Automatic assembling production line compatible with medical kits of various models

An automatic assembly and kit technology, applied in the directions of vibrating conveyors, transportation and packaging, conveyors, etc., can solve the problems of poor compatibility, large space occupation, high price, etc., and achieve the effect of improving versatility and realizing universal functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

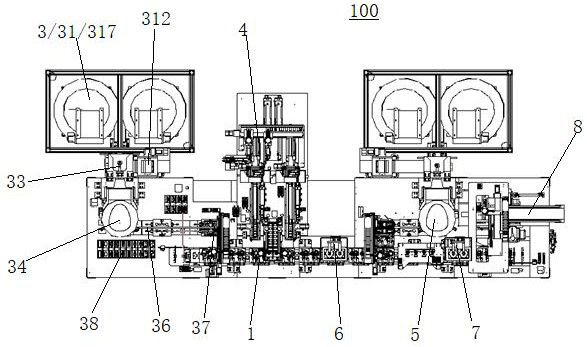

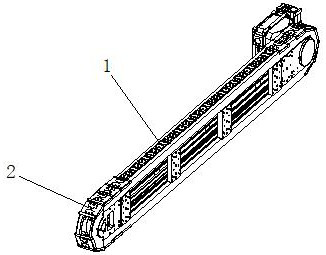

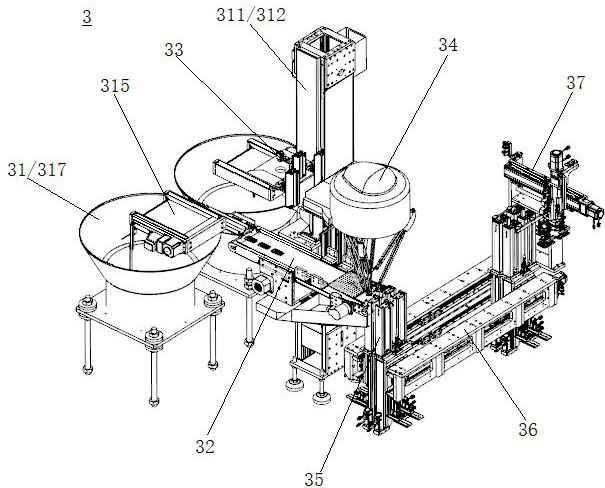

[0058] Please refer to Figure 1-Figure 26 In this embodiment, an automatic assembly production line 100 for medical kits compatible with various types, which includes a circular conveying line body 1, a tooling 2 arranged on the circulating conveying line body 1 for recycling, and a circular conveying line body 1 along the The lower casing feeding sorting and loading device 3, the reagent strip feeding and cutting loading device 4 and the upper casing feeding sorting and loading device 5 are provided, which are located between the reagent strip feeding, cutting and loading device 4 and the upper casing. The first detection device 6 between the shell feeding sorting and loading device 5, the second detecting device 7 located downstream of the upper shell feeding sorting and loading device 5, and the loop conveyor line body 1 for unloading Unloading device 8.

[0059] The lower housing feeding sorting and loading device 3 has the same structure as the upper housing feeding sor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com