Equipment capable of quickly printing license plate

A license plate and equipment technology, applied in printing, printing machines, transfer printing, etc., can solve problems such as complex process, poor temperature stability, product quality, and unsatisfactory work efficiency, and achieve simple process, good thermal stability, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

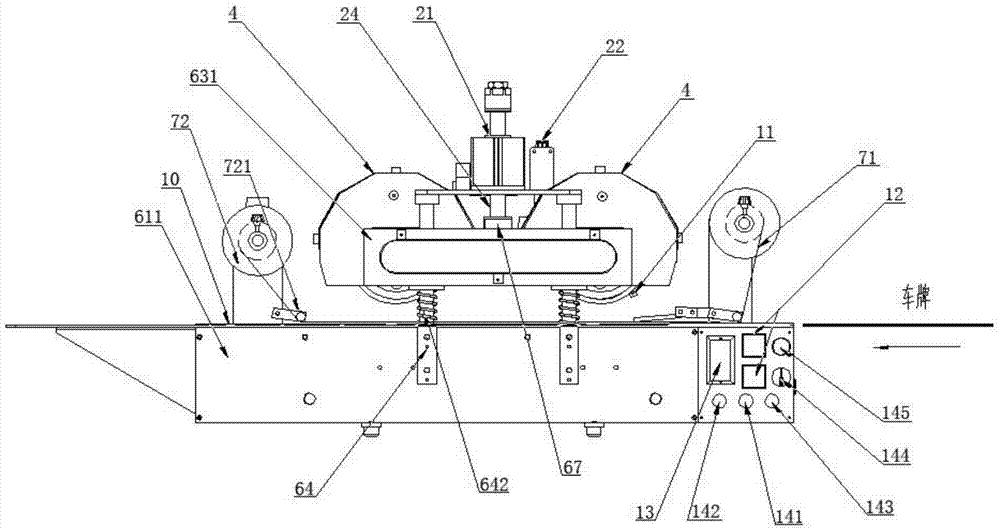

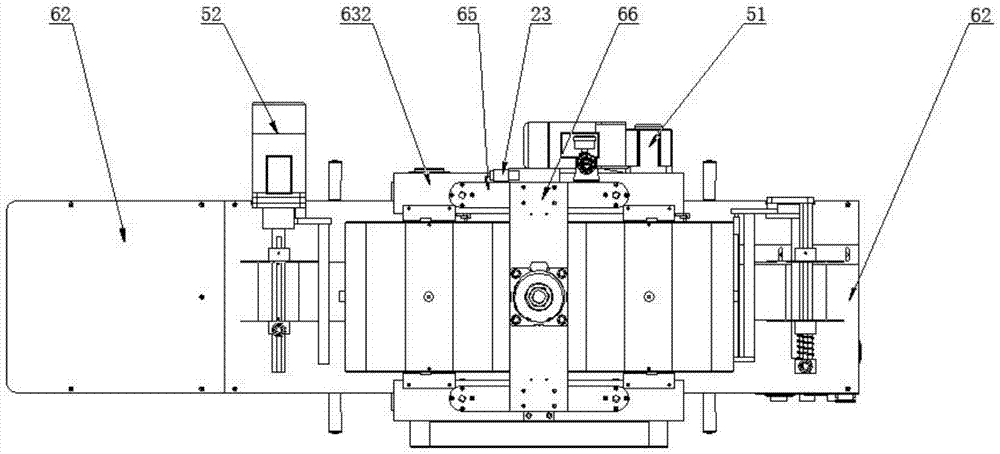

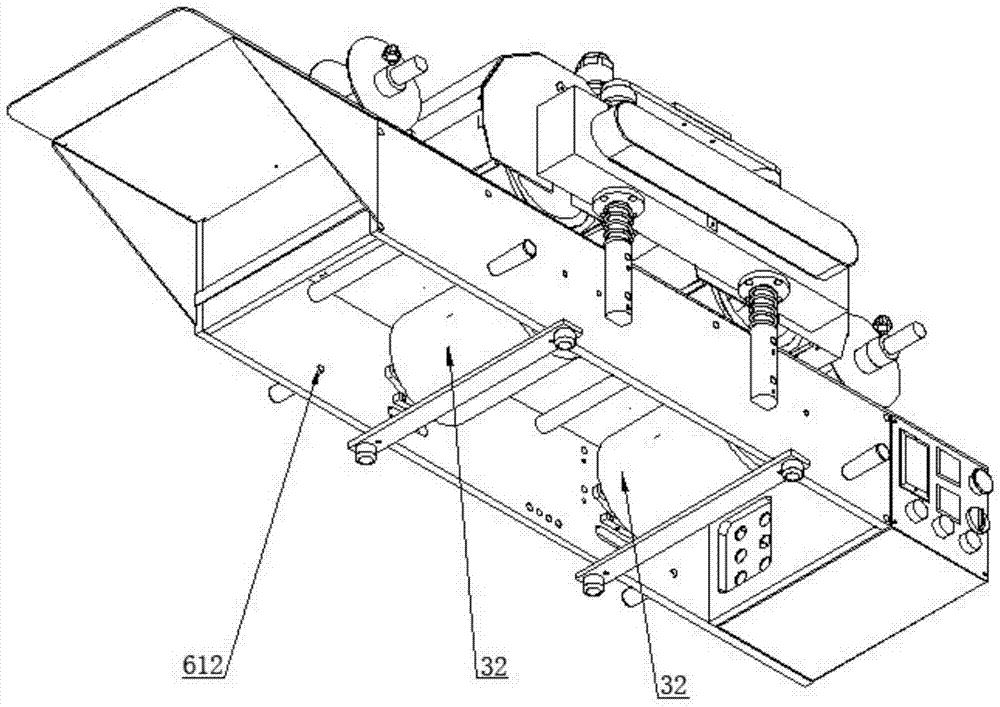

[0054] like Figures 1 to 8 As shown, the present embodiment consists of a control system, a driven wheel set, a heater 4, pneumatic components, a power motor, a frame structure, a discharging device 71 and a receiving device 72. The control system is used to control the temperature, speed and the switch of each component. The pneumatic components are used to automatically lift the driving wheel 31 and other equipment. Wheel 31, the driving and driven wheel set is used for stamping, supporting the license plate and so on.

[0055] The control system includes a temperature sensor 11, a temperature controller 12, a governor 13, a motor switch 141, a lifting switch 142, a heating switch 143, a power switch 144, an air switch (not shown) and an emergency stop switch 145. Air switch is arranged on the side of the present invention (as front side plate 611, rear side plate 612 etc.), other switches (motor switch 141, lifting switch 142, heating switch 143, power switch 144, emergen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com