Electromagnetic rolling number plate continuous hot-stamping method and number plate hot-stamping machine

A technology of hot stamping machine and number plate, applied in the field of number plate hot stamping equipment and hot stamping, which can solve the problems of 45 minutes or even longer (may take 60 minutes, high energy consumption, spontaneous combustion of hot stamping rubber rollers, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

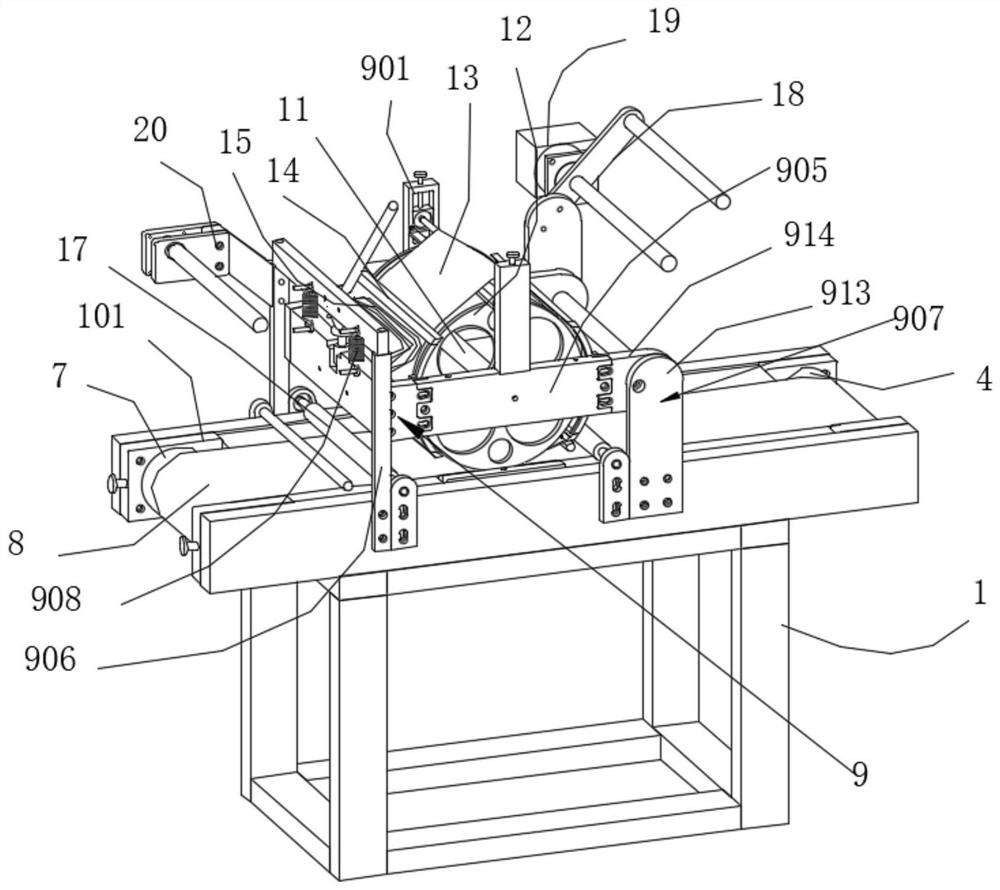

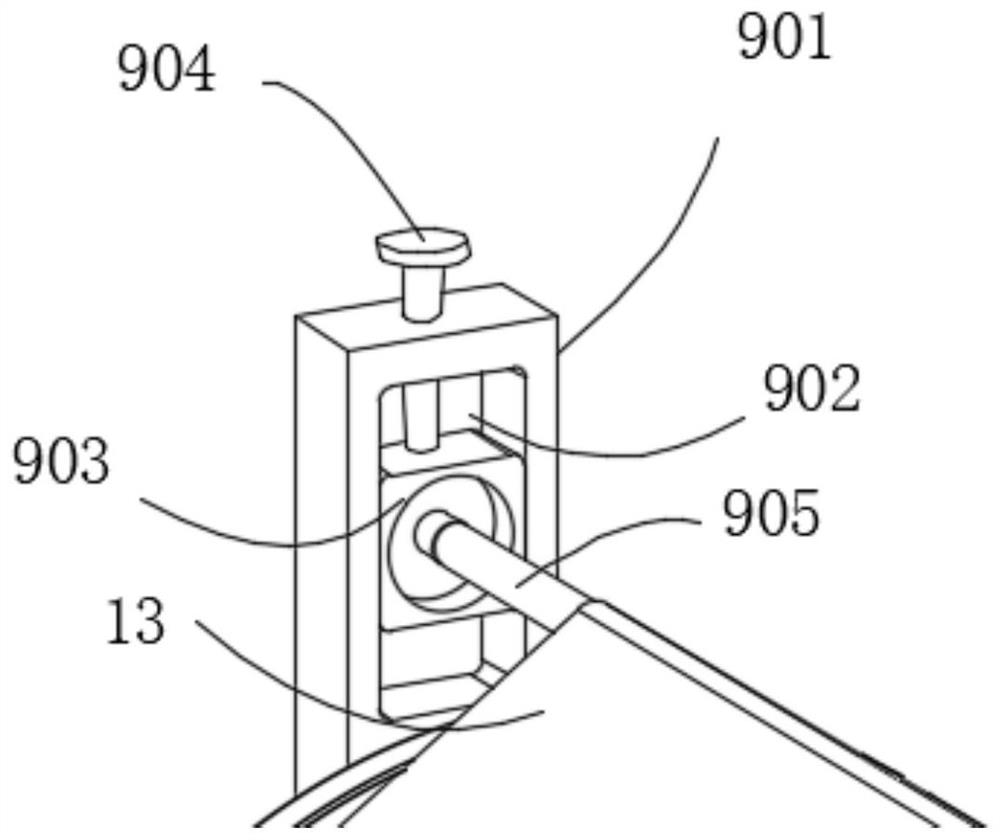

[0032] Embodiment: Electromagnetic rolling number plate continuous hot stamping method, the number plate to be hot stamped is transported to the bottom of the electromagnetically heated roller for continuous rolling heating hot stamping, so as to realize number plate hot stamping. The specific steps are as follows: 1. Electromagnetically heat the metal roller to the required hot stamping temperature; 2. Place the number plate to be hot stamped on one end of the conveyor belt, and then transfer it to the bottom of the metal roller; 3. The metal roller will The thermal energy is transmitted to the hot stamping film through the silica gel layer, and then hot stamped on the number plate below, realizing continuous rolling hot stamping on the number plate, and the hot stamped number plate is sent out from the other end by the conveyor belt. Before hot stamping the number plate, do a good job of adjusting the parts, first adjust the tightness of the conveyor belt, and turn the roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com