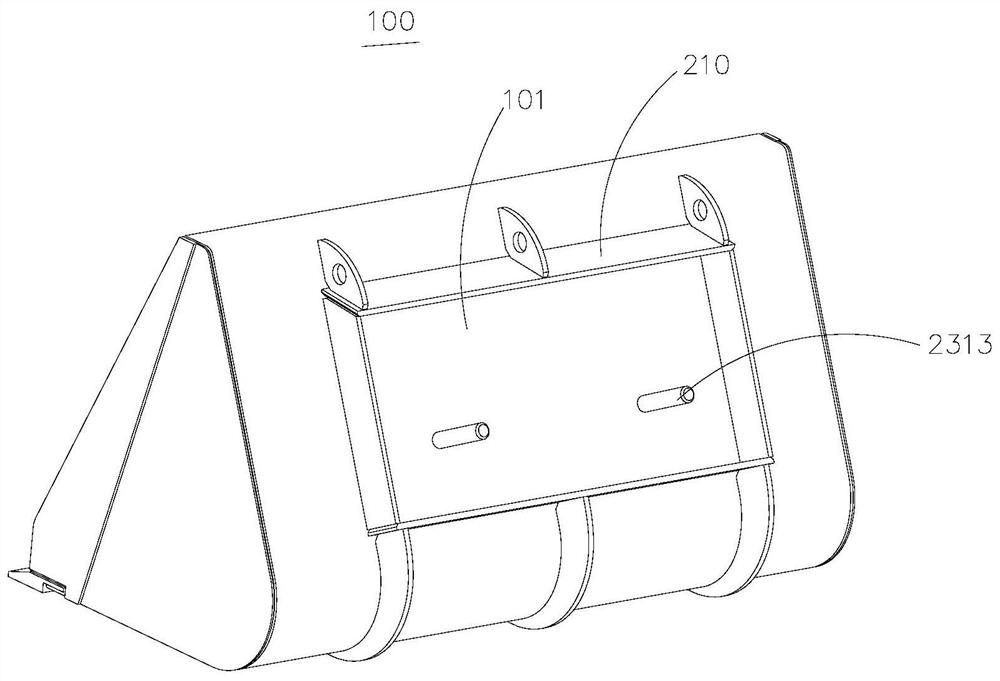

Quick change structure, workpiece assembly and loader

InactiveCN114687397ARealize quick changeExtend your lifeMechanical machines/dredgersStructural engineeringMechanical equipment

The invention provides a quick change structure, a workpiece assembly and a loader, and relates to the field of engineering mechanical equipment. The quick-change structure is suitable for connecting a workpiece with a mounting surface to the vehicle arm, the quick-change structure comprises a main body, a clamping piece and an adjusting mechanism, and the main body is used for being connected with the vehicle arm. The clamping piece is used for being fixed to the installation face of a work piece, the clamping piece can form a limiting groove with a lateral opening in the installation face, and after the first edge of the main body is clamped into the limiting groove, the first edge of the main body can be fixed. The adjusting mechanism is used for being detachably connected with the main body so as to fix the second edge of the main body and enable the first edge to be embedded in the limiting groove. The structure is compact, operation is easy, in the actual using process, a work piece and the machine arm are stably fixed together through the quick-changing structure, the conditions of separation and shaking are avoided, and the service life of parts such as a pin shaft used for connecting the main body and the machine arm is prolonged.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com