Electric EGR valve

An EGR valve, electric technology, applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of inability to accurately control the opening of the valve body, high difficulty in returning springs, and inability to achieve rapid return. The vibration function is perfect, the assembly accuracy requirements are reduced, and the effect of preventing jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

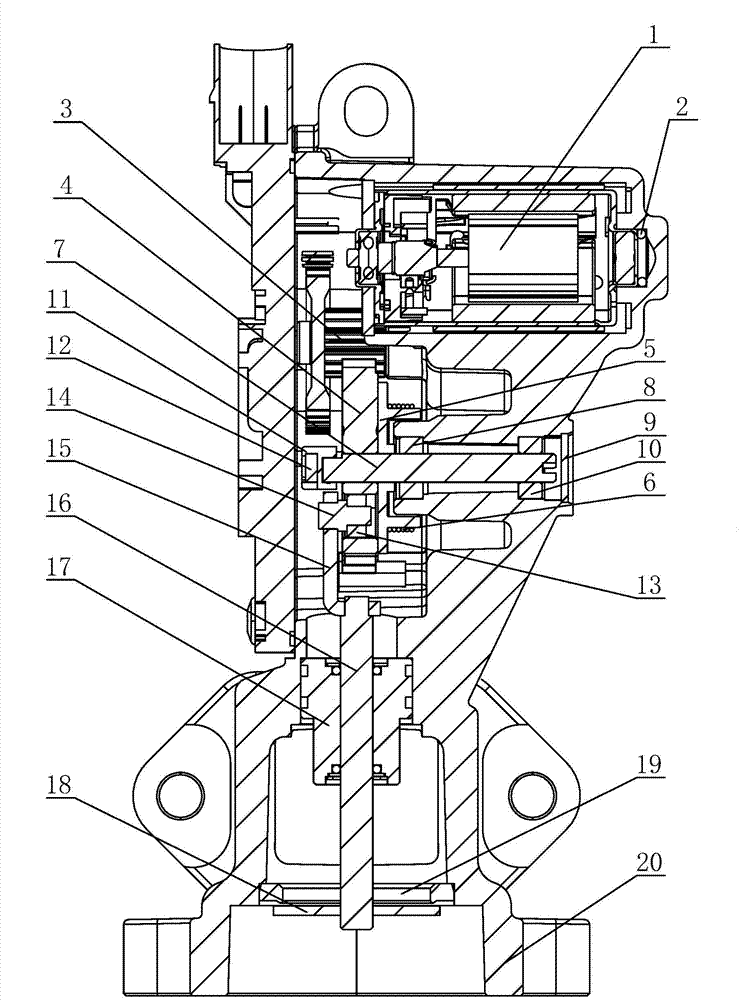

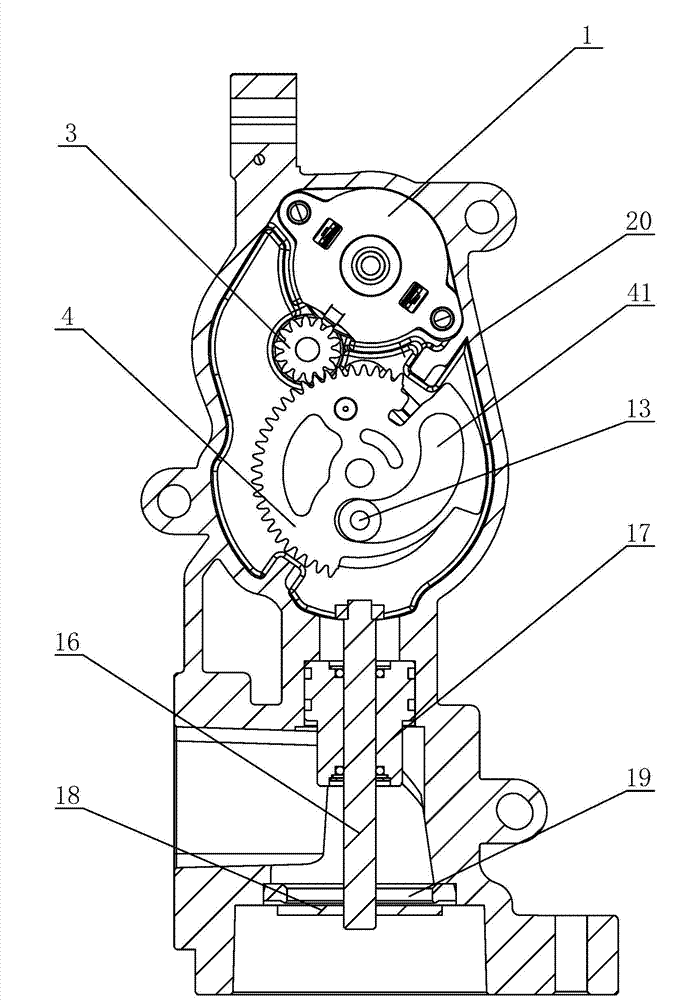

[0024] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

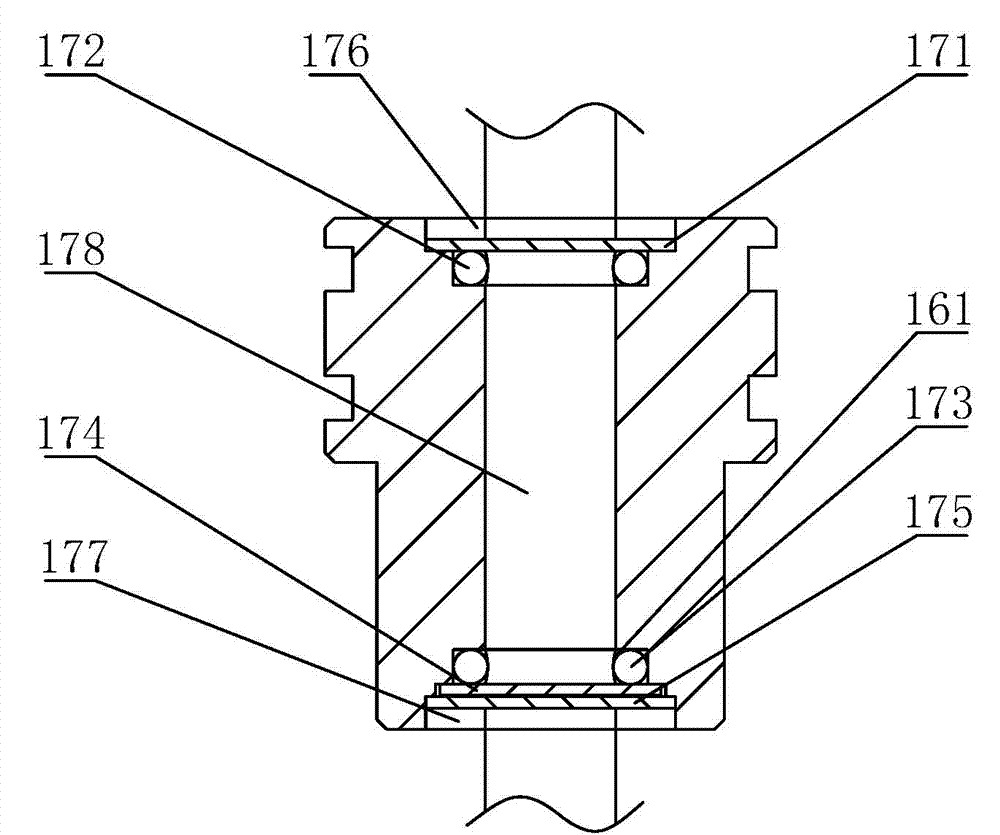

[0025] See Figure 1 to Figure 4 The electric EGR valve includes a housing 20, a drive motor 1, a valve stem 16 and a valve plate 18. The drive motor 1 is arranged in the uppermost end of the housing 20, and the rear end of the drive motor 1 is between the housing 20 A shock-absorbing wave spring 2 is provided between the drive motor 1 and an intermediate gear 3 is connected to the intermediate gear 3. The intermediate gear 3 is meshed with a sector gear 4. The rear end of the sector gear 4 is integrally connected with a torsion spring seat 5. A return torsion spring 6 is connected to the spring seat 5, the other end of the return torsion spring 6 is fixed on the housing 20, and the sector gear 4 and the integrally connected torsion spring seat 5 are fixed on one end of a drive shaft 7. The drive shaft 7 is rotatably arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com