Hot stamping film for digital printing machine and preparation method of hot stamping film

A technology for hot stamping film for printing presses, which is applied in the process of producing decorative surface effects, decorative arts, coatings, etc. problem, to achieve the effect of hot stamping with delicate cutting surface and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A hot stamping film for a digital printing machine, comprising a PET stamping substrate, a release layer, a laserable resin layer, a laser information layer, an aluminum coating layer and a glue layer arranged in sequence;

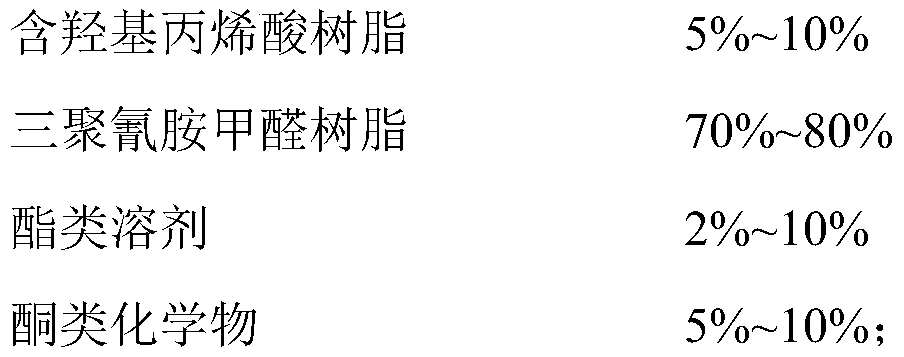

[0041] Wherein, the laserable resin layer includes the following components by weight percentage:

[0042]

[0043] Glue layer comprises the following components by weight percentage:

[0044]

[0045]

[0046] Wherein, the release layer is OP wax.

[0047] In this embodiment, the ester solvent is ethyl acetate.

[0048] In this embodiment, the ketone chemical is butanone.

[0049] The preparation method of above-mentioned a kind of digital printing machine hot stamping film, it comprises the following steps:

[0050] The first step, the preparation of the composition of the laser resin layer: after mixing the formula amount of hydroxyl-containing acrylic resin and melamine formaldehyde resin, then add the formula amount of ester solvent...

Embodiment 2

[0054] A hot stamping film for a digital printing machine, comprising a PET stamping substrate, a release layer, a laserable resin layer, a laser information layer, an aluminum coating layer and a glue layer arranged in sequence;

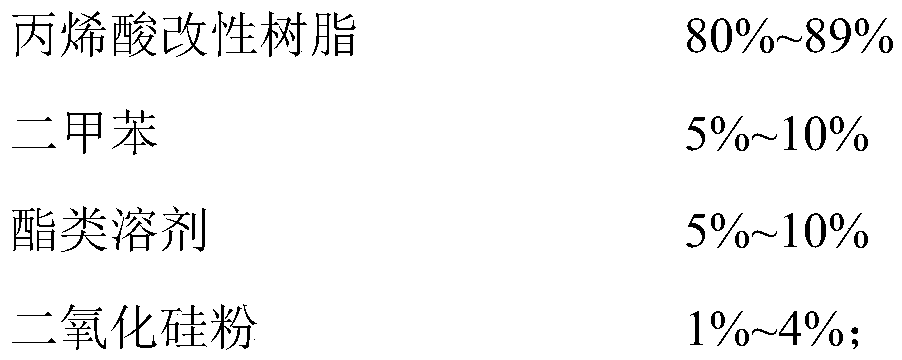

[0055] Wherein, the laserable resin layer includes the following components by weight percentage:

[0056]

[0057]Glue layer comprises the following components by weight percentage:

[0058]

[0059] Wherein, the release layer is OP wax.

[0060] In this embodiment, the ester solvent is ethyl propionate.

[0061] In this embodiment, the ketone chemical is acetone.

[0062] The preparation method of above-mentioned a kind of digital printing machine hot stamping film, it comprises the following steps:

[0063] The first step, the preparation of the composition of the laser resin layer: mix the formula amount of hydroxyl-containing acrylic resin and melamine formaldehyde resin, then add the formula amount of ester solvent and ketone chemical...

Embodiment 3

[0067] A hot stamping film for a digital printing machine, comprising a PET stamping substrate, a release layer, a laserable resin layer, a laser information layer, an aluminum coating layer and a glue layer arranged in sequence;

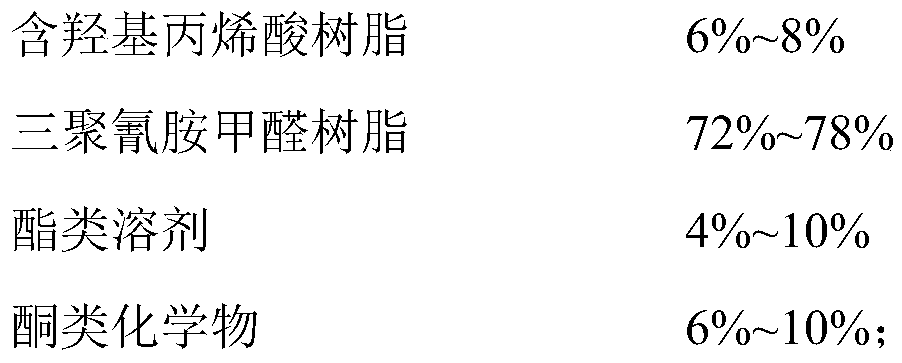

[0068] Wherein, the laserable resin layer includes the following components by weight percentage:

[0069]

[0070]

[0071] Glue layer comprises the following components by weight percentage:

[0072]

[0073] Wherein, the release layer is OP wax.

[0074] In this embodiment, the ester solvent is a composition of ethyl acetate and ethyl propionate.

[0075] In this embodiment, the ketone chemical is ethyl ketone.

[0076] The preparation method of above-mentioned a kind of digital printing machine hot stamping film, it comprises the following steps:

[0077] The first step, the preparation of the composition of the laser resin layer: mix the formula amount of hydroxyl-containing acrylic resin and melamine formaldehyde resin, then add th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com