Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Hot stamping effect is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

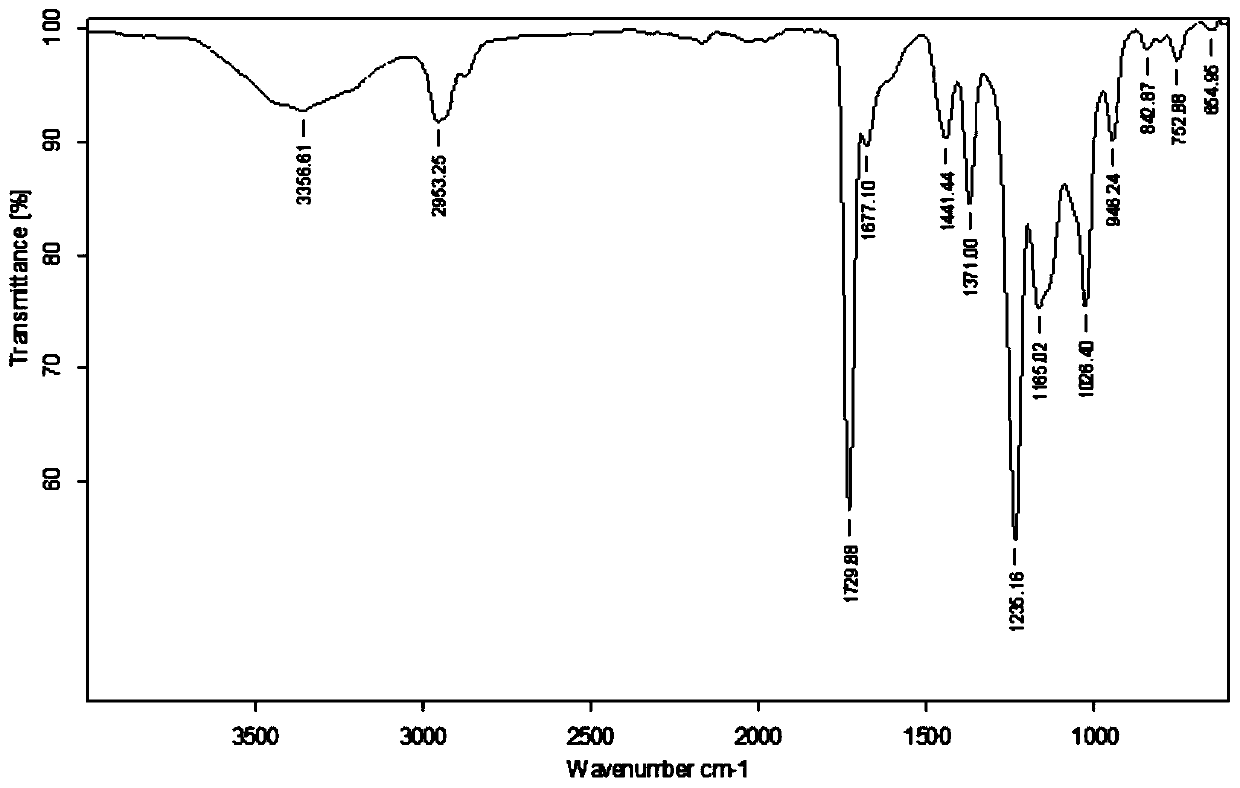

Environment-friendly aqueous adhesive for electrochemical aluminum and preparation method thereof

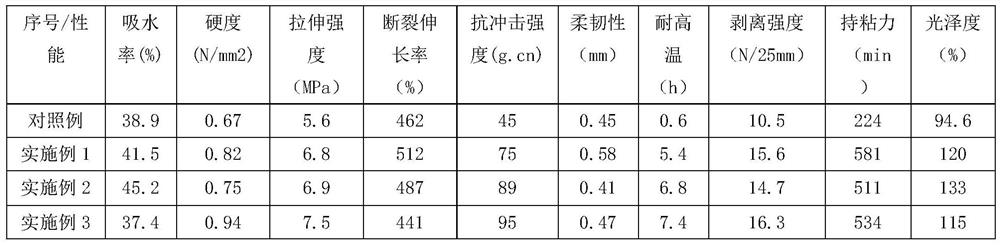

ActiveCN101942285AReduce contentReduce pollutionAldehyde/ketone condensation polymer adhesivesEpoxy resin adhesivesAdhesiveSolvent

The invention relates to the field of dye, coating and adhesive, in particular to aqueous adhesive for electrochemical aluminum, and provides environment-friendly aqueous adhesive for electrochemical aluminum and a preparation method thereof. Compared with the conventional solvent type adhesive, the aqueous adhesive is environmental protection and low cost; and meanwhile, compared with common aqueous coating, the aqueous adhesive has the advantages of good printing adaptability, wide thermoprinting temperature range, good thermoprinting effect and easy control of production process. The invention adopts the following technical means that: the formula of the aqueous adhesive comprises the following components in part by weight: 30 to 35 parts of aqueous resin, 42 to 47 parts of water, 18 to 23 parts of cosolvent, 2 to 4 parts of white carbon black and 0.01 to 0.02 part of defoaming agent; and the preferable formula of the aqueous adhesive comprises the following components in part by weight: 32 to 34 parts of aqueous resin, 44 to 46 parts of water, 20 to 22 parts of cosolvent, 2 to 3 parts of white carbon black and 0.015 to 0.02 part of defoaming agent.

Owner:云南玉溪东魅包装材料有限公司

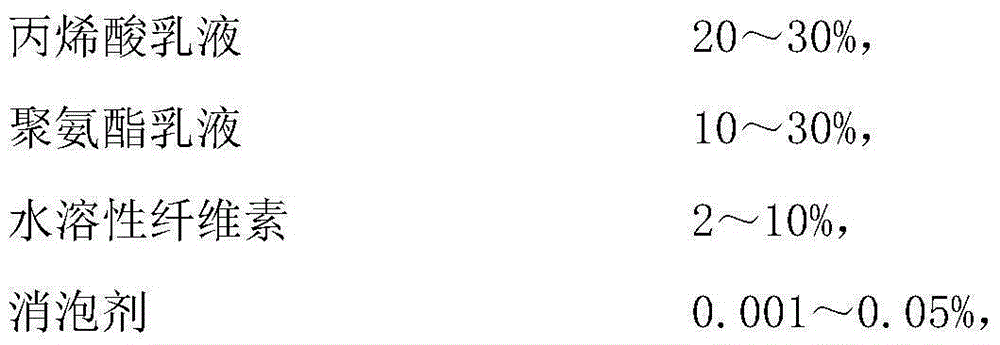

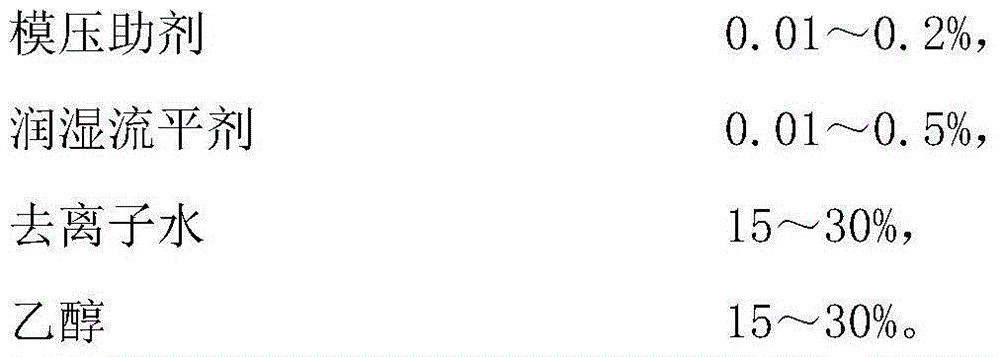

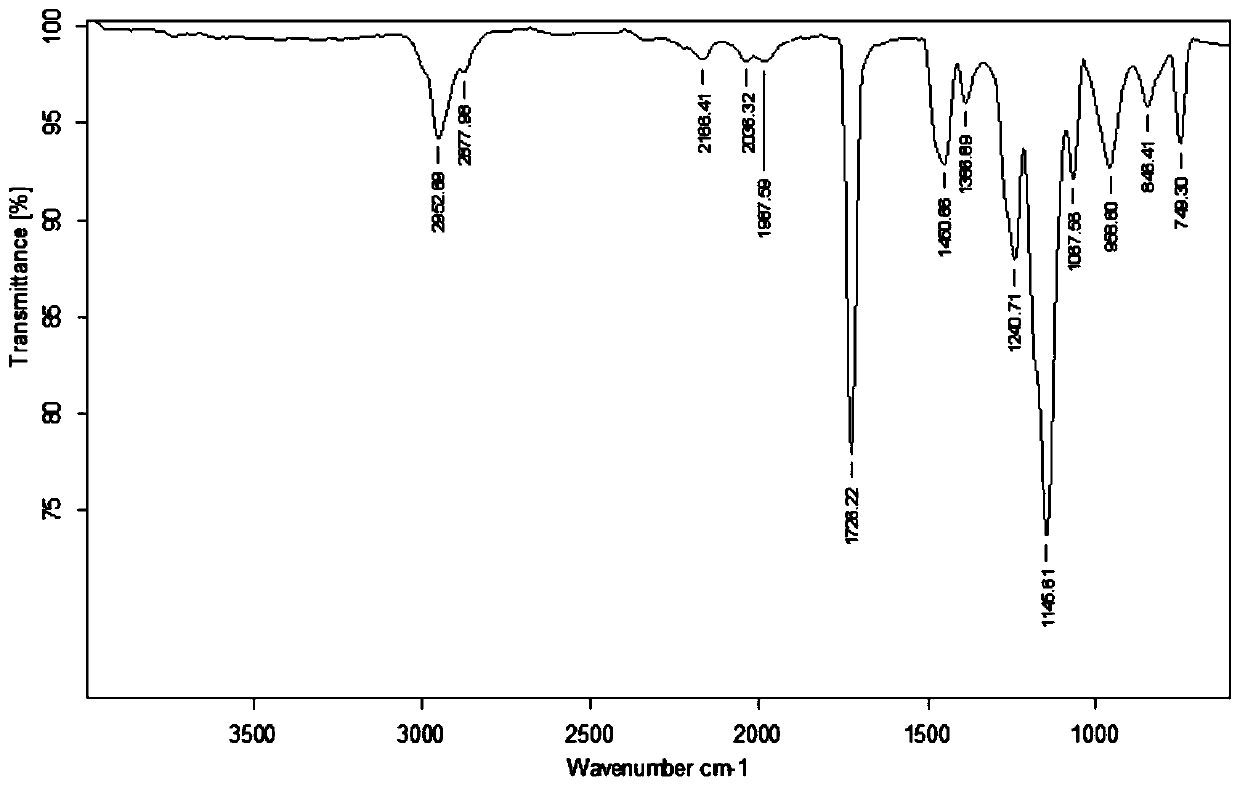

Water-based laser alumite coating without release layer and preparation method thereof

ActiveCN105038555AHot stamping effect is goodSimple production processCellulose coatingsPolyurea/polyurethane coatingsIonHot stamping

The invention provides a water-based laser alumite coating without a release layer and a preparation method thereof. The coating comprises 20-30% of acrylic emulsion, 10-30% of polyurethane emulsion, 2-10% of water-soluble cellulose, 0.001-0.05% of defoaming agent, 0.01-0.2% of die pressing assistant, 0.01-0.5% of wetting leveling agent, 15-30% of deionized water and 15-30% of ethyl alcohol. The water-based laser alumite coating is environmentally friendly, low in cost and excellent in performance; it can be guaranteed that alumite has good slitting performance and a high hot stamping speed just by coating a base film with the water-based laser alumite coating directly, so that the technological process of release layer coating is simplified, the cost is lowered to some degree, and resources are saved to some degree.

Owner:SHANGHAI CHENGYING NEW MATERIALS +2

Non-plate gold blocking method

InactiveCN105216468AEasy transferImprove efficiencyDuplicating/marking methodsOther printing apparatusBlock effectBase oil

The invention relates to and provides a non-plate gold blocking method. The non-plate gold blocking method comprises the following steps that firstly, the surfaces of various package materials are coated with base oil through a printer; and secondly, alumite is attached to the surfaces of the materials, the alumite is transferred after passing a hot pressing roller, and gold blocking is finished. The non-plate gold blocking method has the beneficial effects that the base oil can be printed into various high-precision patterns, the printing coating weight can be adjusted, and therefore a protruding emboss effect can be formed; compared with traditional gold blocking, plate making is not needed, and gold blocking patterns are finer; a special gold blocking machine is not needed, and pattern transferring can be easily finished through an ordinary film laminating machine; too long plate correcting time is not needed, and the concept of local pressure supplementing is avoided; the method is not influenced by the breadth or the batch, efficiency is extremely high, and the gold blocking effect is better; and the thickness of gold blocking emboss manufacturing materials is not limited, and the non-plate gold blocking method is suitable for the gold blocking effect of various materials.

Owner:SHANGHAI JIELONG ART PRINTING +1

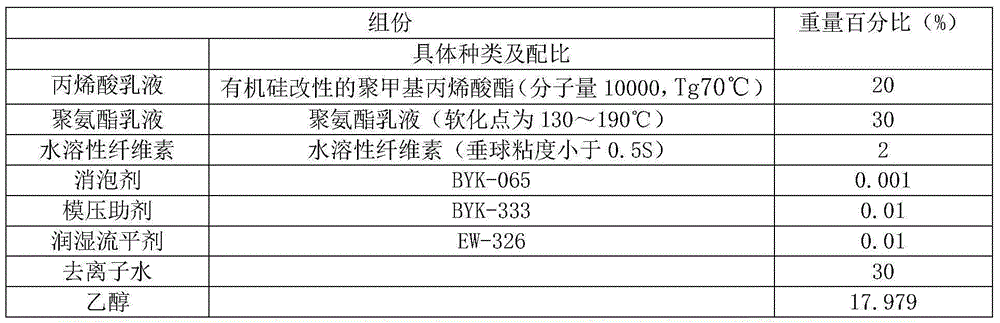

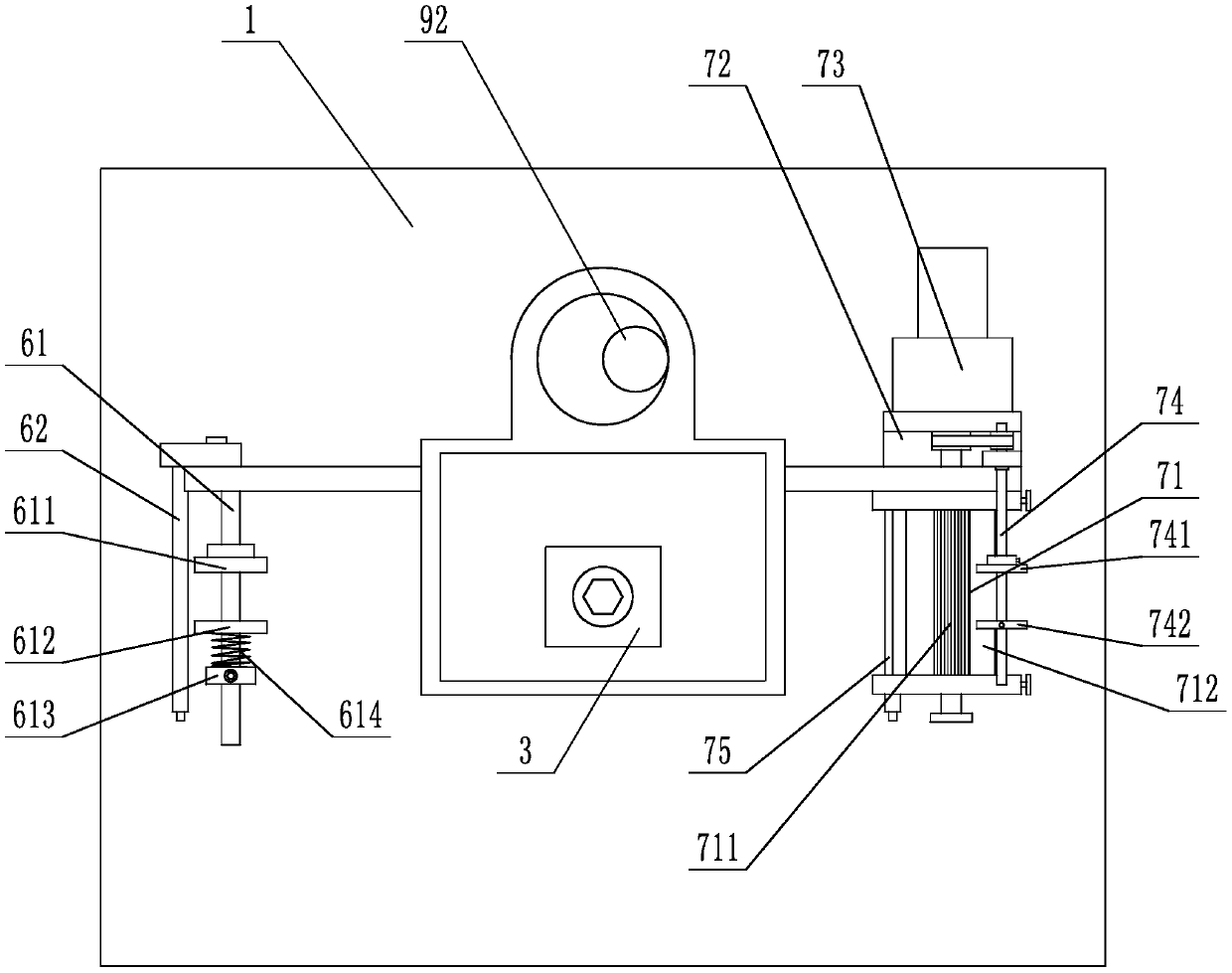

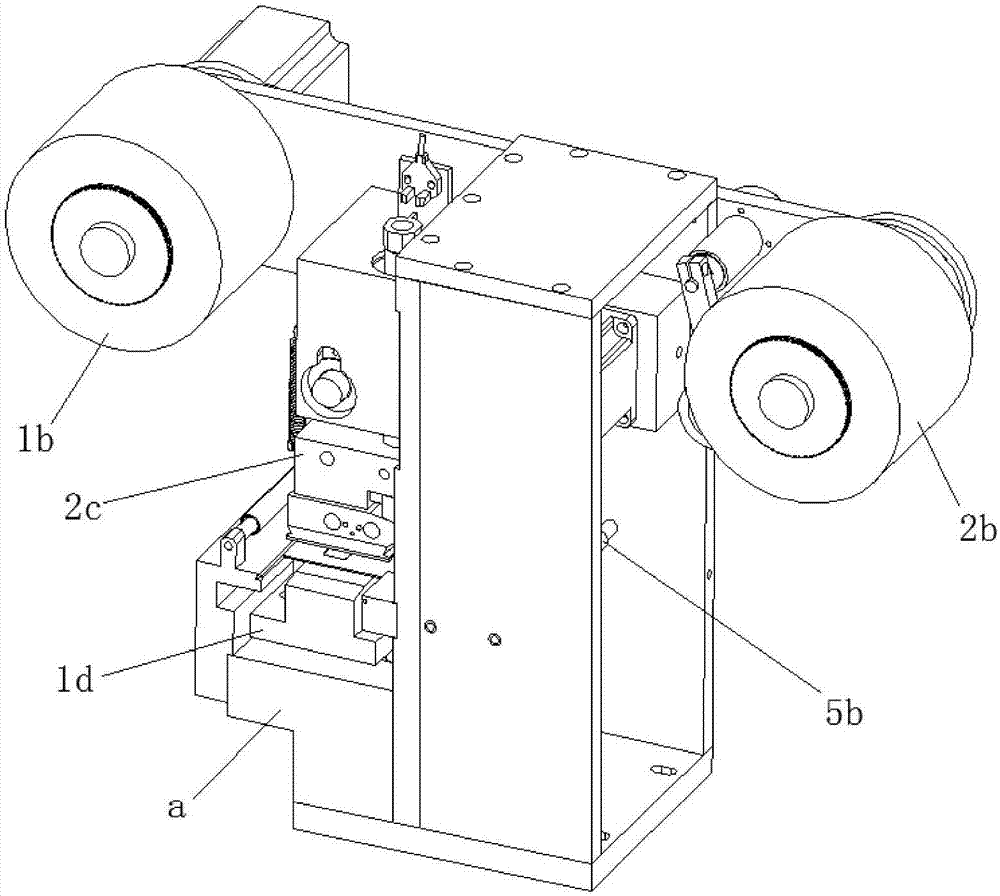

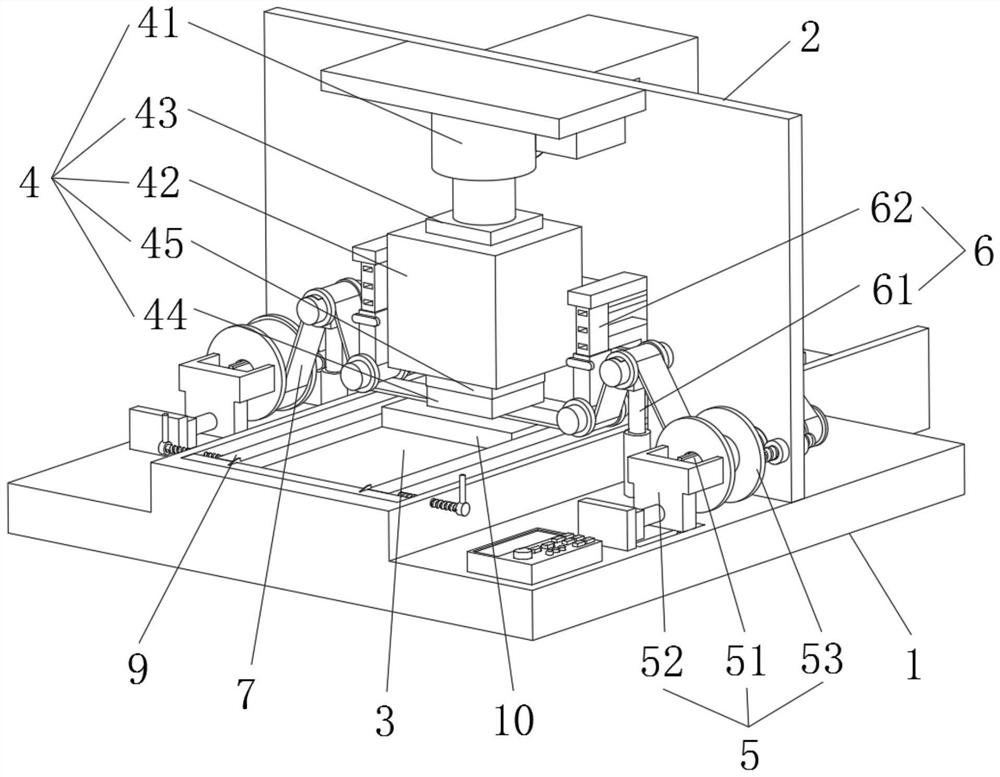

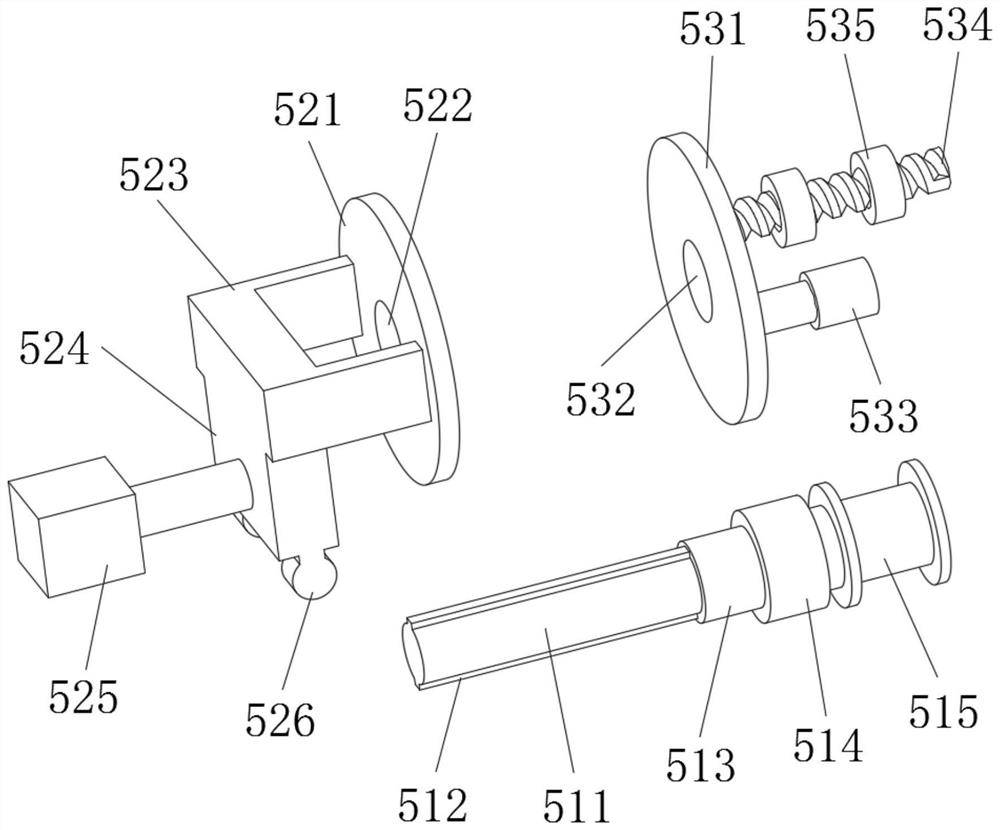

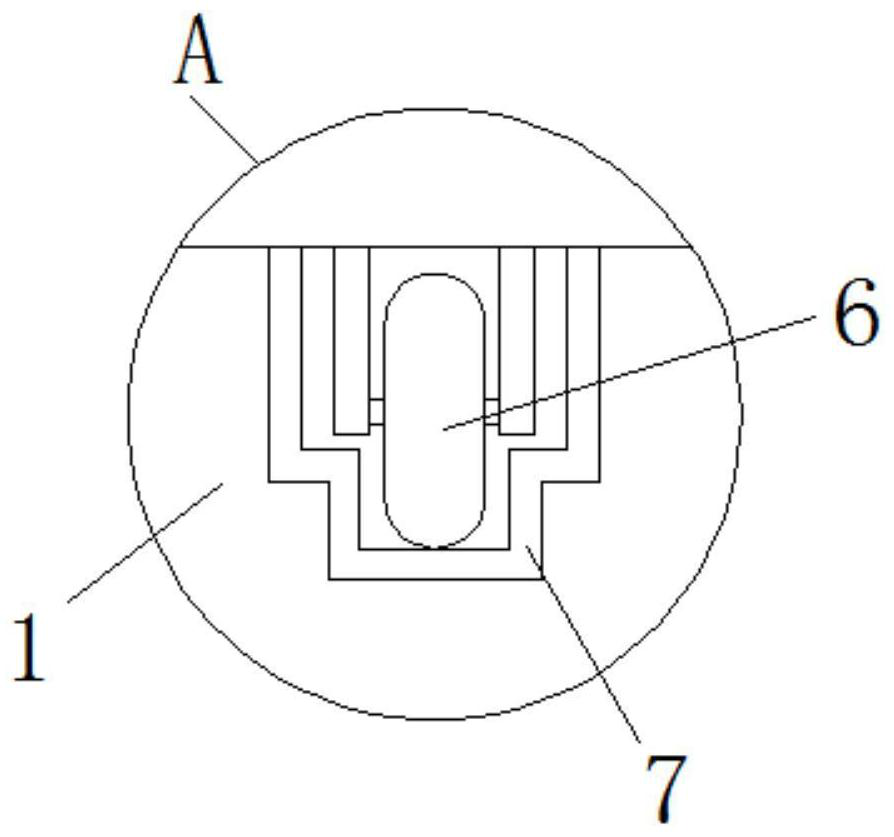

Gold stamping machine

The invention provides a gold stamping machine. The gold stamping machine comprises a workbench, a base arranged on the workbench, locating blocks arranged on the base and used for fixing a printed material, a fixed frame used for fixing hot gold foil, a heating plate arranged on the fixed frame, a hot stamping plate arranged at the bottom of the heating plate and a drive device used for driving the heating plate to move up and down. The gold stamping machine further comprises a tension device used for tensioning the hot gold foil, a conveying device used for conveying the printed material anda discharging device. The tension device comprises a paper discharging mechanism and a paper collection mechanism which are arranged at the two ends of the fixed frame. A through opening communicating with the workbench is formed in the base. The conveying device comprises a conveying belt arranged in the through opening and transmission rollers cooperating with the conveying belt. The multiple locating blocks are detachably mounted on the conveying belt. The two ends of each transmission roller are fixed to the inner wall of the through opening. A detection head is arranged at the position,facing the locating blocks, of the base. The gold stamping machine is simple in structure, high in work efficiency, good in hot stamping effect, high in rate of finished products and low in cost.

Owner:温州市剑峰文具有限公司

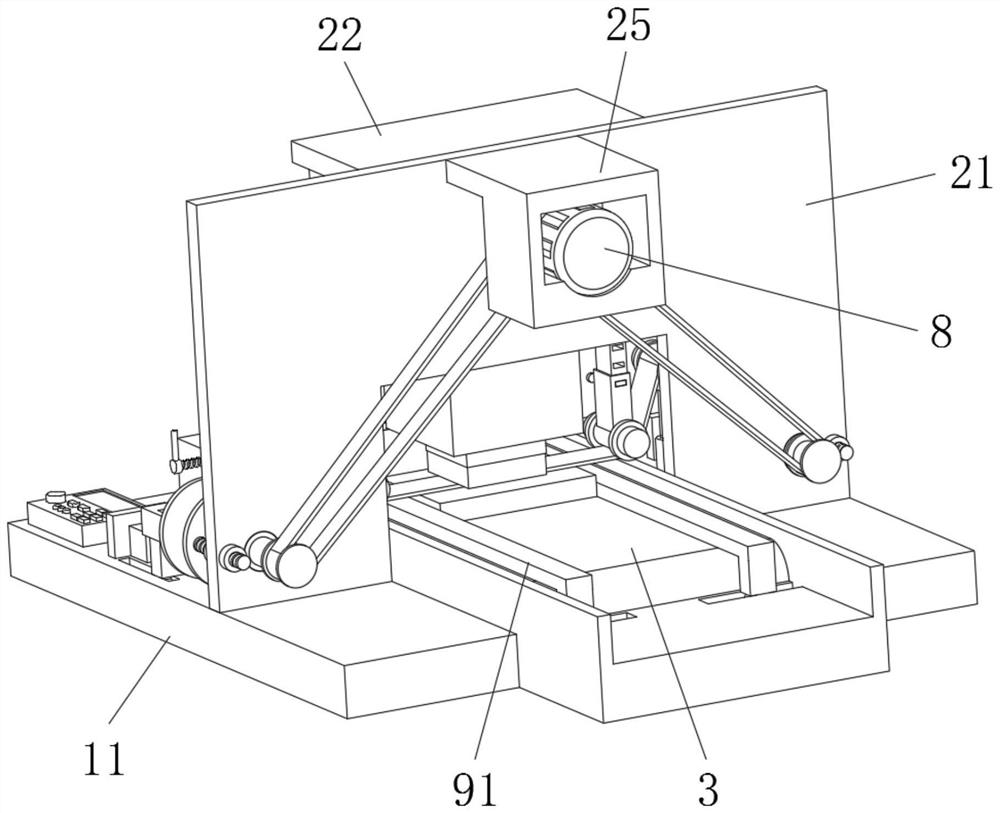

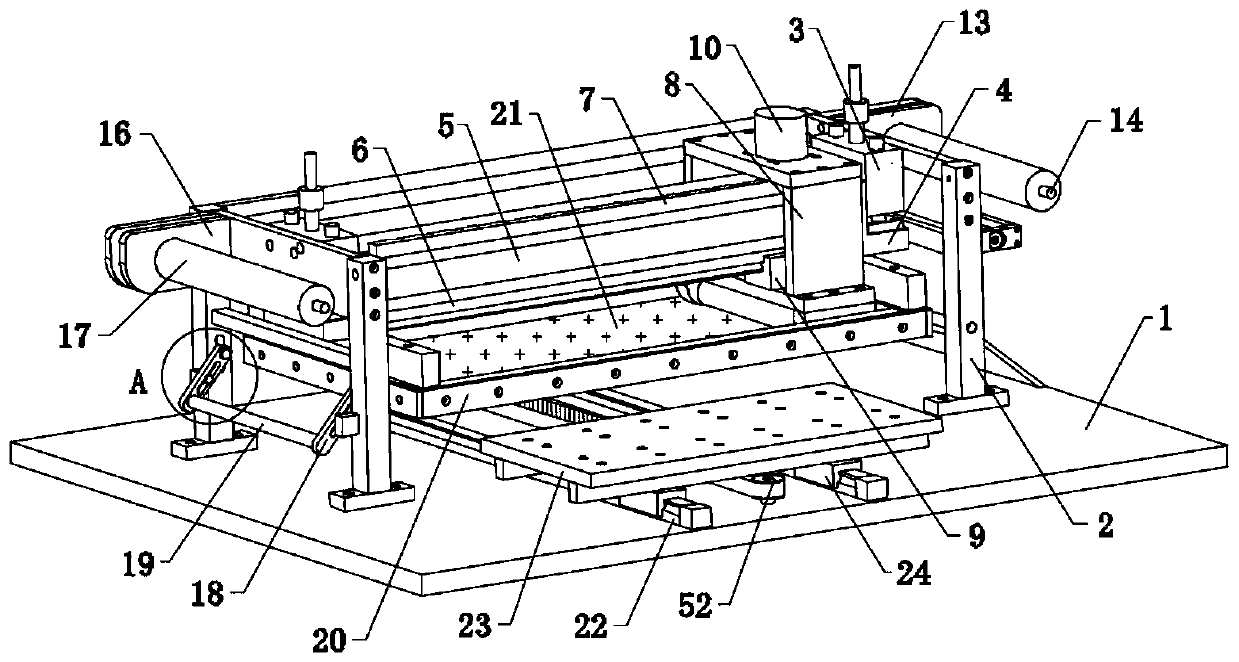

Automatic thermoprinting machine and thermoprinting method thereof

ActiveCN110509663ARealize transmissionSimple structureTransfer printingOther printing apparatusEngineeringSilica gel

The invention discloses an automatic thermoprinting machine and a thermoprinting method thereof. The automatic thermoprinting machine includes a workbench, the top of the workbench is provided with arack, the inner sides at two ends of the rack are symmetrically provided with telescopic driving pieces, the end of each telescopic driving piece is provided with a lifting plate, a cross beam is arranged between the two lifting plates, and a transmission compression roller mechanism is arranged on the cross beam; the bottoms of the two lifting plates are provided with heating sheet frames, and the middles of the heating sheet frames are provided with silica gel heating sheets positioned below the transmission compression roller mechanism; a film transmission mechanism fixed on the rack is arranged below the cross beam; the workbench is provided with a feeding mechanism which is perpendicular to the film transmission mechanism. According to the automatic thermoprinting machine, through thearrangement of the integral structure, the feeding process is simpler and more convenient to control, a film is heated more uniformly, the thermoprinting effect is improved, the operation steps are simplified, and the operation difficulty is reduced.

Owner:浙江智博交通科技有限公司

Alumite hot stamping adhesive and preparation method thereof

ActiveCN110079257AImprove the level ofImprove the exhaust effectMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesHot stampingGas phase

The invention discloses an alumite hot stamping adhesive. The alumite hot stamping adhesive is prepared from components in parts by weight as follows: 10-20 parts of a styrene thermoplastic elastomer,40-65 parts of tackifying resin, 5-25 parts of auxiliary resin and 8-18 parts of fumed silica. Due to addition of the styrene thermoplastic elastomer, the alumite hot stamping adhesive has good bonding performance and thermoplasticity at high temperature, the added tackifying resin can provide better initial viscosity, and the auxiliary resin can enhance adhesion to an aluminum layer. Under the synergistic effect of the styrene thermoplastic elastomer, the tackifying resin and the auxiliary resin, the hot stamping adhesive has proper softening point to meet high-speed hot stamping, good adhesion performance and certain temperature resistance; the added fumed silica improves the appearance effect and the hot stamping effect of the hot stamping adhesive. The invention also provides a preparation method of the alumite hot stamping adhesive.

Owner:WUHAN HUAZHONG KEDA FINE CHEM

Hydraulic gold stamping machine

InactiveCN1727185AIncrease pressureHot stamping effect is goodDuplicating/marking methodsBronze printingHydraulic cylinderEngineering

A hydraulic gilding press is composed of base, lower platform on said base and with 4 regulating and fixing screwed axles at its 4 corners, upper platform a lift bench with vertical hydraulic cylinders under it, motor, and heating plate under the upper platform. Its advantage is high pressure.

Owner:江敦景

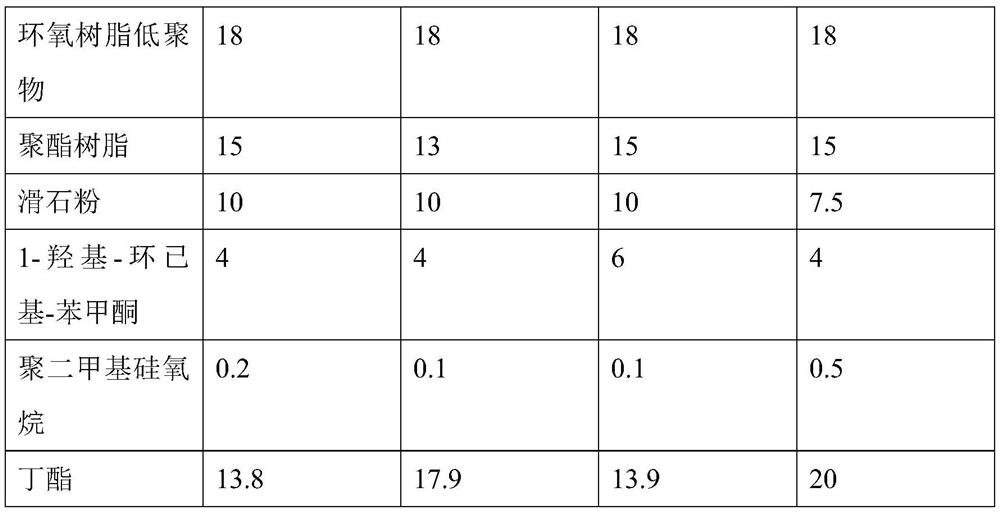

Novel matte alumite hot-stamping foil coating and manufacturing method

InactiveCN103849308AReduce glossGood matte effectPolyurea/polyurethane coatingsHot stampingBenzoic acid

The invention discloses a novel matte alumite hot-stamping foil coating, and the coating is characterized by preparing the following materials in parts by weight: 20-40 parts of acrylic acid modified polyurethane, 2-5 parts of tributyl citrate, 1-10 parts of pure acrylate, 10-20 parts of benzoic acid diallyl acid resin, 30-60 parts of butanone, 5-20 parts of butyl ester and 10-20 parts of matte powder. The novel matte alumite hot-stamping foil coating disclosed by the invention is simple in production process and in favor of large-scale production, the produced alumite hot-stamping foil is low in gloss, good in matte performance and excellent in hot-stamping effect, the product is good in adhesive force and good in abrasive resistance, the coating is hard to precipitate and in favor of long-term storage.

Owner:ZHEJIANG HENGFENG PACKING

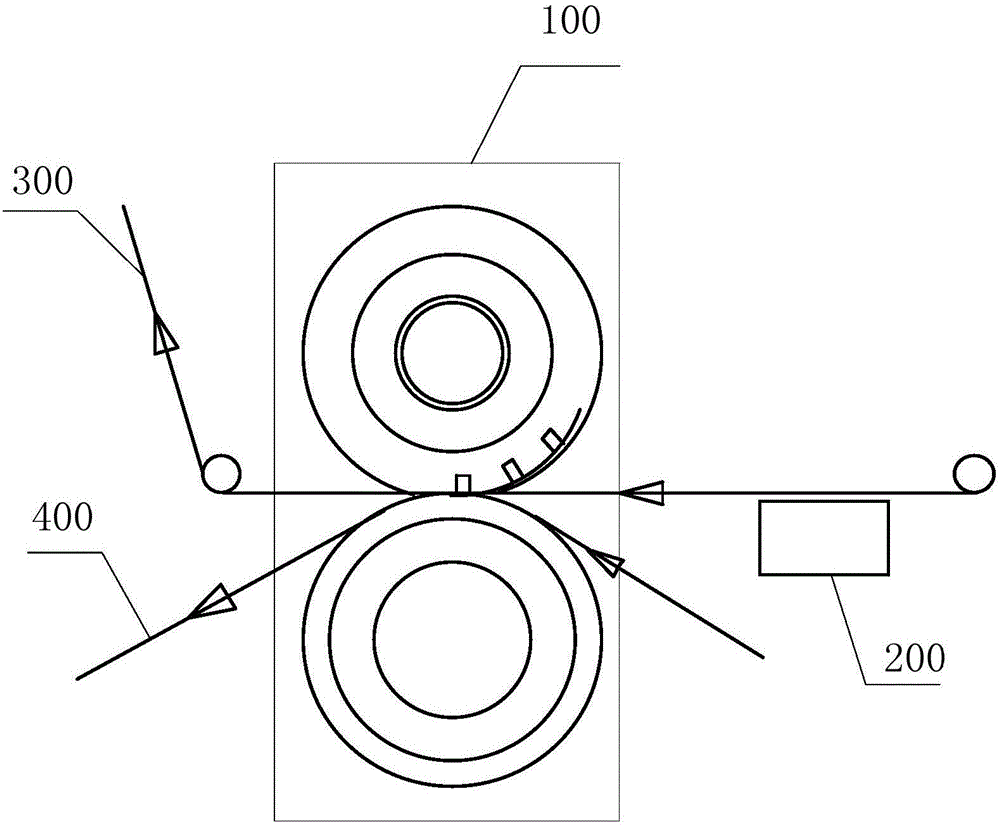

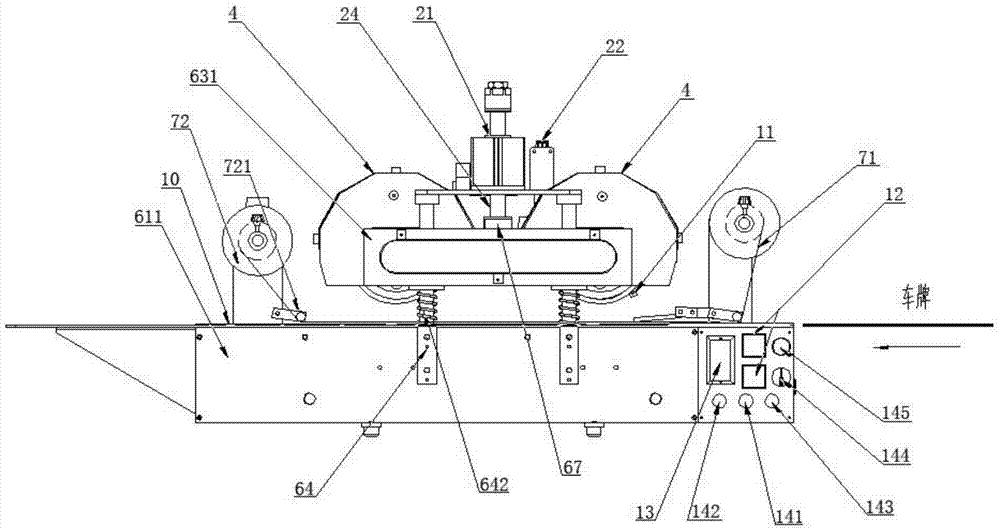

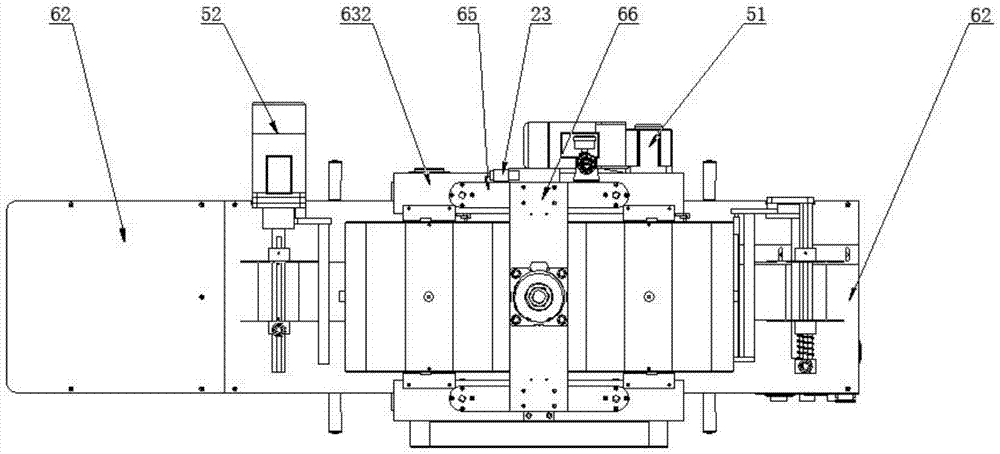

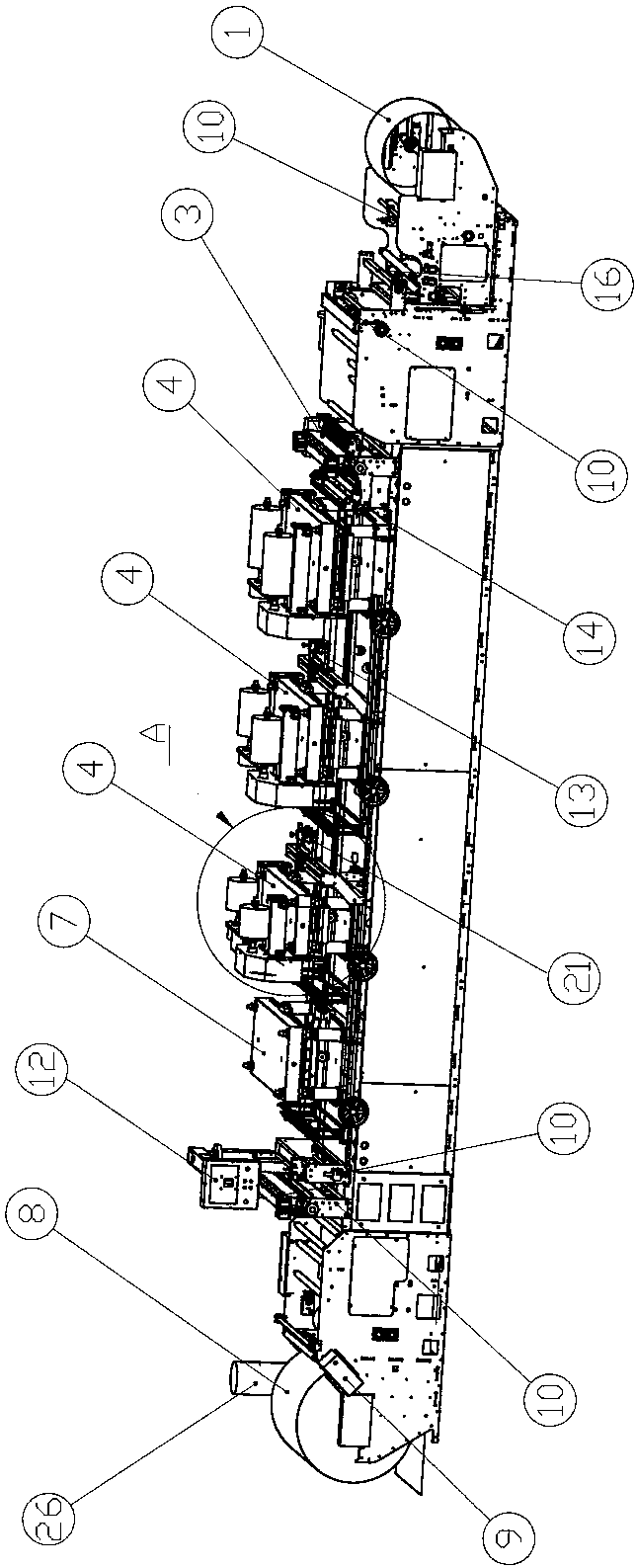

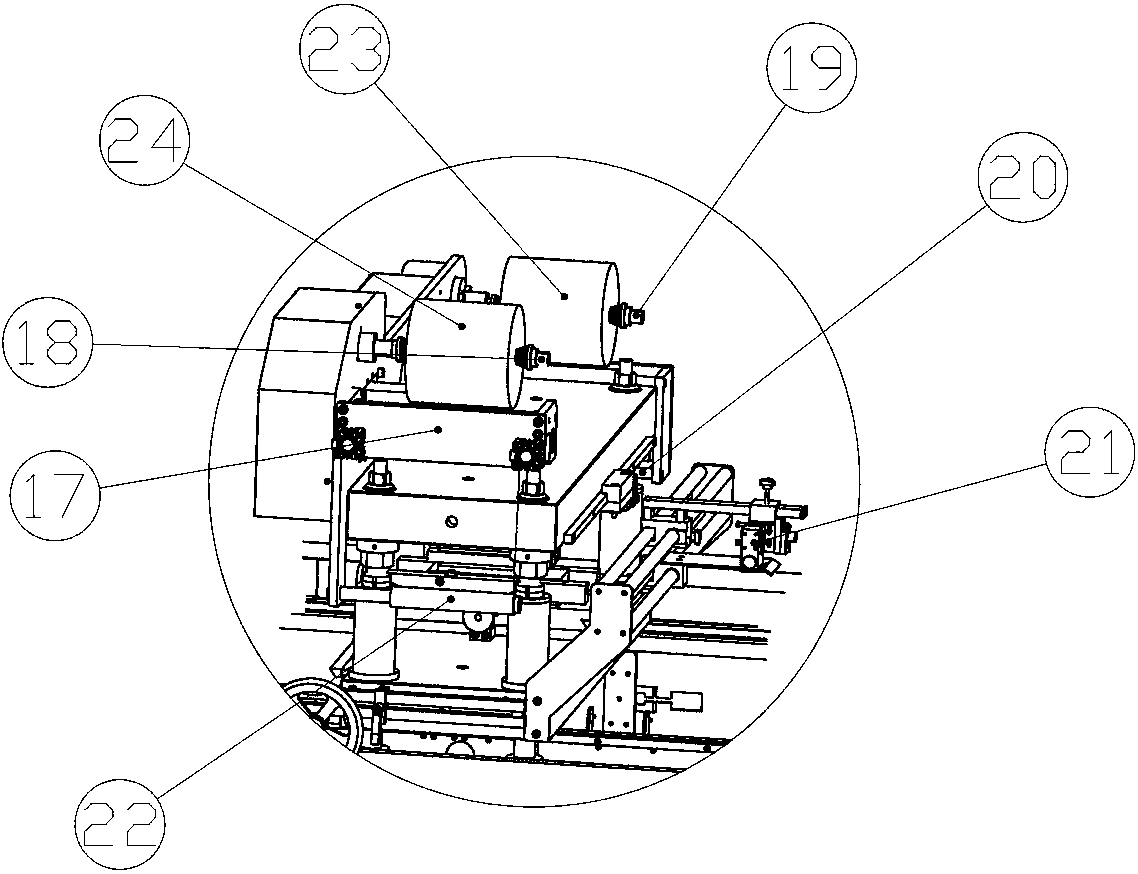

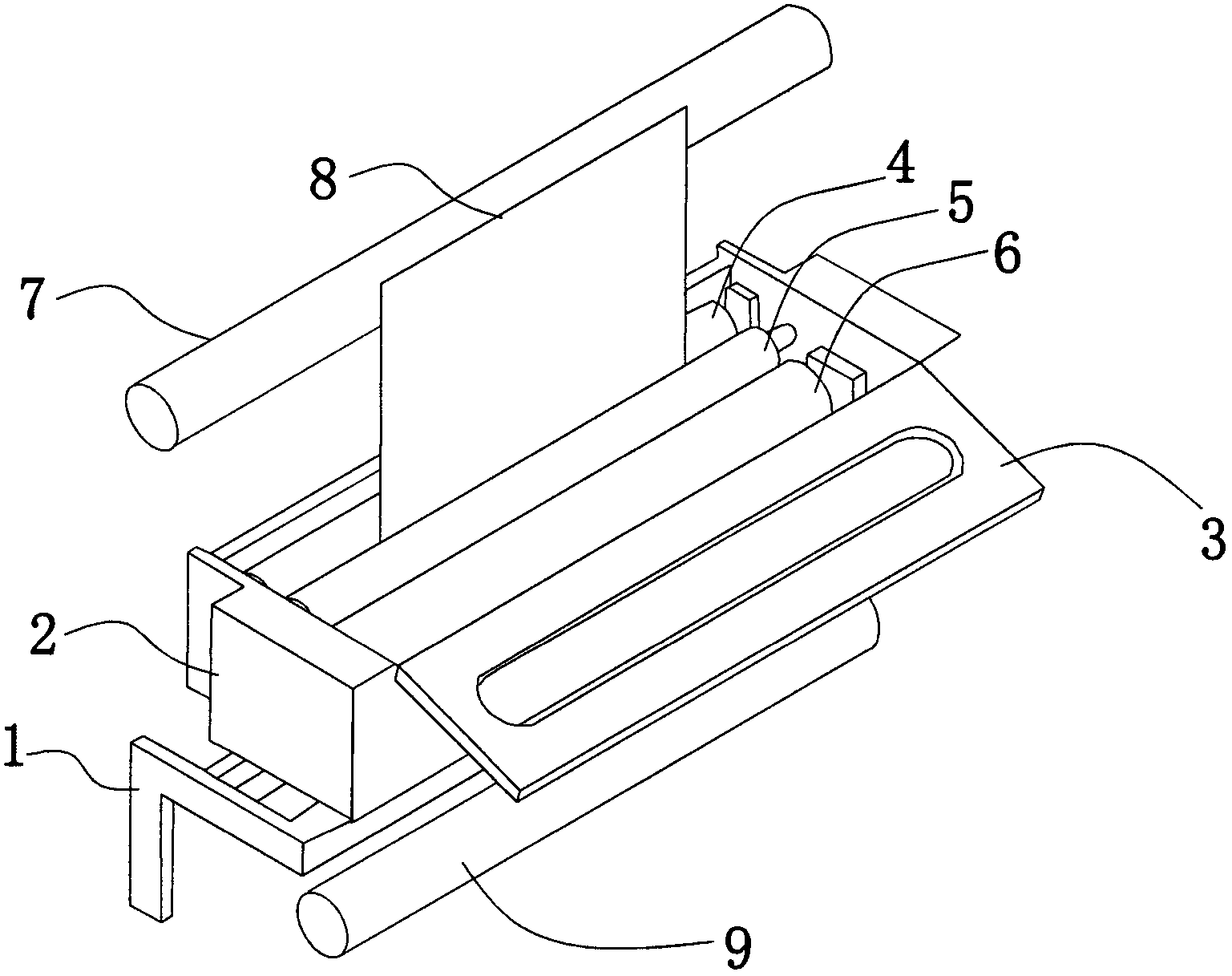

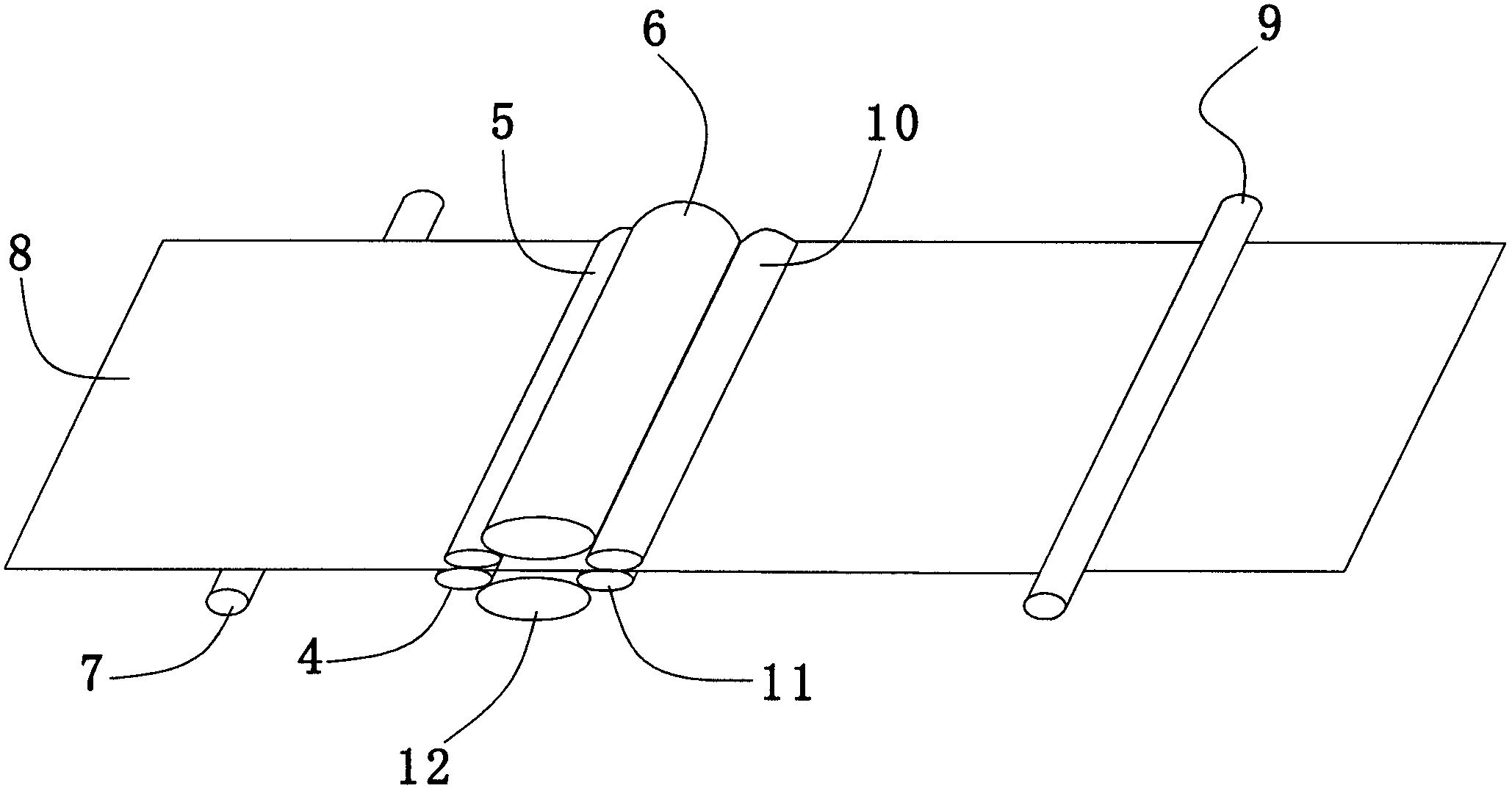

Electromagnetic rolling number plate continuous hot-stamping method and number plate hot-stamping machine

ActiveCN111806071AImprove work efficiencyHot stamping effect is goodTransfer printingInk transfer from master sheetStamping processHot stamping

The invention discloses an electromagnetic rolling number plate continuous hot-stamping method. Number plates needing to be hot-stamped are heated and hot-stamped through electromagnetically-heated rollers, and therefore the number plates are hot-stamped. A number plate hot-stamping machine comprises a body seat, a motor is arranged on one side of the body seat, a first belt wheel is arranged at the stretching-out end of the motor, the driving roller is arranged on the body seat, a second belt wheel is arranged at one end of the driving roller, a belt is wound around the first belt wheel and the second belt wheel jointly, the driven roller is arranged at one end of the body seat, and a conveying belt is wound around the driven roller and the driving roller. By means of an electromagnetic heating rolling hot-stamping manner, the electromagnetic rolling number plate continuous hot stamping method has the beneficial effects that the heating time is short; temperature replenishing is rapidin the hot-stamping process, and the production efficiency is greatly improved; and the number plates are heated uniformly, the percent of pass of hot-stamping is high, the cost depletions are greatly reduced, and the safety is improved.

Owner:浙江智博交通科技有限公司

Gold blocking device

InactiveCN106626749ALower requirementExtended service lifeRotary pressesBronze printingMetallurgyThermal radiation

The embodiment of the invention provides a gold blocking device which comprises a coining device and a preheating device, wherein the coining device is used for coining an electrochemical aluminum foil onto a printing stock; the preheating device is used for preheating the electrochemical aluminum foil and / or the printing stock before entering into the coining device; and the preheating device comprises at least one of heat conduction device, thermal radiation heating device and hot air device. The gold blocking device provided by the embodiment of the invention is capable of increasing the coining speed and reducing the pressure required by coining under the condition of guaranteeing the coining quality, in the manner of preheating the electrochemical aluminum foil and / or the printing stock before entering into the coining device; the pressure difference within a same plate block can be reduced, the pressure endured by the printing stock is more uniform and the mark on the rear side of the printing stock is relieved, so that the coining effect is promoted; the coining pressure is reduced, the demand on the coiling device is reduced and the overall load of the device is reduced, so that the service life of the coining device is prolonged.

Owner:MASTERWORK GROUP CO LTD

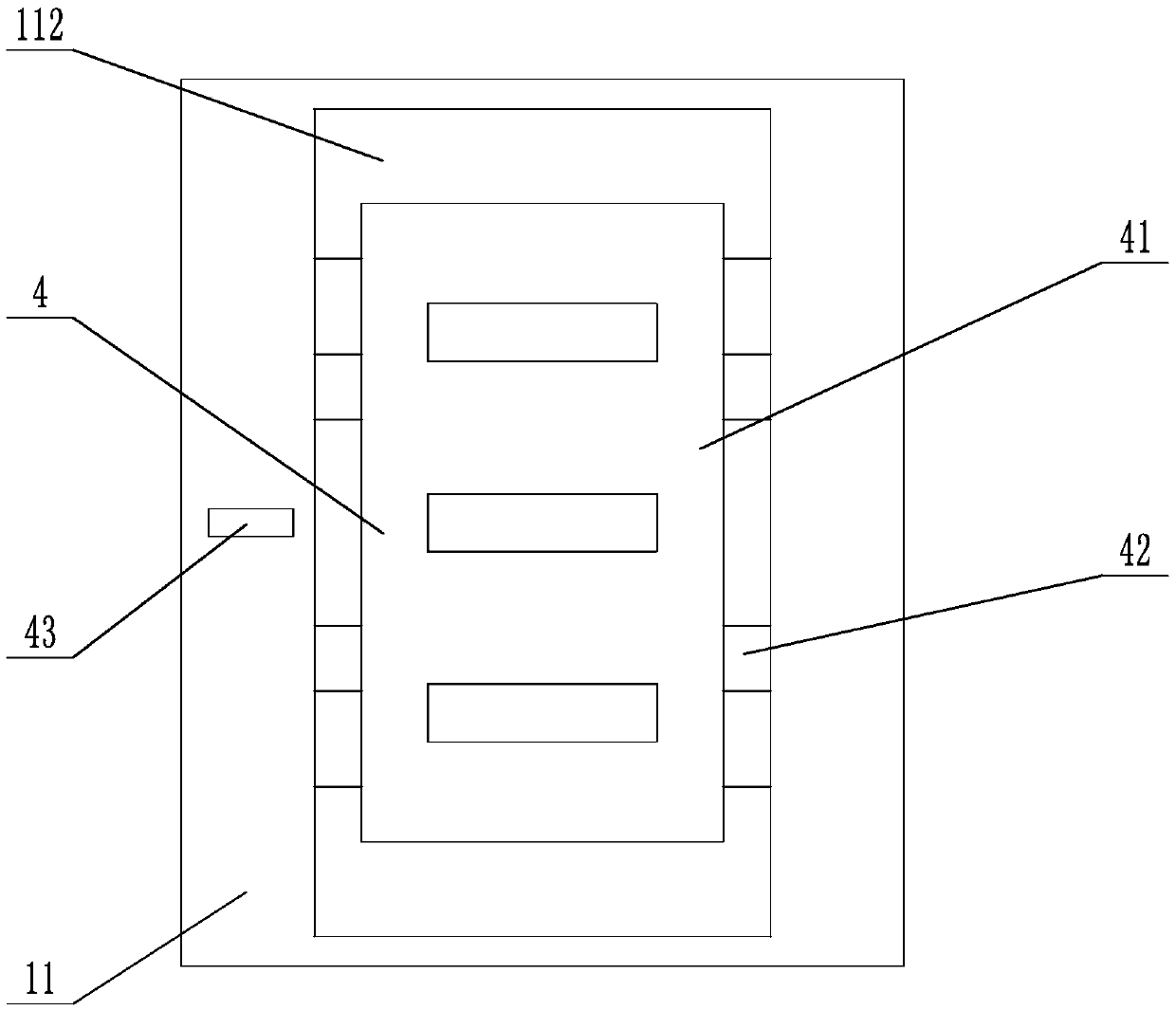

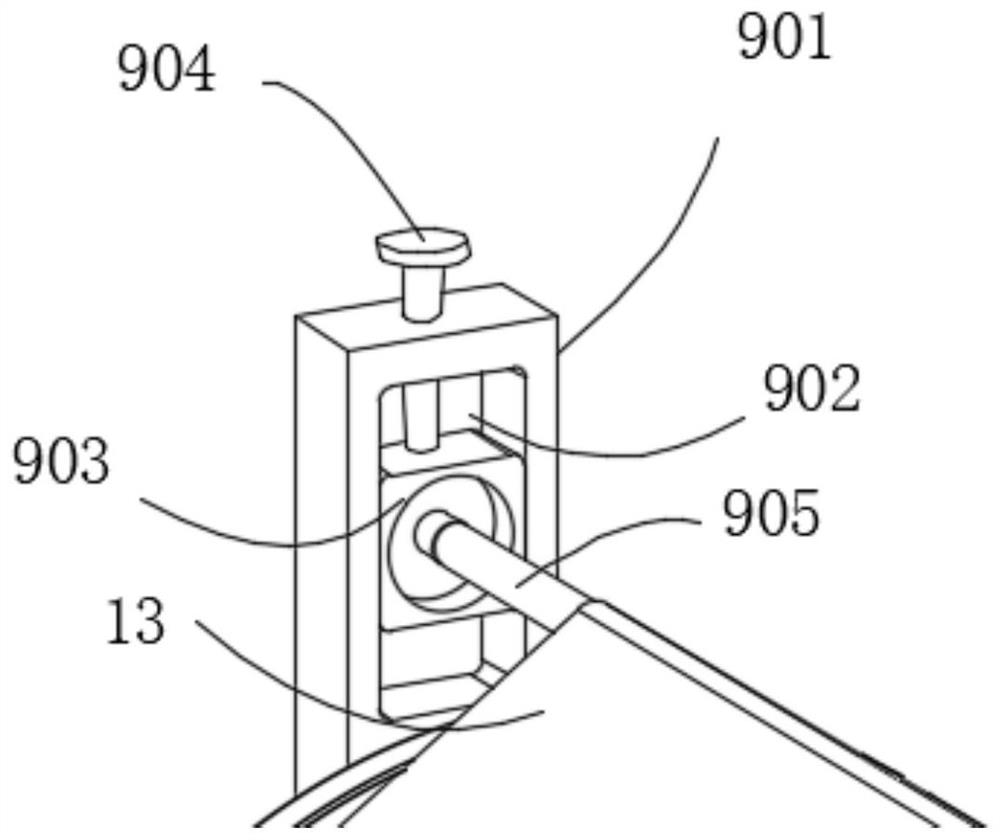

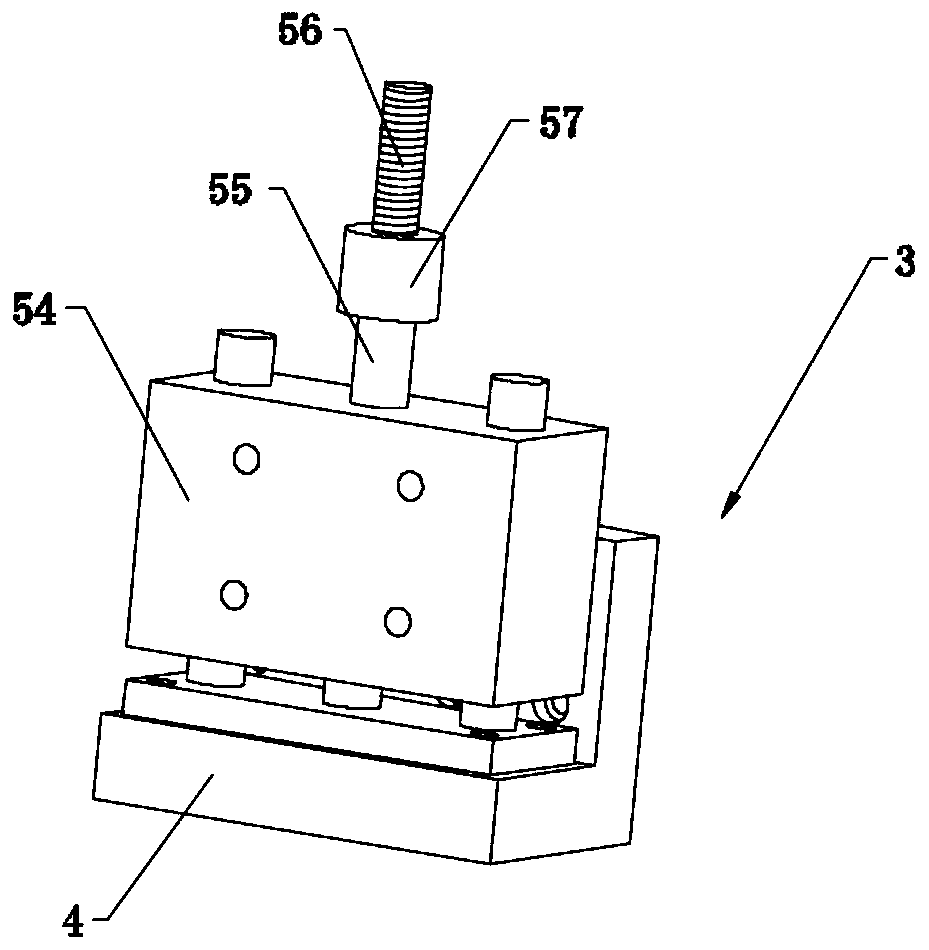

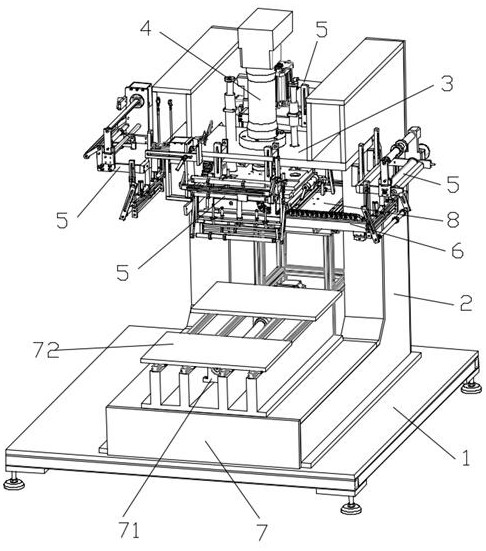

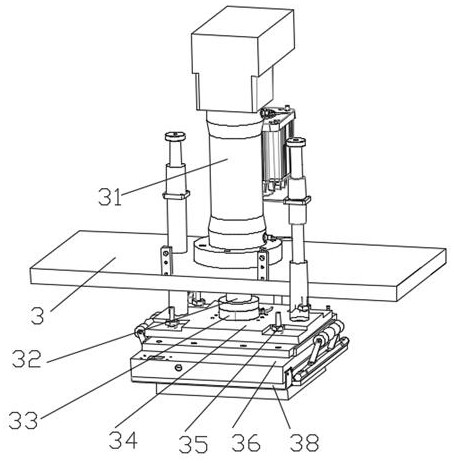

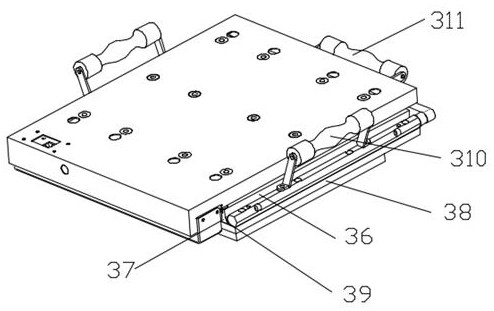

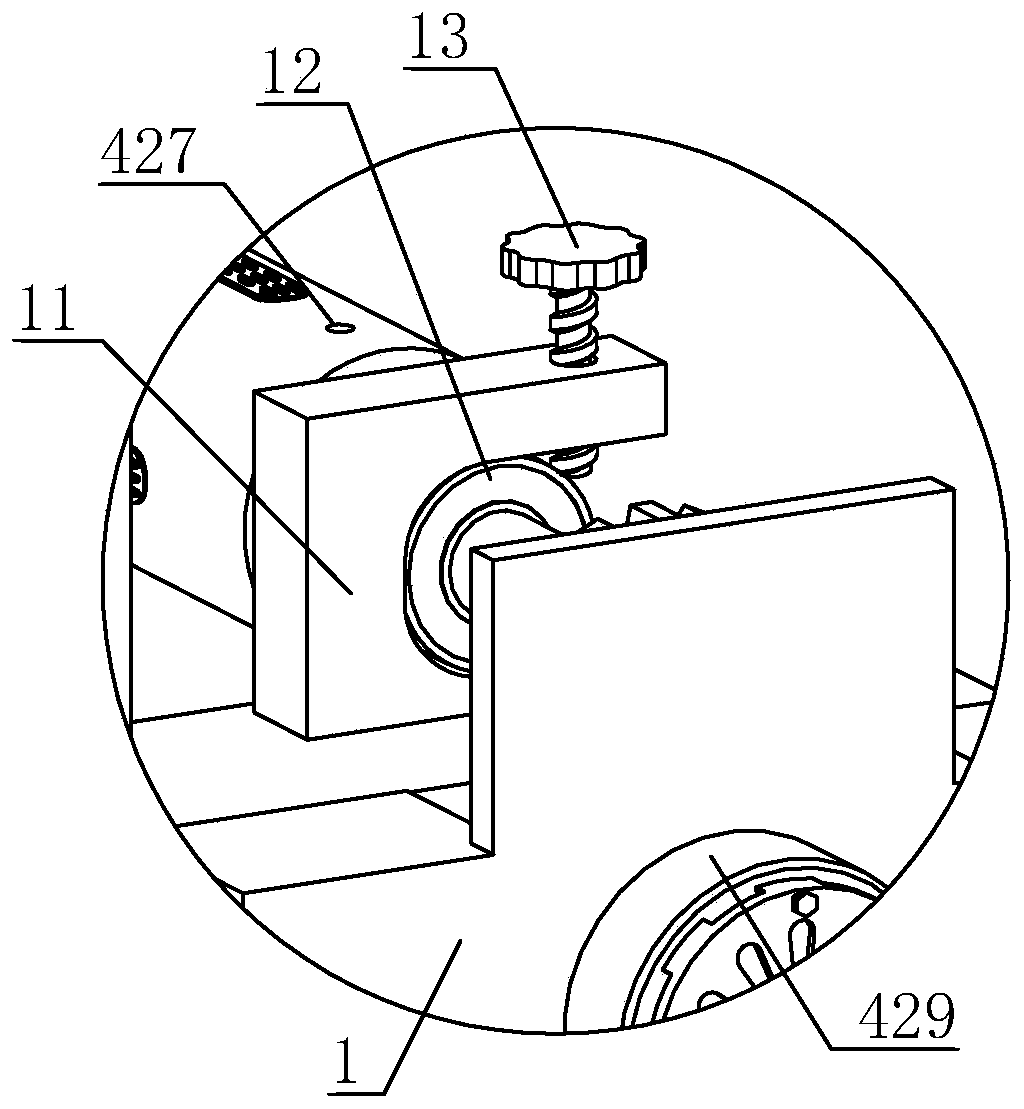

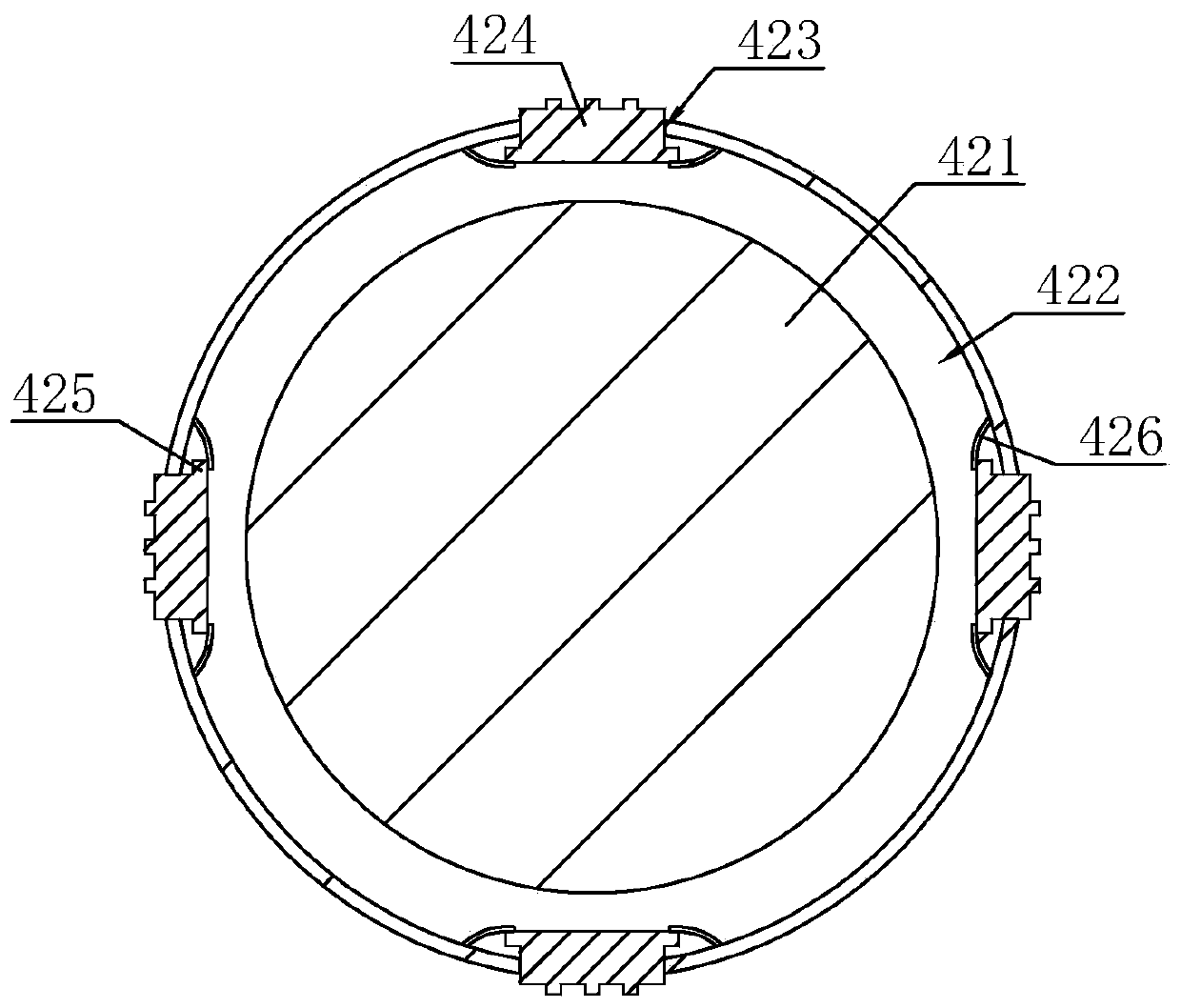

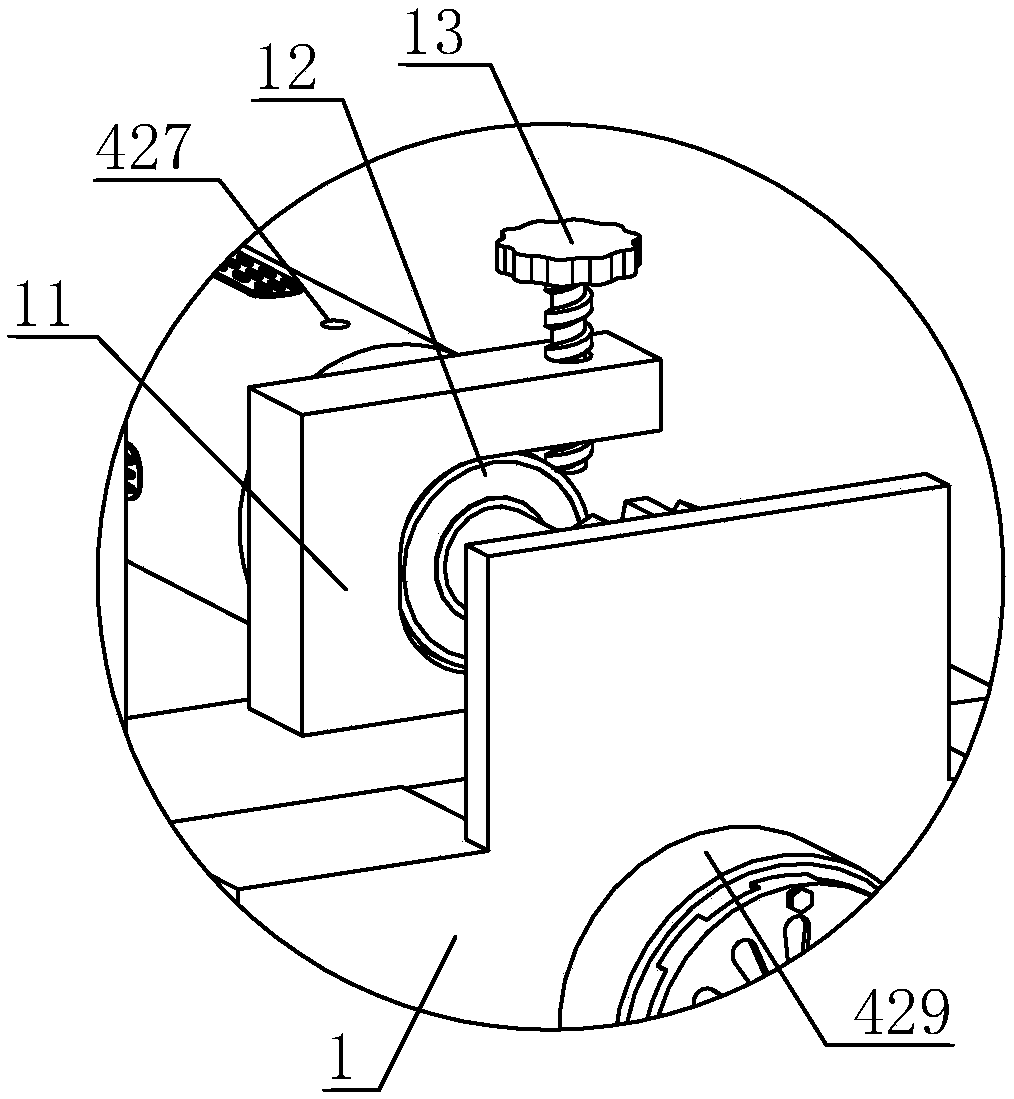

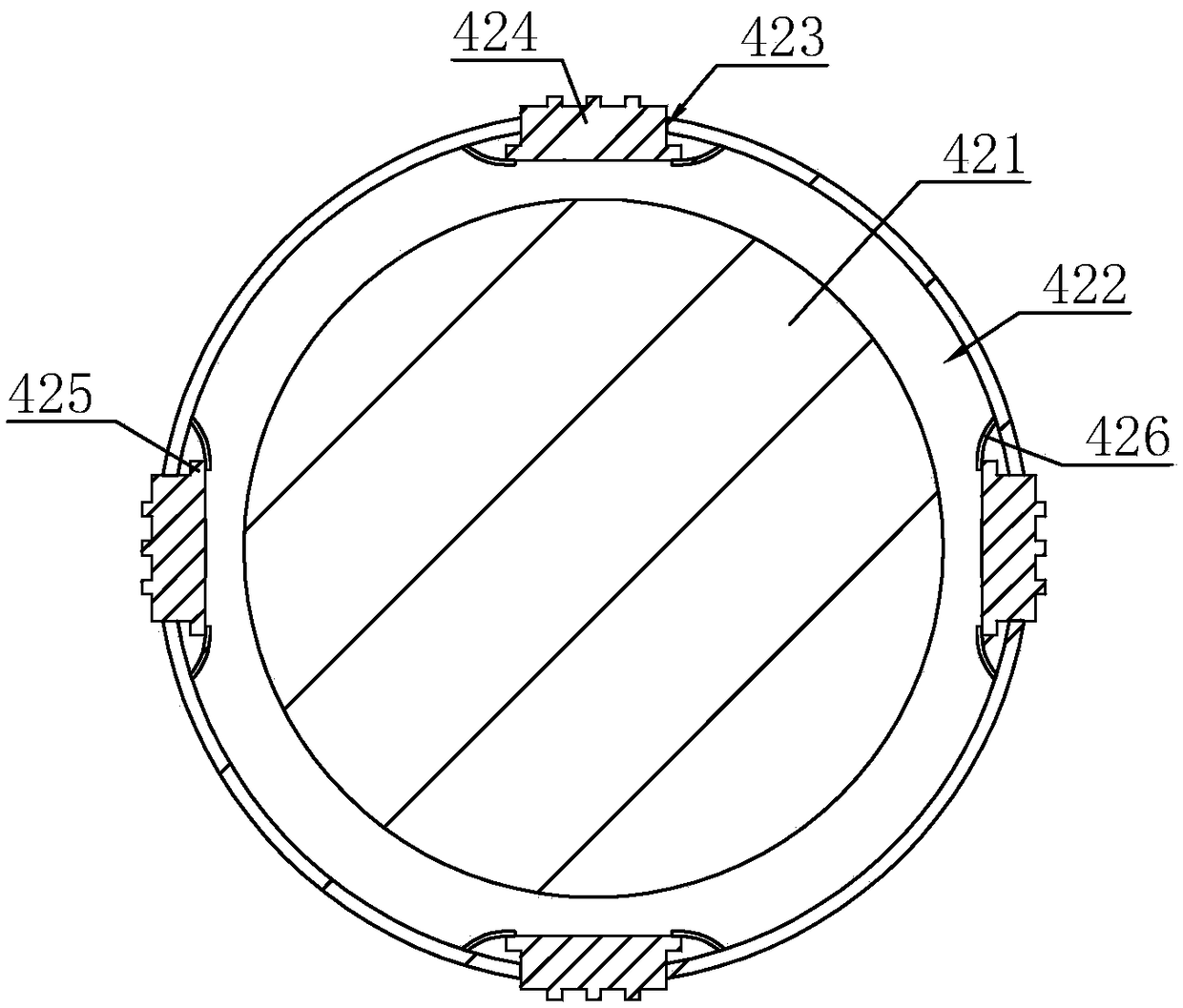

Intelligent card thermoprinting machine

PendingCN107297949AReduce adhesionHot stamping effect is beautifulRotary pressesSmart cardEngineering

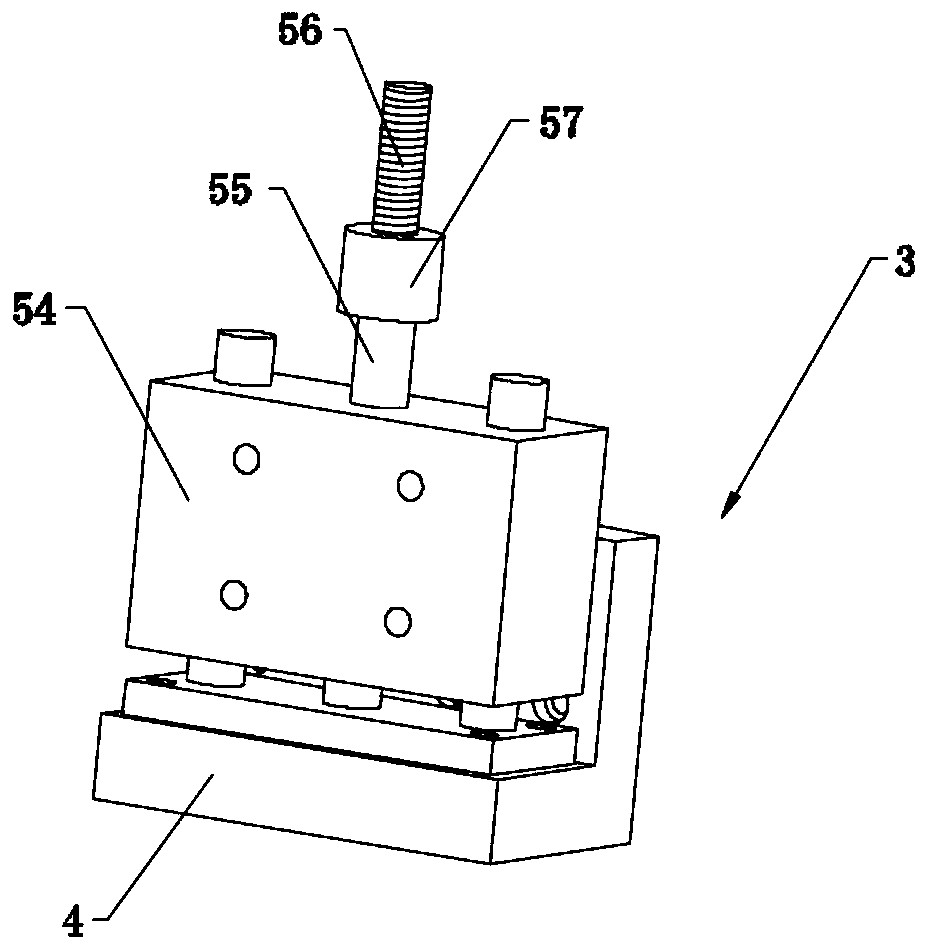

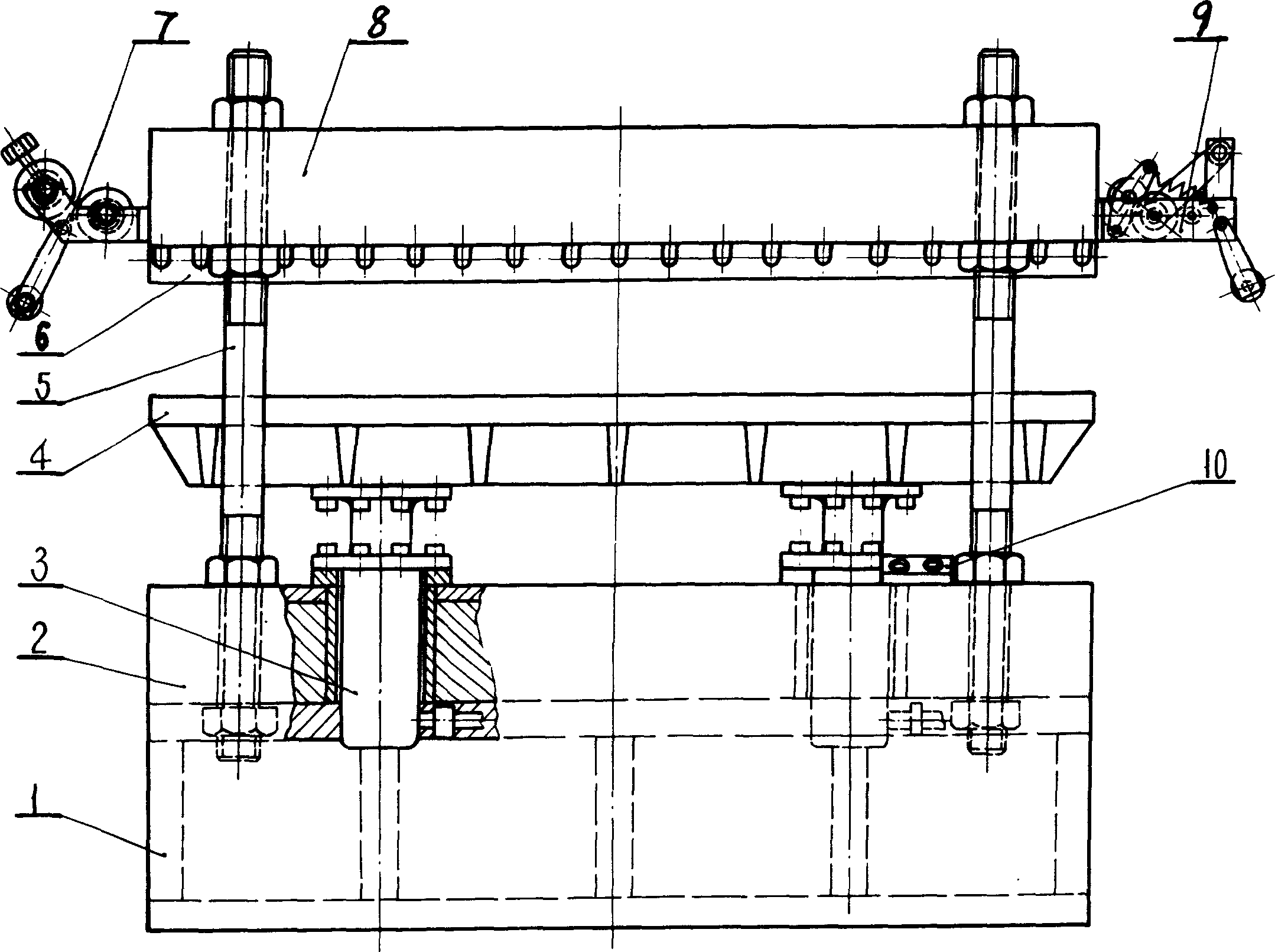

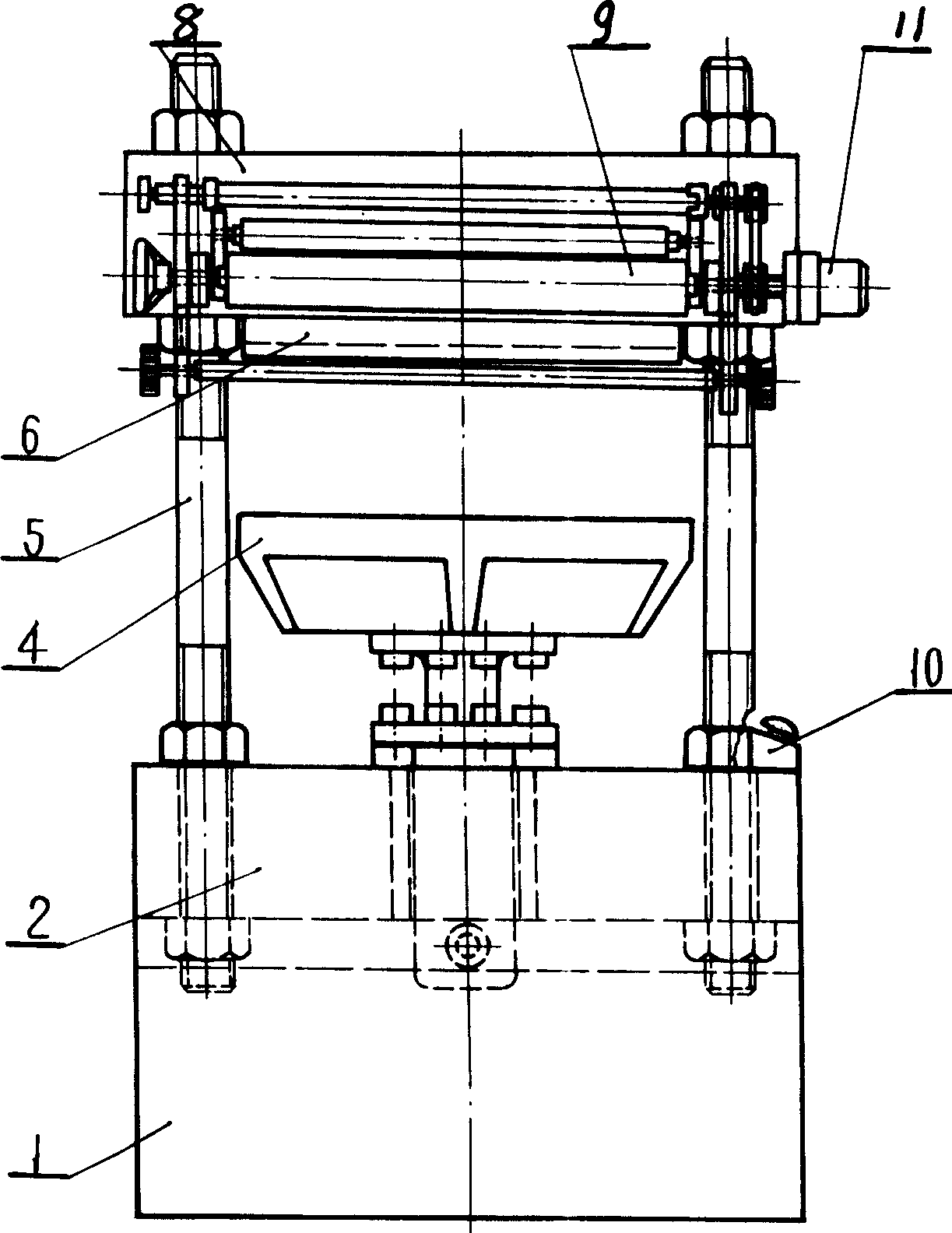

The invention discloses an intelligent card thermoprinting machine which comprises a rack, a thermoprinting belt conveying mechanism, a thermoprinting head and card parallelism adjusting mechanism, a card positioning mechanism and a feeding mechanism. The thermoprinting belt conveying mechanism comprises a thermoprinting belt winding mechanism and a guide component, the guide component comprises a first guide rod and a second guide rod, the lower edge of the first guide rod is positioned above a horizontal plane of the card, and the lower edge of the second guide rod is positioned below the horizontal plane of the card; the thermoprinting head and card parallelism adjusting mechanism comprises a thermoprinting head, a compressing block and a parallelism adjusting component, the parallelism adjusting component comprises a first adjusting unit and a second adjusting unit, and the card positioning mechanism comprises a card positioning seat, a sliding component and a transverse driving mechanism. The intelligent card thermoprinting machine is supportive of adjusting parallelism between the thermoprinting head and the card to enable the two to be relatively parallel, avoiding the card conveying mechanism and providing balanced supporting force to the card and is more uniform and more attractive in thermoprinting effect.

Owner:GUANGZHOU MINGSEN TECH CO LTD

Method for carrying out hot stamping on printed product

InactiveCN109941025AHot stamping error is smallUniform pressureDecorative surface effectsRotary pressesHot stampingHoneycomb

The invention discloses a method for carrying out hot stamping on a printed product, and belongs to the technical field of printing. The method comprises the steps that a printing material is firstlyflatly spread on a printing table face, UV base oil is printed on the surface of the printing material, the UV base oil is cured on the surface of the printing material through UV illumination, then hot stamping plates are selected according to patterns for hot stamping, after films are precisely aligned to the positions of the hot stamping plates, the hot stamping plates are riveted to a honeycomb plate, and then the honeycomb plate with the hot stamping plates is mounted at the corresponding position on a gold stamping machine; hot stamping foil is mounted on a guide roller of the gold stamping machine, and then one end of the hot stamping foil is drawn to a winding roller; and finally the cured printing material is placed on a bearing table of the gold stamping machine, and after gold stamping process parameters are set, flat hot stamping is carried out on the surface of the printing material through the hot stamping foil. By means of the method, the lock-up procedures of the hot stamping plates are improved, lock-up alignment of the hot stamping plates can be simplified, plate discharging is easy, preservation is convenient, repetition is facilitated for second edition production, and the work efficiency is improved.

Owner:SHANGHAI PUDONG HUANGGONG PRINTING

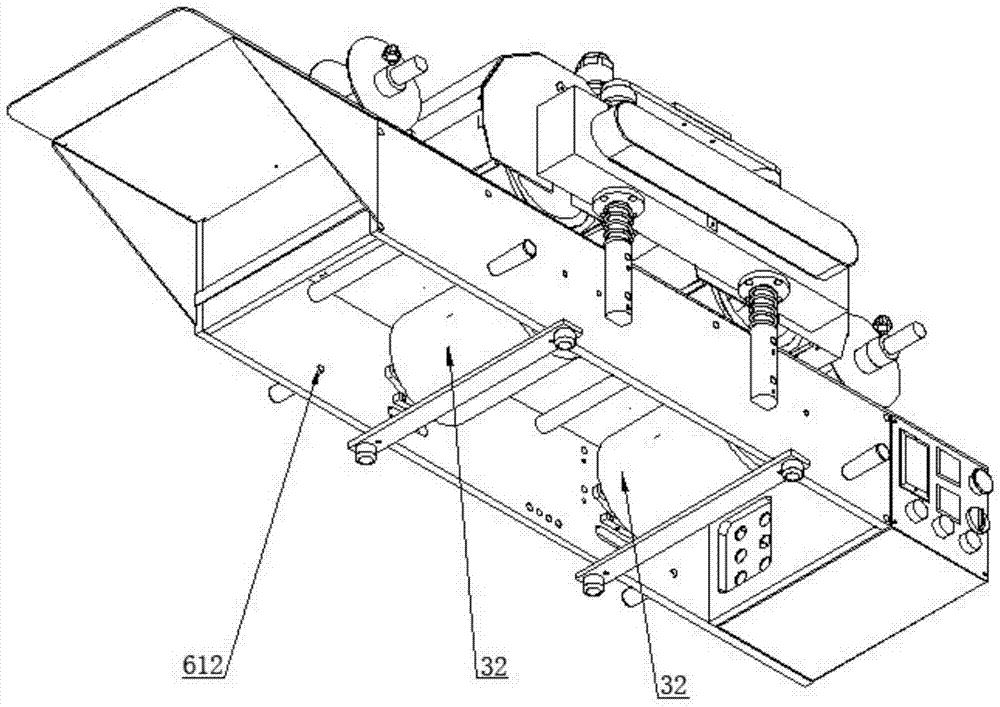

Equipment capable of quickly printing license plate

The invention relates to equipment capable of quickly printing a license plate. The equipment comprises a control system, a driving and driven wheel set, heaters, a pneumatic component, a power motor and a rack structure, wherein the control system is used for controlling temperature, speed and all switches; the pneumatic component is used for automatically lifting driving wheels; the rack structure comprises a side plate, a bedplate, sliding bases, a guide post and a steel plate and is used for supporting and fixing; the driving and driven wheel set comprises two driving wheels and two driven wheels, the driving wheels are respectively arranged between the front sliding base and the back sliding base, and the driven wheels are used for supporting the license plate and roll along with the forward movement of the license plate; the heaters surround columns of the driving wheels and are used for heating the driving wheels. According to the equipment, a heat transfer printing mode is used, so that license plate characters on a heat transfer printing film are heated by the heaters and then are covered on the license plate, thereby preventing human bodies and environment from being influenced by printing ink and omitting the steps of wiping, cleaning and drying.

Owner:HANZHOU YINGTIAN SCI INSTR

Gold blocking transfer chalking membrane and preparation method thereof

InactiveCN102815161AStrong adhesionImprove trimming effectSpecial ornamental structuresCoatingsChemistryCoating

The invention relates to the technical field of a transfer membrane, and particularly relates to a gold blocking transfer chalking membrane and a preparation method thereof. The preparation method comprises the following process steps of: uniformly mixing and stirring chalking glue with volume percent of 60%-80% and a diluent with volume percent of 20%-40% and high water absorbability to prepare an oil material; feeding the prepared oil material into a coating material groove of a coating machine; performing reverse coating on a wire-drawing carrier membrane in a manner that the coating direction of a net roller carved with a net pattern shape interwoven by reticles in the coating material groove is opposite to the feeding direction of the wire-drawing carrier membrane, thus forming a chalked glue layer; spraying water vapor to the outer surface of the chalked glue layer; and drying the wire-drawing carrier membrane coated with the chalked glue layer in a drying device, thus obtaining the gold blocking transfer chalking membrane. The preparation method provided by the invention has the advantages of simple and mature process and low production cost and is beneficial to general popularization and application. The manufactured gold blocking transfer chalking membrane has the advantages of being strong in adhering force, good in edge cutting property and beneficial to the entire transfer of the wire-drawing carrier membrane, and having a good gold blocking effect.

Owner:DONGGUAN GUODING OPTICAL MEMBRANE TECH

Hot-stamping equipment and hot-stamping method used for anti-counterfeit printing technology

PendingCN113232414APressure real-time monitoringSo as not to damageTransfer printingBronze printingStructural engineeringMechanical engineering

The invention relates to the technical field of the anti-counterfeit printing technology, and discloses hot-stamping equipment and a hot-stamping method used for the anti-counterfeit printing technology. The hot-stamping equipment comprises a bottom supporting device, wherein the bottom supporting device comprises a supporting bottom plate and a mounting slot; a conveying device is arranged inside the mounting slot; blocking devices are respectively arranged at the two sides of the upper surface of the conveying device; a side surface supporting device is arranged at the upper end of the supporting bottom plate; one side of the side surface supporting device is equipped with a hot-stamping device; the hot-stamping device comprises a first electric cylinder; a planar pressure sensor is arranged to precisely control pressure on a hot-stamping block, and pressure from a hot-stamping film on a first flattening roller is monitored in real time through a curved surface pressure sensor; and a second electric cylinder drives the first flattening roller to lift, so that pressure applied by the hot-stamping film just reaches a limited value, and thus, the hot-stamping film is guaranteed to be in a flat stretching state all the time, and hot-stamping quality is improved; and position adjustable positioning mechanisms are respectively arranged at the two sides of the conveying mechanism to posit hot-stamping films with different widths.

Owner:章胜军

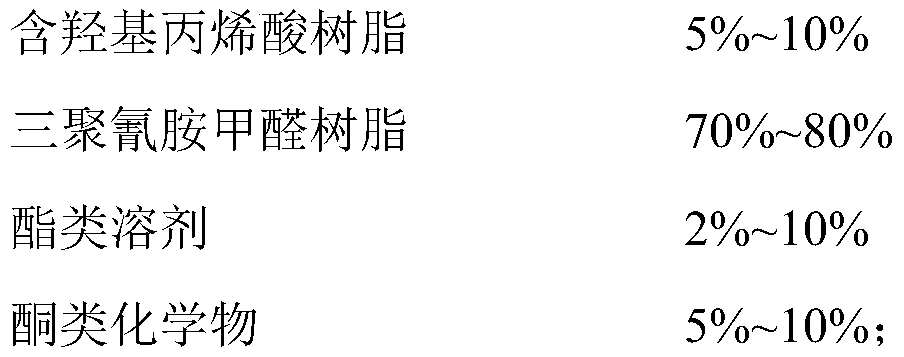

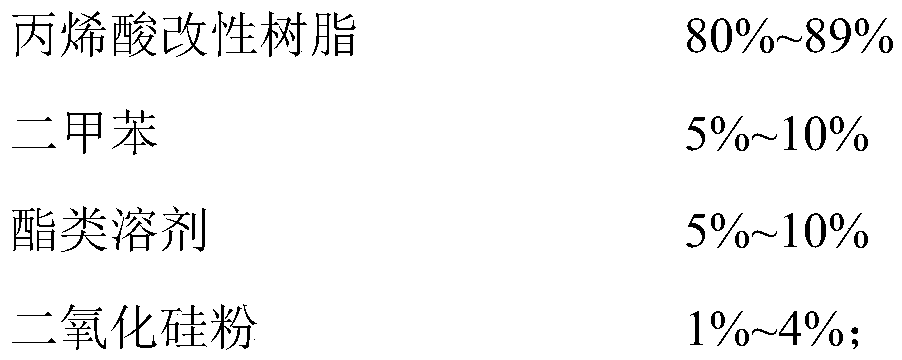

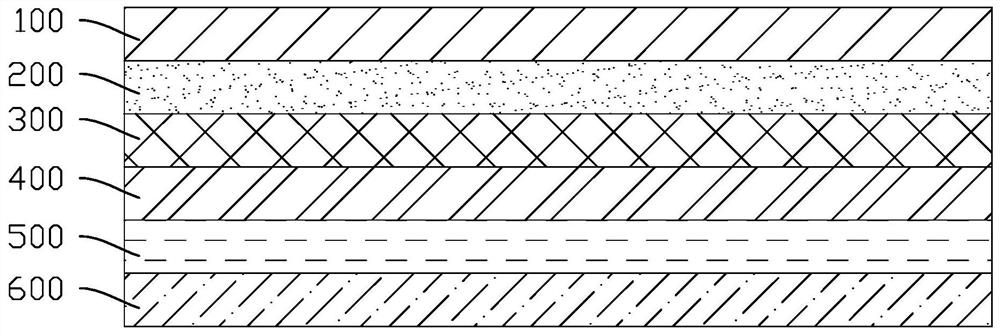

Hot stamping film for digital printing machine and preparation method of hot stamping film

InactiveCN110722911AWide adaptabilityAvoid stickingNon-macromolecular adhesive additivesDecorative surface effectsHot stampingXylylene

The invention relates to the technical field of hot stamping films, in particular to a hot stamping film for a digital printing machine and a preparation method of hot stamping film. The hot stampingfilm for the digital printing machine includes a PET hot stamping substrate, a release layer, a laser resin layer, a laser information layer, an aluminized layer, and a glue layer, wherein the PET hotstamping substrate, the release layer, the laser resin layer, the laser information layer, the aluminized layer, and the glue layer are sequentially arranged, the laser resin layer includes hydroxy-containing acrylic resins, melamine formaldehyde resins, ester solvents, and ketone chemicals. The glue layer includes an acrylic modified resin, xylene, an ester solvent, and silica powder, and the release layer is OP-wax and thus has the advantage of having low releasing force. The temperature resistance of the laser resin layer can reach above 150 DEG C. The hot stamping film for the digital printing machine is both resistant to high temperature and capable of stamping, and can be used for hot stamping different patterns without the need to change a hot stamping plate. The preparation methodof the hot stamping film for the digital printing machine has the characteristics of being simple in technology and low in production cost, and the preparation method can be suitable for large-scaleproduction.

Owner:DONGGUAN K LASER TECH

Environment-friendly aqueous adhesive for electrochemical aluminum and preparation method thereof

ActiveCN101942285BReduce contentReduce pollutionAldehyde/ketone condensation polymer adhesivesEpoxy resin adhesivesAdhesiveSolvent based

The invention relates to the field of dye, coating and adhesive, in particular to aqueous adhesive for electrochemical aluminum, and provides environment-friendly aqueous adhesive for electrochemical aluminum and a preparation method thereof. Compared with the conventional solvent type adhesive, the aqueous adhesive is environmental protection and low cost; and meanwhile, compared with common aqueous coating, the aqueous adhesive has the advantages of good printing adaptability, wide thermoprinting temperature range, good thermoprinting effect and easy control of production process. The invention adopts the following technical means that: the formula of the aqueous adhesive comprises the following components in part by weight: 30 to 35 parts of aqueous resin, 42 to 47 parts of water, 18 to 23 parts of cosolvent, 2 to 4 parts of white carbon black and 0.01 to 0.02 part of defoaming agent; and the preferable formula of the aqueous adhesive comprises the following components in part by weight: 32 to 34 parts of aqueous resin, 44 to 46 parts of water, 20 to 22 parts of cosolvent, 2 to 3 parts of white carbon black and 0.015 to 0.02 part of defoaming agent.

Owner:云南玉溪东魅包装材料有限公司

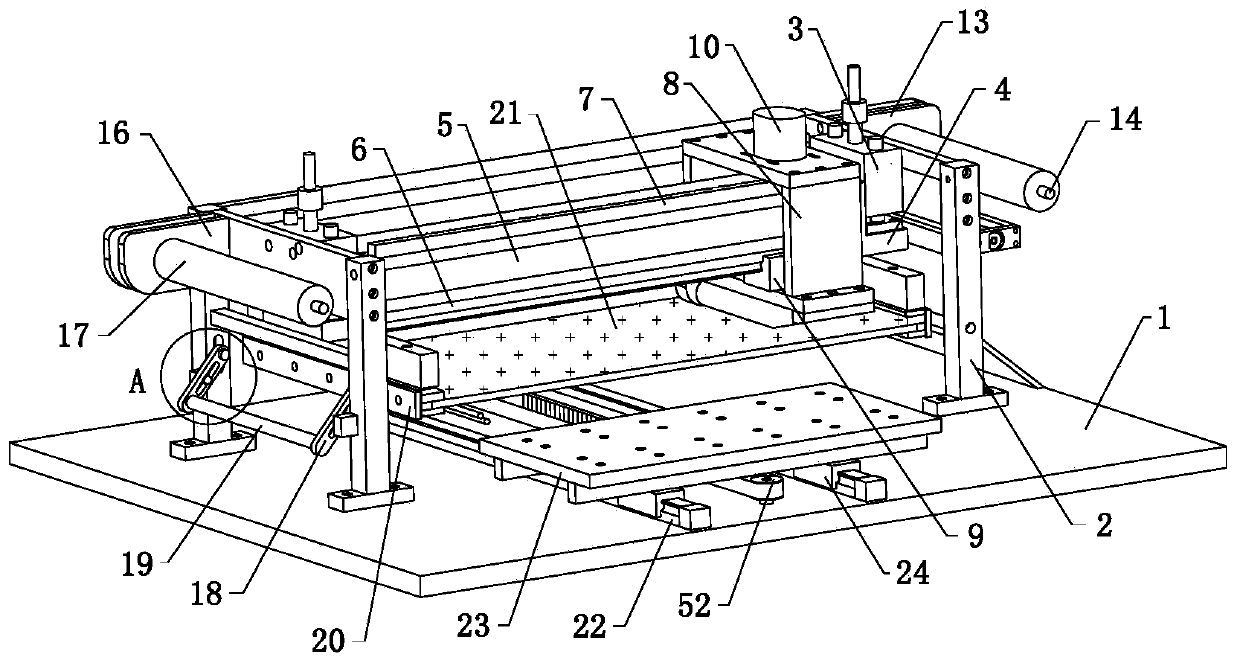

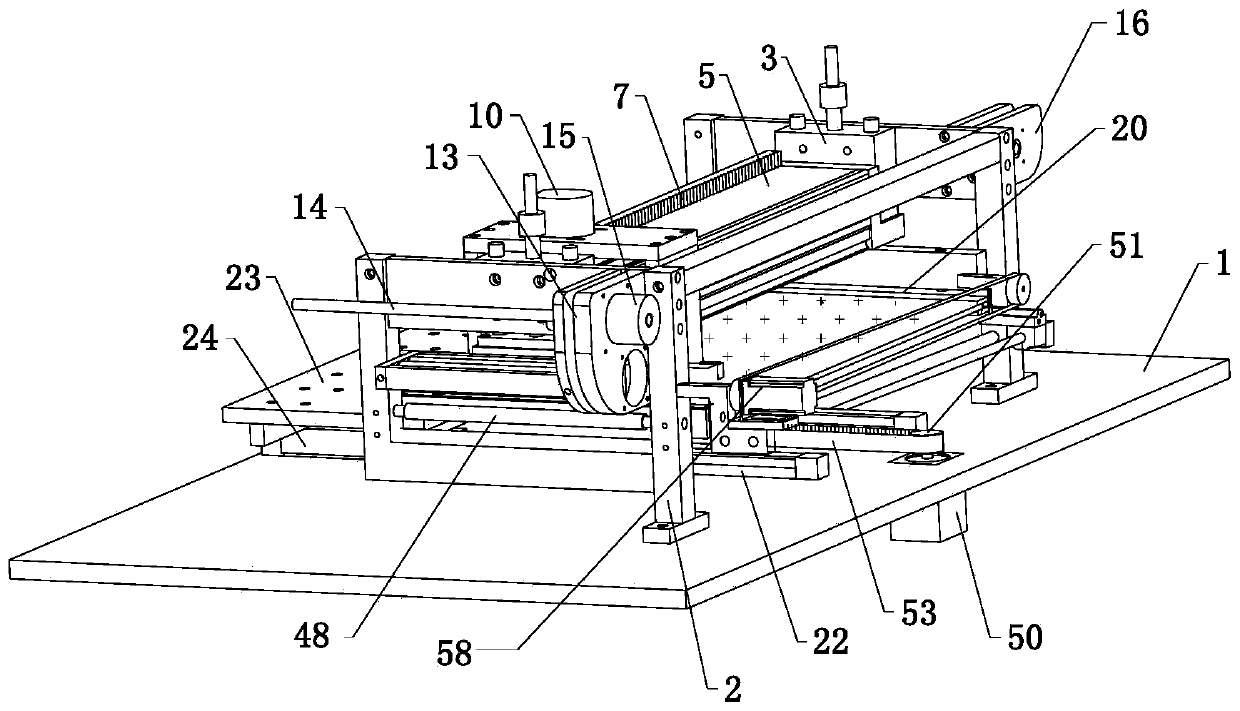

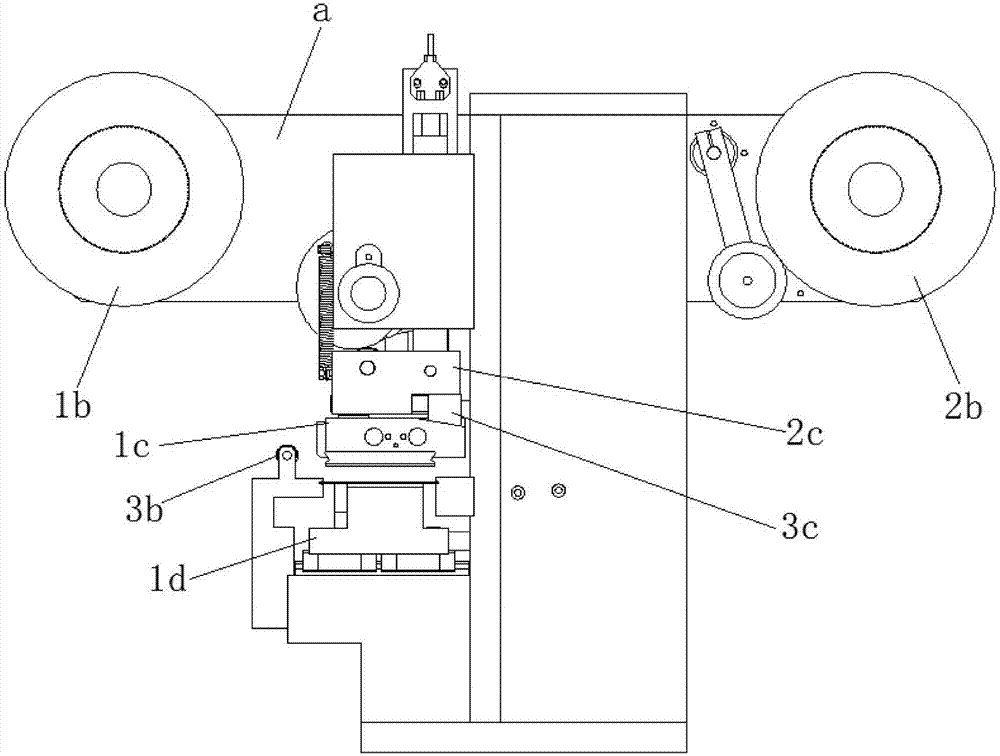

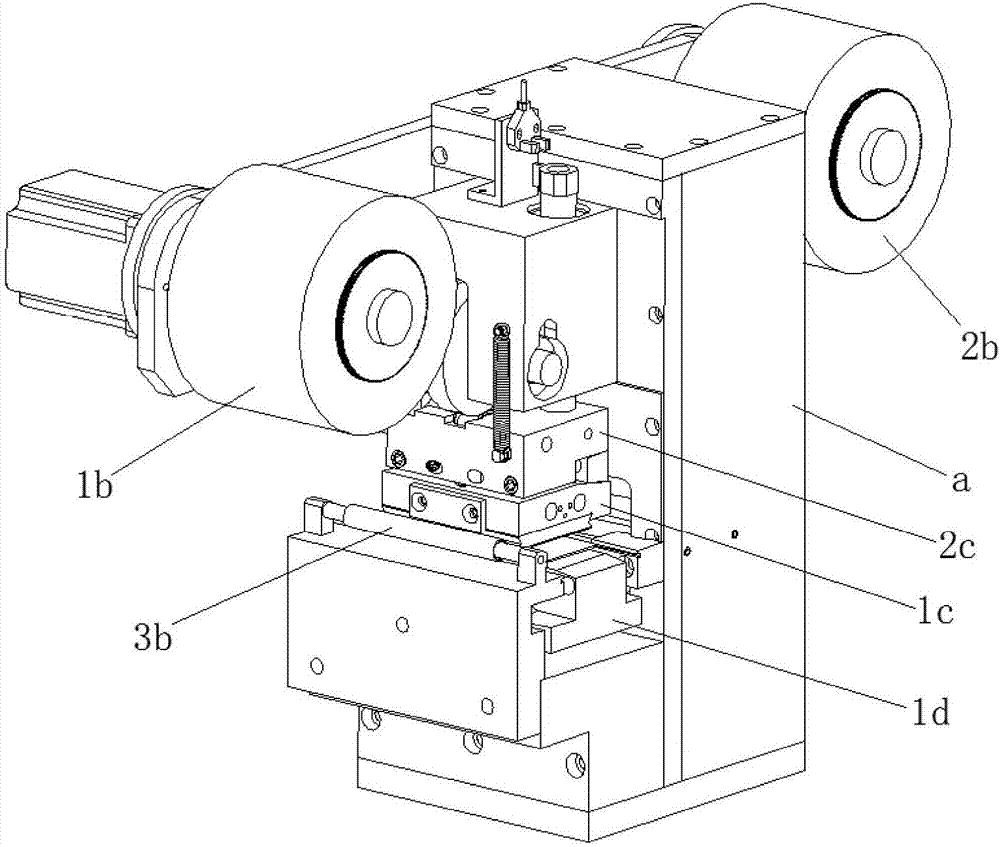

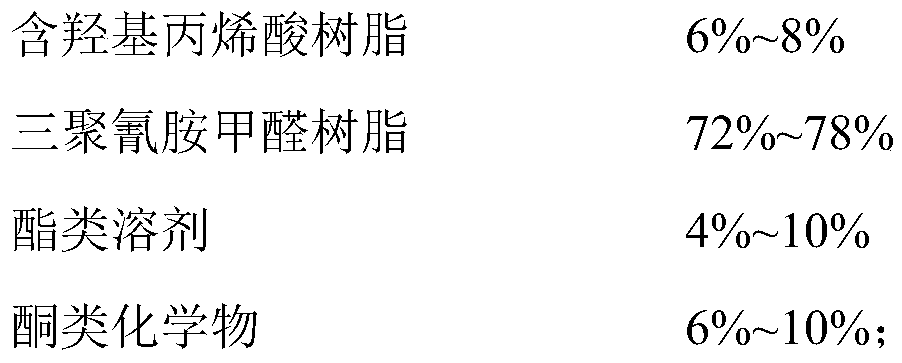

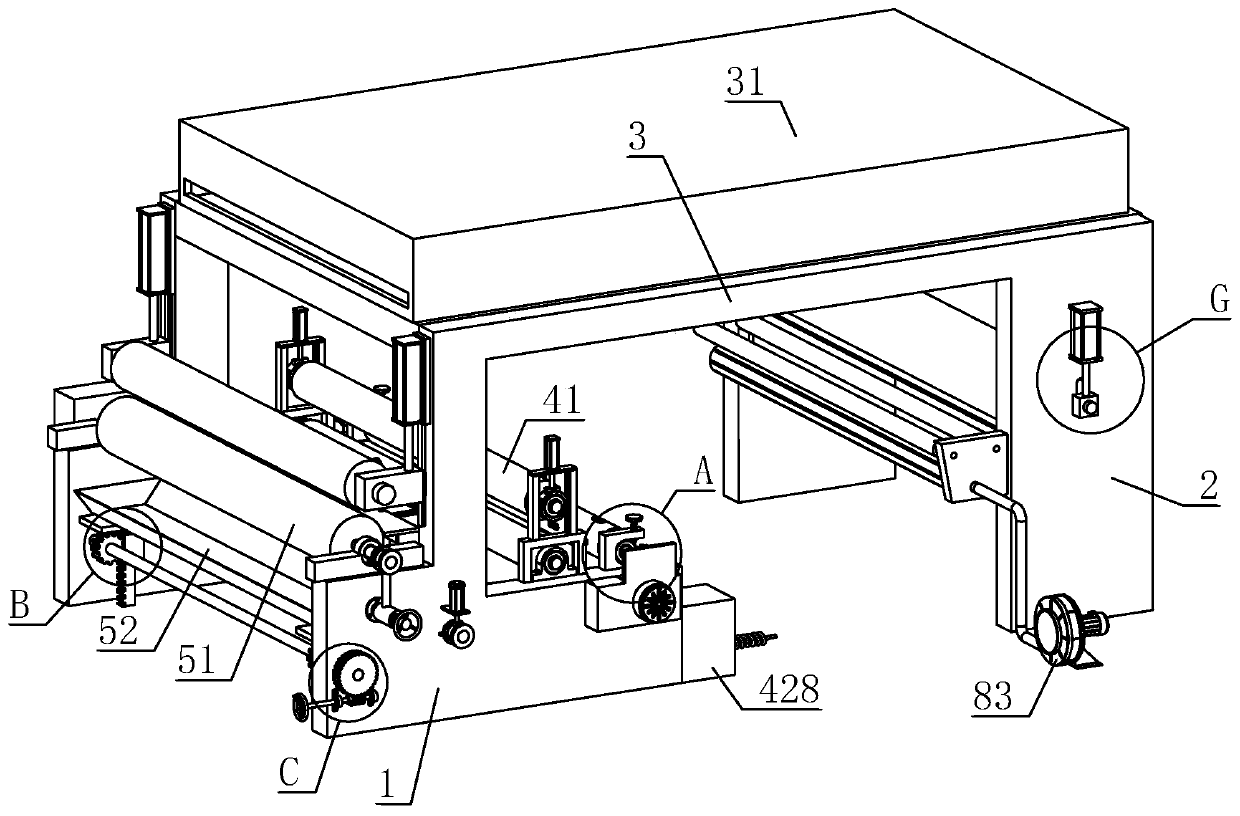

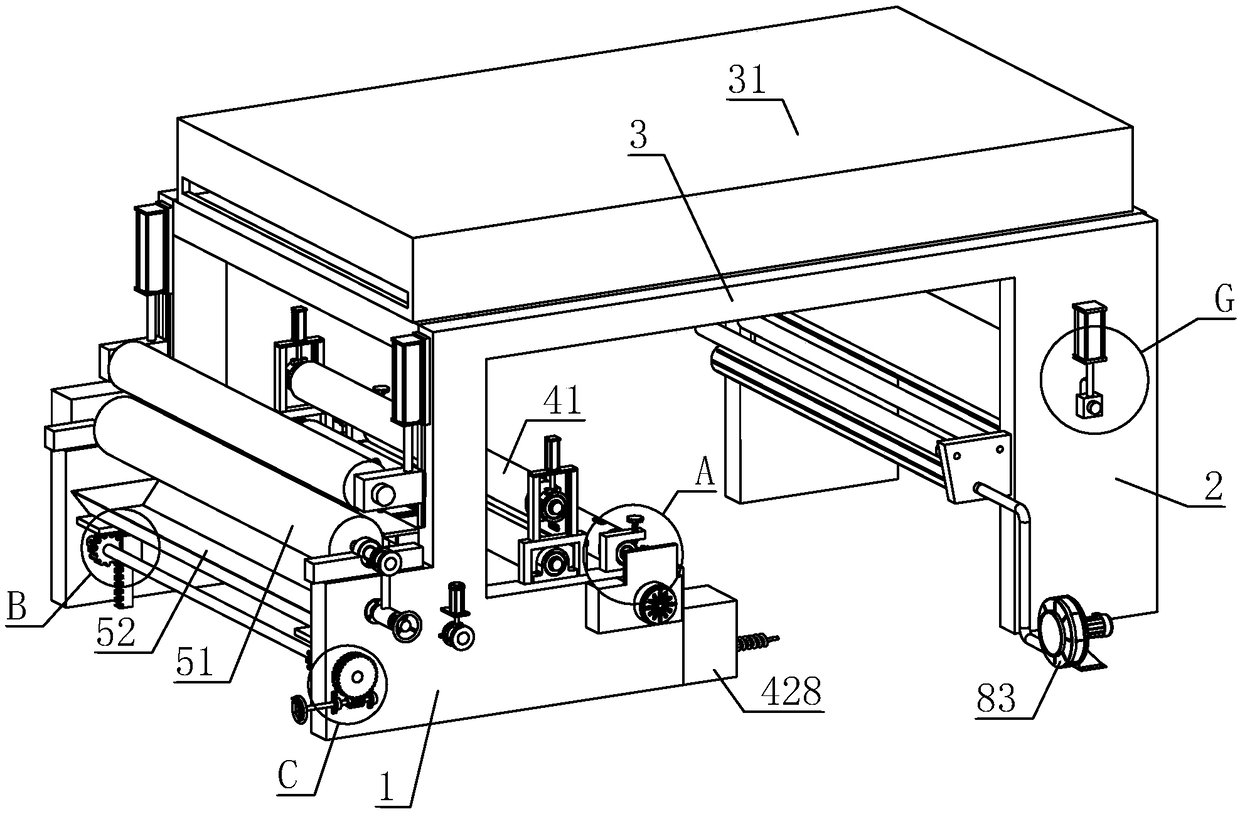

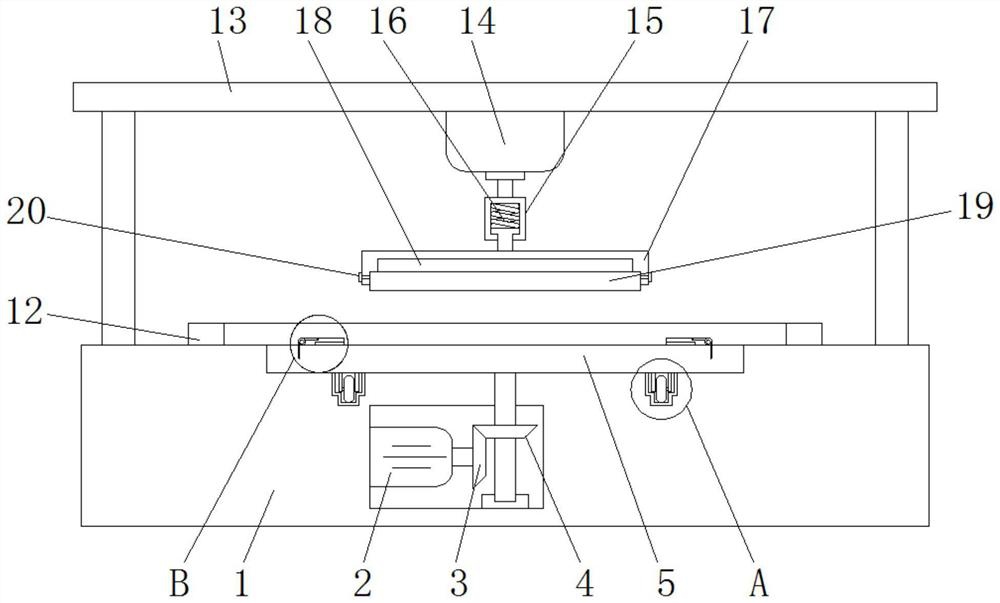

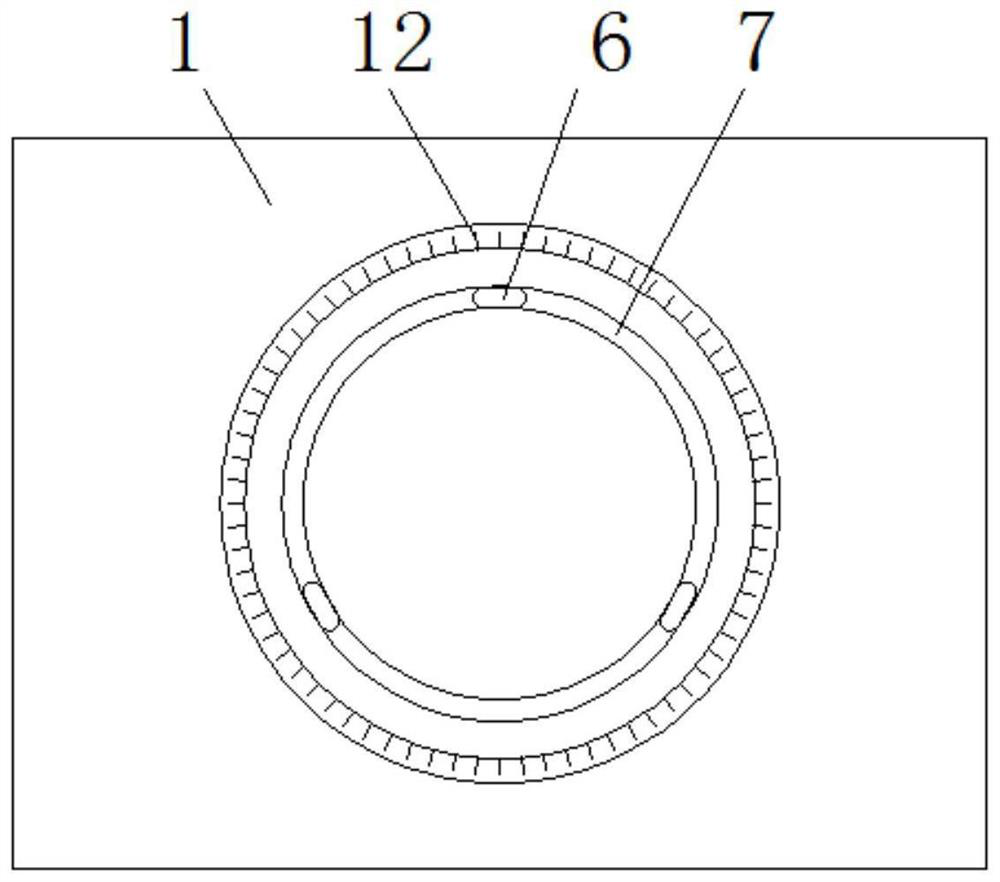

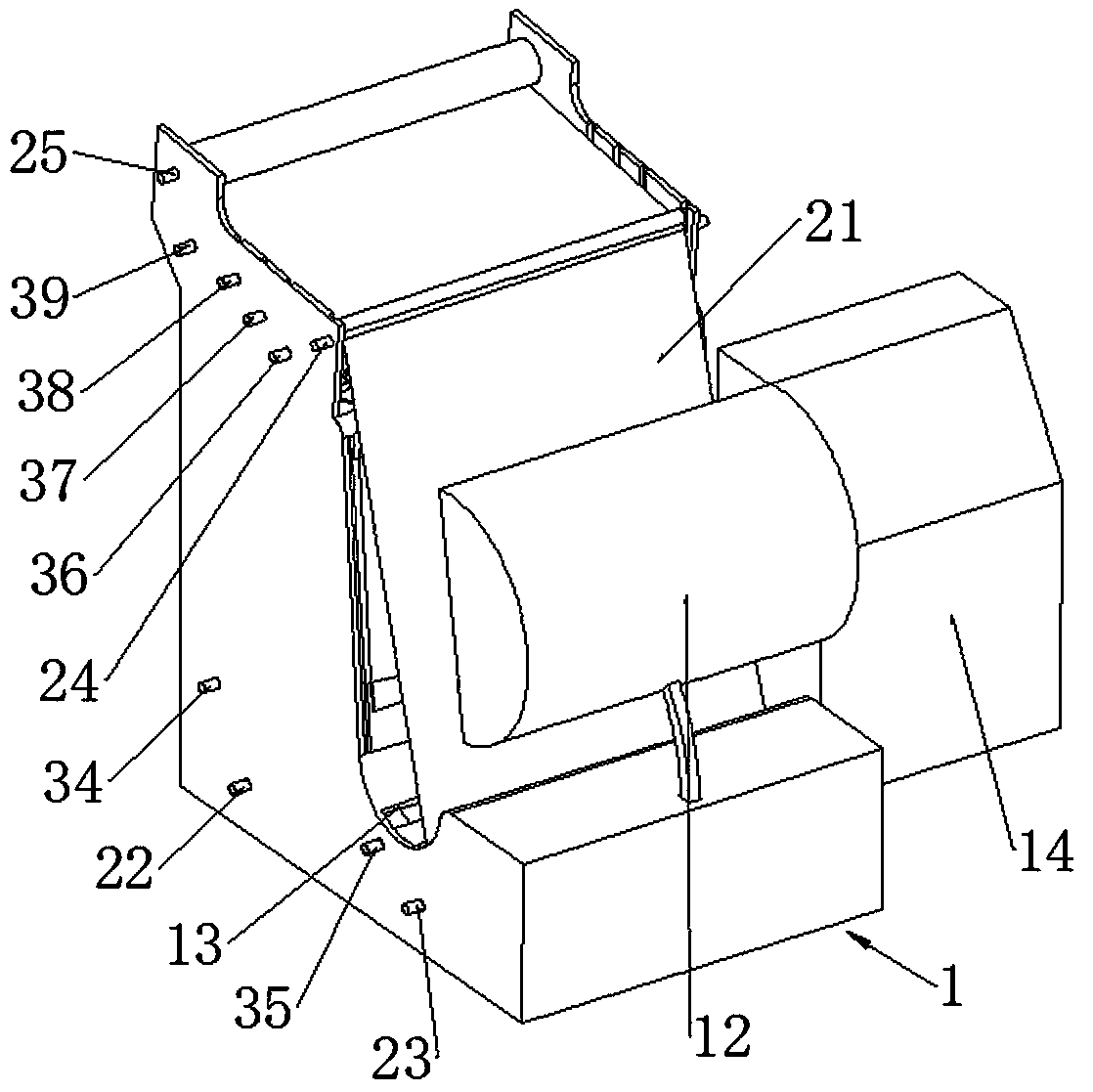

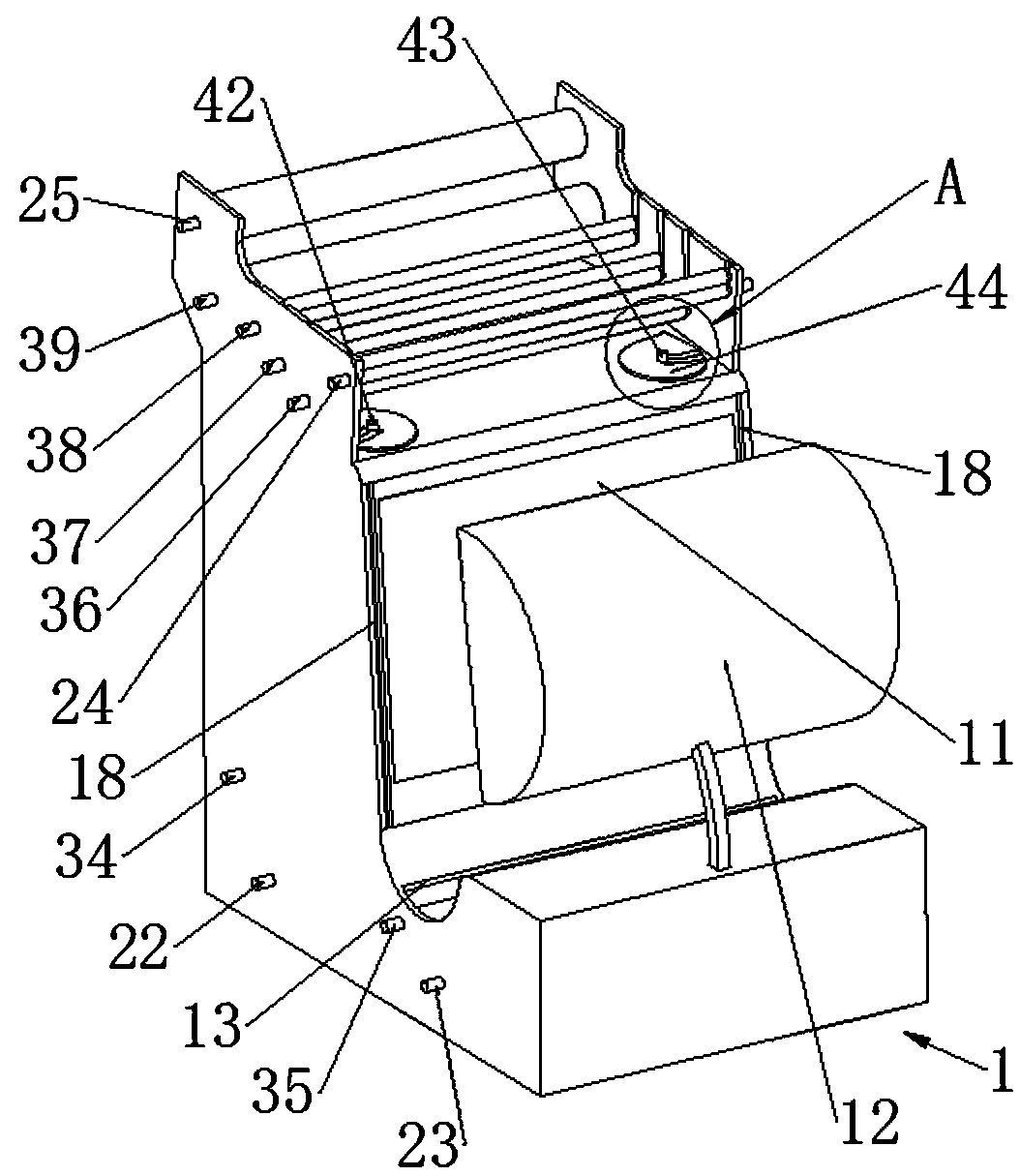

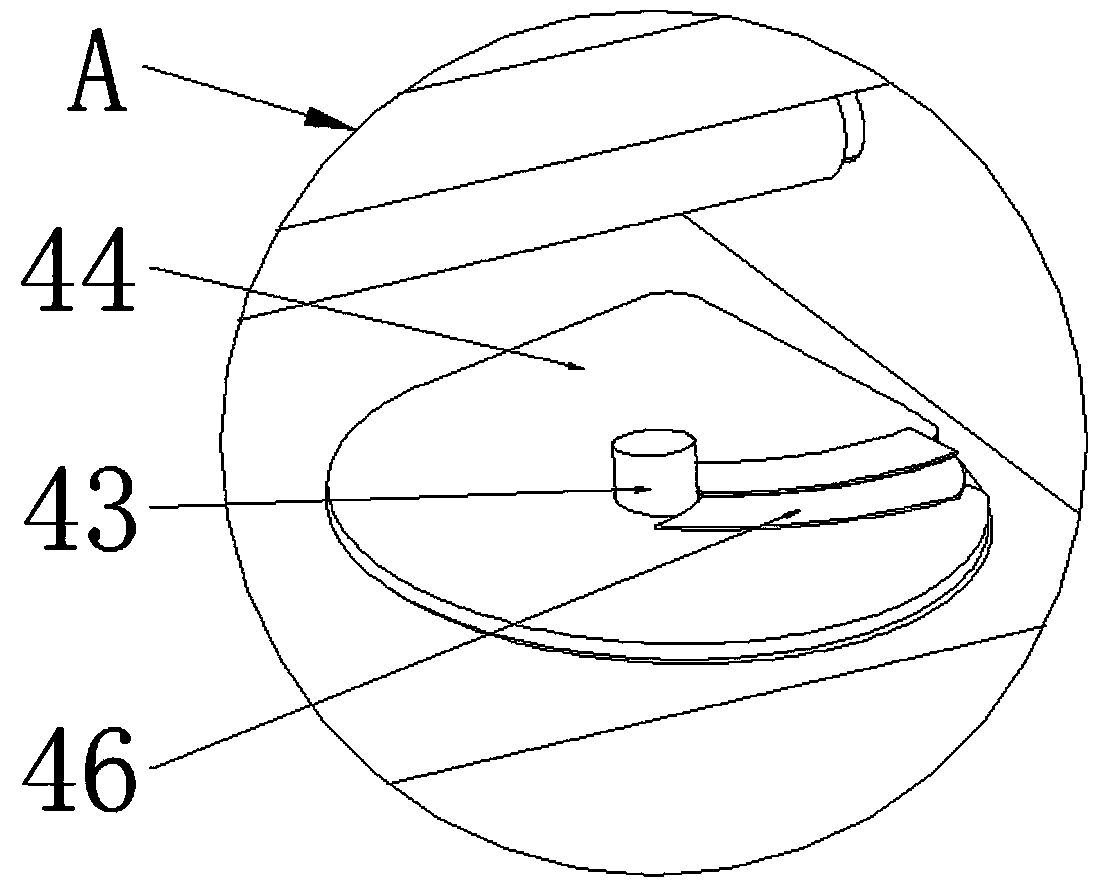

Automatic hot stamping machine and hot stamping method thereof

InactiveCN110370793ARealize transmissionSimple structureTransfer printingOther printing apparatusHot stampingEngineering

The invention discloses an automatic hot stamping machine and a hot stamping method thereof. The automatic hot stamping machine comprises a workbench, wherein the top of the workbench is provided witha rack; the inner sides of two ends of the rack are symmetrically provided with telescopic driving parts; the end part of each telescopic driving part is provided with a lifting plate; a cross beam is arranged between the two lifting plates, and the cross beam is provided with a transmission press roller mechanism; the bottoms of the two lifting plates are provided with heating sheet frames, andthe middle parts of the heating sheet frames are provided with silica gel heating sheets which are positioned at the lower parts of the transmission compression roller mechanisms; a film transmissionmechanism fixed on the rack is arranged at the lower part of the cross beam; and the workbench is also provided with a feeding mechanism which is vertical to the film transmission mechanism. Accordingto the machine, the abovementioned whole structure is adopted, so that the feeding process is simple, and the convenience of control is ensured; a film can be uniformly heated, thus the hot stampingeffect is improved, and meanwhile, the operation steps are simplified, and the operation difficulty is reduced.

Owner:浙江智博交通科技有限公司

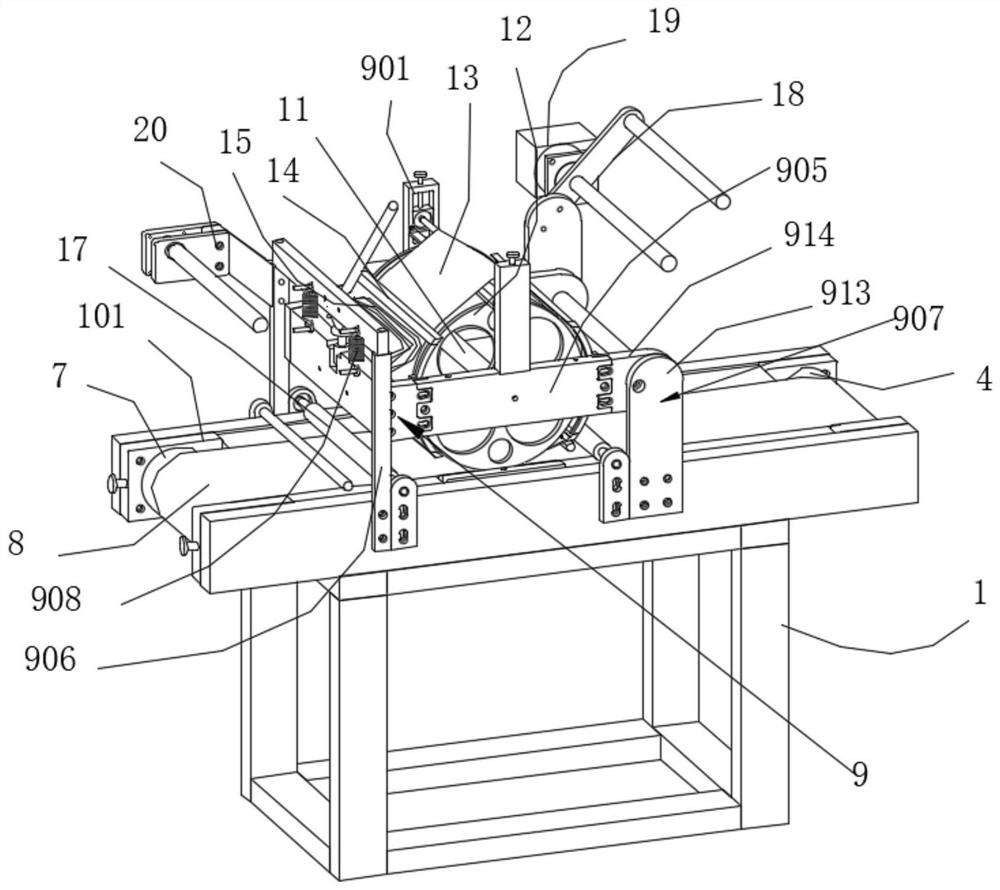

Automobile grille thermoprinting machine

InactiveCN112644156AHot stamping effect is goodRealize quick changeRotary pressesPrinting press partsAdhesive beltStructural engineering

The invention discloses an automobile grille thermoprinting machine. The machine comprises a bottom frame, integrated thermoprinting frames are installed at the upper side of the bottom frame, a thermoprinting bottom plate is connected between the integrated thermoprinting frames, a thermoprinting device is installed at the middle side of the thermoprinting bottom plate, and thermoprinting foil tape winding and unwinding devices are installed at the two sides of the front side of the thermoprinting bottom plate respectively. Thermoprinting foil tape winding and unwinding devices are installed at the two sides of the left sides of the integrated thermoprinting frames correspondingly, and foil tape adhesive tape tearing mechanisms are installed on the thermoprinting foil tape winding and unwinding device at the left side of the thermoprinting bottom plate and the thermoprinting foil tape winding and unwinding devices at the front sides of the integrated thermoprinting frames correspondingly. The automobile grille thermoprinting machine has the beneficial effects that a thermoprinting machine servo press drives and is provided with a pressure sensor, and the thermoprinting effect is good; a thermoprinting feeding mechanism can be placed in the left-right direction and the front-back direction; and a thermoprinting silica gel plate on a thermoprinting machine heating plate is mounted on the heating plate in a drawing and inserting manner, so that the silica gel plate can be quickly replaced, and the working time is saved.

Owner:苏州汇取智能机械有限公司

Cooling flat-type bronzing machine with three colored tapes

PendingCN108501522AHot stamping effect is goodImprove bronzing speedRotary pressesHot stampingEngineering

The invention discloses a cooling flat-type bronzing machine with three colored tapes. An unwinding device, a winding device and a delivery roll between the unwinding device and the winding device arefixedly arranged on a main frame body. The delivery roll is driven by a motor for delivering the paper to be bronzed. Three bronzing parts and a cooling part are fixed sequentially on the main framebody in the direction of moving of the paper to be bronzed. Unwinding shafts and winding shafts are arranged on upper portion of the bronzing parts in parallel, and first separating rollers and secondseparating rollers are arranged on the lower portion of the bronzing parts, material drawing rollers are arranged under the winding shafts, and heating units and drying units are arranged in the bronzing parts. A hot stamping machine unit with three heating devices and one cooling device is adopted, the bronzing speed is accelerated, automatic moving marking function is achieved, the overprintingaccuracy is higher, and is generally 40-60 meters per minute, the number of bronzing paper is reduced, vibration is extremely small, and the noise is small. Because heat conduction, heat absorption and melting of a hot melt adhesive take a certain time, the hot stamping effect of flat-type bronzing machine is better than that of other machines, and the efficiency is improved.

Owner:DALIAN ALTMA IND CO LTD

Aluminum-plated and gold-stamped nonwoven fabric

ActiveCN108116144AHigh strengthHigh elongationDecorative surface effectsMetallic material coating processesHot stampingChemical plating

The invention discloses aluminum-plated and gold-stamped nonwoven fabric, which comprises a nonwoven fabric matrix layer, wherein the nonwoven fabric matrix layer is provided with an aluminum film layer; the aluminum film layer is provided with a gold-stamped layer. A preparation method of the aluminum-plated and gold-stamped nonwoven fabric comprises the following steps of using polypropylene nonwoven fabric as a matrix; plating aluminum on the surface of the matrix under a vacuum plating or chemical plating method; carrying out gold stamping treatment on the surface of the aluminum film layer by utilizing a hot stamping device after plating the aluminum, so as to realize the production of the aluminum-plated and gold-stamped nonwoven fabric. The nonwoven fabric has the effects of beautiful surface, water imperviousness and light reflection, and meanwhile, has quite good appearance quality, and the quality of the nonwoven fabric is visually and actually improved.

Owner:嘉兴市宏景无纺面料有限公司

A bronzing machine

ActiveCN108790395BIncrease temperatureSmall temperature differenceRotary pressesPrinting press partsHot stampingIndustrial engineering

Owner:SHAOXING XINHANG TEXTILE CO LTD

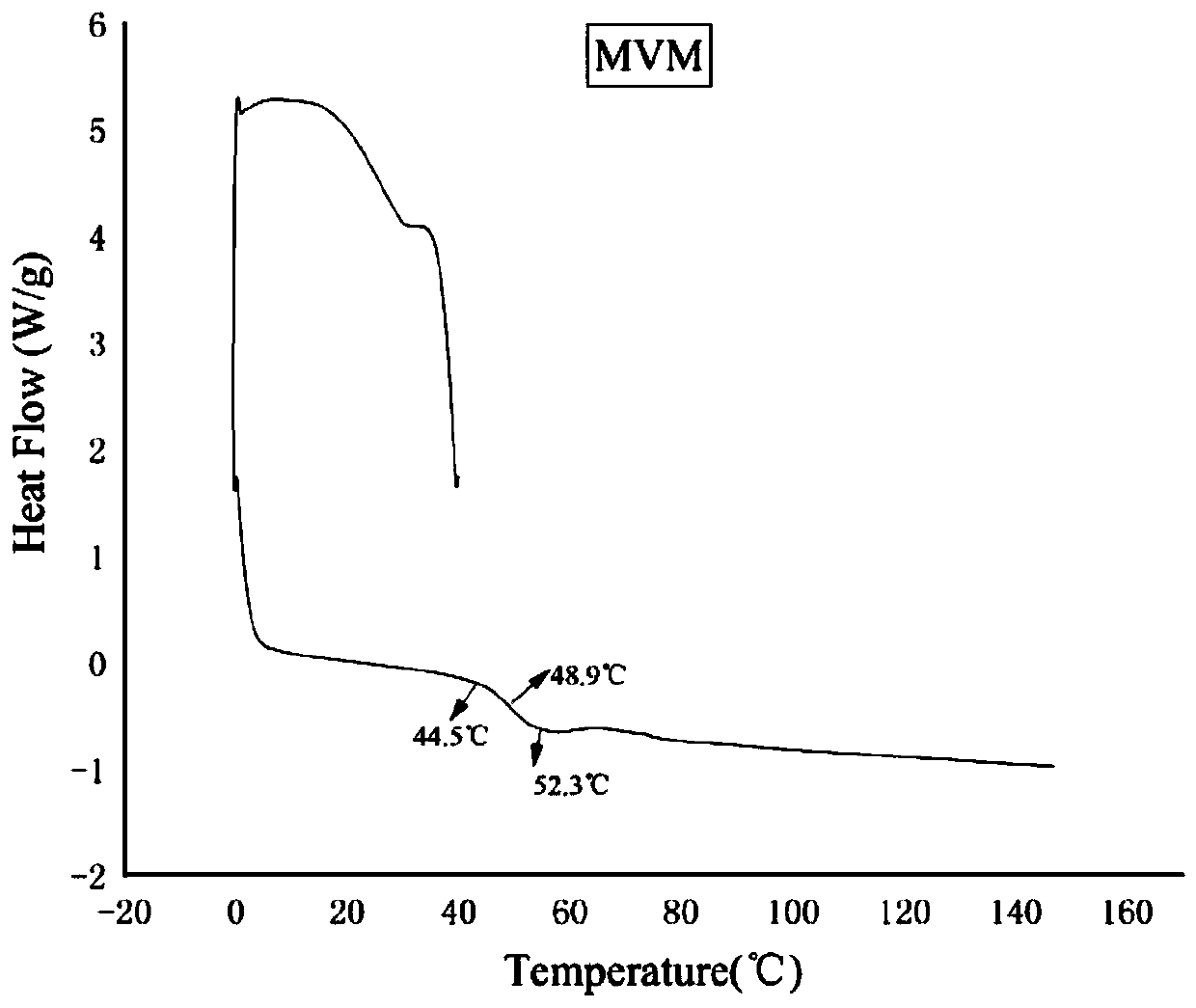

Laser alumite hot stamping back gum and preparation method thereof

ActiveCN110804407AImprove adhesionEnhanced resistance to peelingNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceButadiene Dioxide

The invention discloses a laser alumite hot stamping back gum and a preparation method thereof. The laser alumite hot stamping back gum comprises the raw materials: a maleic anhydride-vinyl acetate-methacrylate copolymer, a chloroprene-acrylic acid-acrylate copolymer, fumed silica and a solvent; the maleic anhydride-vinyl acetate-methacrylate copolymer comprises the raw materials by weight: 1 to 2parts of maleic anhydride, 1 to 2 parts of vinyl acetate and 5 to 8 parts of methacrylate monomers; the chloroprene-acrylic acid-acrylate copolymer comprises the raw materials by weight: 2 to 4 partsof chloroprene, 2 to 4 parts of acrylic acid and 4 to 8 parts of acrylate monomers. The laser alumite hot stamping back gum has good adhesive force and stripping resistance, and when the back gum isused, the hot stamping effect is good, and the definition is high; the softening point is proper, and the anti-adhesion phenomenon is avoided.

Owner:WUHAN HUAZHONG KEDA FINE CHEM

Gold powder cleaning device of flat-pressing and flat-winding roll paper gold-stamping machine

InactiveCN104108237ARealize static eliminationImprove qualityPrinting press partsHot stampingRolling paper

The invention discloses a gold powder cleaning device of a flat-pressing and flat-winding roll paper gold-stamping machine. The gold powder cleaning device is used for cleaning gold powder during gold-stamping of paper, an electrostatic eliminator is mounted on one side of each of a paper inlet and a paper outlet of a machine body to realize electrostatic elimination during gold-stamping of the paper, and two upper dedusting rollers and two lower dedusting rollers are mounted in the machine body; when the paper goes through from space between the upper dedusting rollers and the lower dedusting rollers, dust left on the paper can be removed, and the removed dust is correspondingly transferred onto a viscous dust-collecting adhesive tape of a dust-collecting adhesive taper roller through the dedusting rollers. By the above mode, the problem that the gold powder is left on the surface of a product after hot stamping is effectively solved, and quality and hot-stamping effect of the product are improved greatly.

Owner:永发印务(东莞)有限公司

Laser corrosion-resistant water-based paint for plate making

InactiveCN113025163AHot stamping effect is goodHigh speedCellulose coatingsAnti-corrosive paintsEpoxyCellulose

The invention discloses a laser corrosion-resistant water-based paint for plate making. The laser corrosion-resistant water-based paint comprises the following components in percentage by weight: 10 to 60 percent of hydrophilic coating material, 0.1 to 10 percent of nano-scale or micron-scale inorganic oxide particles and the balance of solvent. The hydrophilic coating material comprises the following components in percentage by weight: 10%-30% of water-soluble epoxy resin, 20%-30% of water-based acrylic resin, 1%-3% of other auxiliaries, 10%-30% of polyurethane emulsion, 2%-10% of water-soluble cellulose, 0.1%-10% of aromatic amine, 15%-30% of deionized water and the balance of a PH regulator. According to the invention, three different types of components including the water-based acrylic resin, the polyurethane emulsion and the water-soluble cellulose generate a synergistic effect, so that the coating has a better hot stamping effect, hot stamping speed and mold pressing brightness.

Owner:南通立方新材料科技有限公司

Stamping machine

ActiveCN108790395AIncrease temperatureSmall temperature differenceRotary pressesPrinting press partsHot stampingTemperature difference

The invention discloses a stamping machine and relates to the technical field of printing and stamping equipment. The stamping machine comprises a second rack; a hot-stamping device is arranged on thesecond rack and comprises an abutting roller and a hot-stamping roller which are rotationally installed on the second rack; printing stock and alumite are clamped through the hot-stamping roller andthe abutting roller; the second rack is provided with an incubator, the hot-stamping roller is arranged in the incubator, and the incubator is provided with an inlet and an outlet; and a connection hole is formed in the side, facing the abutting roller, of the incubator, and the hot-stamping roller and the abutting roller press the alumite and the printing stock entering the incubator through theconnection hole. Through arrangement of the incubator, direct convection with air is avoided, the temperature of air surrounding the hot-stamping roller is increased, temperature difference between the hot-stamping roller and the surrounding air is reduced, heat dissipation of the hot-stamping roller is reduced accordingly, the probability of image and text floating or base exposure or hot-stamping failure is reduced, and thus the hot-stamping quality is improved.

Owner:SHAOXING XINHANG TEXTILE CO LTD

Positioning ironing device for paper printing

PendingCN114379208AReduce usage limitationsHot stamping effect is goodTransfer printingHot stampingCoupling

The invention relates to the technical field of paper printing, and discloses a positioning ironing device for paper printing, which comprises an operation table, a motor is fixedly mounted in the operation table, a first bevel gear is fixed on an output shaft of the motor through a coupling, and a second bevel gear is movably connected to the periphery of the first bevel gear. A placing plate is fixed to the tops of the second bevel teeth, an auxiliary wheel is fixed to the bottom face of the placing plate, a guide groove matched with the auxiliary wheel is formed in the surface of the inwards-concave position of the operation table, a positioning plate is movably connected to the surface of the placing plate, a pin rod penetrates through the connecting position of the positioning plate and the placing plate, and the pin rod is sleeved with a torsional spring. According to the positioning hot stamping device for paper printing, through the rotatable arrangement of the placing plate, a user can adjust the use angle of the placing plate according to hot stamping requirements of different patterns, so that the paper angle is matched with the patterns, the use limitation of the device is reduced, and the hot stamping effect of the device is optimized.

Owner:星光印刷(苏州)有限公司

A kind of water-based anodized aluminum adhesive resin with high adhesion and high temperature resistance and preparation method thereof

ActiveCN111533841BReduce surface tensionHigh glass transition temperatureNitrile polymer adhesivesEster polymer adhesivesPolymer scienceAdhesive

The invention relates to a water-based anodized aluminum adhesive resin with high adhesion and high temperature resistance and a preparation method thereof. The composition of the water-based anodized aluminum adhesive resin is as follows in terms of mass fraction: 20-30 parts of acrylonitrile, diethylamino methacrylate 25-35 parts of ethyl ester, 35-55 parts of hydroxypropyl acrylate, 4-8 parts of emulsifier, 15-24 parts of deionized water, 0.1-0.4 parts of initiator, balanced combination of hard monomers with high glass transition temperature and high viscosity Cohesion, solvent resistance, self-thickening, and hydroxypropyl acrylate are more hydrophilic, sticky, and peel strength. The pre-emulsification process is used to prepare the seed pre-emulsion first, and then add the emulsion and initiator dropwise by heating Polymerize cross-linked micelles, increase the concentration of free radicals and branched chain products, ensure the dispersion, heat transfer and mass transfer performance of the system, improve the stability of the system, fully emulsify and reduce the phenomenon of implosion and gelation, and the water-based anodized aluminum adhesive resin is heat-resistant Stability performance and adhesive curing performance are improved, anodized aluminum hot stamping performance, stickiness, peel strength are improved, and the scope of applicable substrates is broadened.

Owner:SUQIAN WANSHANG NEW MATERIAL TECH CO LTD

Pearlescent transfer film as well as preparation method and application thereof

ActiveCN112592630ABrilliant colorFull brightnessNon-macromolecular adhesive additivesDecorative surface effectsHot stampingWeather resistance

The invention belongs to the field of transfer printing films, and discloses a pearlescent transfer printing film and a preparation method and application thereof. The pearlescent transfer printing film sequentially comprises a base material layer, a UV release layer, a stabilizing layer, a pearlescent image-text layer, an ink image-text layer and an adhesive layer from top to bottom; the base material layer is a PET film; the UV release layer is formed by UV gloss oil; the stabilizing layer is composed of a stabilizing agent; the pearlescent image-text layer is formed by pearlescent connecting materials; the ink image-text layer is formed by ink; and the adhesive layer is made of hot melt adhesive. The pearlescent transfer film has the advantages of gorgeous color, full brightness, good hot stamping effect, good weather resistance, scratch resistance, wear resistance, good waterproofness, acid and alkali resistance and corrosion resistance.

Owner:GUANGDONG T&H NEW MATERIALS CO LTD +1

Manual and automatic dual hot stamping machine

PendingCN110774749AAvoid blowingHot stamping effect is goodRotary pressesHot stampingElectric machinery

The invention relates to a manual and automatic hot stamping machine which comprises a machine body, a paper feeding mechanism, a longitudinal feeding mechanism and an electric control cabinet. A cutgroove is formed in the lower portion of the machine body. The paper feeding mechanism comprises a paper unrolling roller, a paper guide roller, a paper feeding roller and a paper rolling roller. Oneend of a roll is wound around the paper unrolling roller, the middle portion of the roll penetrates the cut groove and is attached to the outer side of the paper guide roller and the outer side of thepaper feeding roller, and the other end of the roll is wound around the paper rolling roller. The longitudinal feeding mechanism comprises a longitudinal unrolling roller, an aluminum foil paper guide roller, multiple sets of longitudinal feeding rollers and a longitudinal rolling roller. one ends of multiple sets of longitudinal aluminum foil paper are wound on the longitudinal unrolling roller,the middle portions of the multiple sets of longitudinal aluminum foil paper penetrate the cut groove and can be attached to the outer side of the aluminum foil paper guide roller, and the other endsof the multiple sets of longitudinal aluminum foil paper are wound around the longitudinal rolling roller. The middle portions of the multiple sets of longitudinal aluminum foil paper are further attached to the outer sides of the different longitudinal feeding rollers. The roll is arranged on the outer side of the longitudinal aluminum foil paper, and multiple drive motors are in transmission connection with the paper feeding roller, the paper rolling roller, the multiple sets of longitudinal feeding roller and the longitudinal rolling roller correspondingly.

Owner:唐绪明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com