Spray water distribution system in plate-type indirect evaporative cooling system

A technology of water distribution system and evaporative cooling, which is applied in the water system part of the system, in the field of high-efficiency and durable spray water distribution subsystem, which can solve the problem of mismatching between the plate spacing and plate orientation, and the inability to form thin, Uniform water film, evenly covered with water on the board surface, etc., to avoid corrosion, low-cost operation and maintenance, and reduce energy consumption of water pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

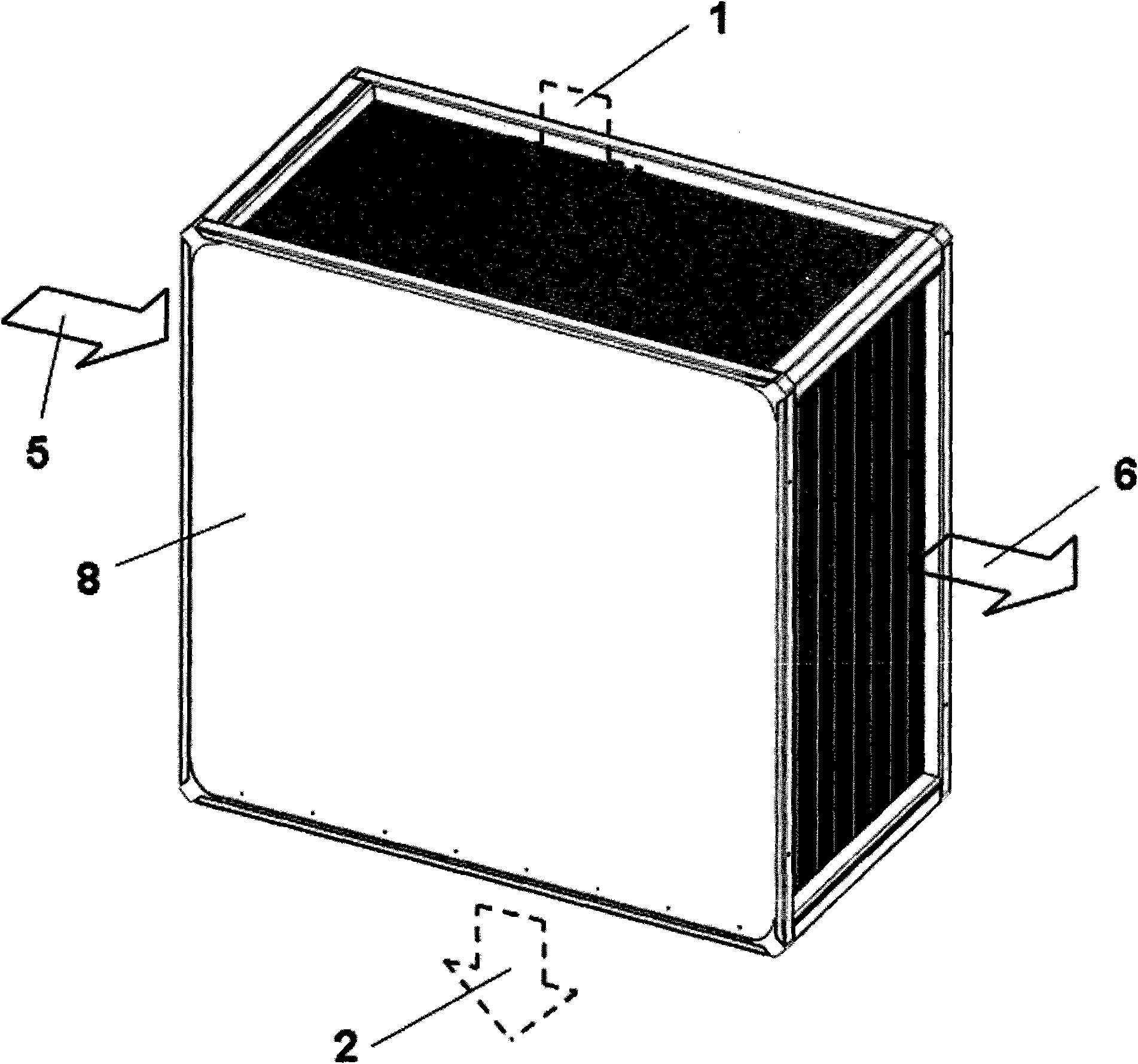

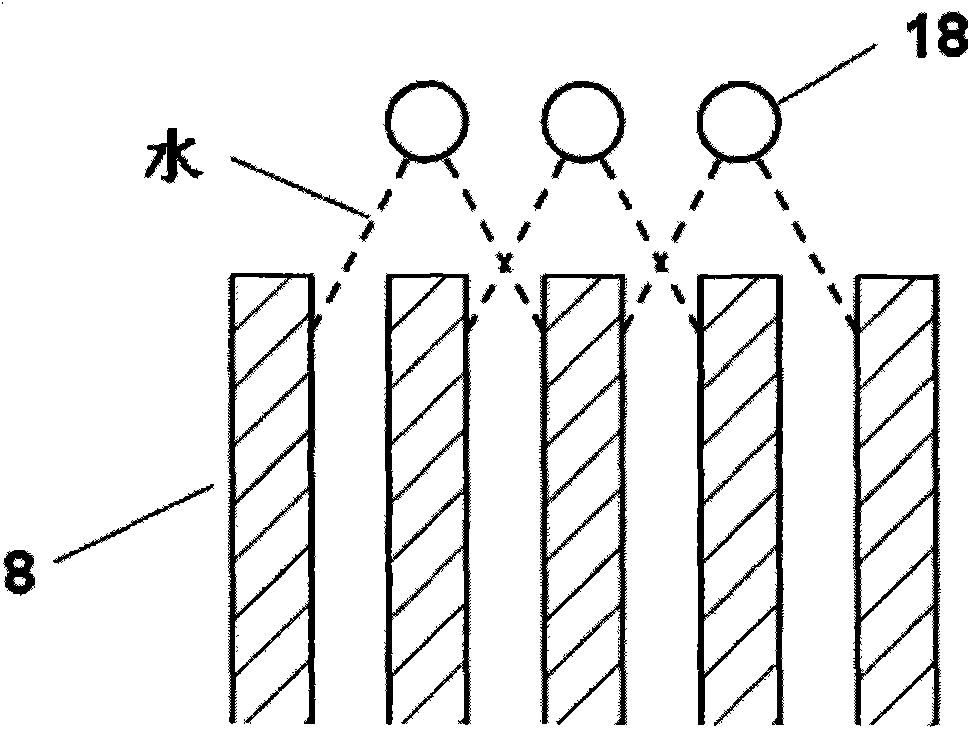

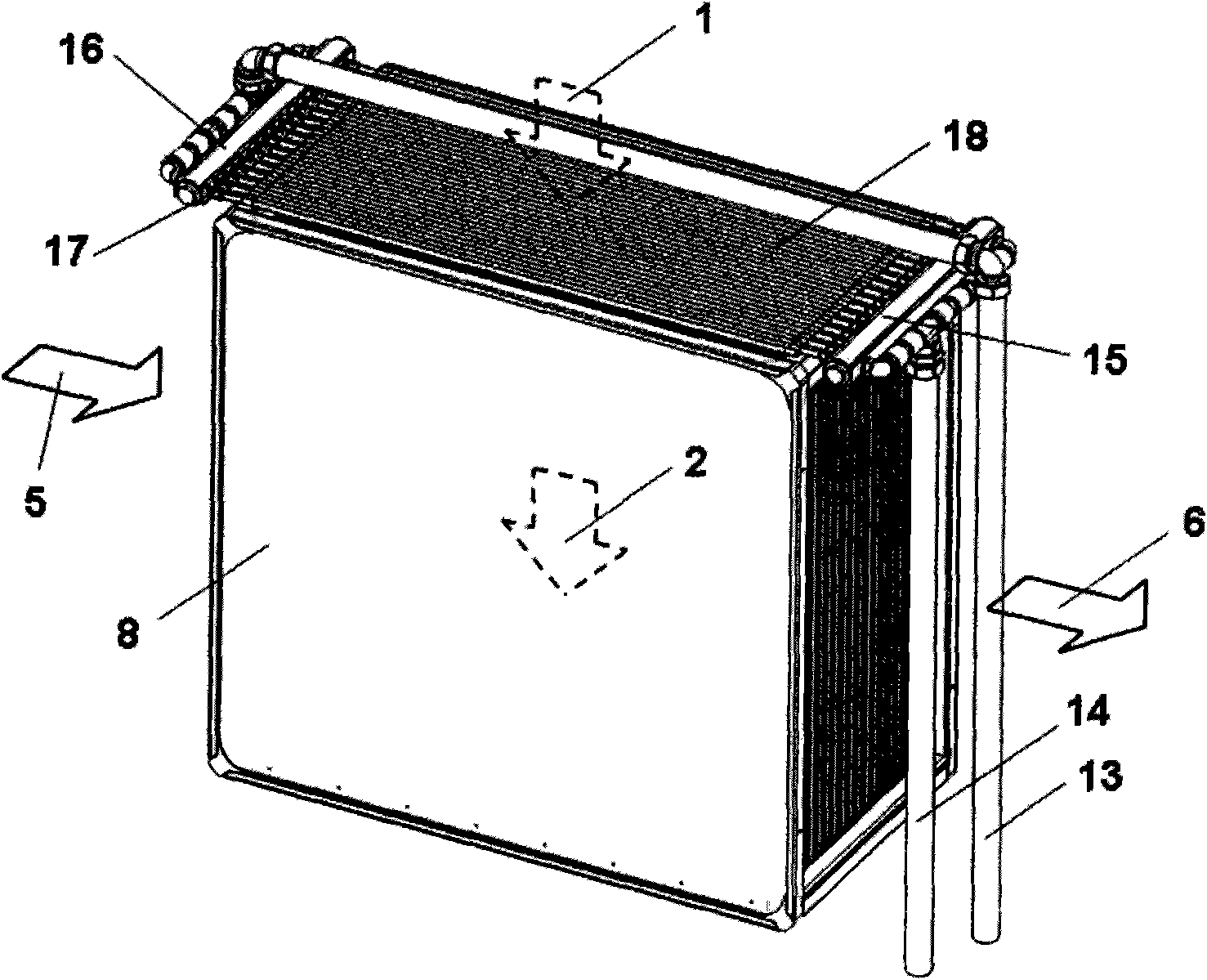

[0059] Embodiment 1 is to use the water spray subsystem, plate air-air heat exchanger, fan, frame structure, panel, air filter and control system of the present invention to form an integrated air conditioning system. Figure 5 It is a three-dimensional perspective view of the water system and part of the wind system in Embodiment 1, and the remaining parts belong to the structures and technologies known to those skilled in the art and are not shown.

[0060] Figure 5 The main components of the plate air-to-air heat exchanger 8 and the entire water system are shown. The fresh air fan introduces the outdoor fresh air into the heat exchanger from 5. The fresh air undergoes an isohumid cooling process inside the exchanger, and the cooling capacity obtained comes from the evaporative wet enthalpy generated by the evaporation of water in the return air channel and the sensible heat recovery transferred in the exchanger by the temperature difference between the indoor return air and...

Embodiment approach 2

[0070] The basic structure is the same as that of Embodiment 1, except that the water distribution pipes 15 and 16 are changed into a pair of guide rails, and one or more water spray pipes are directly connected to the water pump. Driven by the motor, the water spray pipes reciprocate on the water nozzle along the guide rails Scan, and also complete the water distribution of the entire return air inlet. As long as the scanning frequency of the guide rail is adjusted so that the interval is less than the water evaporation time in the heat exchanger, the same overall water distribution can be achieved, and the effect of saving energy consumption of the water pump and reducing the amount of circulating water used can be achieved. This rail scanning mechanism is a common electromechanical structure, and no specific schematic diagram is drawn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com