A precision progressive die for multi-bending forming

A precision-level, die-in-progress technology, applied in the field of sheet metal bending, can solve the problems of discontinuous processing, non-promotion of use, and increased labor intensity of workers, and achieve the effects of compact structure, increased production output, and improved bending efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings. The protection scope of the present invention is not limited to the following:

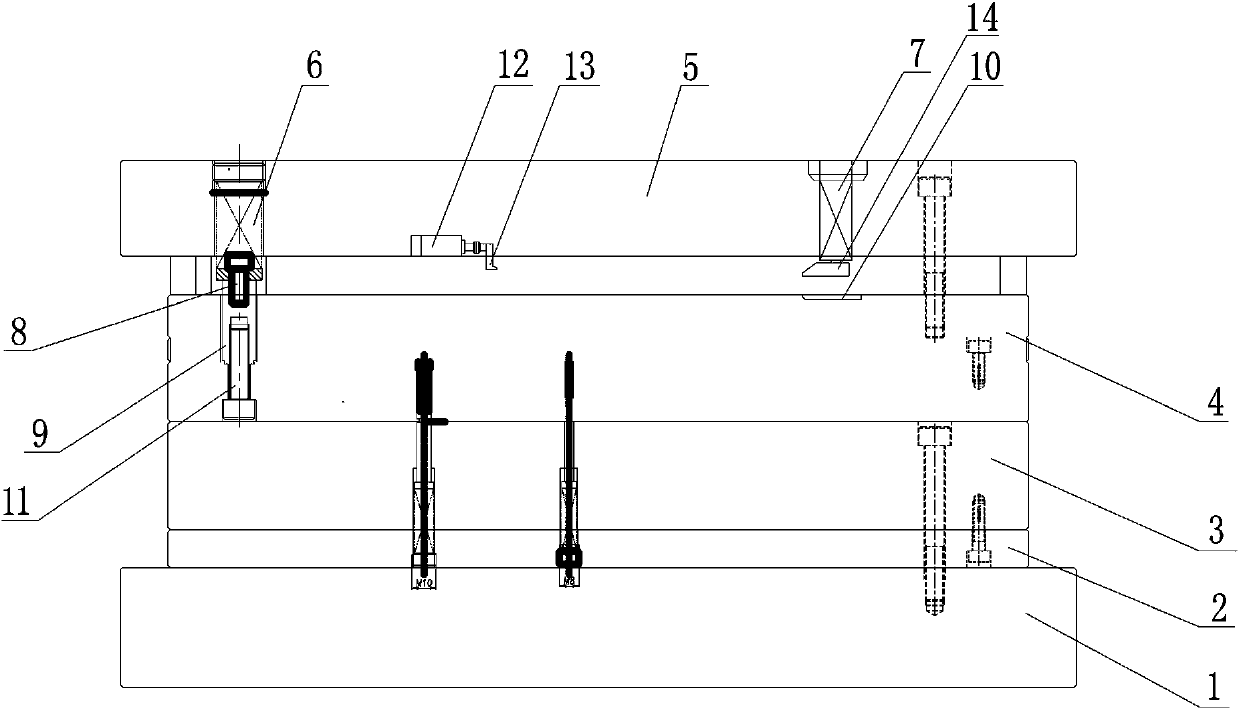

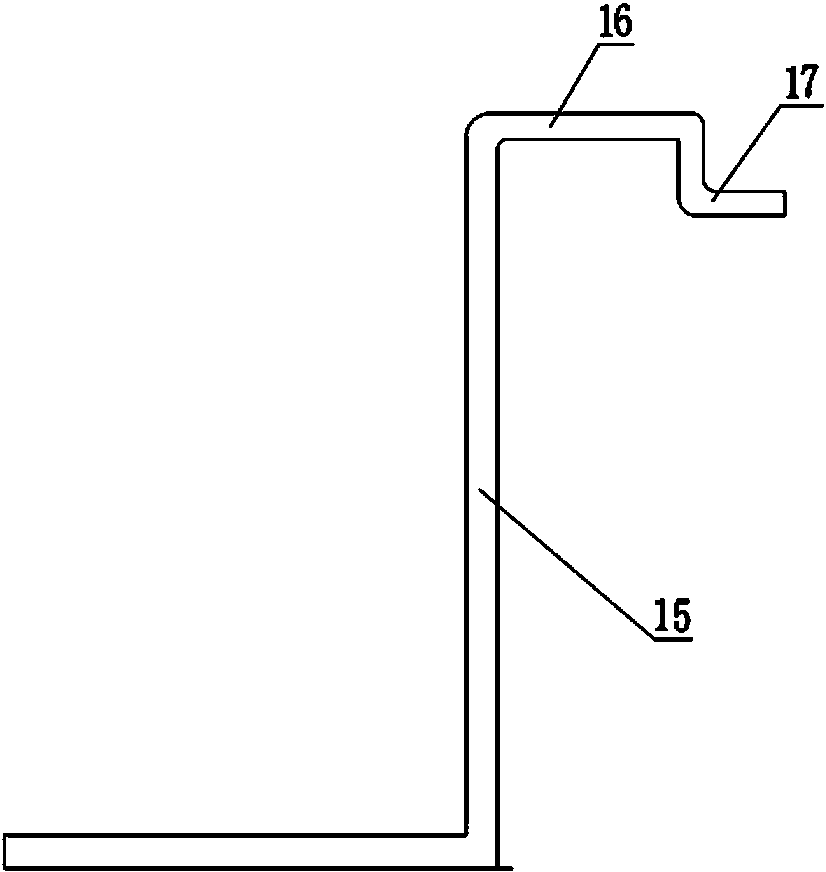

[0012] Such as figure 1 As shown, a precision progressive die for multiple bending forming includes a base 1, a lower backing plate 2, an upper backing plate 3, and a concave mold 4, which are arranged on the base 1 and connected sequentially from bottom to top. An upper bracket 5 is provided above 4, a female mold insert A6 and a female mold insert B7 are arranged in the upper support 5, a pressure die 8 is connected to the lower end of the female mold insert A6, and a square cavity 9 is provided in the female mold 4 And the cavity 10, the square cavity 9 is provided with a mandrel 11 directly below the die 8, a cylinder 12 is fixedly installed at the front end of the upper bracket 5, the cylinder 12 is horizontally arranged, and the piston rod of the cylinder 12 is connected The oblique wed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com