Energy-saving cooking range

An energy-saving, stove technology, applied in the field of stoves, can solve the problems of stoves being unusable, lost, and flue gas transmission pipes are easily corroded and broken, and achieve the effects of simple structure, accurate installation position, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

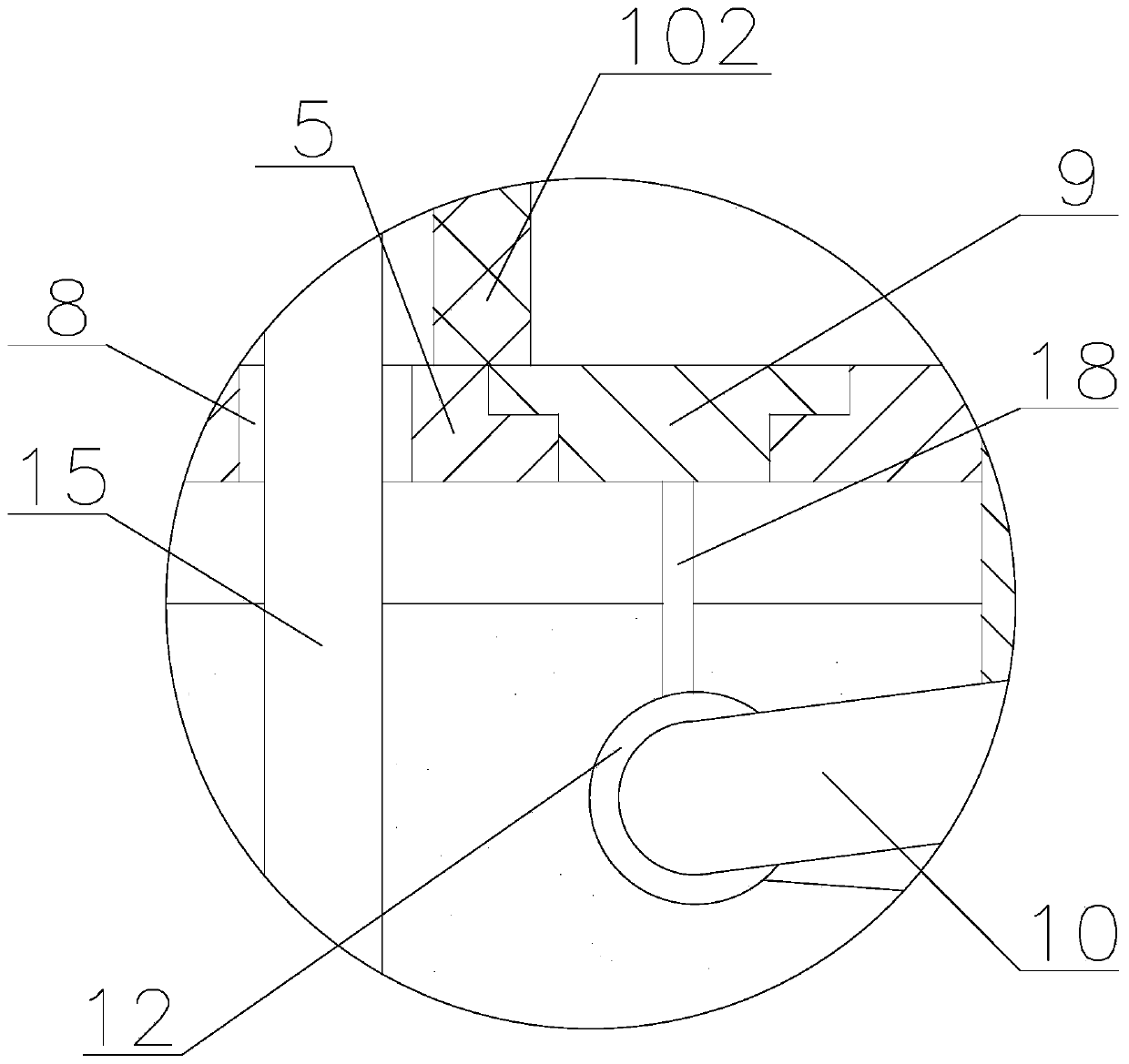

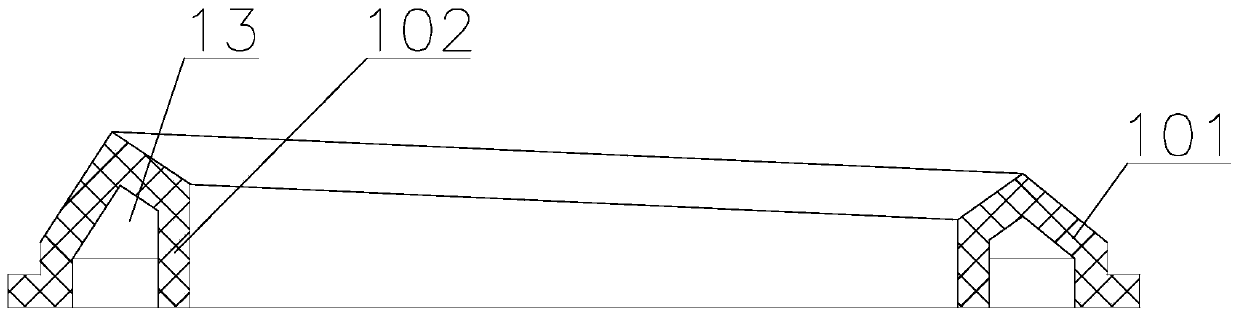

[0018] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0019] like Figure 1-6 As shown, an energy-saving stove of the present invention includes a hearth 1, a furnace body 2 and a water tank 3. The furnace body 2 is composed of an inner furnace wall 202 and an outer furnace wall 201. The back side of the outer furnace wall 201 is The back plate is detachably installed, the hollow area surrounded by the inner furnace wall 202 is the furnace 4, the inner furnace wall 202 and the outer furnace wall 201 are welded with a support plate 5, the inner furnace wall 202, the outer furnace wall The cavity formed between 201 and the support plate 5 is the heating cavity 6,

[0020] The support plate 5 is provided with an annular stepped hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com