A vertical electric servo tool holder and its use method

A technology of electric servo and tool holder, which is applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of low reliability of the tool holder encoder, high failure rate, increased tool holder volume, etc., and achieve high performance Stability, high degree of standardization, economic and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

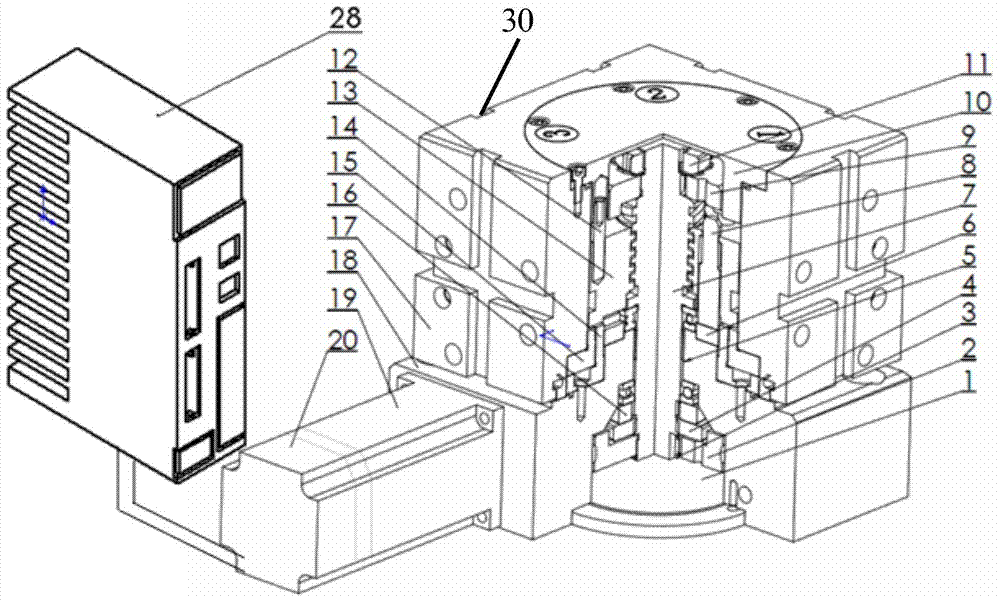

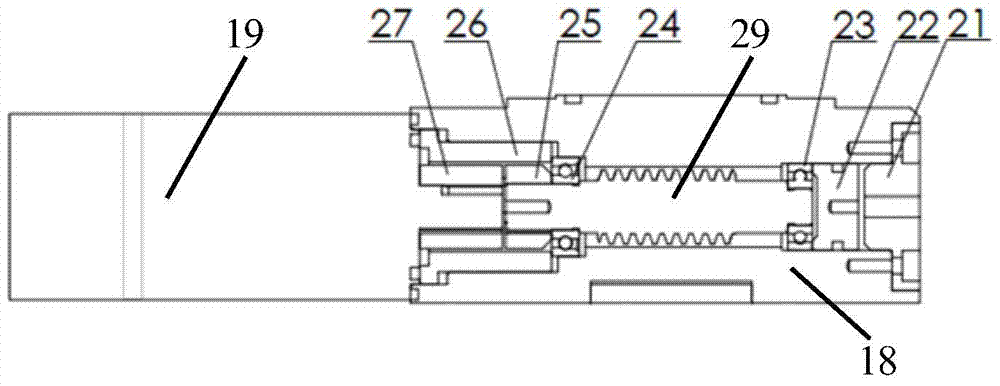

[0028] Such as Figure 1-Figure 2 As shown, the vertical electric servo tool rest of the present invention mainly includes: a square knife platform, a transmission mechanism, a locking mechanism, etc., and the specific structure is as follows:

[0029] The square knife table 17 is located above the base 18, the side of the square knife table 17 has a keyway 30, the keyway 30 can be connected with a quick-change tool holder mechanism, the square knife table 17 and the base 18 are hollow structures, and the lower end of the base 18 is installed with a flange 1. The connecting plate 10 is installed on the upper end of the square knife table 17, and the center of the square knife table 17 and the base 18 is provided with a screw cover 7, and the screw cover 7 is installed with a round nut 11, a transmission plate 9, and a movable toothed plate 13 from top to bottom. , initial positioning plate 6, steel back bearing 5, back cap 16, stop pad 4, shaft circlip 3, worm wheel 2, etc., r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com