Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Avoid wiping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

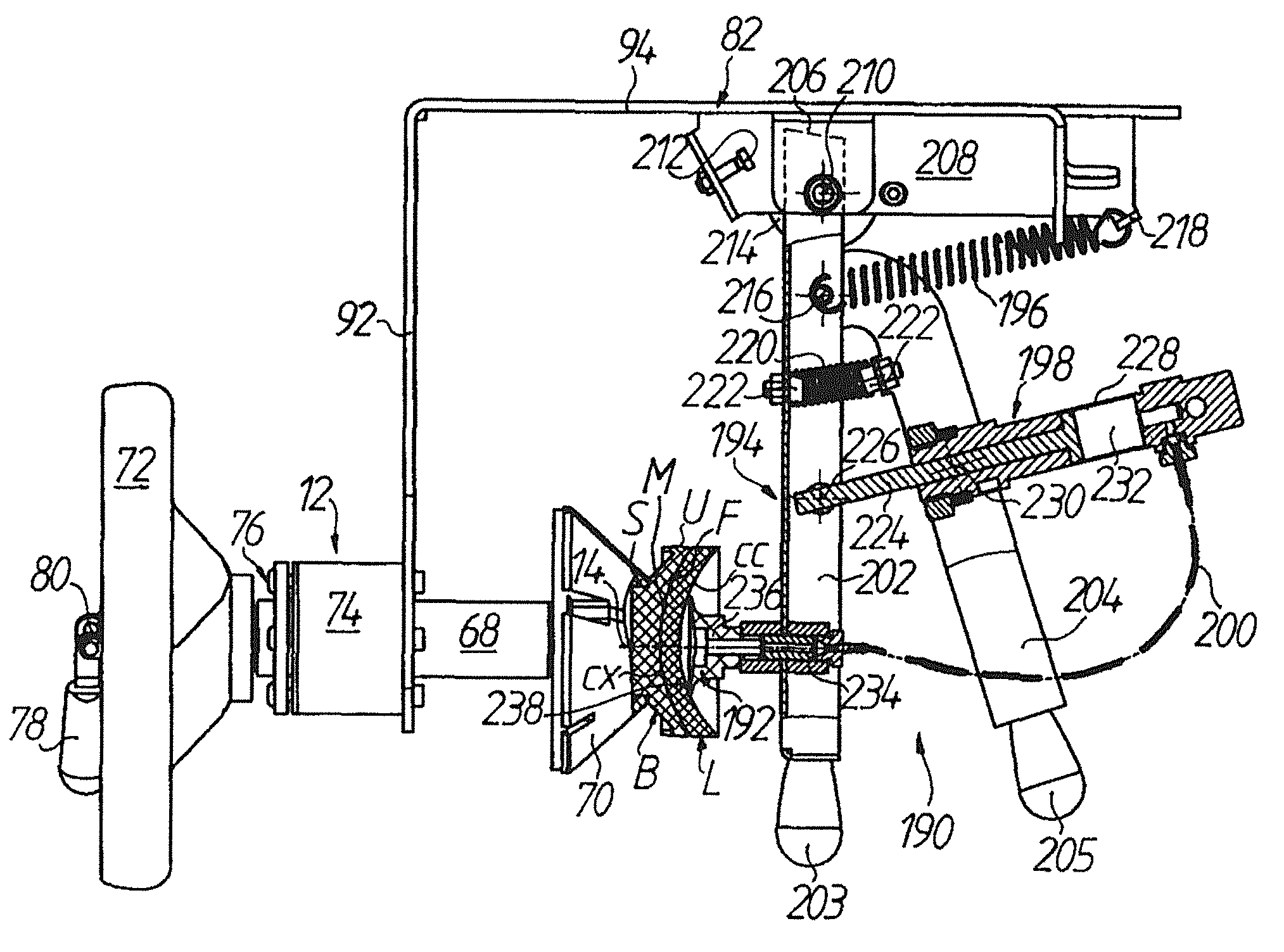

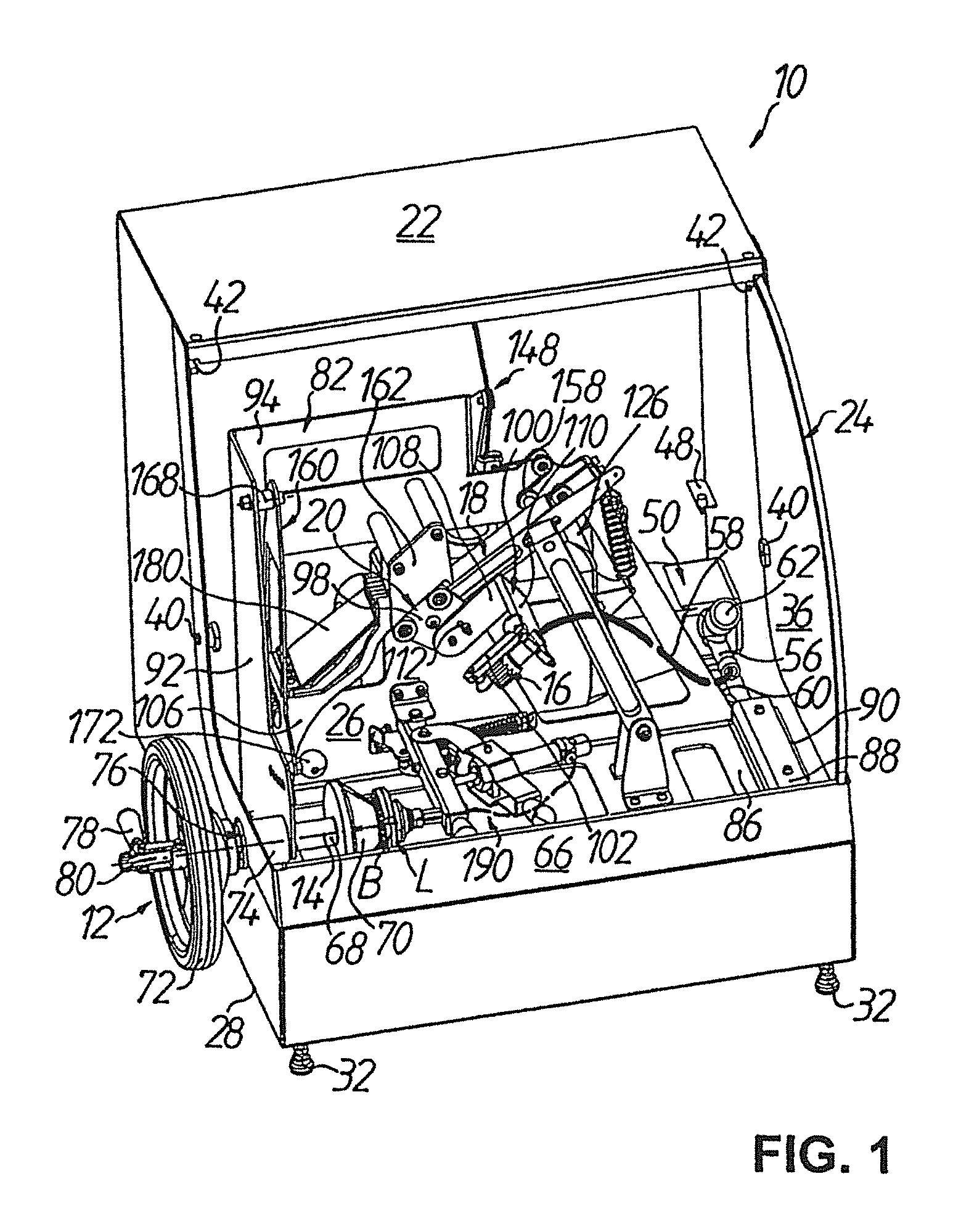

Method and apparatus for ink jet printing

InactiveUS20050174412A1Efficient curingHigh color saturation potentialDuplicating/marking methodsSpacing mechanismsPolyesterPorous substrate

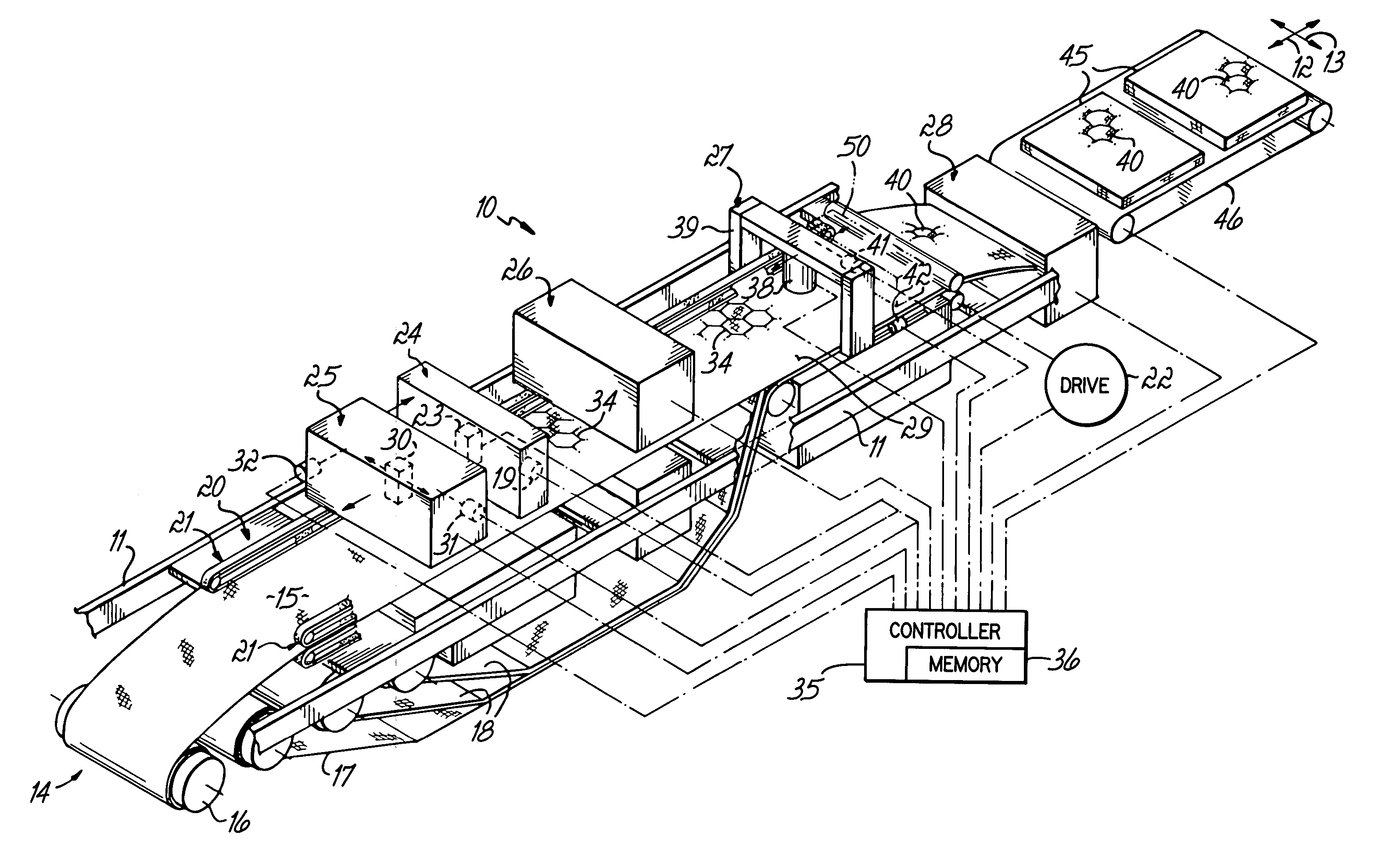

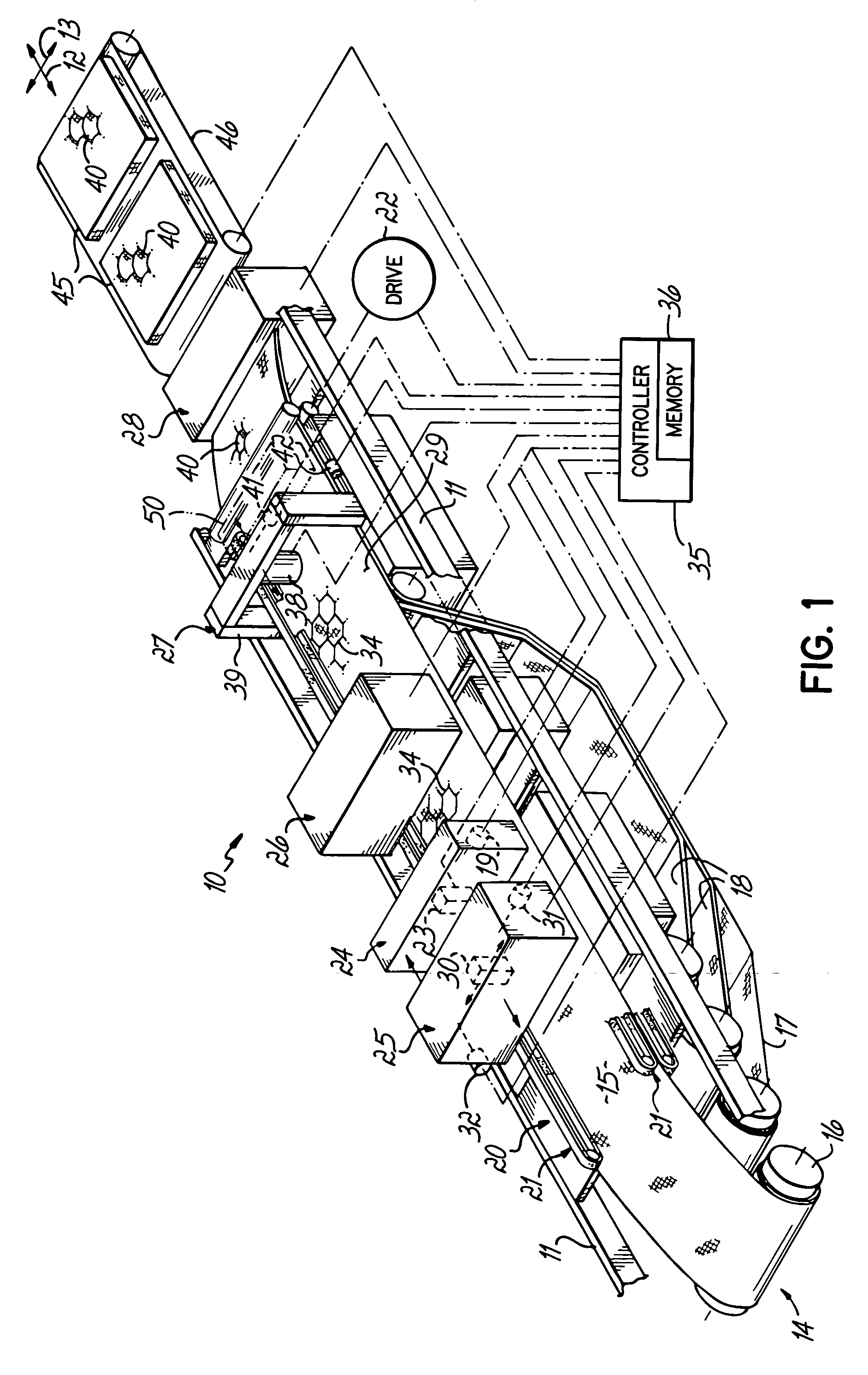

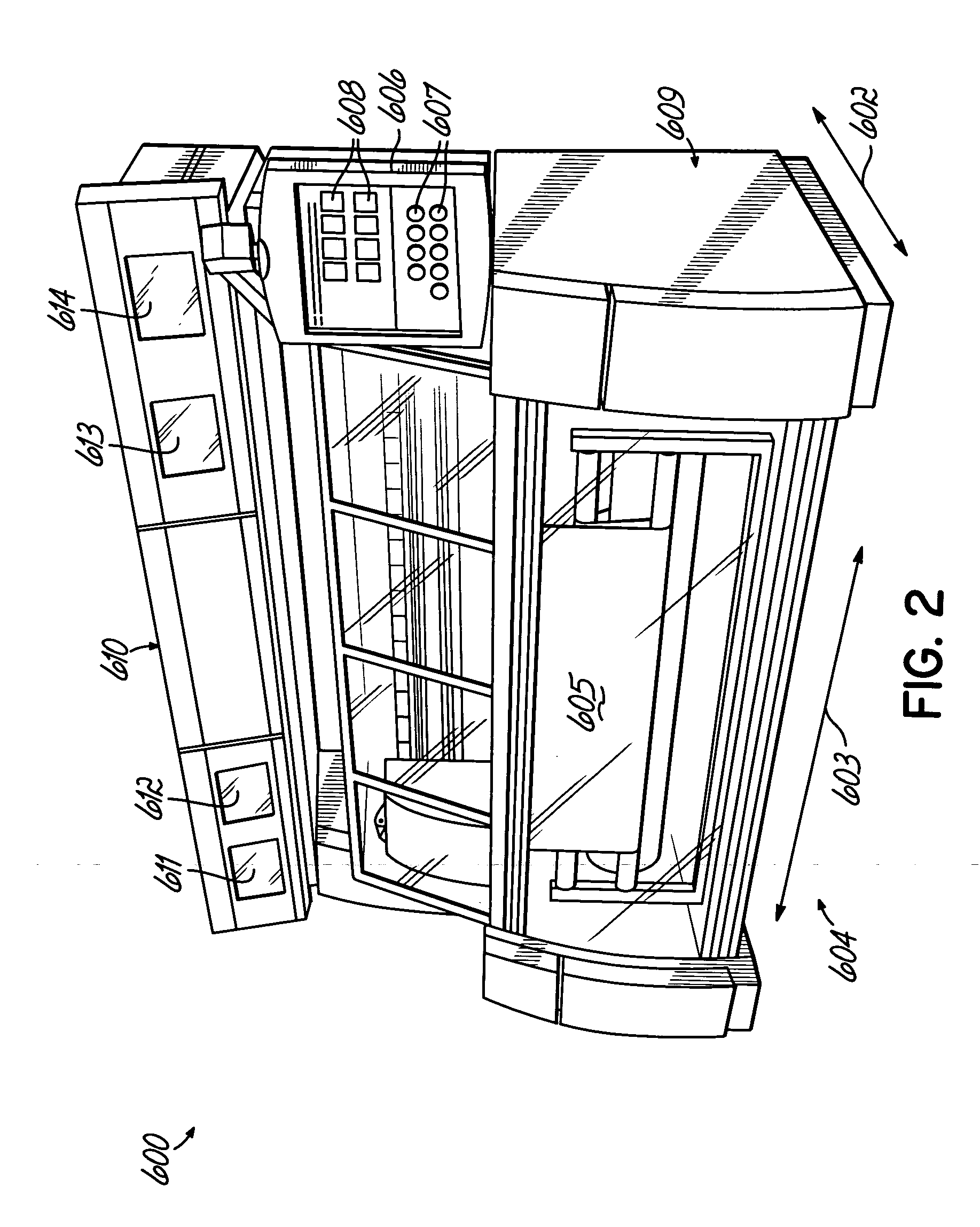

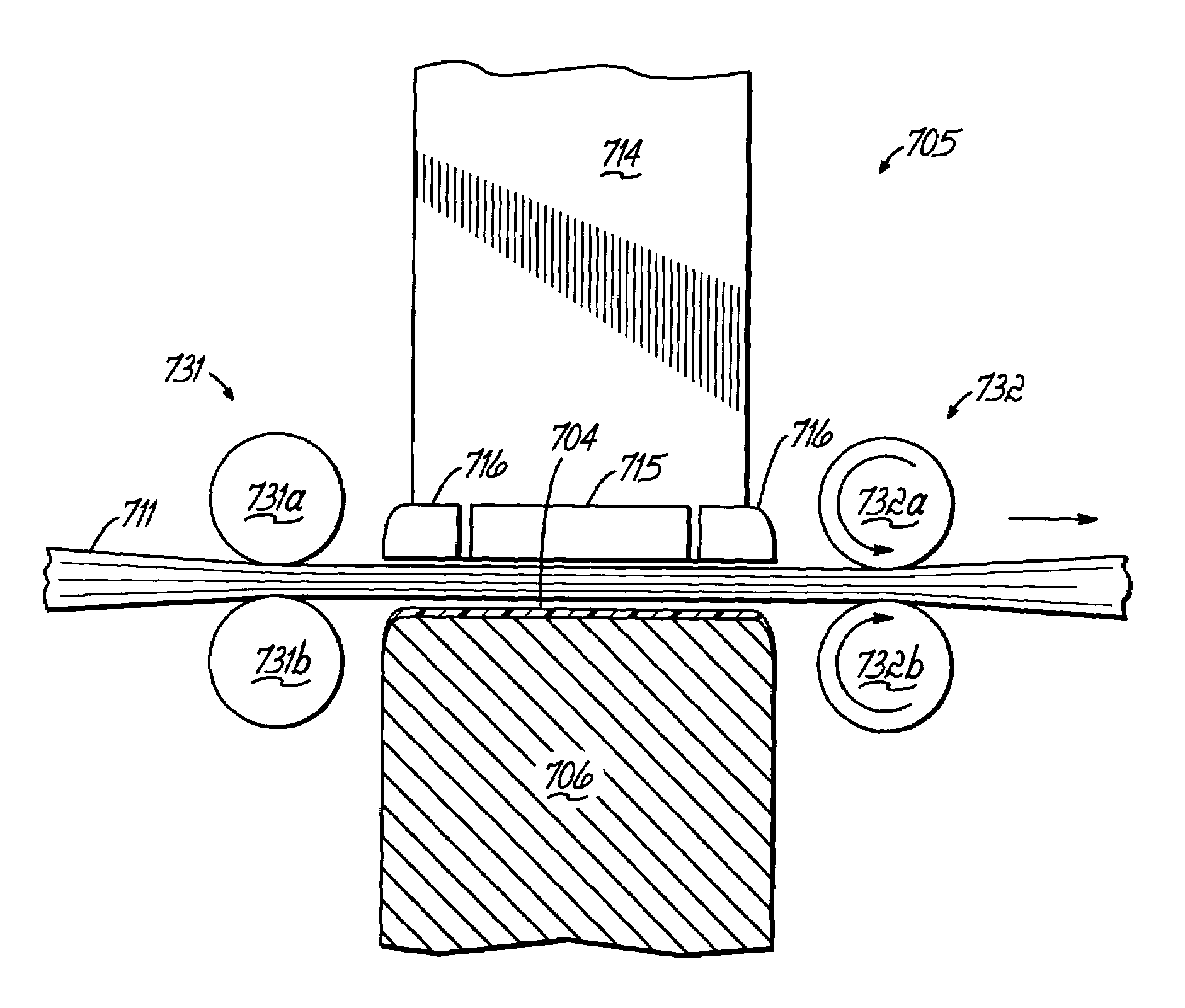

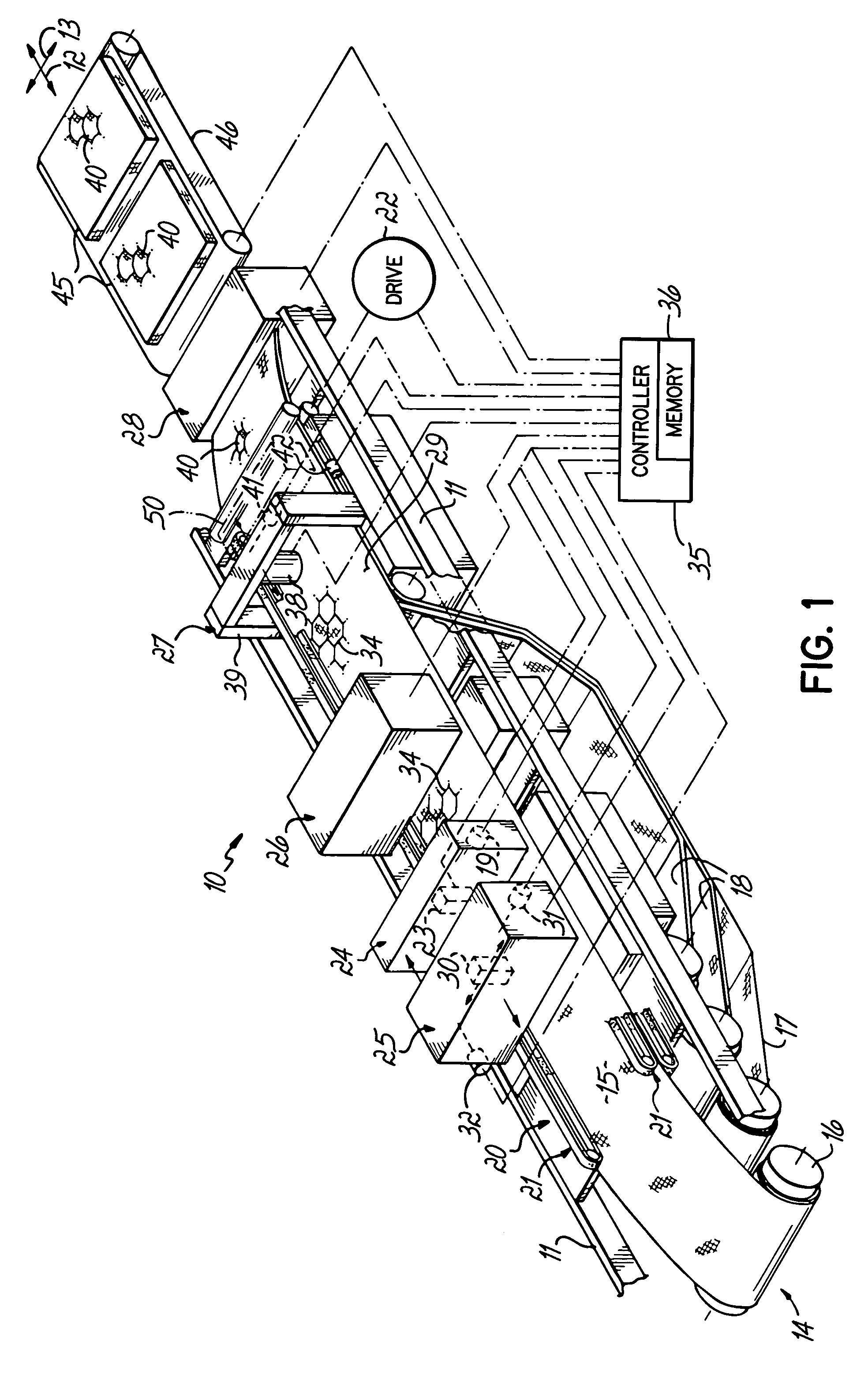

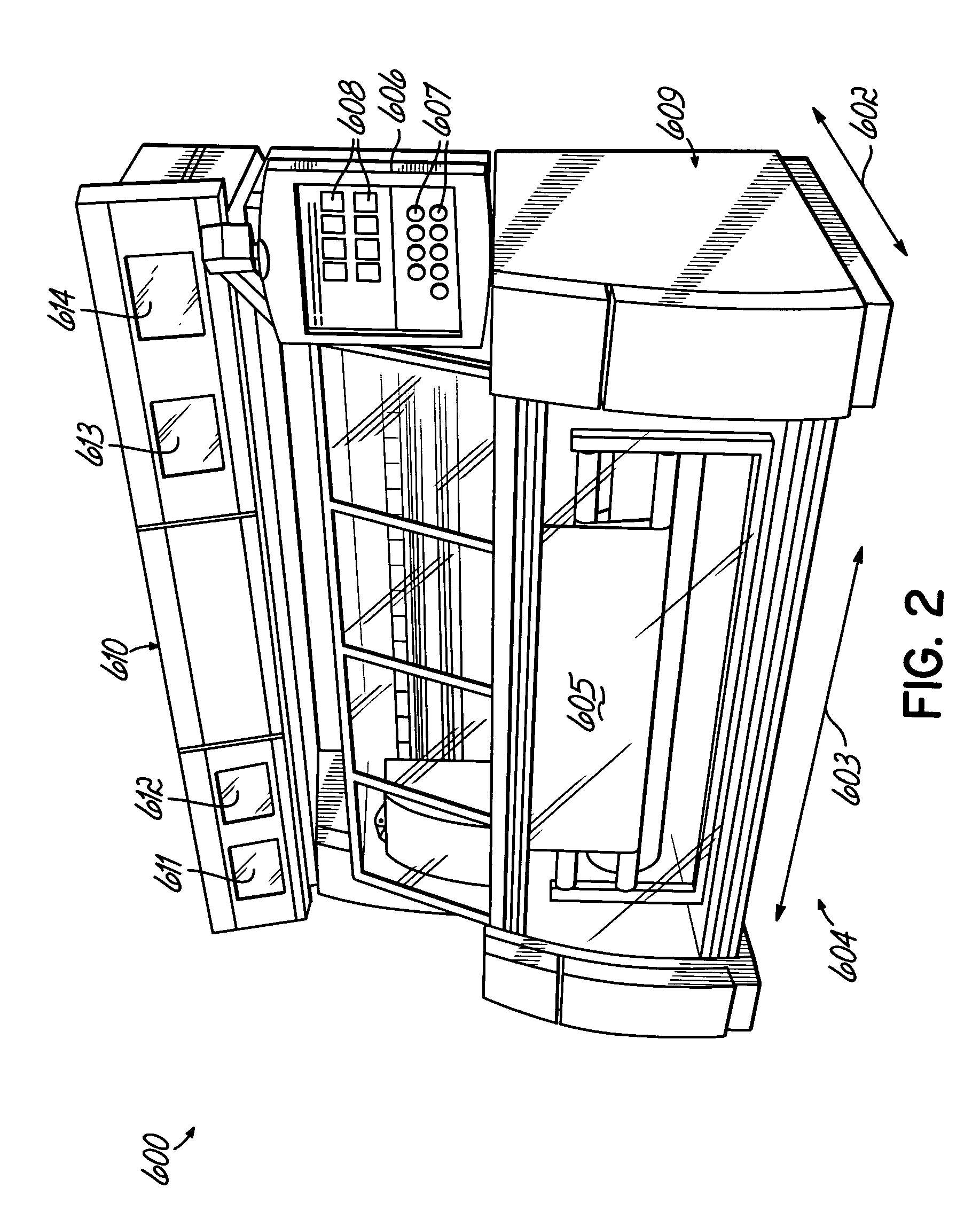

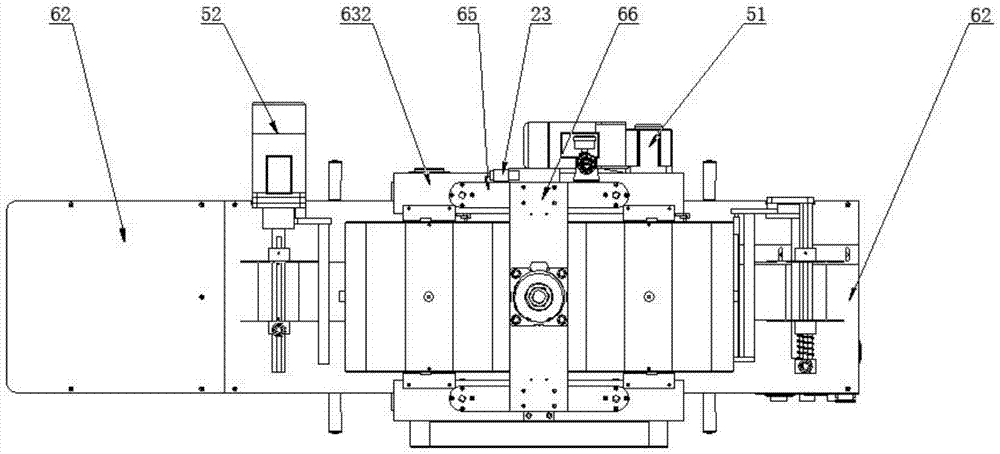

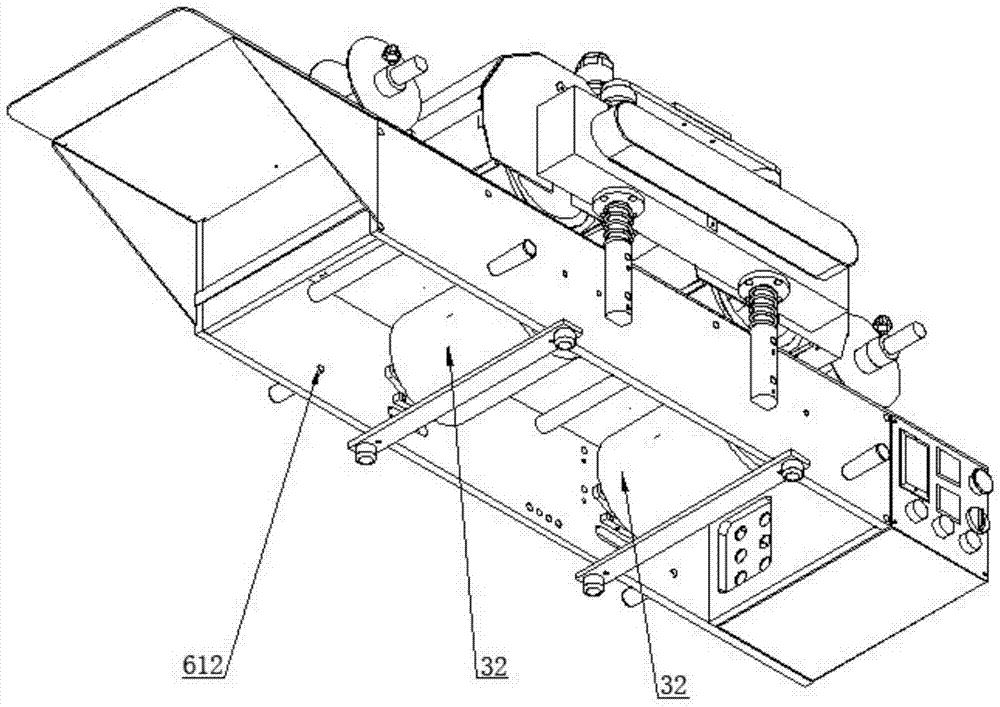

Ink jet printing is provided on large area substrates such as wide width textile webs. The printheads are driven by linear servo motors (633) across a bridge (630) that extends across the substrate. The timing of the jetting of the ink is coordinated with the motion of the printheads (640,641), so that the heads can be rapidly moved and the ink can be jetted while the printheads are accelerating or decelerating as they move on the bridge. Preferably, ultraviolet (UV) light curable ink is jetted and first partially cured with UV light (645,646) and then subjected to heating to more completely reduce uncured monomers of the ink on the substrate. Preferably, the heat is applied by contacting the substrate with a heated plate (661,662). Ink jet printing is provided using ultraviolet (UV) light curable or other curable composition or stable or other printable substance. In certain embodiments the UV ink has a dye-component therein. The ink is jetted onto a substrate, the composition is cured, then heated to set the dye. Sublimation dye-based UV ink printing onto polyester is preferred. A release layer of protective material (702,704), such as a TEFLON film or sheet, covers a substrate support (705,706). A porous substrate to be printed, such as a textile material (711), is supported on or above the support. Ink is jetted onto the substrate, with some of the ink passing through pores in the substrate and landing on the protective material. UV curable ink is preferably used and is exposed by UV light from a UV light curing head, which solidifies the ink on the substrate. The UV curing light has a long enough focal length to focus on the surface of the substrate and also, where it passes through pores in the substrate, on ink on the protective material, thereby solidifying the ink on the protective material. When the substrate is removed from the support, the solidified ink on the protective material may be wiped from the protective material. The protective material may be a coating on the support over which the substrate slides or a belt that moves with the substrate. A textile substrate may be preconditioned by singeing or shaving to remove fuzz from the fabric that could clog the printheads. A printhead cleaning station is also provided.

Owner:L & P PROPERTY MANAGEMENT CO

Method and apparatus for ink jet printing

InactiveUS7073902B2Efficient curingInhibit migrationDuplicating/marking methodsSpacing mechanismsEngineeringMechanical engineering

An ink jet printing is provided on large area such as wide textile webs, having such pores or other opening therethrough such that, when ink is jetted from a print head onto the web, some of the ink jets through the opening to a side of the web opposite the print head. At the printing station, maintaining a space between the web and the surface such that the web is out of contact with the surface at the printing station so that when ink jetted through the web and onto the surface it does not contaminate the web.

Owner:L & P PROPERTY MANAGEMENT CO

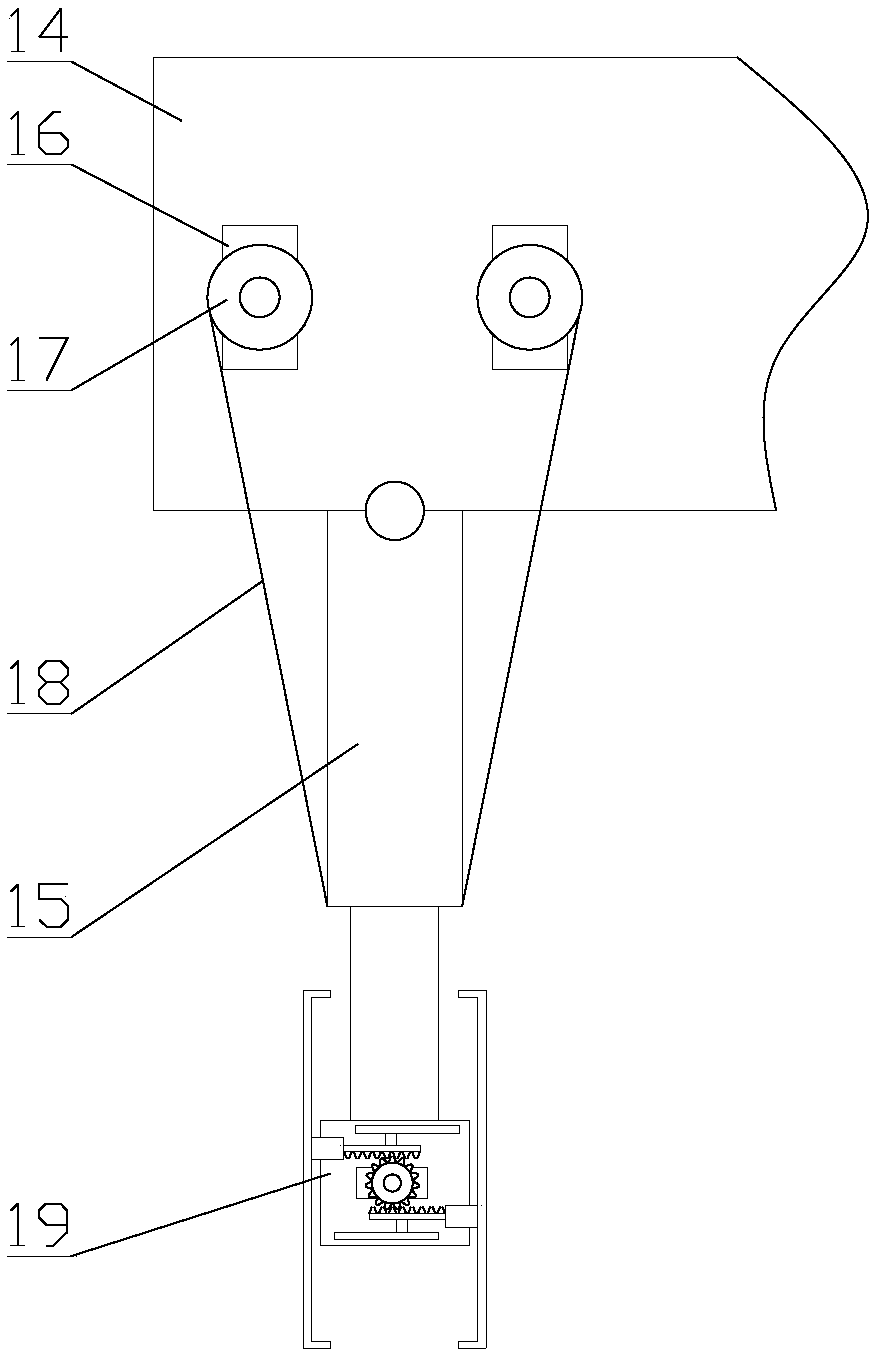

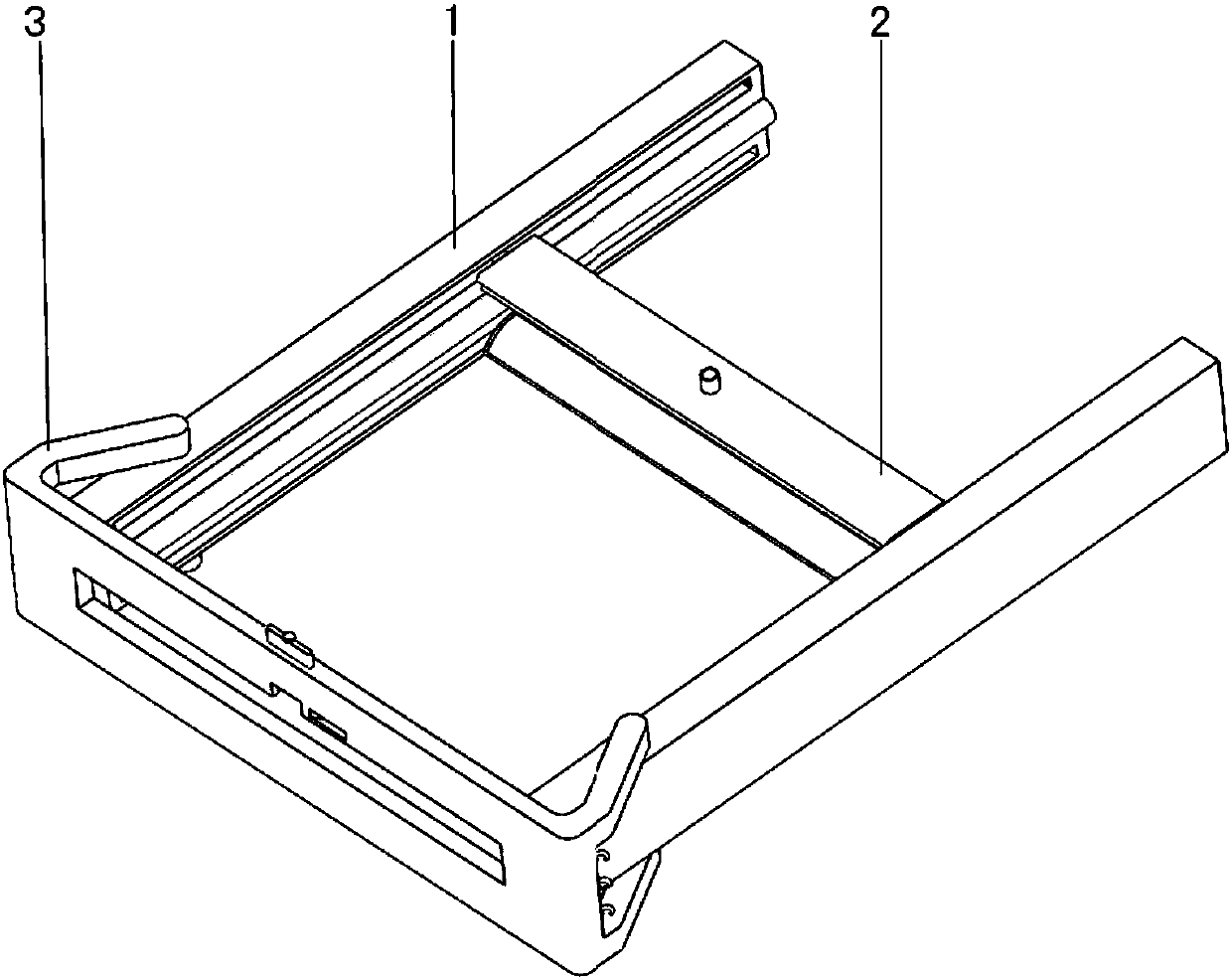

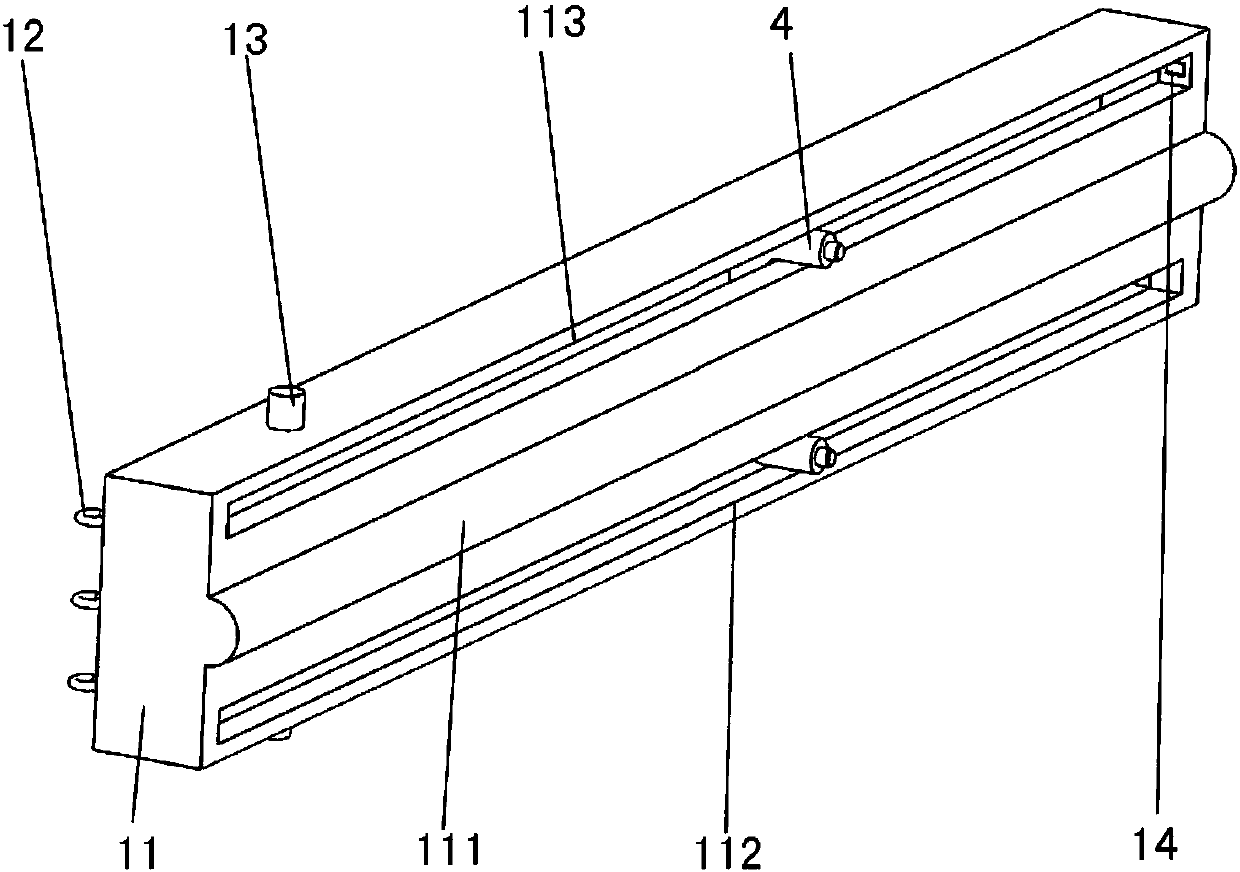

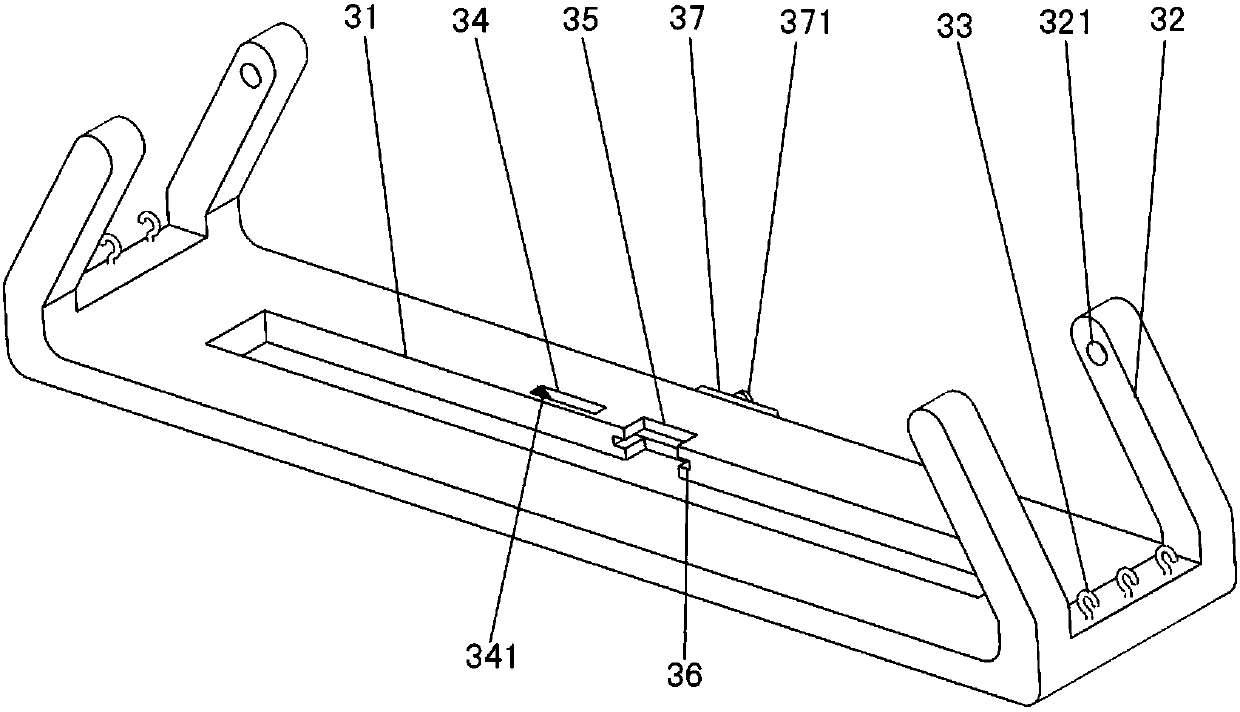

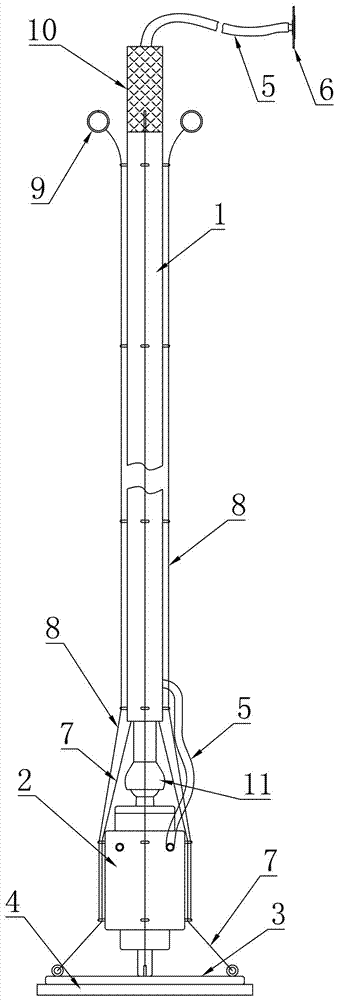

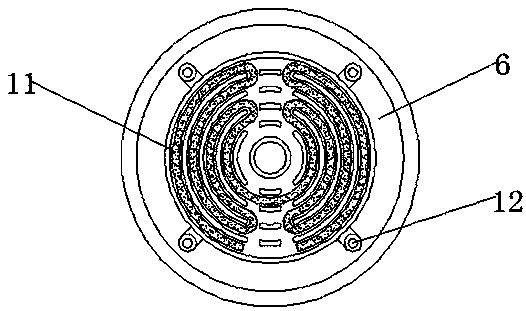

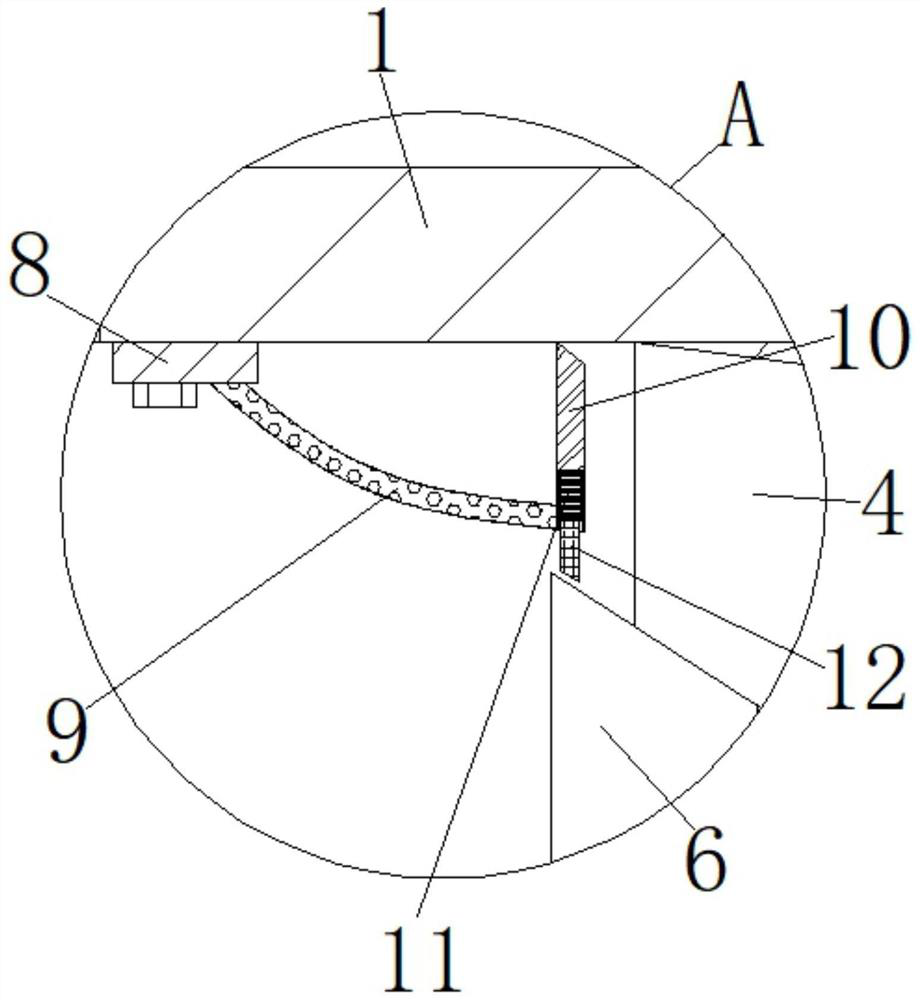

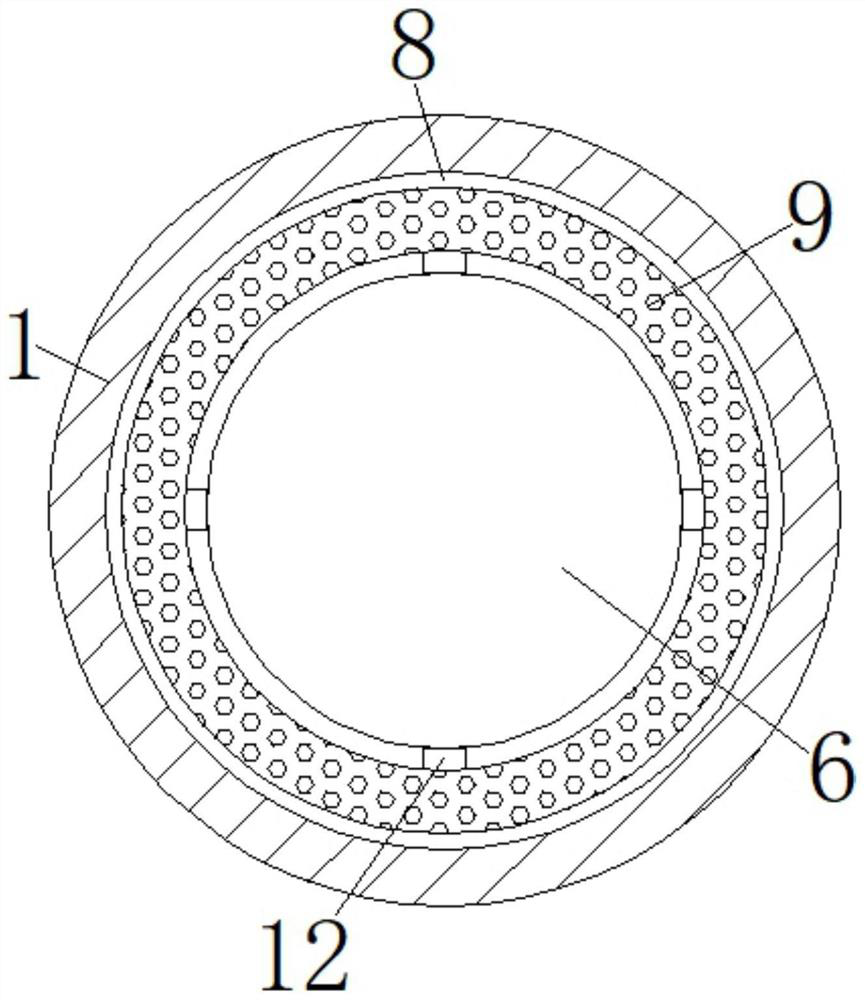

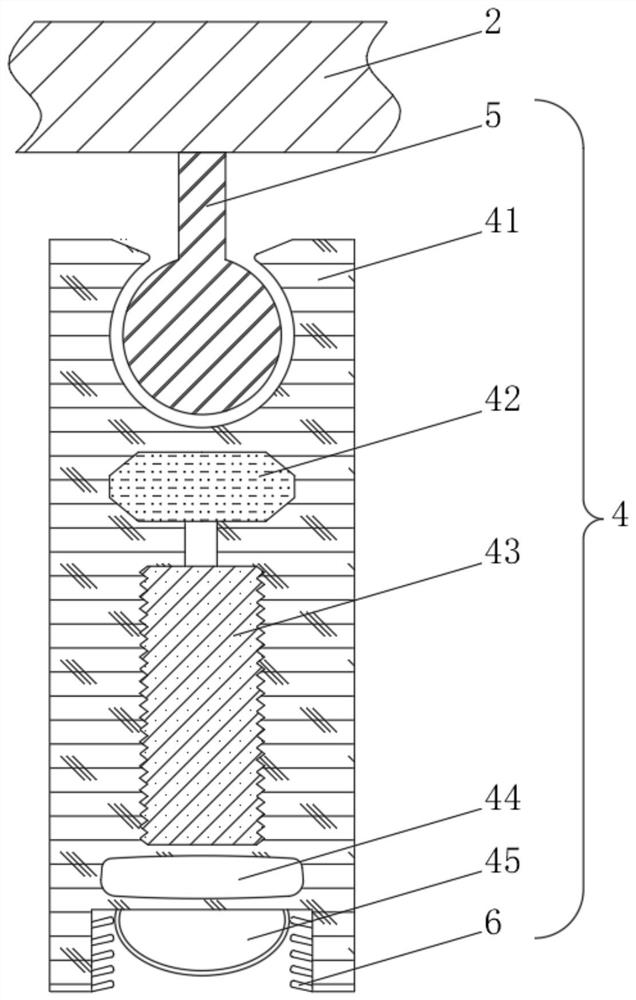

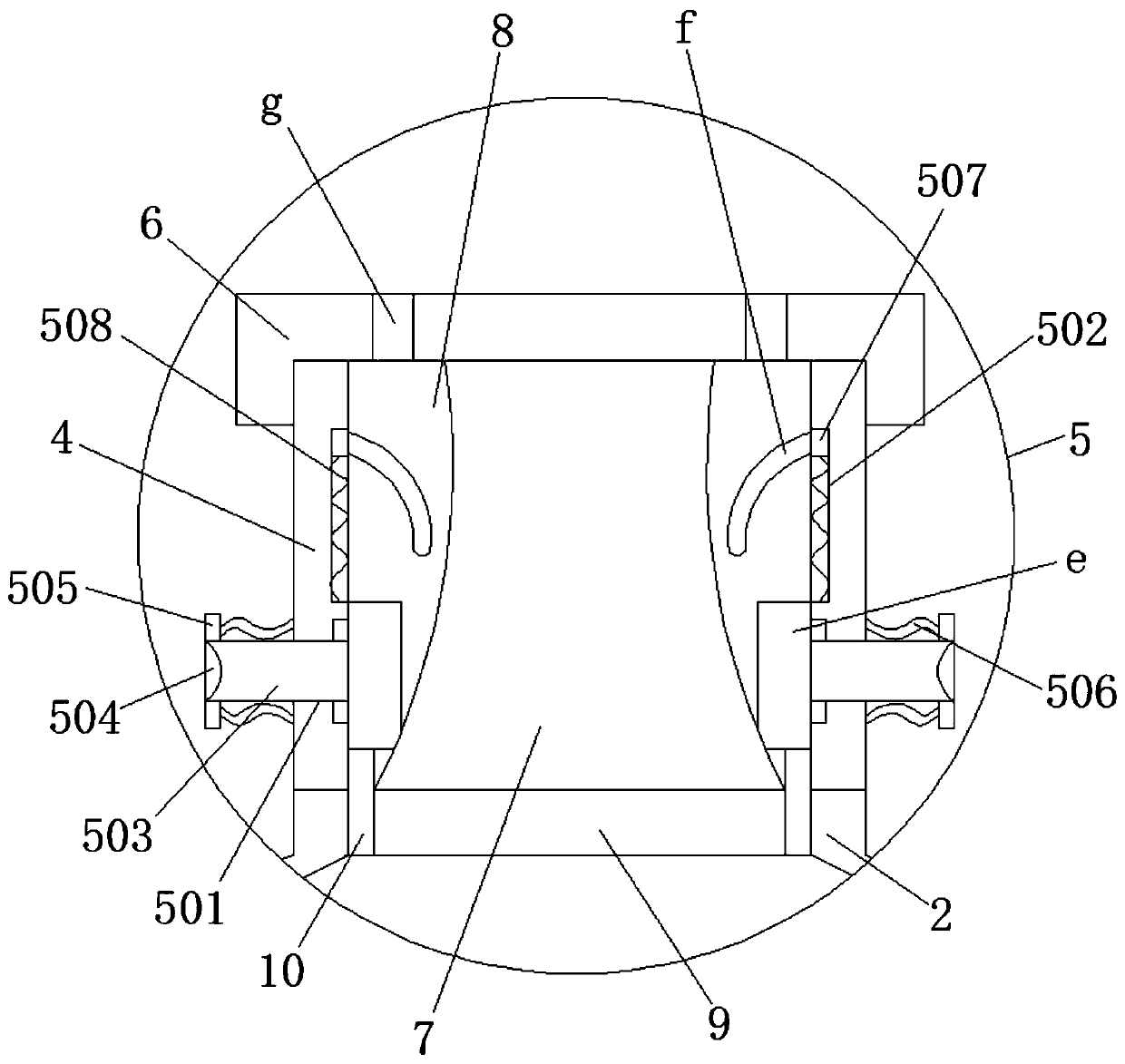

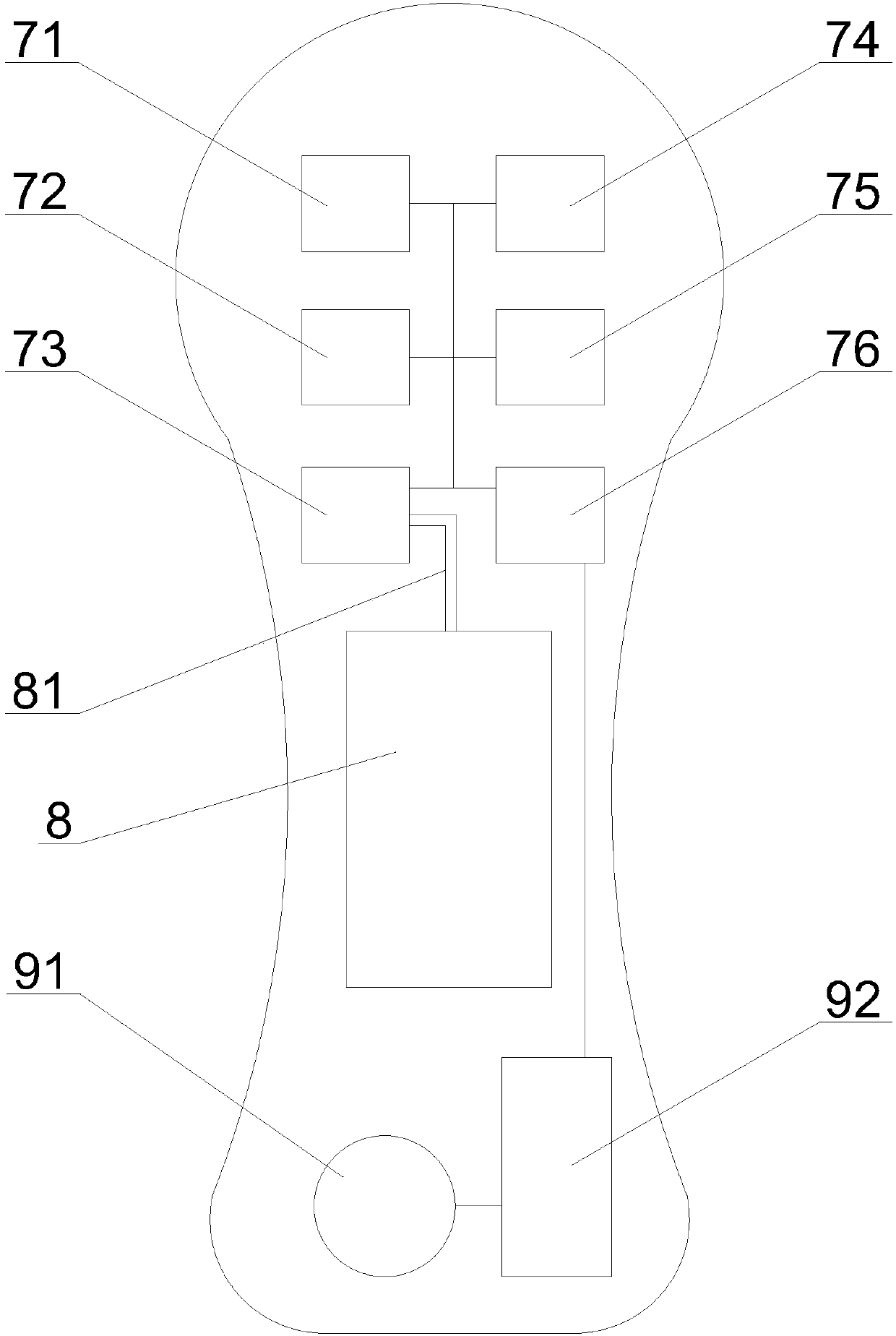

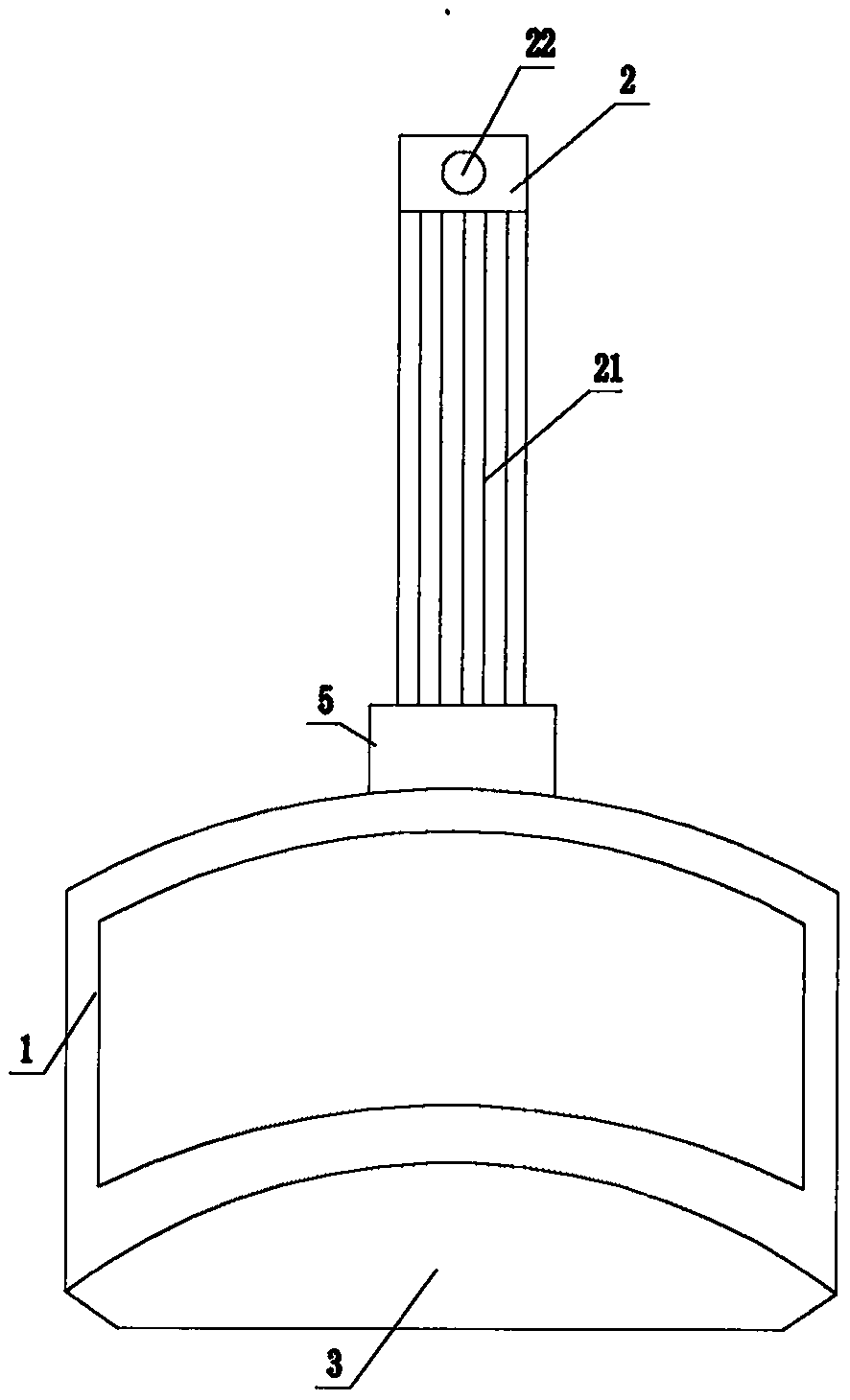

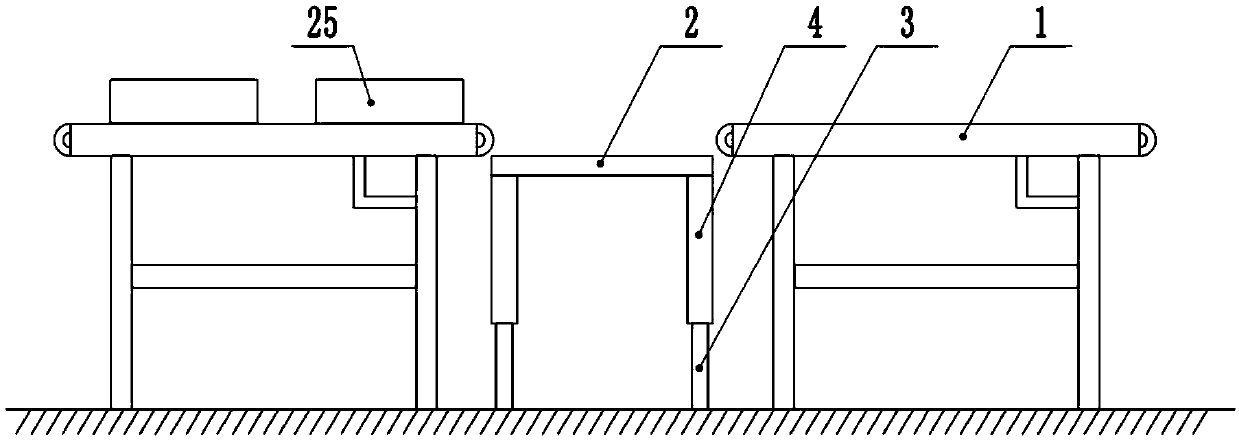

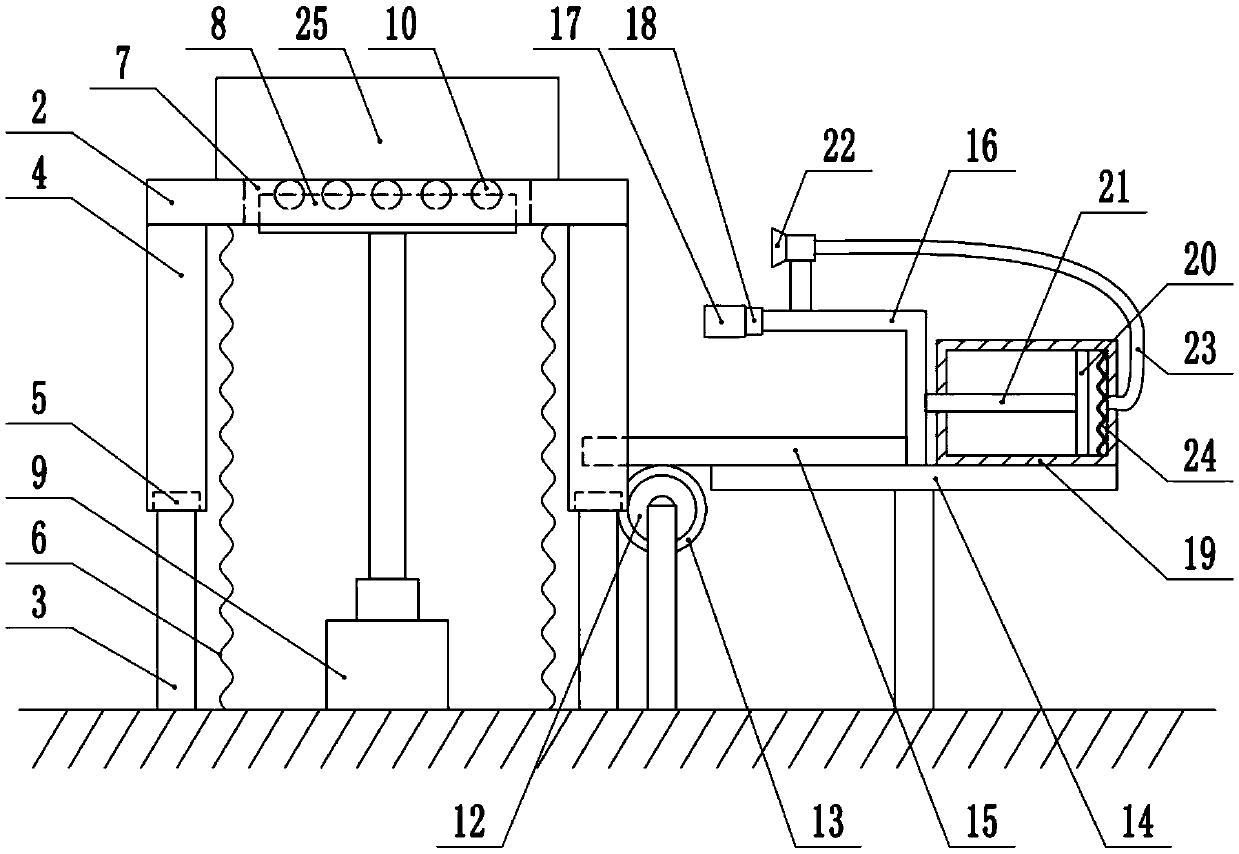

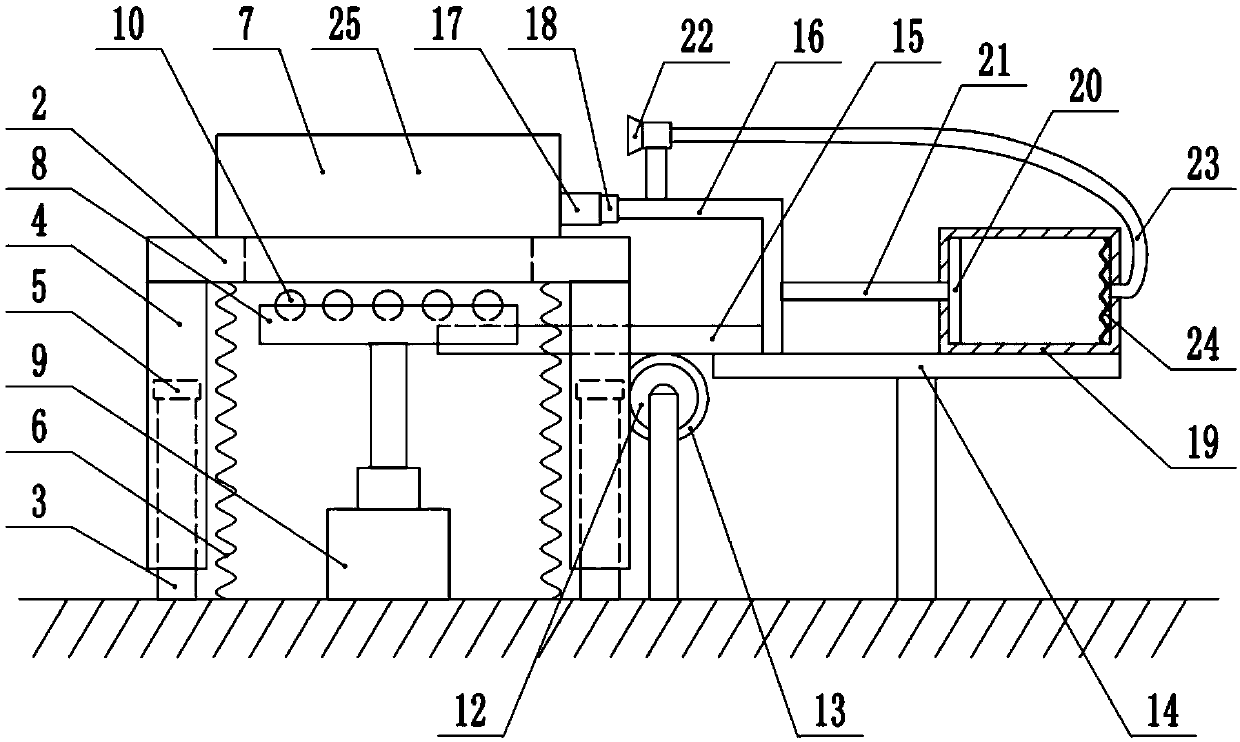

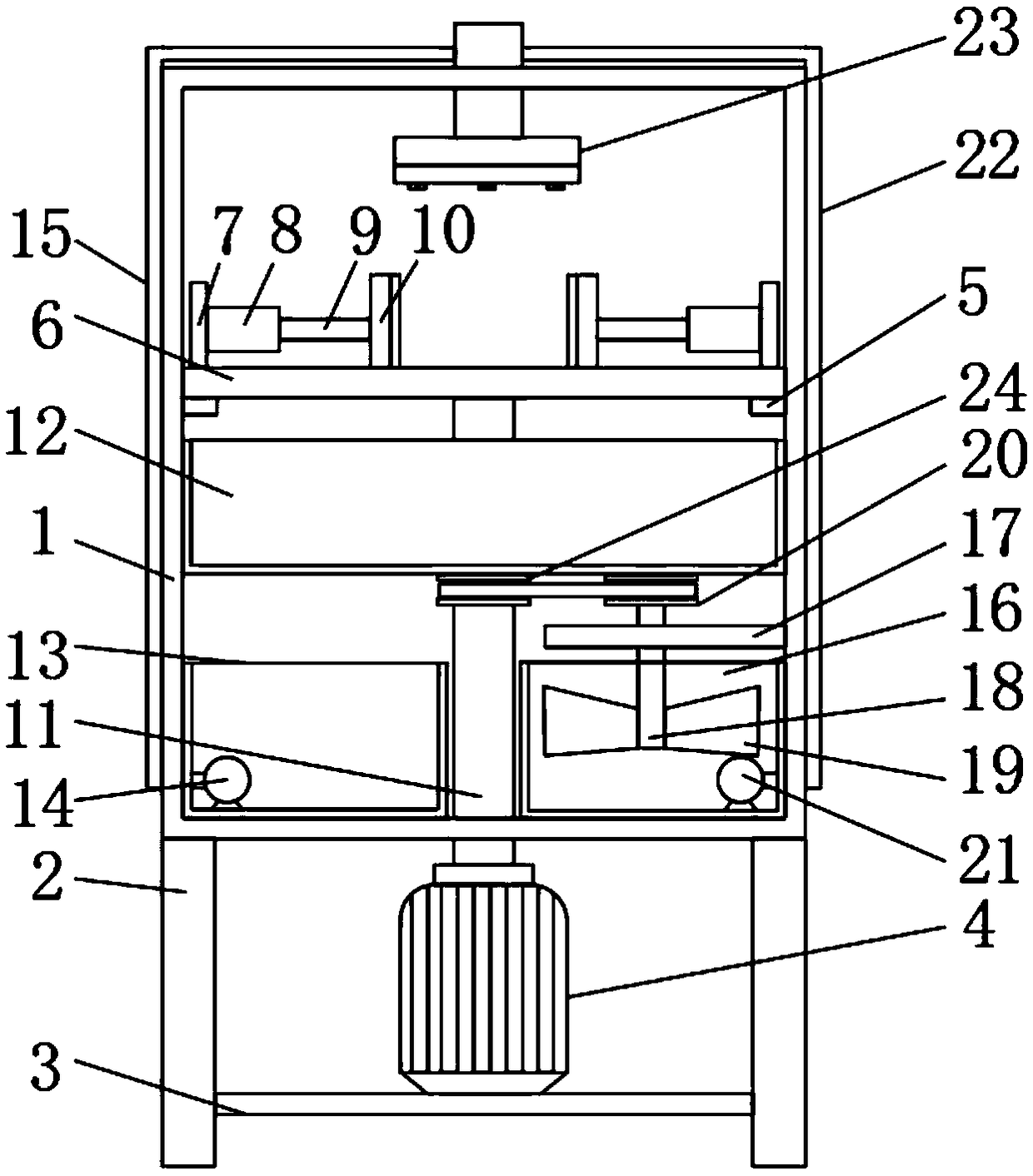

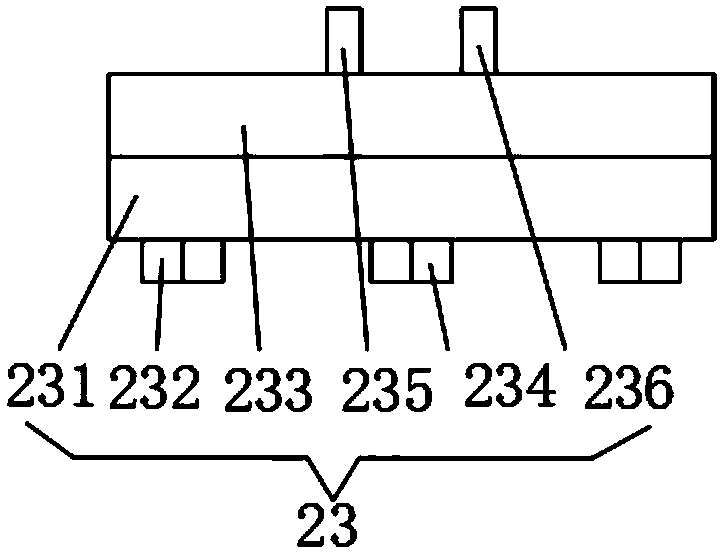

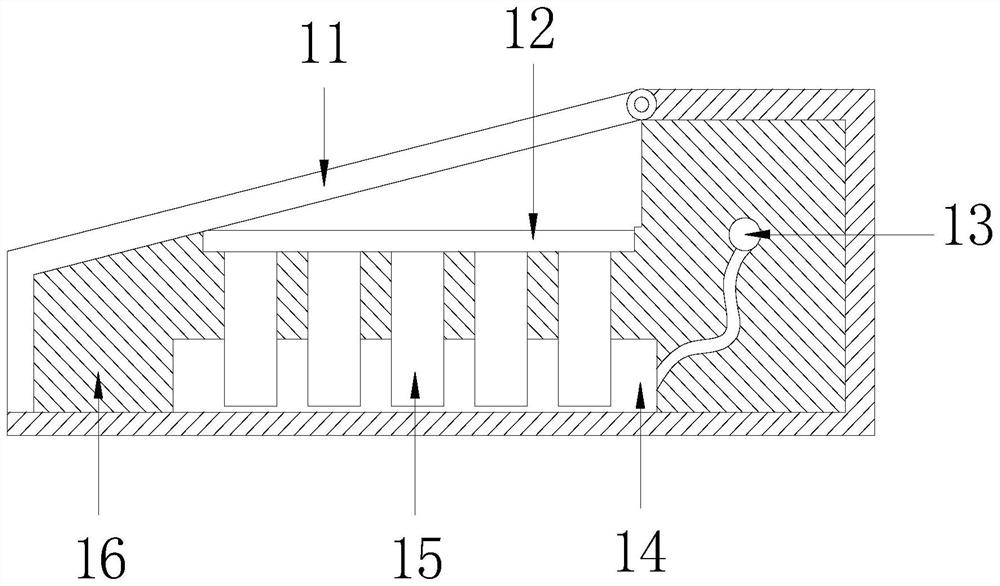

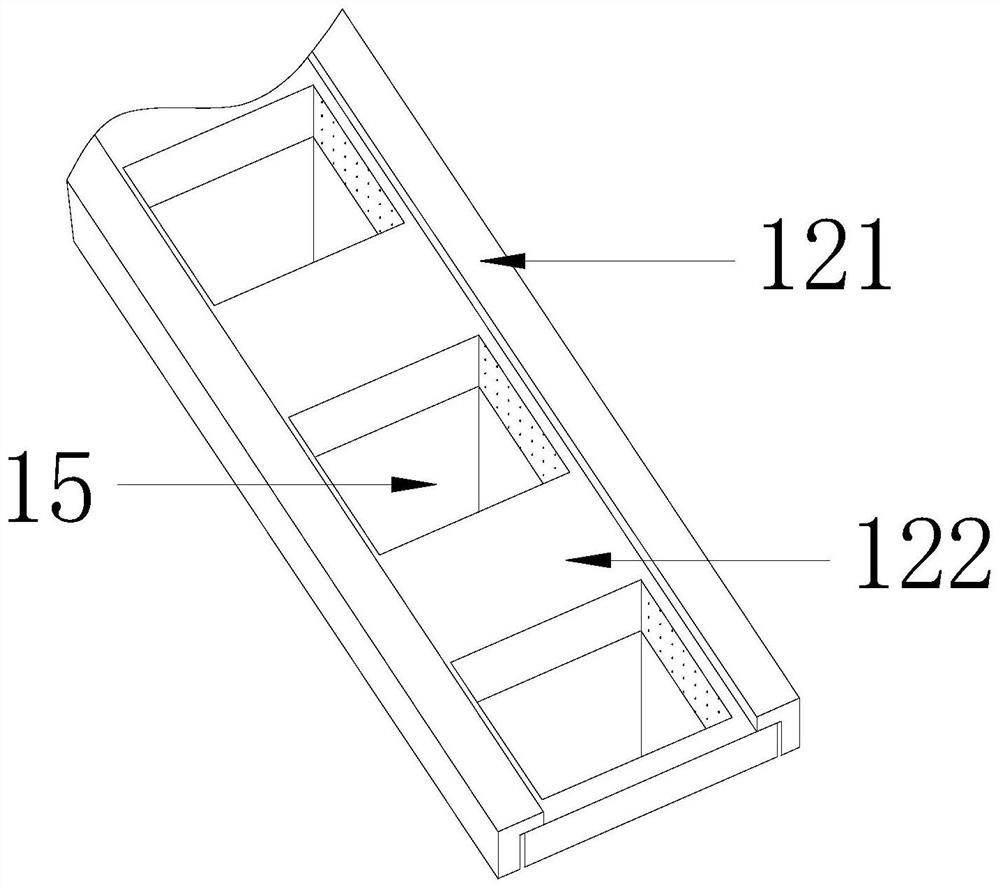

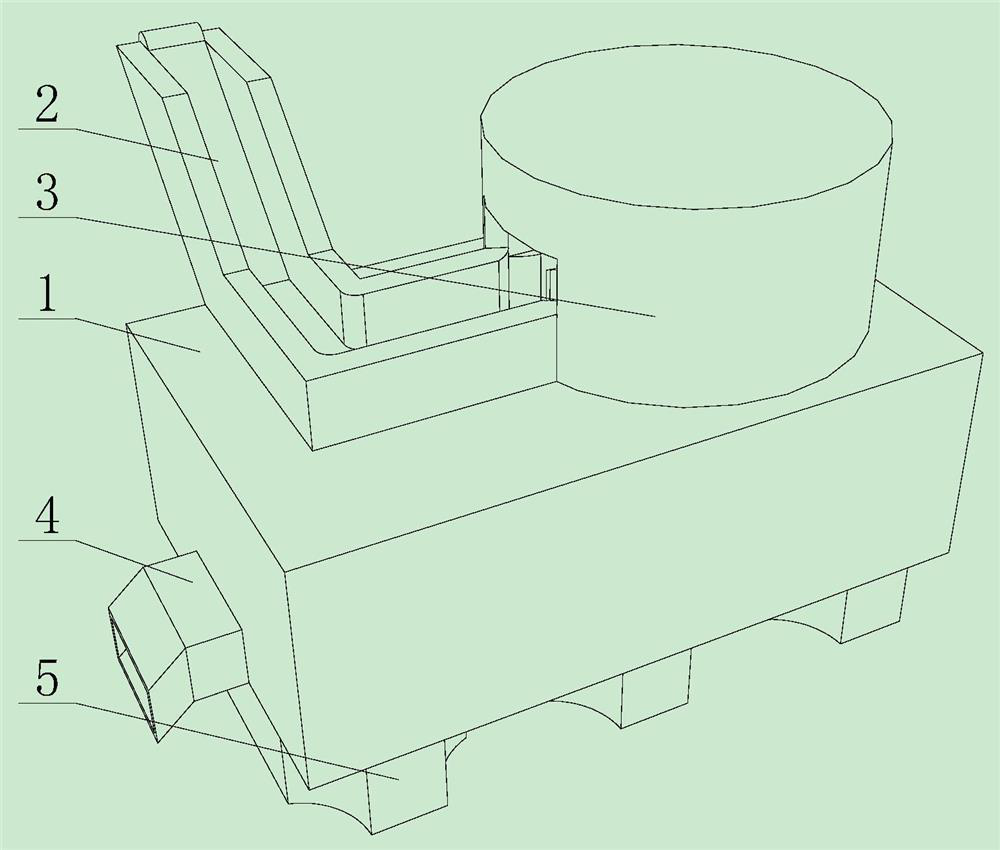

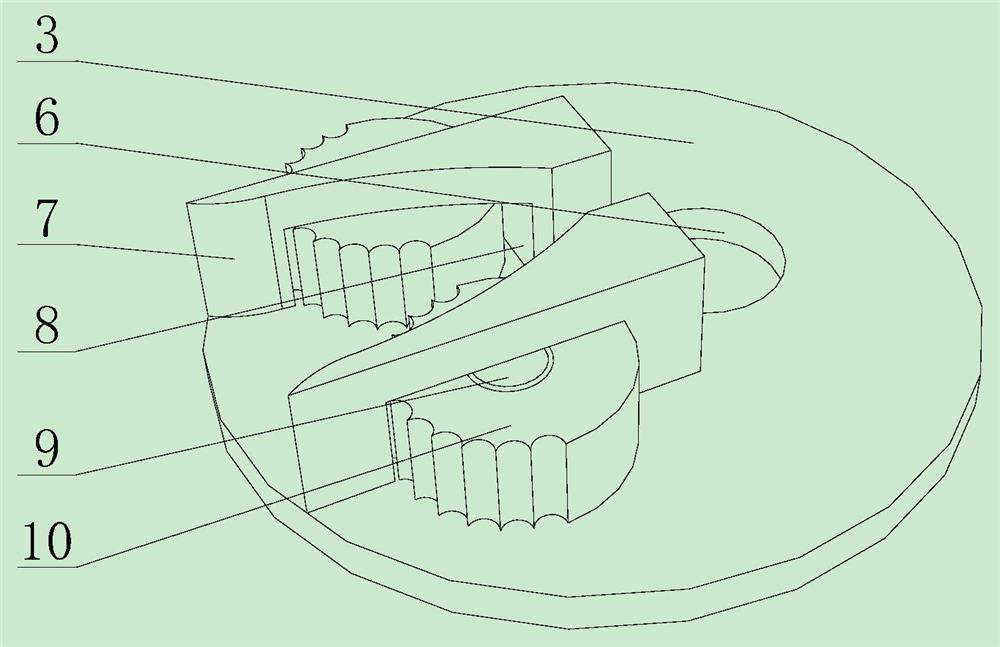

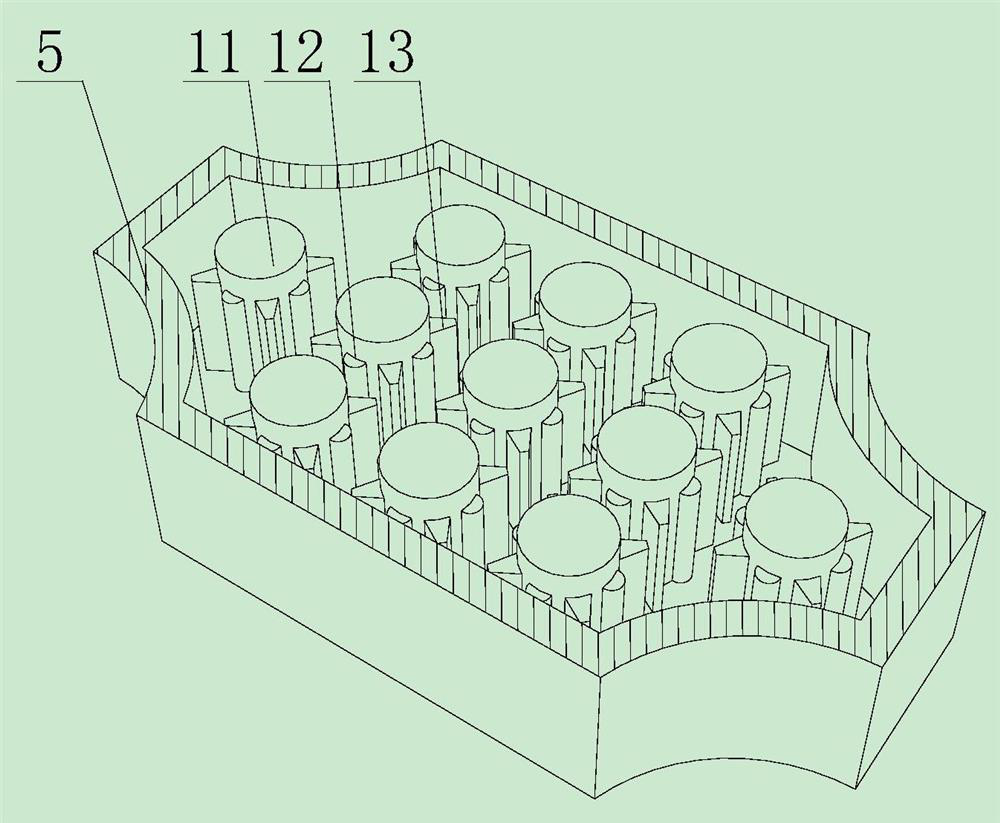

Intelligent device with blackboard wiping and dust absorbing functions

ActiveCN107856450APrevents dirty wipingAvoid dust accumulationBoard cleaning devicesPhysical healthEngineering

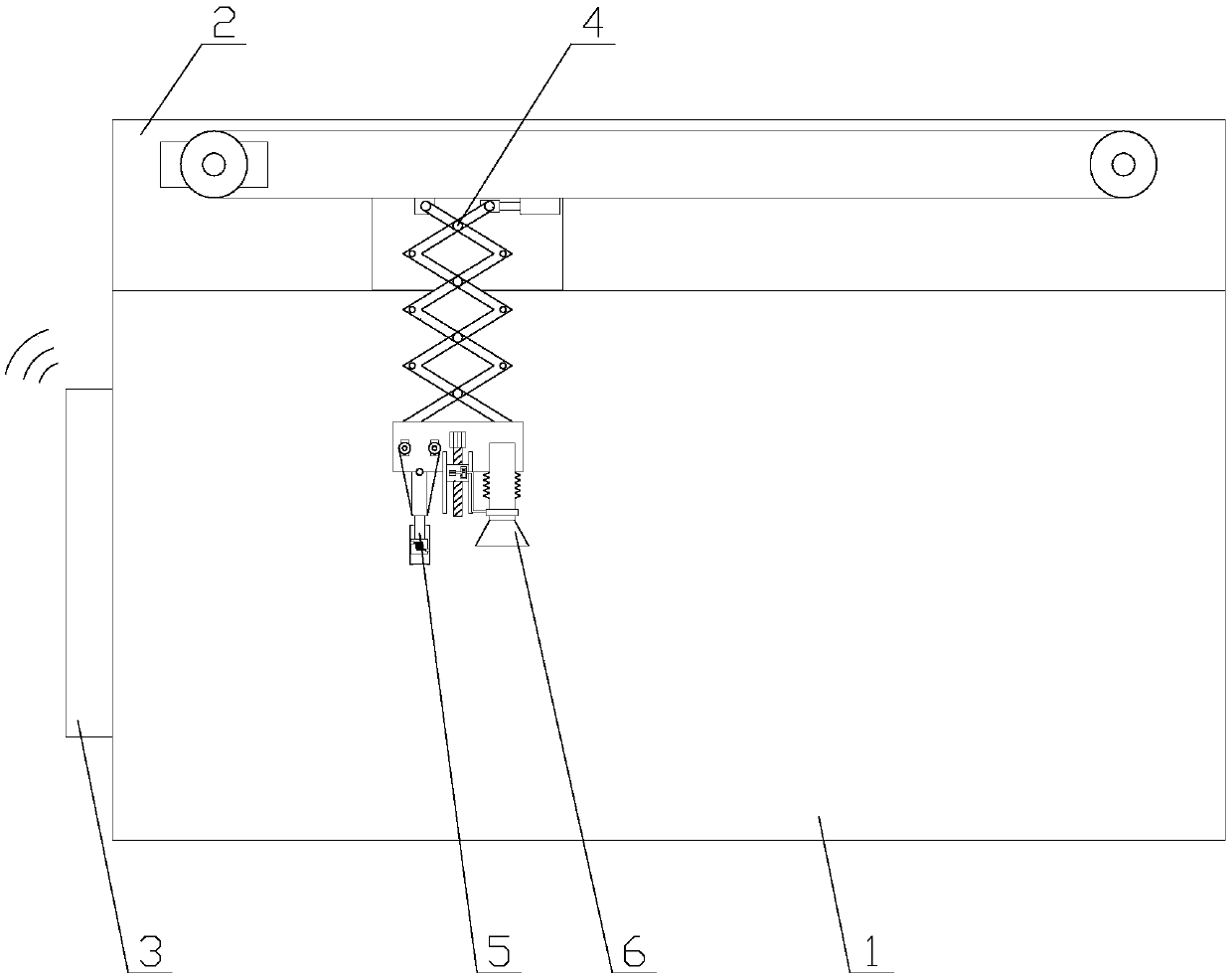

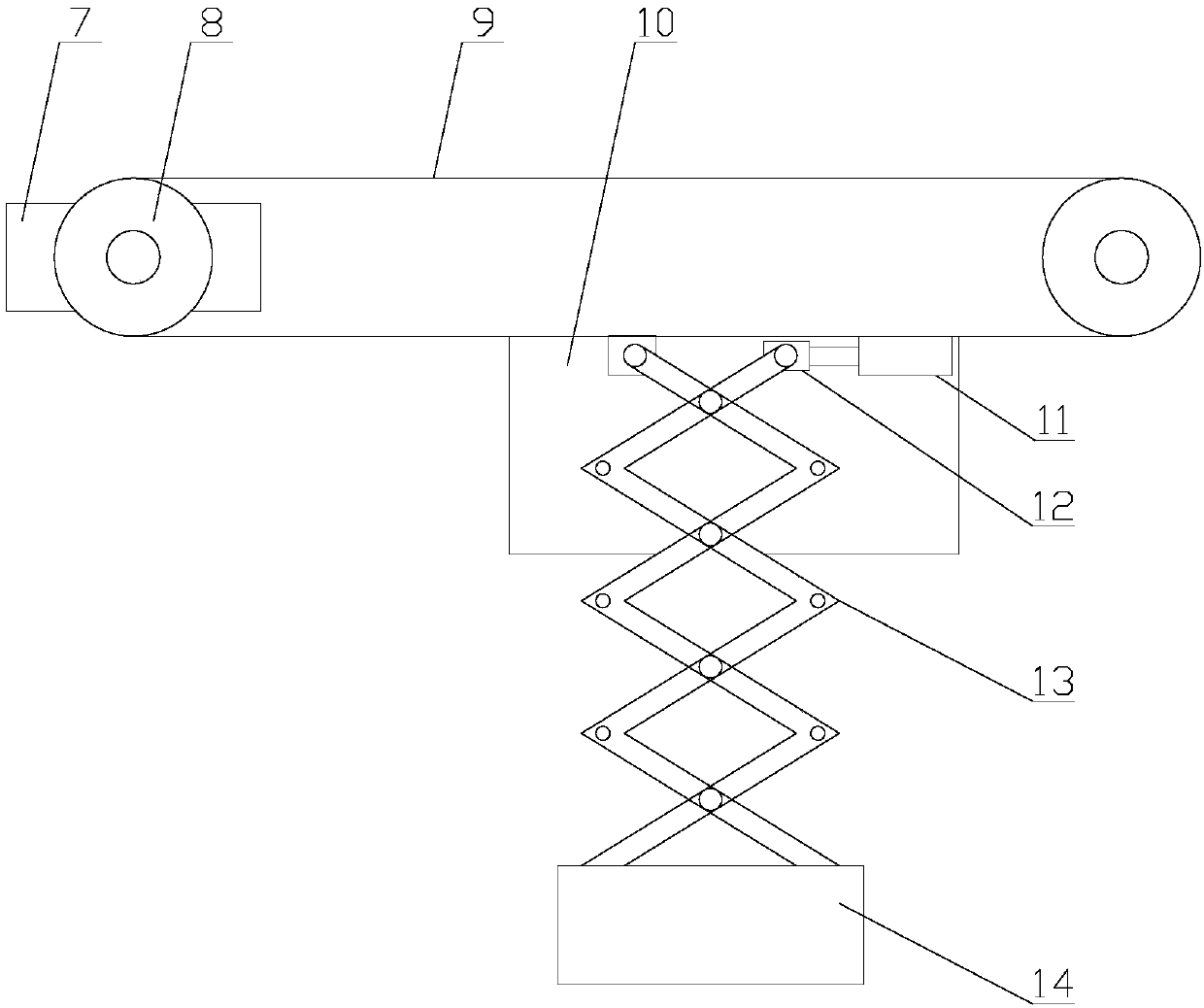

The invention relates to an intelligent device with blackboard wiping and dust absorbing functions. The intelligent device comprises a board body, a shell, a center control mechanism, a displacement mechanism, a wiping mechanism and a dust absorbing mechanism. The displacement mechanism comprises a movement assembly and a telescopic assembly. The wiping mechanism comprises a swing assembly and a fastening assembly. The dust absorbing mechanism comprises a dust absorbing pipe, a lantern ring, a curved bar, a lifting assembly and a reciprocating assembly. In the intelligent device with the blackboard wiping and dust absorbing functions, manual blackboard wiping is avoided through the wiping mechanism, and the intelligent device is more convenient and faster; through the fastening of clampingclaws, a blackboard eraser is replaced conveniently, and the situation that the blackboard is not wiped completely after the blackboard eraser is used for a long time is prevented; through the dust absorbing mechanism, the concentrated dust can be absorbed, the air environment of a classroom can be clean and neat, influences of the dust on the eyes and the respiratory tract are lowered, and thusthe physical health of students and teachers in the learning process is guaranteed; and through the mechanisms, the practicability and safety of the device are greatly improved.

Owner:广东轩宇实业发展有限公司

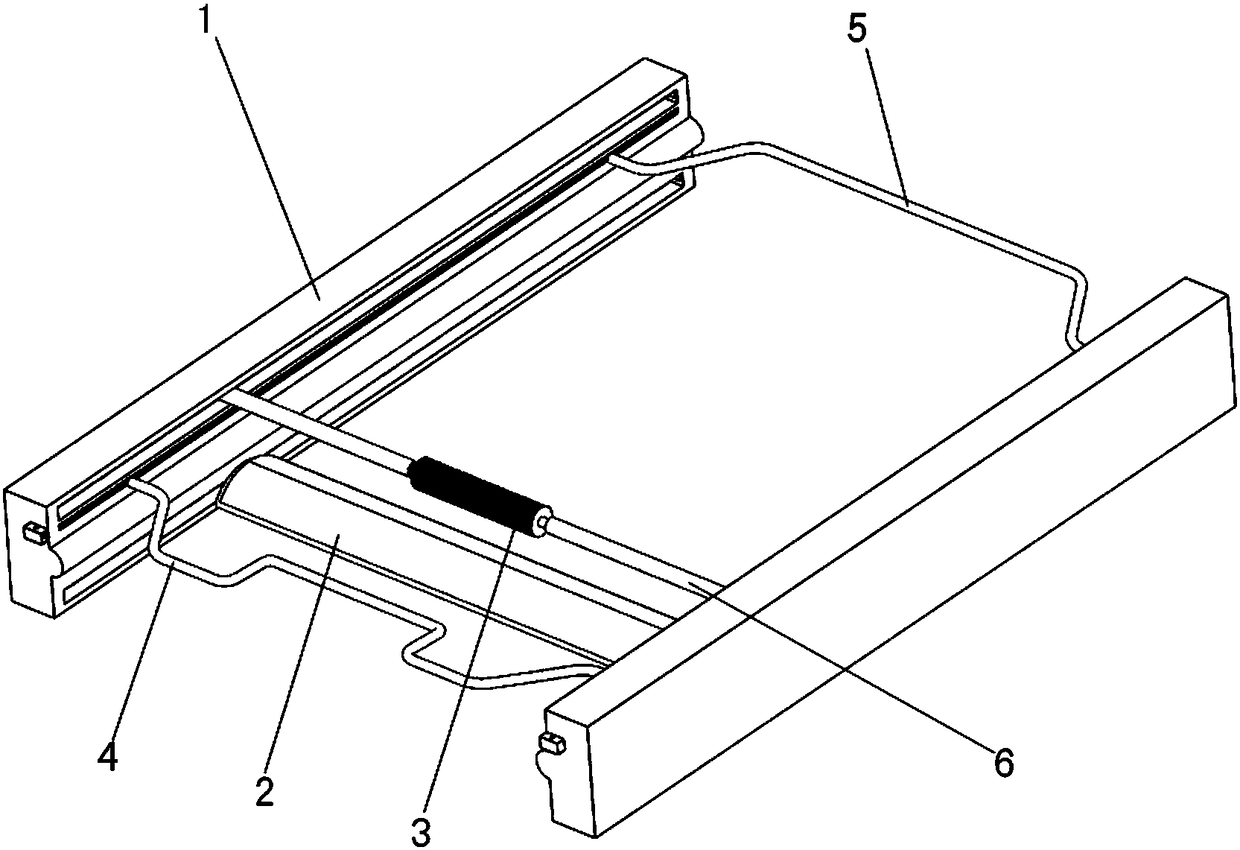

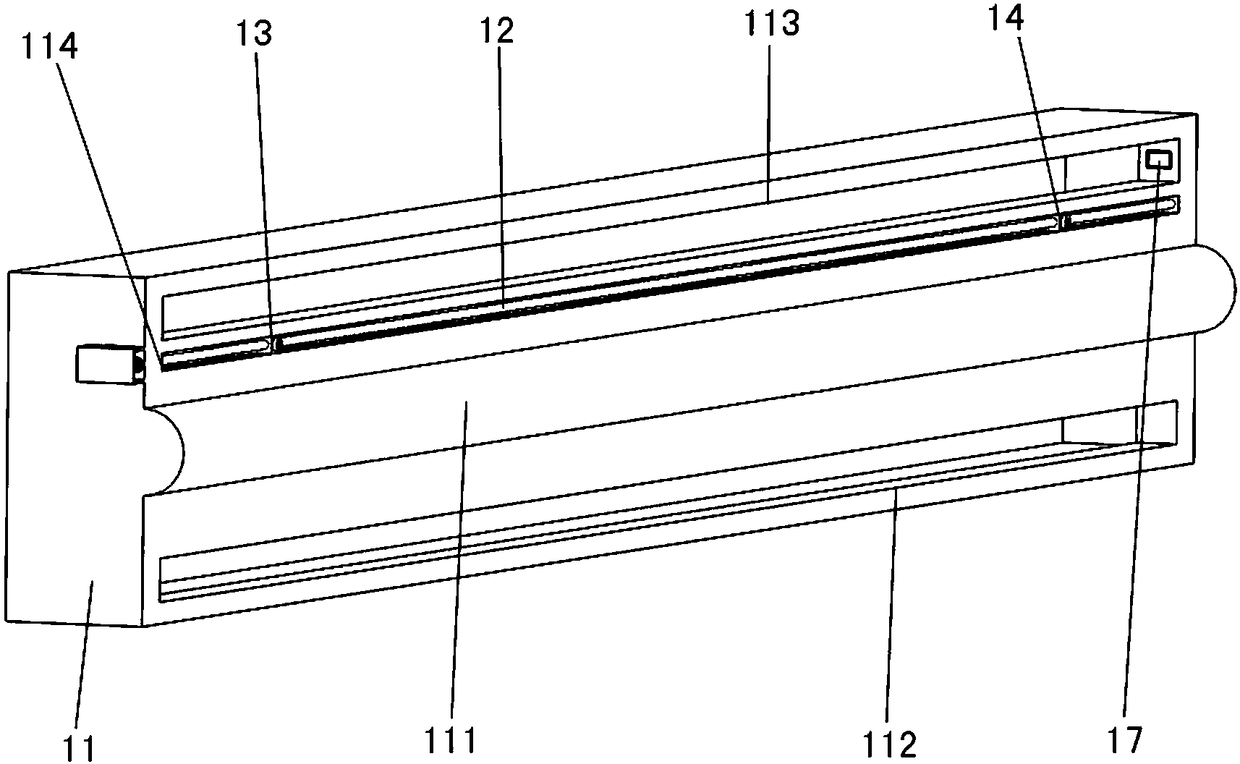

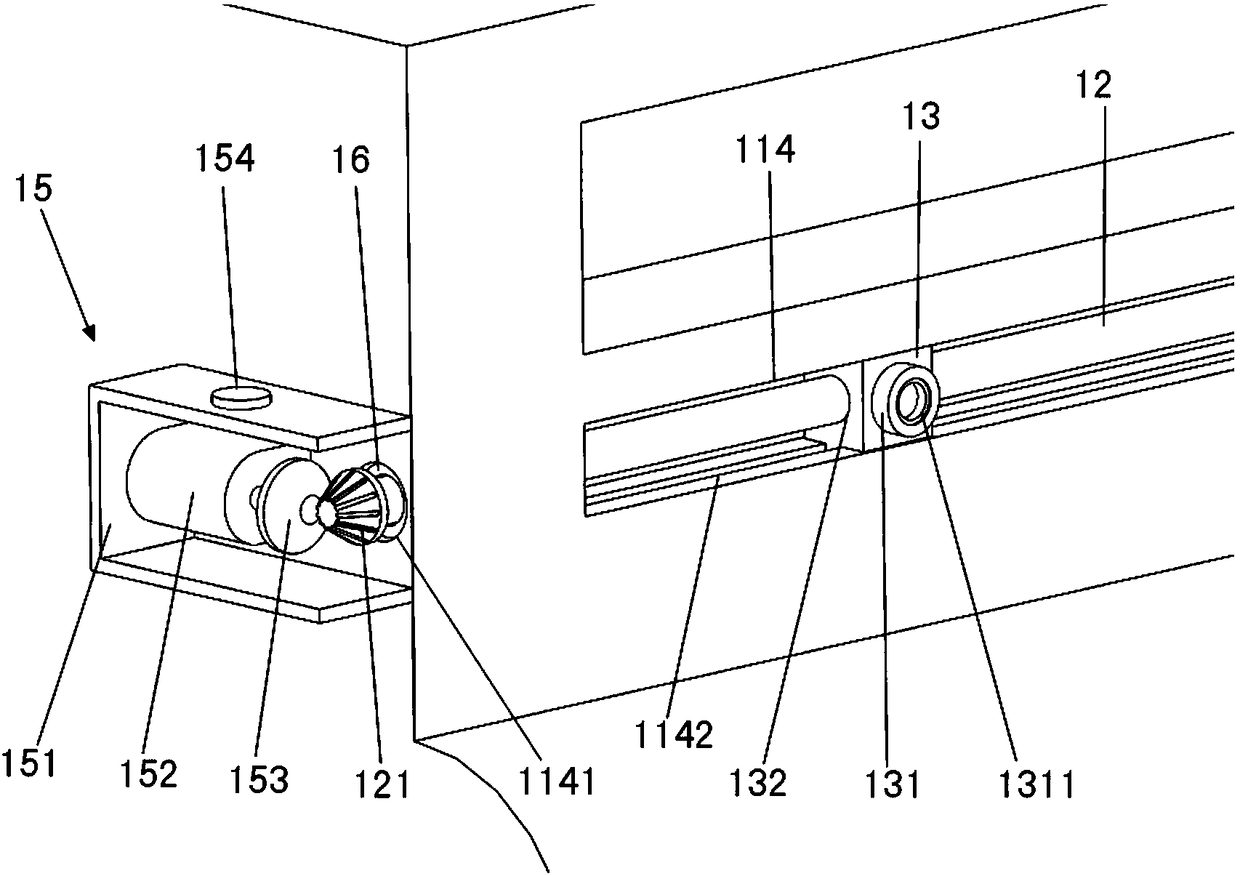

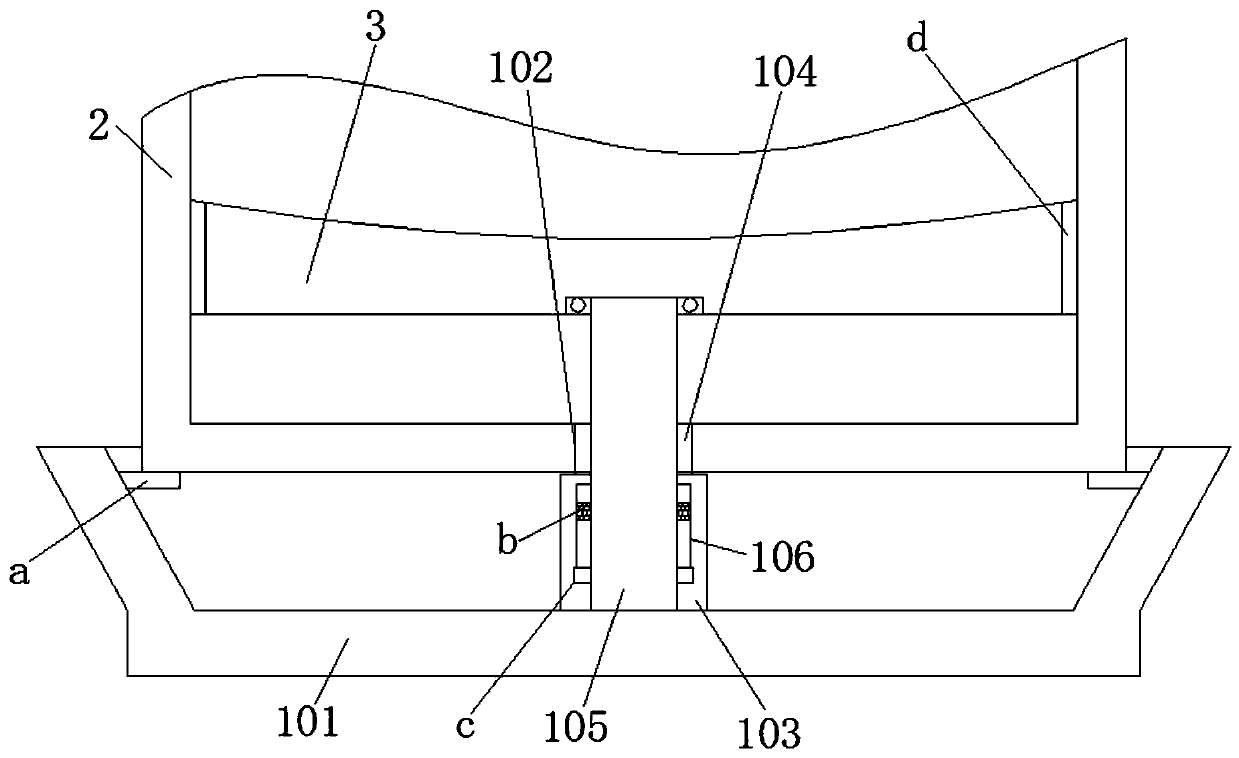

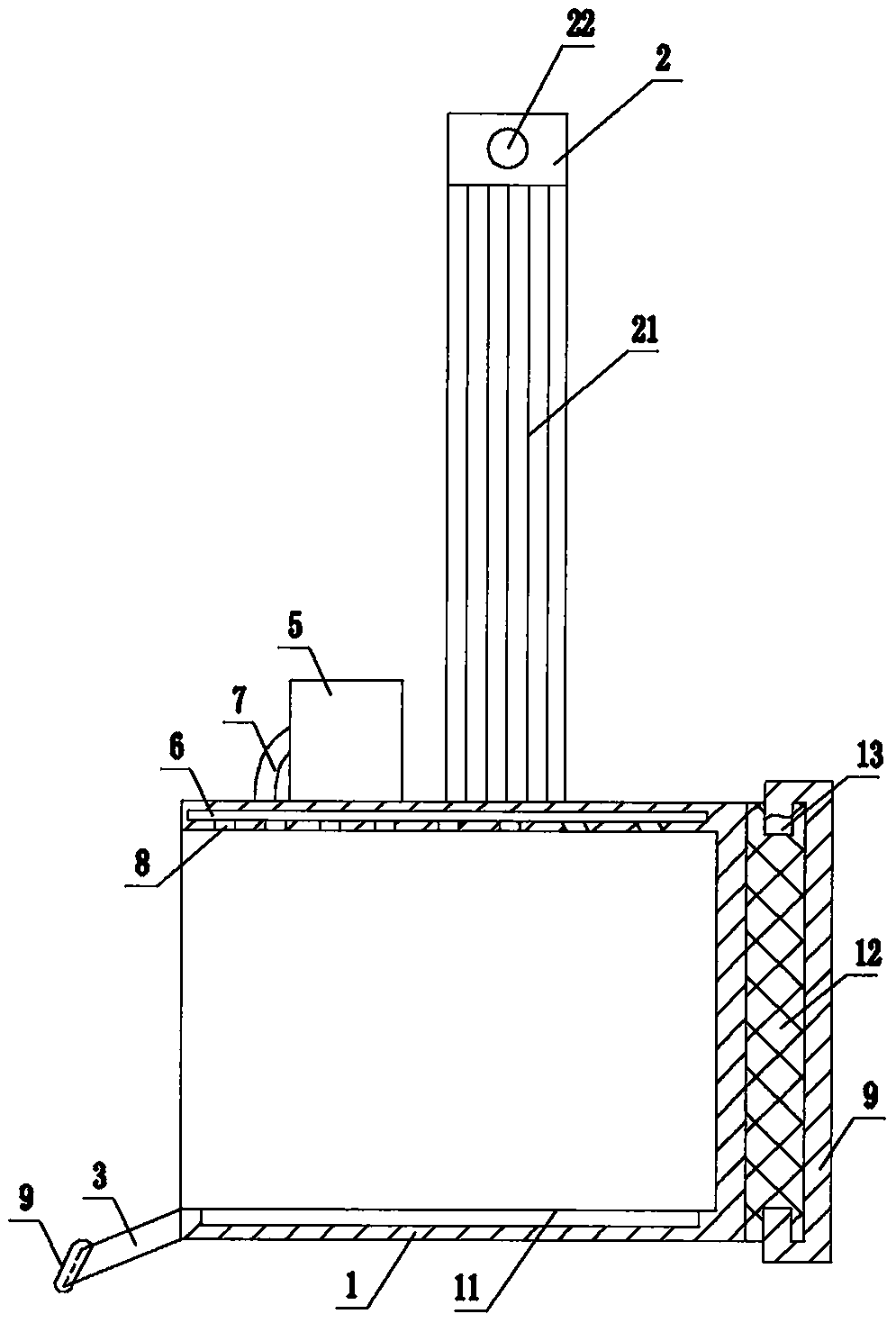

High altitude glass dust collector capable of scrubbing double sides of glass

The invention discloses a high altitude glass dust collector capable of scrubbing double sides of glass. The dust collector comprises two clamping slide seats and a fixed seat, wherein the two clamping slide seats are rotatably connected to two ends of the fixed seat and separately clamp two sides of a glass window; a mobile connecting device capable of moving automatically is arranged in each clamping slide seat; a pair of dust collecting seats is arranged between the mobile connecting devices; and a plurality of notches are formed in the bottom of the fixed seat for locking the glass window.The dust collector has the advantages that by means of the characteristics of a common glass window structure on a building at present, the two clamping slide seats are clamped in the grooves in twosides of the glass window, and by means of the structural characteristics of a switch handle of the glass window, the switch handle is locked into an inclined notch of the fixed seat, so that the whole device is fixed on the glass window; and the mobile connecting devices capable of moving automatically are arranged between the two clamping slide seats to move to drive a dust collecting seat to move so as to scrub double sides of the glass window.

Owner:HUZHOU YOUCHUANG TECH CO LTD

Tin paste printing screen plate cleaning method based on infrared high-temperature radiation

InactiveCN105082752AAvoid wipingNot subject to wear and tearPrinting press partsFree coolingEngineering

The invention discloses a tin paste printing screen plate cleaning method based on infrared high-temperature radiation. The method comprises the following steps: (1) a scraper is used for scraping a tin paste printing screen plate by at least 3 times; and the same scraping direction is kept in each scraping; (2) the scraped tin paste printing screen plate is put in a reflow welding furnace for high-temperature cleaning and low-temperature condensation; (3) the tin paste printing screen plate is put in an infrared high-temperature roaster for infrared high-temperature radiation cleaning after the operation in the reflow welding furnace; and (4) the tin paste printing screen plate is taken out from the roaster for natural cooling after the infrared high-temperature radiation cleaning, and is put in a seal packing bag for storage. The method can improve the cleaning efficiency, guarantees the cleaning quality, and prevents the use of cleaning agents.

Owner:SUZHOU ENOUXI INTELLIGENT TECH CO LTD

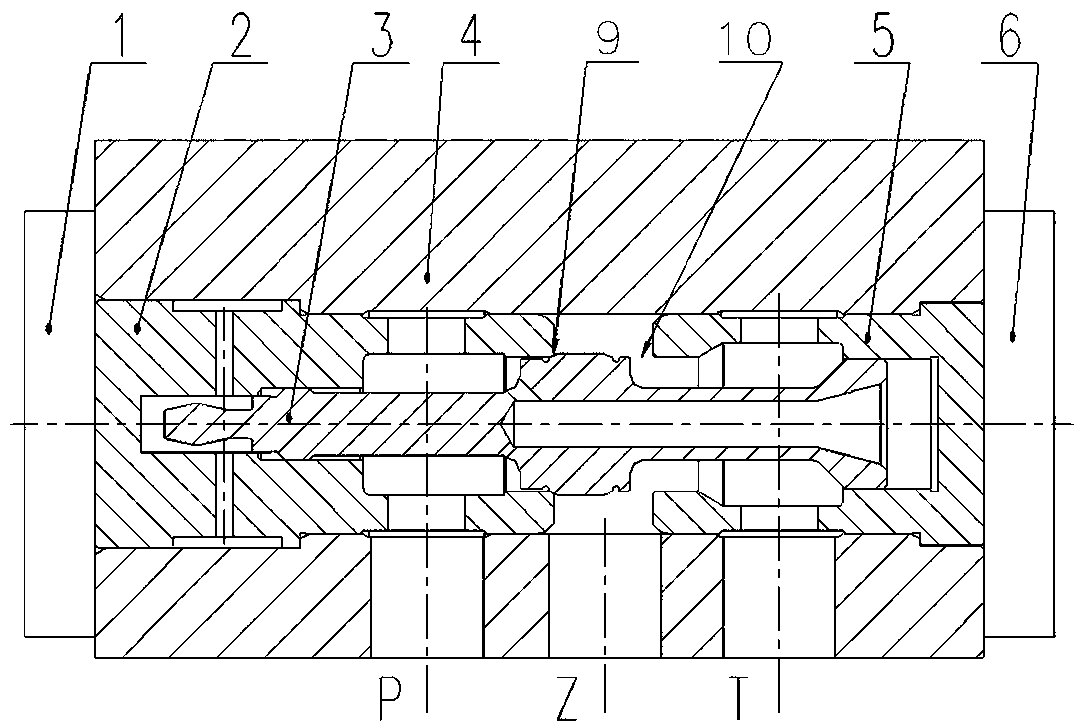

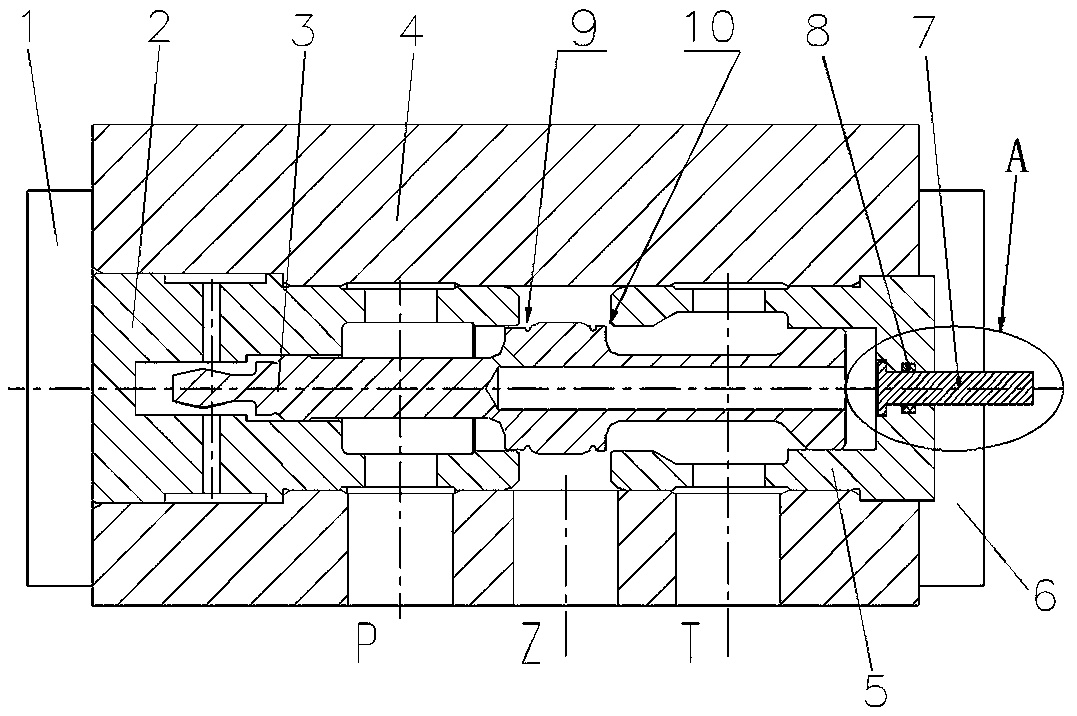

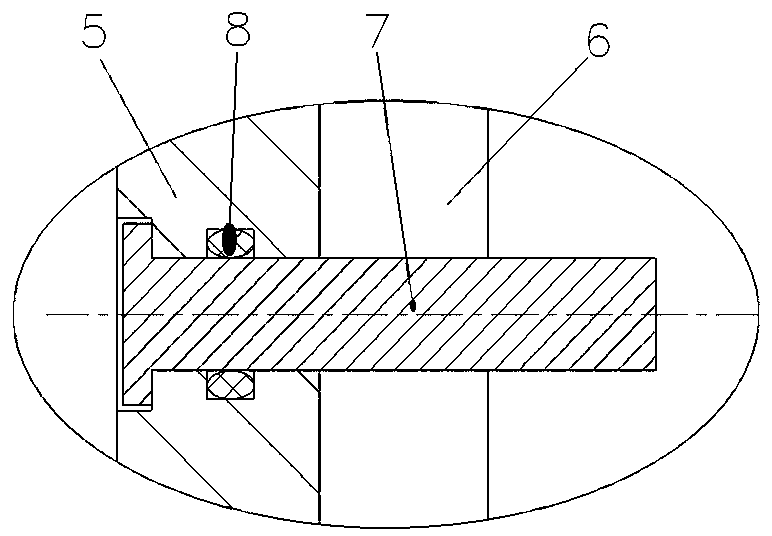

Hydraulic operating mechanism, control valve and primary valve of control valve

ActiveCN110552924AAvoid draining oilAvoid wipingServomotor componentsMultiple way valvesEngineeringControl valves

The invention relates to a hydraulic operating mechanism, a control valve and a primary valve of the control valve. The control valve comprises the primary valve and a secondary valve arranged on theprimary valve. The primary valve comprises a primary valve body and a primary valve element arranged in the primary valve body. The position, corresponding to the end of the primary valve element, ofthe primary valve body is provided with an operating rod penetration hole allowing an operating rod to penetrate through so as to drive the primary valve element to move. The primary valve further comprises a blocking part used for blocking the operating rod penetration hole. In case of misoperation, when the primary valve element does not move to the right position and two primary valve ports arenot blocked, the blocking part is dismantled, the operating rod penetration hole is opened, the operating rod is inserted into the primary valve to drive the primary valve element to motion to blockthe primary valve element on one side, and the system stores energy again. Thus, when maintained, the control valve does not need to be dismantled from the mechanism, operations such as oil drainage,oil injection, wire connection, cleaning and wiping are avoided, and the working efficiency is greatly improved.

Owner:PINGGAO GRP +2

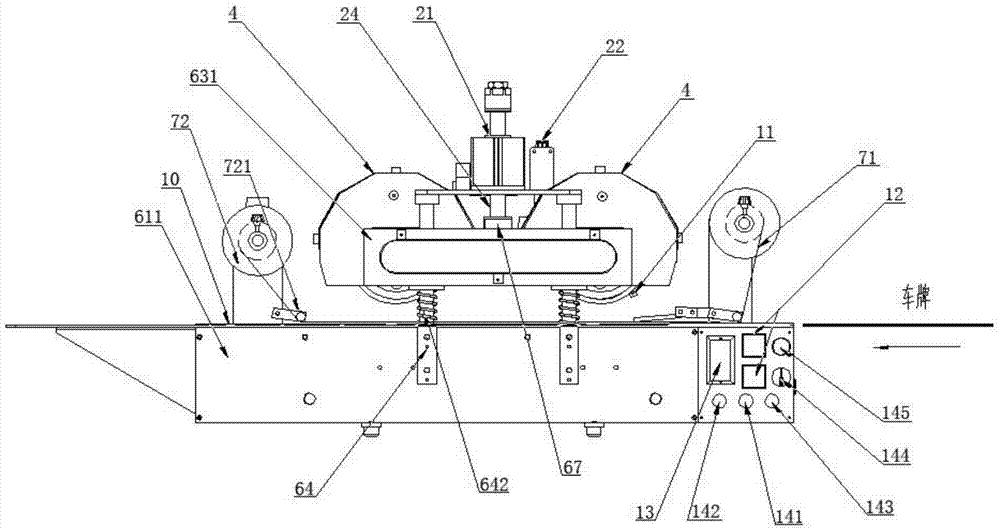

Equipment capable of quickly printing license plate

The invention relates to equipment capable of quickly printing a license plate. The equipment comprises a control system, a driving and driven wheel set, heaters, a pneumatic component, a power motor and a rack structure, wherein the control system is used for controlling temperature, speed and all switches; the pneumatic component is used for automatically lifting driving wheels; the rack structure comprises a side plate, a bedplate, sliding bases, a guide post and a steel plate and is used for supporting and fixing; the driving and driven wheel set comprises two driving wheels and two driven wheels, the driving wheels are respectively arranged between the front sliding base and the back sliding base, and the driven wheels are used for supporting the license plate and roll along with the forward movement of the license plate; the heaters surround columns of the driving wheels and are used for heating the driving wheels. According to the equipment, a heat transfer printing mode is used, so that license plate characters on a heat transfer printing film are heated by the heaters and then are covered on the license plate, thereby preventing human bodies and environment from being influenced by printing ink and omitting the steps of wiping, cleaning and drying.

Owner:HANZHOU YINGTIAN SCI INSTR

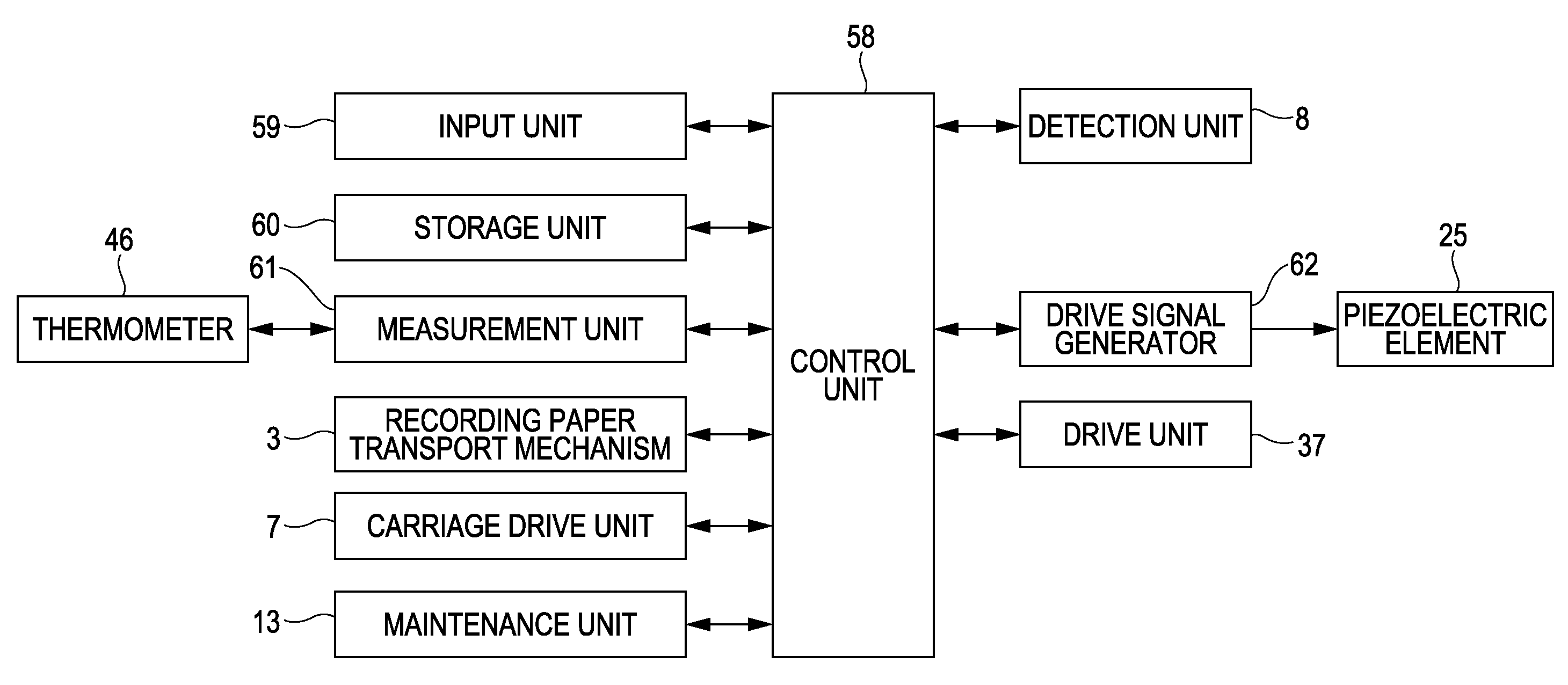

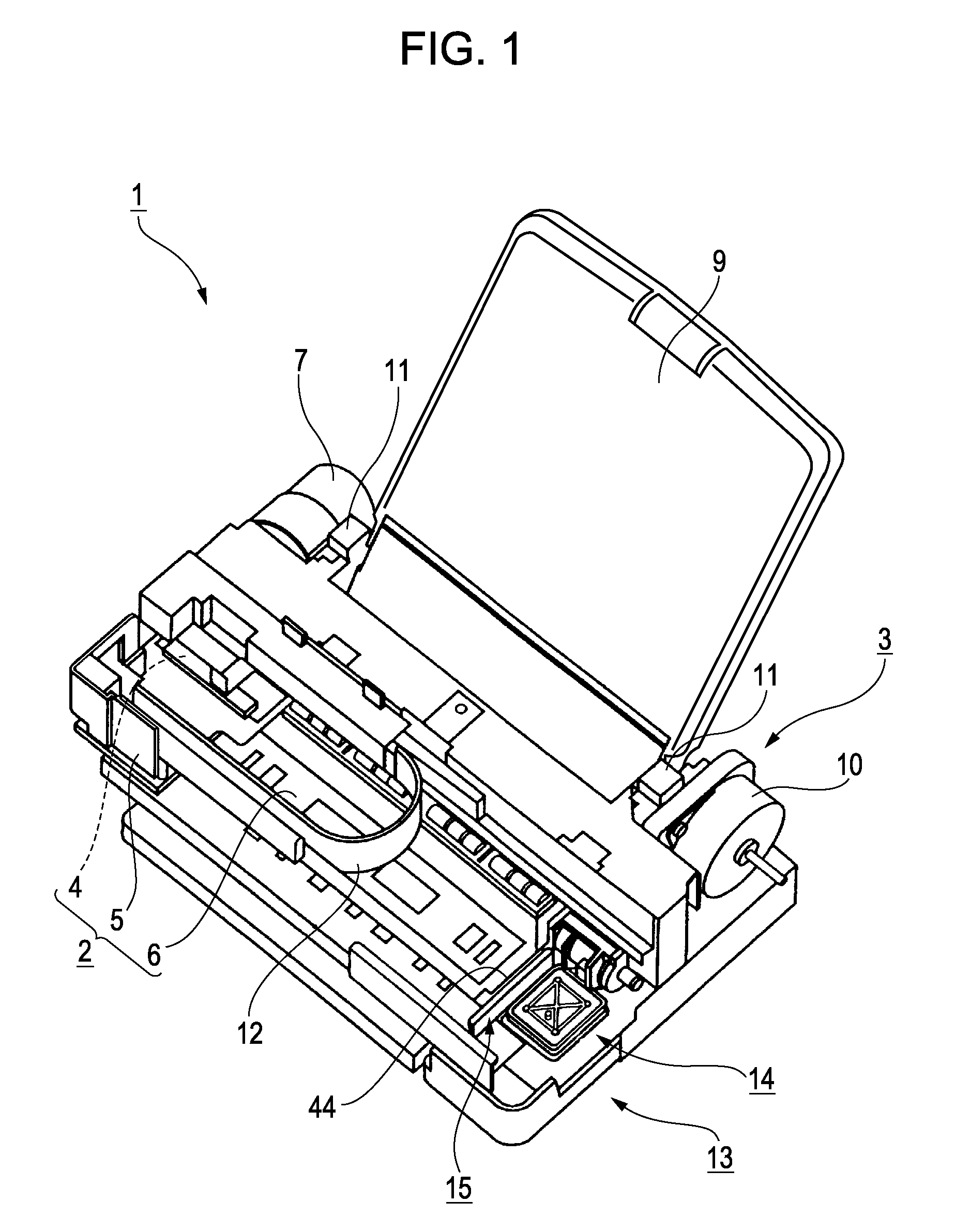

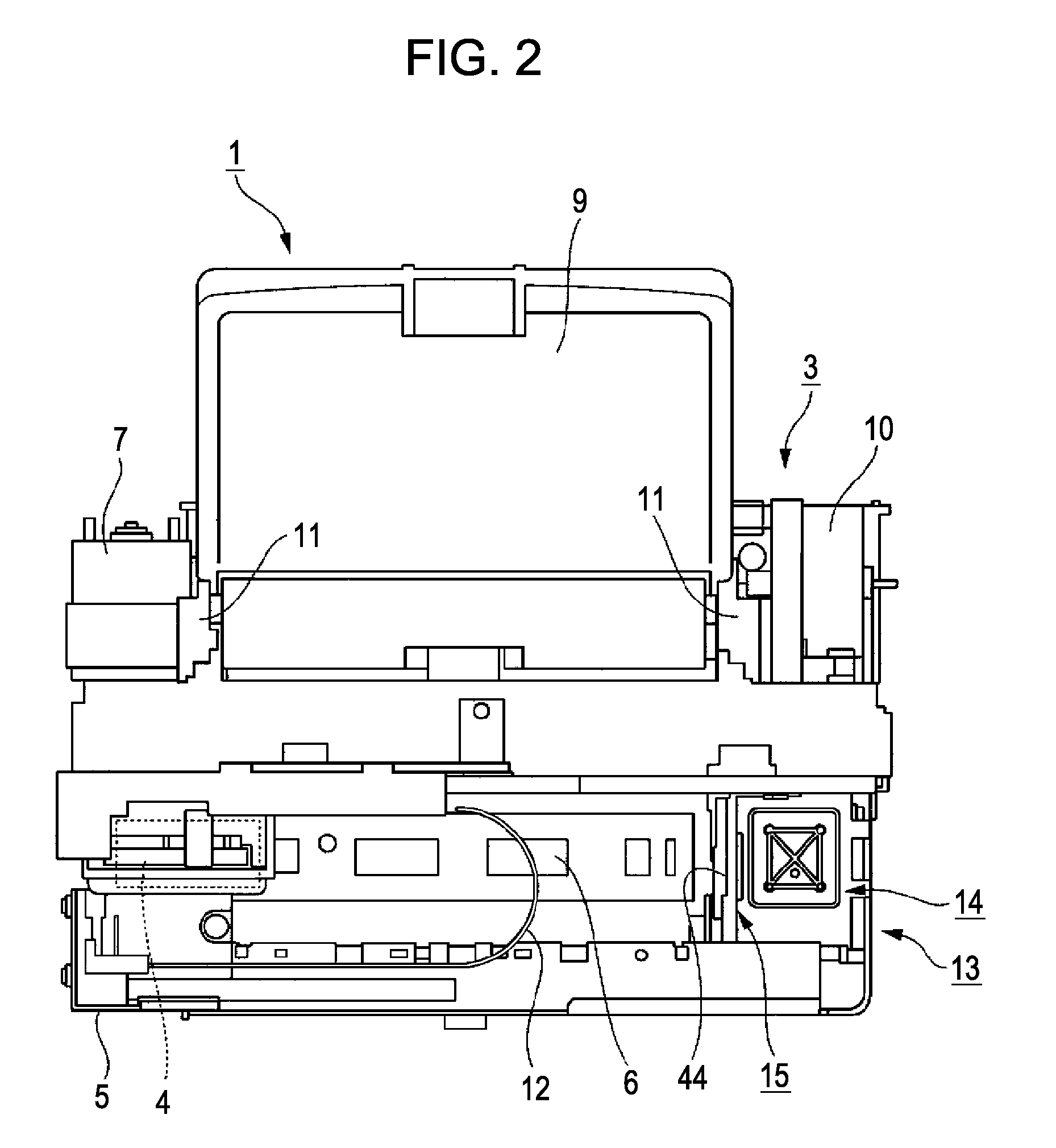

Fluid ejecting apparatus and ejecting head maintenance method

A method for maintaining a fluid ejecting apparatus including an ejecting head that has an ejecting surface in which a plurality of ejecting ports that eject fluid are formed, and a maintenance portion that performs maintenance processing to recover the ejection of fluid from the ejecting ports and that has a cap member and a wiping member. The method includes performing capping processing to put the cap member on the ejecting surface and to suck, and then wiping processing to wipe the ejecting surface with the wiping member, and performing the capping processing again and then waiting a predetermined time without performing the wiping processing.

Owner:SEIKO EPSON CORP

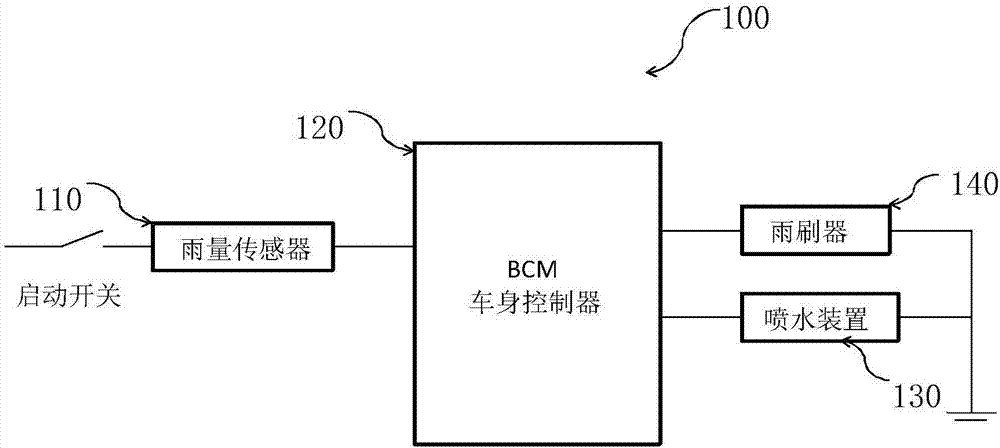

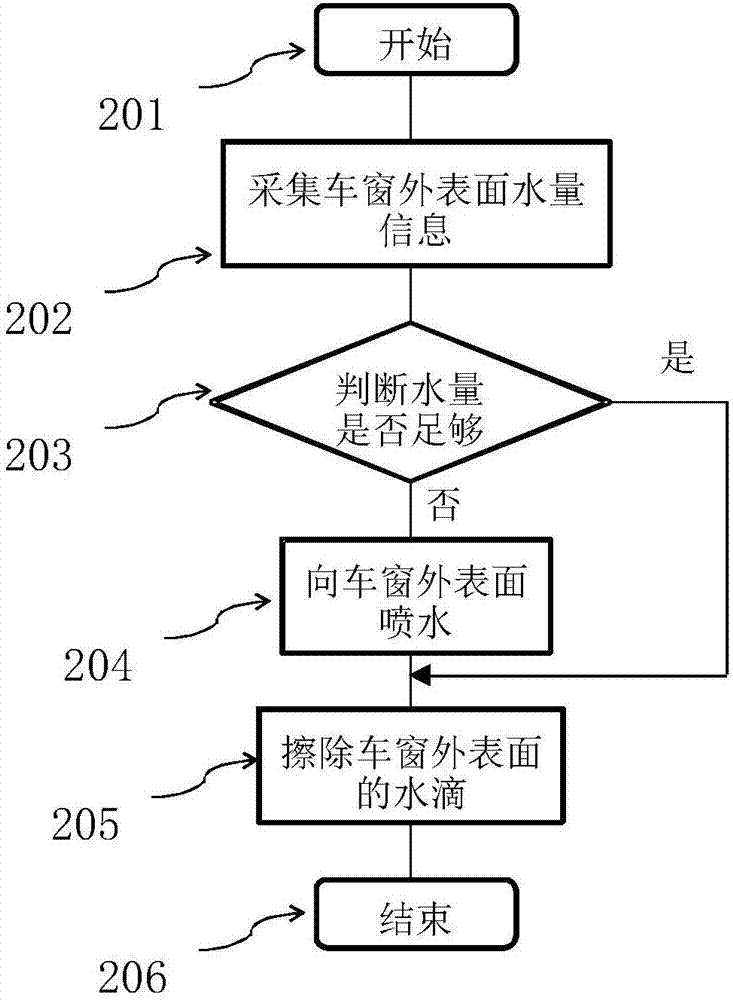

Wiper control system and wiper control method

The invention provides a wiper control system and a wiper control method and relates to the wiper control system and the wiper control method which can prevent dry brushing. The wiper control system comprises a rain sensor, a controller, a water injector and a wiper; the wiper control system is used for collecting water yield information of the outer surface of a car window; the controller is configured to judge whether water yield is sufficient or not according to the water yield information, a water injection instruction is sent out when the water yield is insufficient, and a wiping instruction is sent out when the water yield is sufficient; the water injector is used for injecting water to the outer surface of the car window according to the water injection instruction of the controller; the wiper is used for wiping out water drops on the outer surface of the car window according to the wiping instruction of the controller. The wiper control method includes: collecting the water yield information of the outer surface of the car window; judging whether the water yield is sufficient or not according to the water yield information, injecting the water to the outer surface of the car window when the water yield required by the outer surface of the car window in insufficient, and wiping out the water drops on the outer surface of the car window when the water yield required by the outer surface of the car window is sufficient. By the arrangement, dry brushing of the wiper can be avoided, and service life of the wiper is prolonged.

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

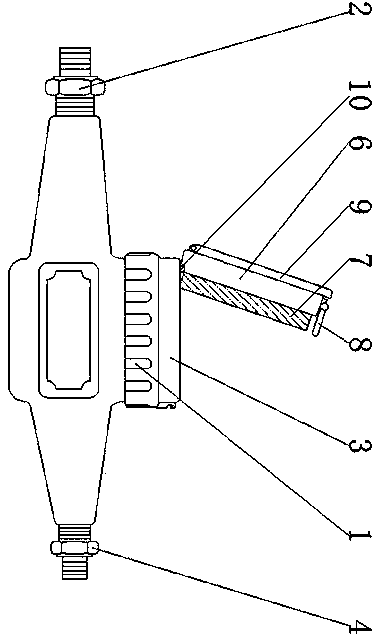

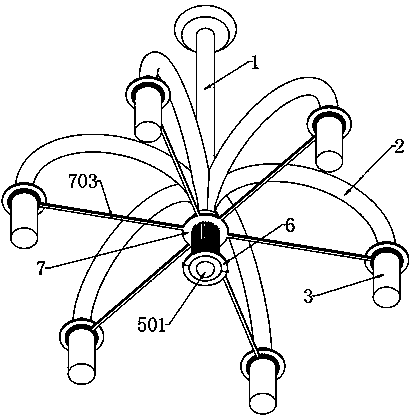

Reaction kettle washing device

ActiveCN107214153AReduce generationPlay the role of wipingHollow article cleaningUniversal jointSemi automatic

The invention relates to a reaction kettle washing device comprising a handheld rod. The rear end of a pneumatic motor is fixedly connected with the handheld through a universal joint, a high-pressure hose is arranged in the handheld rod, and the bottom end of the high-pressure hose is connected with an air inlet of the pneumatic motor; a fixing plate is fixedly arranged at the output shaft end of the pneumatic motor, and a scouring pad is arranged on the fixing plate; the handheld is arranged on an adjusting mechanism for adjusting the angles of the pneumatic motor and the handheld rod, and the adjusting mechanism comprises three or more second pull lines which are arranged along the handheld rod; one ends of the second pull lines are fixedly connected with the front end of the pneumatic motor, and the other ends of the second pull lines are placed at the top end of the handheld rod in an extending mode and provided with pull rings; and the corresponding second pull lines are pulled and dragged through the pull rings to enable the included angle of the pneumatic motor and the handheld rod to be changed. According to the device, wiping and washing operation of the inner wall of a semi-automatic reaction kettle is achieved, the situation that an operator goes into the kettle for wiping can be avoided to a certain extent, the labor intensity is relieved, safe operation of the operator is ensured, and the risks of reaction kettle washing are reduced.

Owner:武穴融泰医药科技有限公司

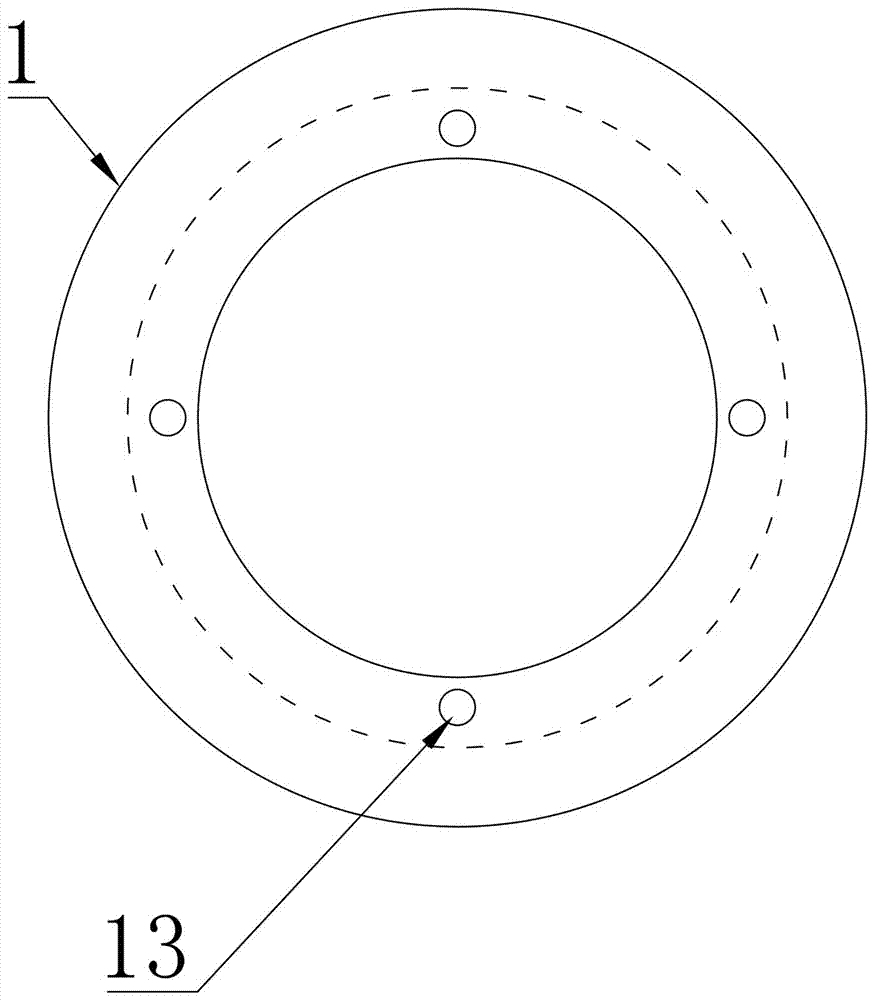

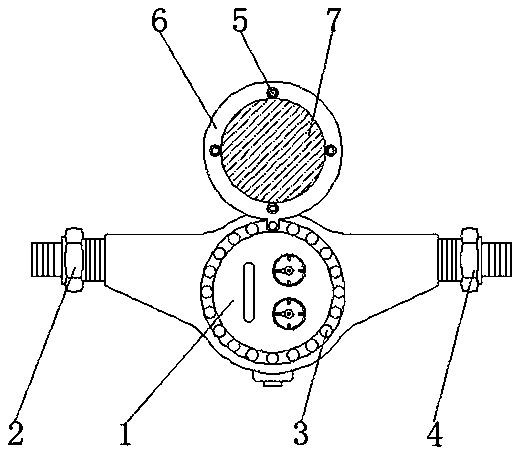

Internet of Things water meter

InactiveCN110715702AObserve clearlySlow down the phenomenon of freezingVolumetric apparatus damage preventionThe InternetHydrology

The present invention belongs to the technical field of Internet of Things, and particularly is an Internet of Things water meter. The Internet of Things water meter comprises a water meter body and an instrument panel installed on the water meter body. A water outlet pipe is installed at one end of the instrument panel, and a water inlet pipe is installed at the end of the instrument panel far away from the water outlet pipe. A bearing is installed on the top of the instrument panel, an iron frame sleeve is installed above the bearing, and the iron frame sleeve and the bearing are rotatablelyconnected by using a spindle. When dust on glass outside the instrument panel needs to be cleaned, the bearing can be first rotated, so that the iron frame sleeve drives a sponge mat to make frictionmotion on the glass of the instrument panel, and dust and stains on the glass of the instrument panel are removed through friction of the sponge mat. The foregoing operation can help a worker observefigures on the instrument panel more clearly. A spiral electric furnace heating wire inside a heating plate converts electric energy into heat energy. Then, a temperature of the sponge mat around theiron frame sleeve and a temperature of the water meter rise through heat conduction. In this way, a freezing phenomenon inside the water meter can be reduced, and normal use of the water meter is ensured.

Owner:YANCHENG INST OF IND TECH

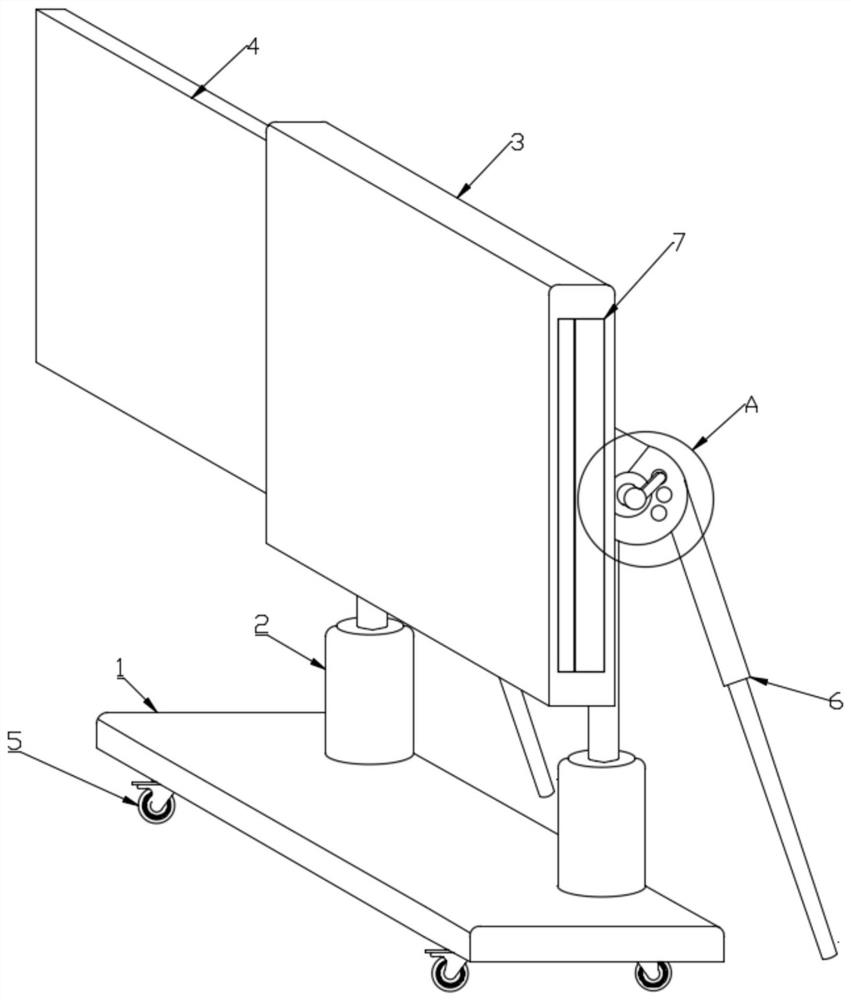

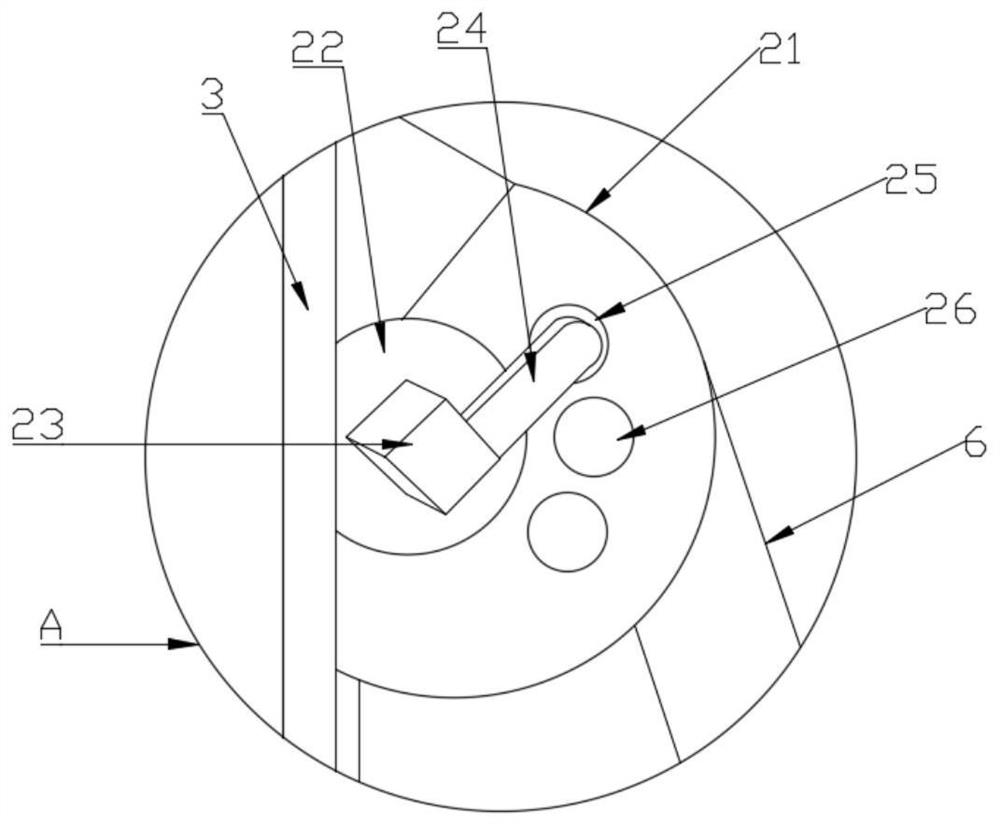

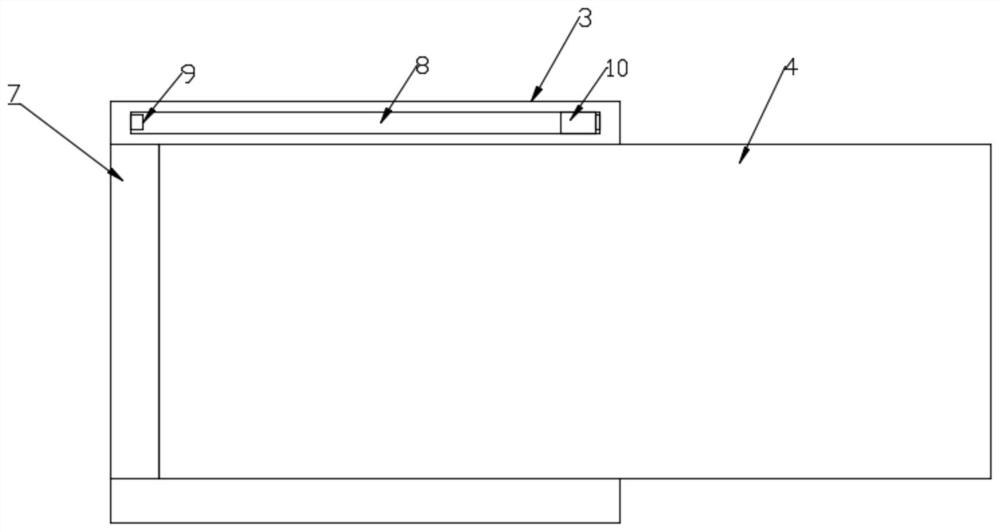

Display device for managing accounting teaching

PendingCN112419842AHigh degree of automationAvoid wipingTeaching apparatusFeetEngineeringDisplay device

The invention discloses a display device for management accounting teaching. The device comprises a base, a display board and a writing board. Two air cylinders are fixedly installed on the base, thetops of telescopic rods of the two air cylinders are fixedly connected with a fixing frame, and the display board is installed on the fixing frame through an angle adjusting mechanism. The writing board is installed in a through groove formed in the display board in a sliding mode, and a wiping mechanism acting on the writing board and a control mechanism acting on the wiping mechanism are installed in the display board. During use, the angle of the display board and the angle of the writing board can be adjusted through the angle adjusting mechanism, so that the device can be suitable for more occasions; when the writing board is filled with the content, only the end, filled with the content, of the writing board needs to be inserted into the through groove, the end, not filled with the content, of the writing board can extend out of the other end of the through groove, meanwhile, the control mechanism can be triggered, the wiping mechanism begins to wipe the writing board, and therefore, a user is prevented from frequently wiping the writing board.

Owner:JIAMUSI UNIVERSITY

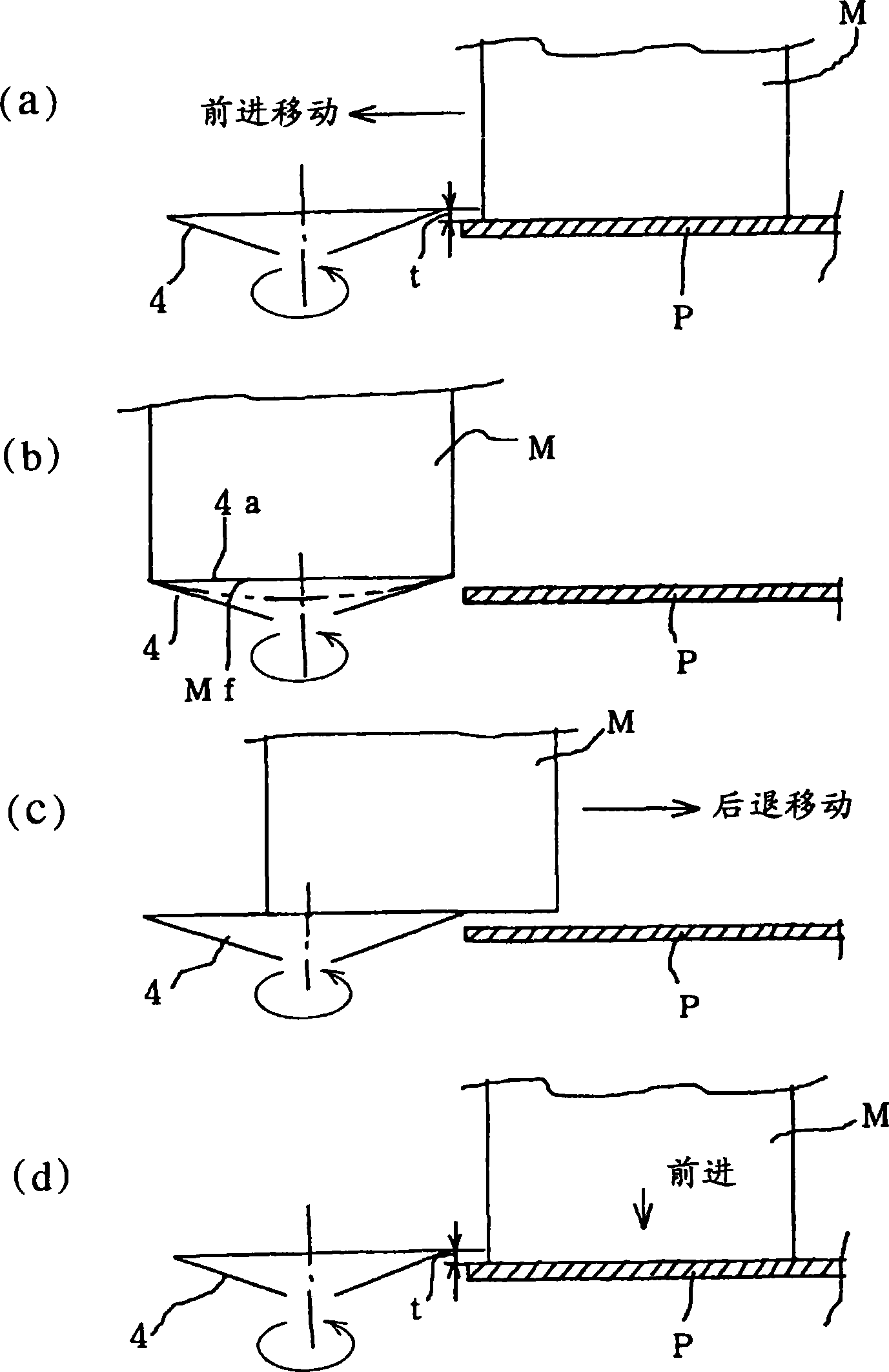

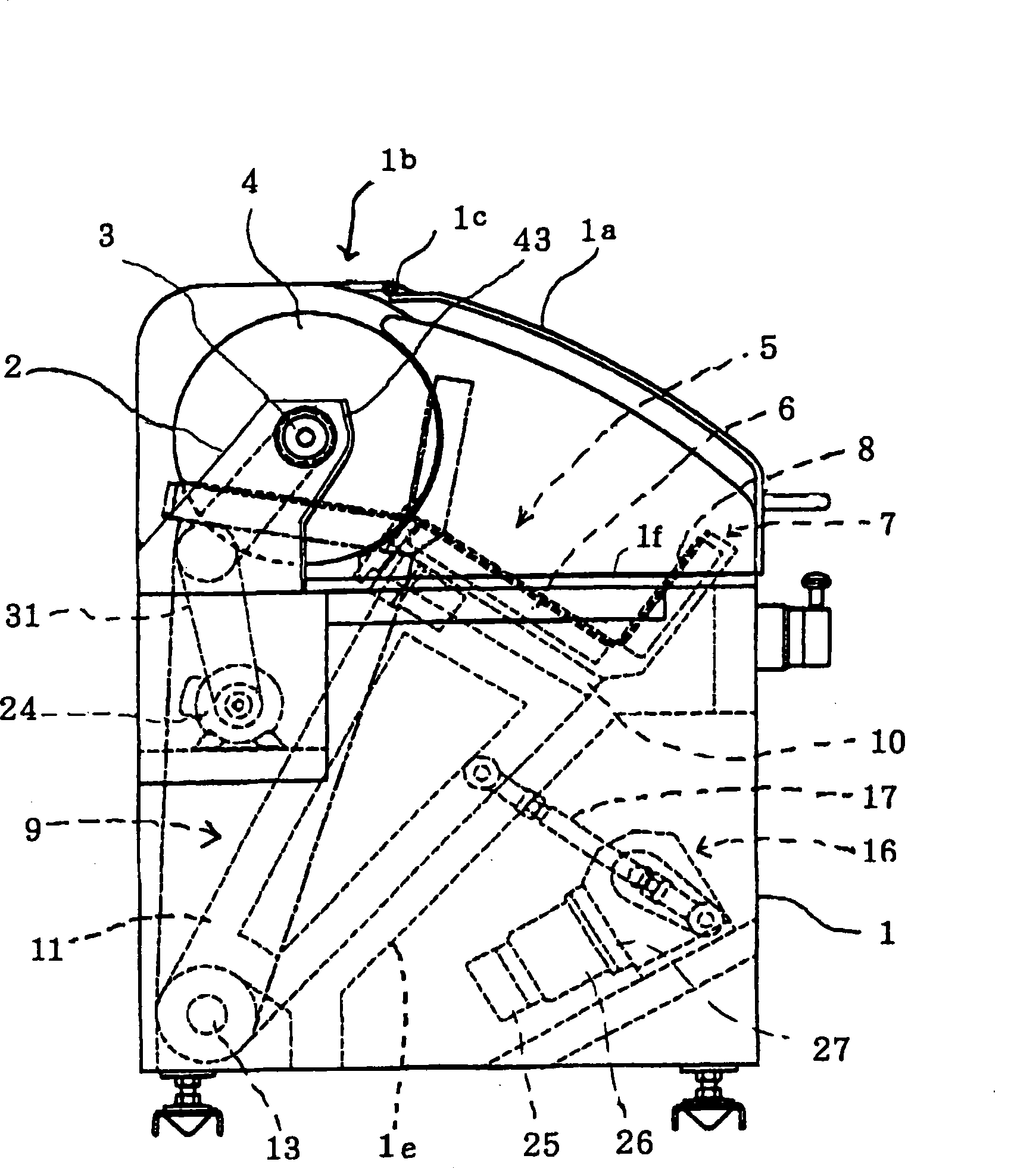

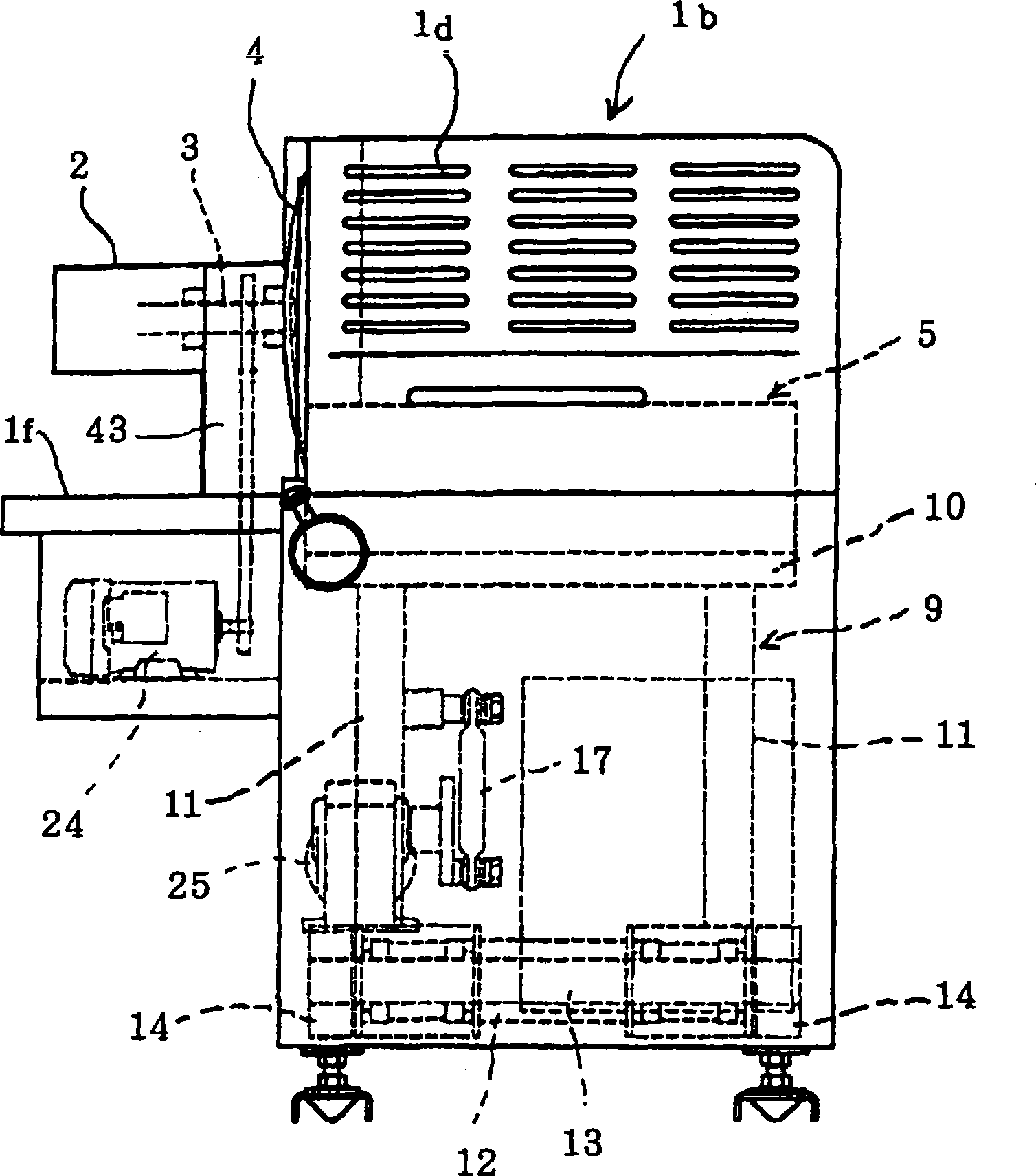

Slicer for edible meat with round cutter

InactiveCN101456190AReduce wipingWon't hurtMetal working apparatusMeat processing devicesEngineeringFlesh

The invention provides a meat slicing machine easily suitable for meat slicing machine with a cutting disc, capable of easily reducing the meat scrap on the cutting disc and obtaining the sliced meat with beautiful surface. The meat slicing machine comprises a cutting disc (4) capable of slicing the meat by the axial recession and rotation along the axle, and a meat box (5) for loading the meat to be sliced and capable of reciprocating relative to the cutting disc; the meat is sliced when the meat box moves towards; wherein the meat box arrives at the terminal position of the forwards movement when the meat is sliced, and the cutting disc recesses by a preset distance towards the direction apart from the slicing surface of the meat, and then the meat box recesses to the initial terminal and the cutting disc returns to the initial slicing position and then the meat is transferred by the meat box and the meat is sent out according to the amount of the slicing thickness (t).

Owner:NIHON CAREER IND CO LTD

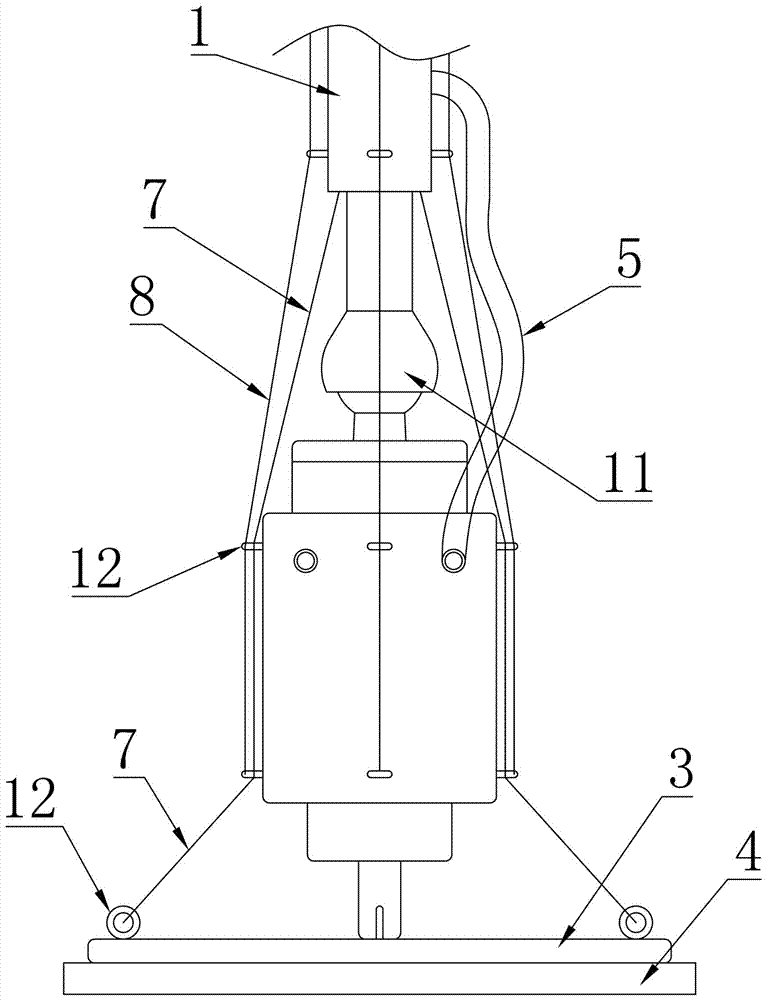

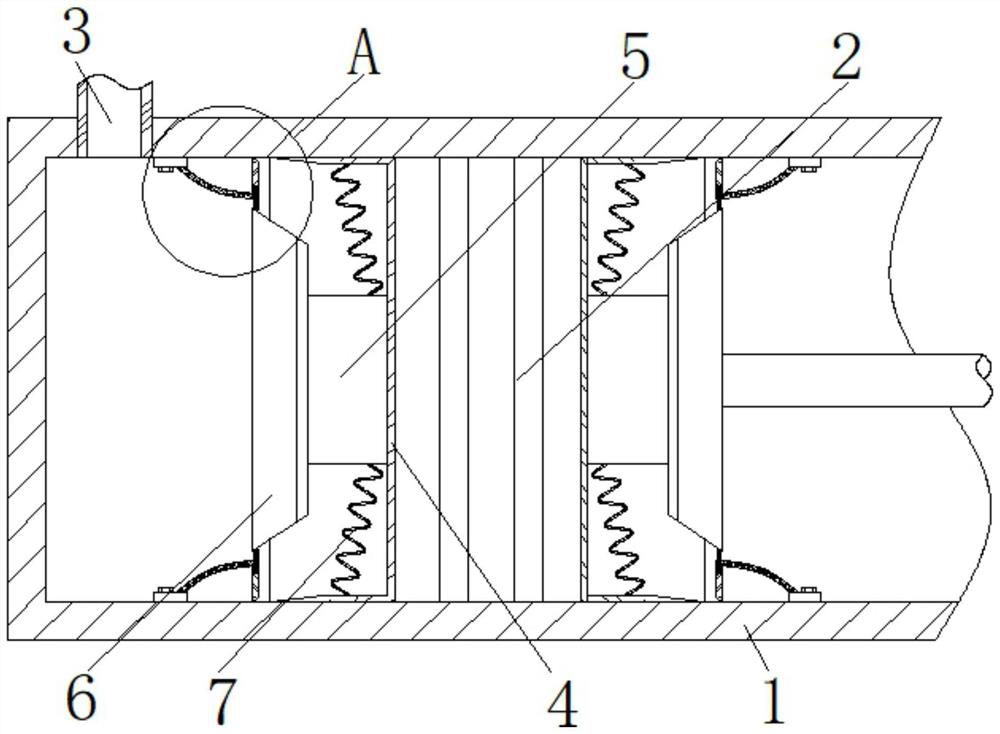

Hydraulic hoist for water conservancy

InactiveCN112943736AExtended service lifeAvoid internal leakage problemsHollow article cleaningFluid-pressure actuatorsPistonGeotechnical engineering

The invention relates to the technical field of hydraulic hoists, and discloses a hydraulic hoist for water conservancy. The hydraulic hoist comprises a hydraulic cylinder, a piston body is movably sleeved with the hydraulic cylinder, an oil inlet and outlet is fixedly connected to the top end of the hydraulic cylinder, bowl-shaped scraping rings are fixedly connected to two sides of the piston body correspondingly, and a fixed base is fixedly connected to one side of each bowl-shaped scraping ring. A fixed block is fixedly connected to one side of each fixed base, springs are evenly distributed on the outer portion of the fixed bases in the circumferential direction, and the other ends of the springs are fixedly connected with the interiors of the bowl-shaped scraping rings. The piston body drives the bowl-shaped scraping rings to scrape impurities attached to the inner wall of the hydraulic cylinder, the fixed blocks collect the impurities attached to the inner wall while removing the impurities on the inner wall through the magnetic action between elastic air bags and movable heads, due to the position arrangement of the bowl-shaped scraping rings, the condition that the impurities enters a piston and abrades the piston part is avoided, the service life of the piston part is prolonged, and the problem of inner leakage caused by abrasion is avoided.

Owner:张伟霞

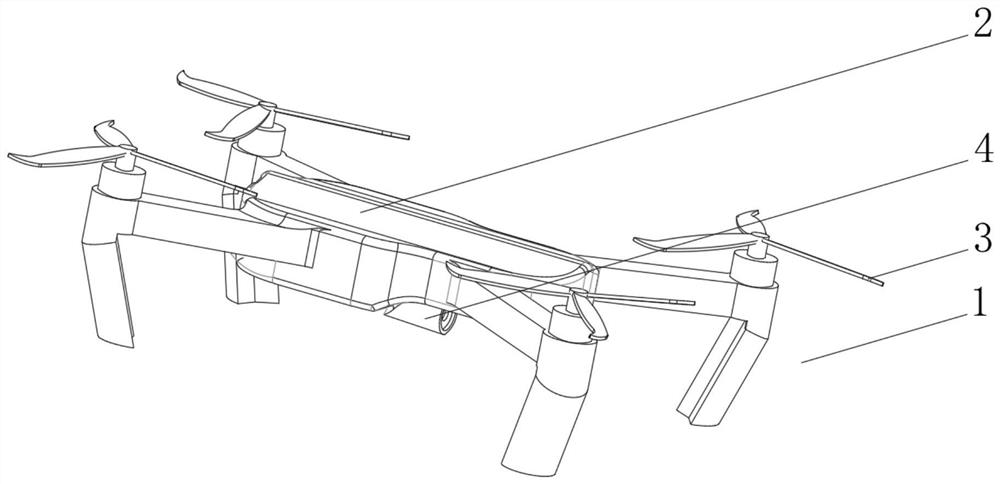

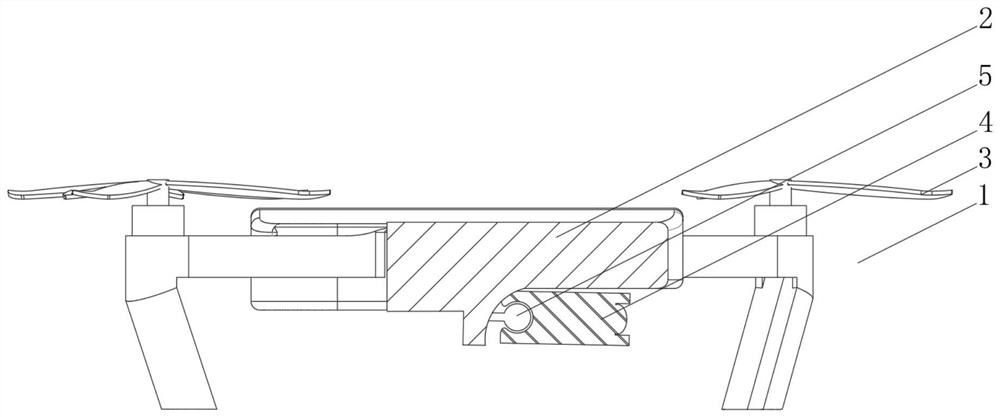

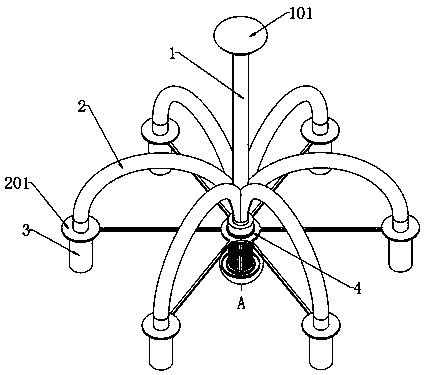

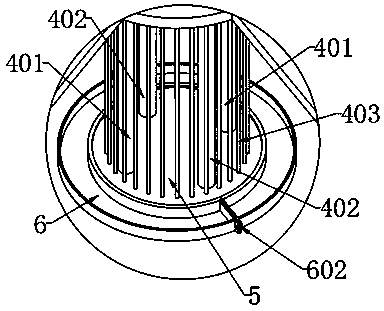

Unmanned aerial vehicle capable of cleaning lens

InactiveCN113102379AMeet needsPlay a supporting roleAircraft componentsCleaning using gasesAutomotive engineeringAerospace engineering

The invention discloses an unmanned aerial vehicle capable of cleaning a lens, and relates to the technical field of unmanned aerial vehicles. The unmanned aerial vehicle comprises an unmanned aerial vehicle body capable of cleaning the lens composed of a vehicle body, wings and a camera shooting mechanism, the top of the vehicle body is rotationally connected with the bottoms of the wings through rotation of a rotating rod, the bottom of the vehicle body is rotationally connected with the top of the camera shooting mechanism through a debugging mechanism, the camera shooting mechanism comprises a camera shooting plate, a micro air blower is fixedly connected to the interior of the camera shooting plate, and the bottom of the micro air blower communicates with an air heater through a vent pipe. According to the unmanned aerial vehicle capable of cleaning the lens, the problems that when a traditional unmanned aerial vehicle is used, in order to obtain high-definition image quality, a protective cover is generally not adopted, during low-altitude operation, the lens is prone to being stained with rainwater, dust and grass clippings, normal shooting of the lens is hindered, thin ice is more prone to being formed on the surface of the lens in winter, the shooting process is seriously affected, manual cleaning is inconvenient, and return cleaning is needed are solved.

Owner:王志强

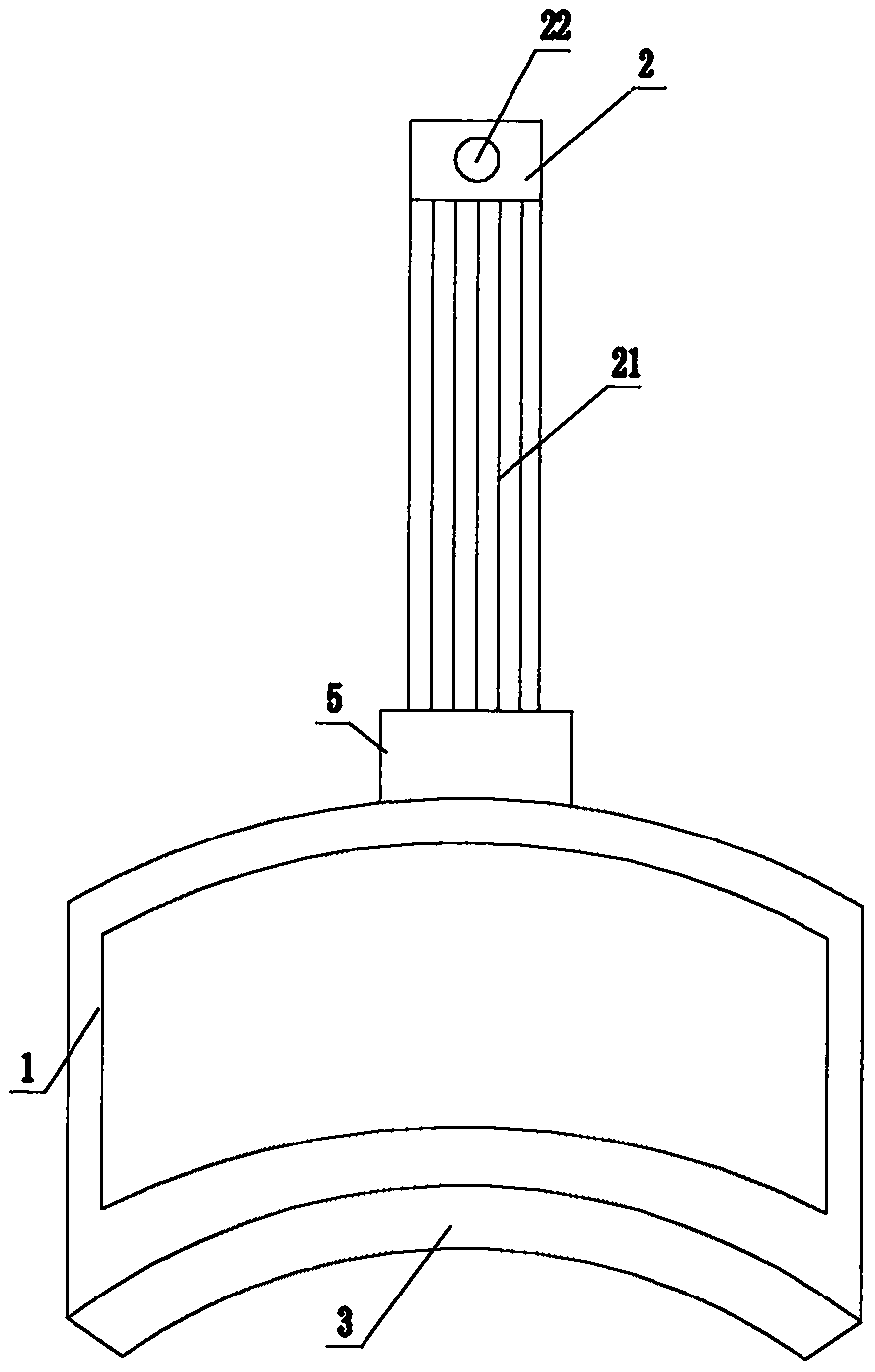

Full-automatic aerial glass dust remover

The invention discloses a full-automatic aerial glass dust remover, comprising two pinch sliding bases that hold a glass window from its two sides respectively. Moving connection devices that are freely movable are arranged in the pinch sliding bases. An adjusting handle and a dust removal seat are arranged between the moving connection devices. A positioning device is arranged in each pinch sliding base; each positioning device includes a screw and two sliding seats; positioning rods are hinged to the sliding seats. The full-automatic aerial glass dust remover has the advantages that the characteristic that a common glass window structure on an existing building is utilized; the two pinch sliding bases are held in channels in two sides of the glass window and are clamped in a window framearound the glass window through the two flexible positioning rods; the moving connection devices freely movable, the adjusting handle and the dust removal seat are arranged between the two pinch sliding bases, tightness between the pinch sliding bases and the glass window is adjusted through the adjusting handle, the moving connection devices can be moved to drive the dust removal seat, and accordingly, exterior glass is wiped.

Owner:HUZHOU YOUCHUANG TECH CO LTD

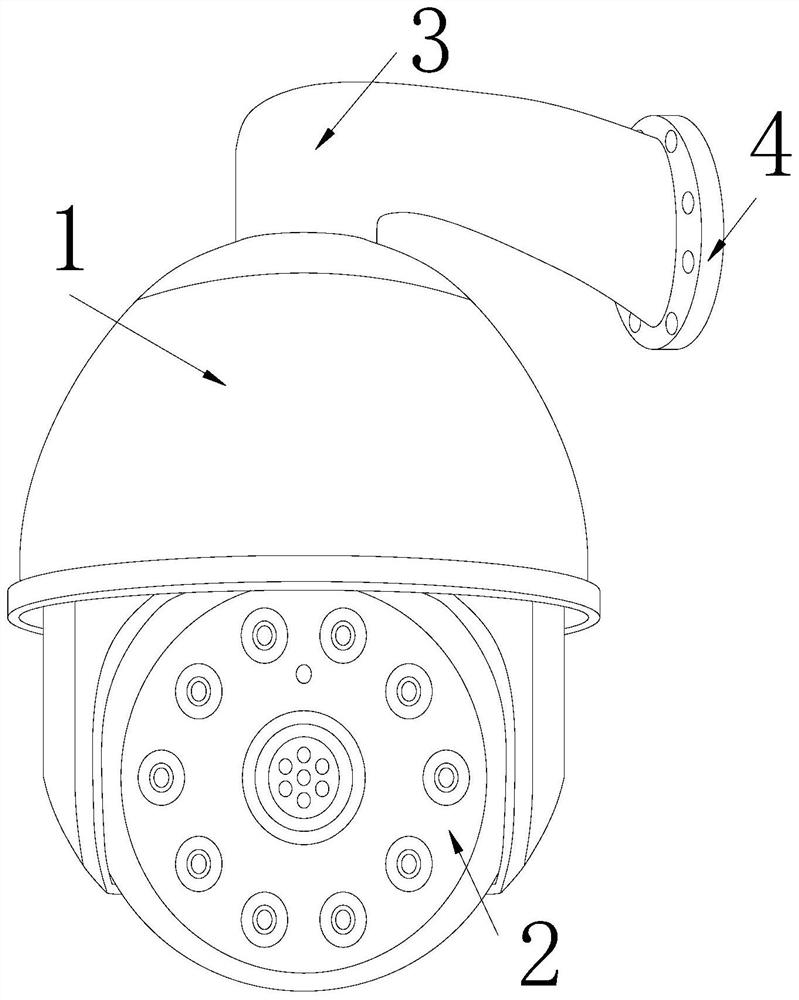

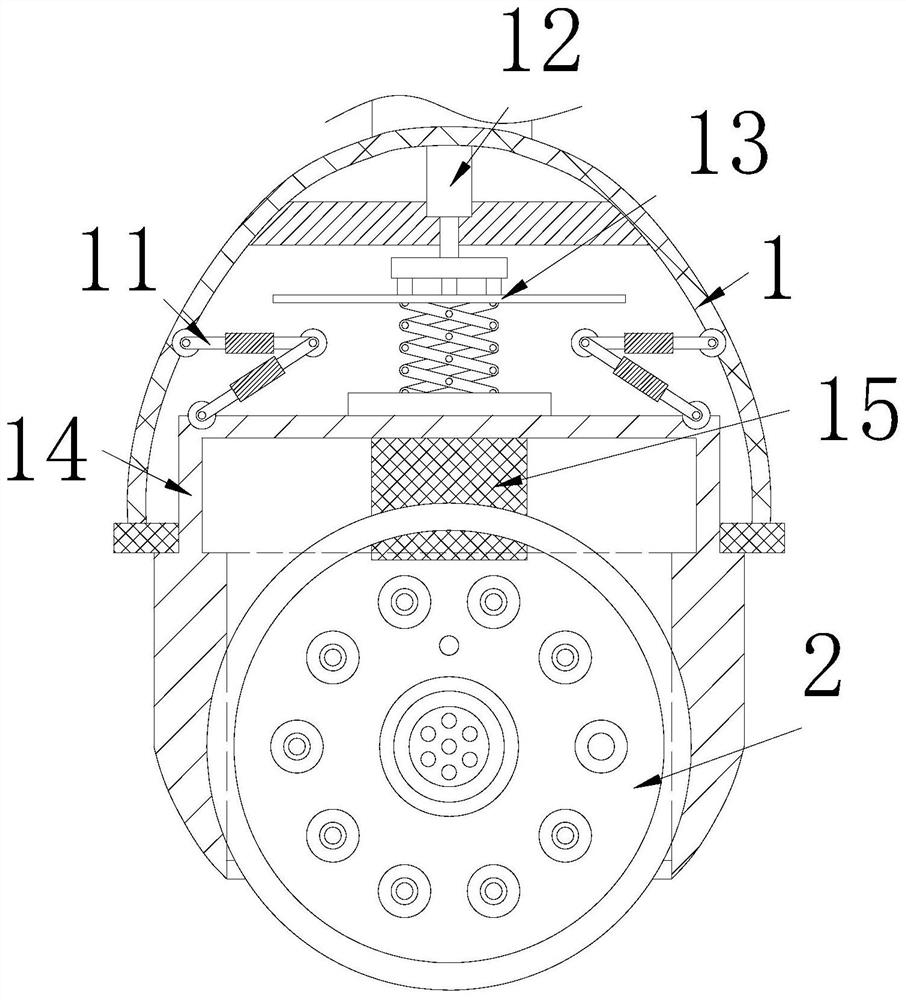

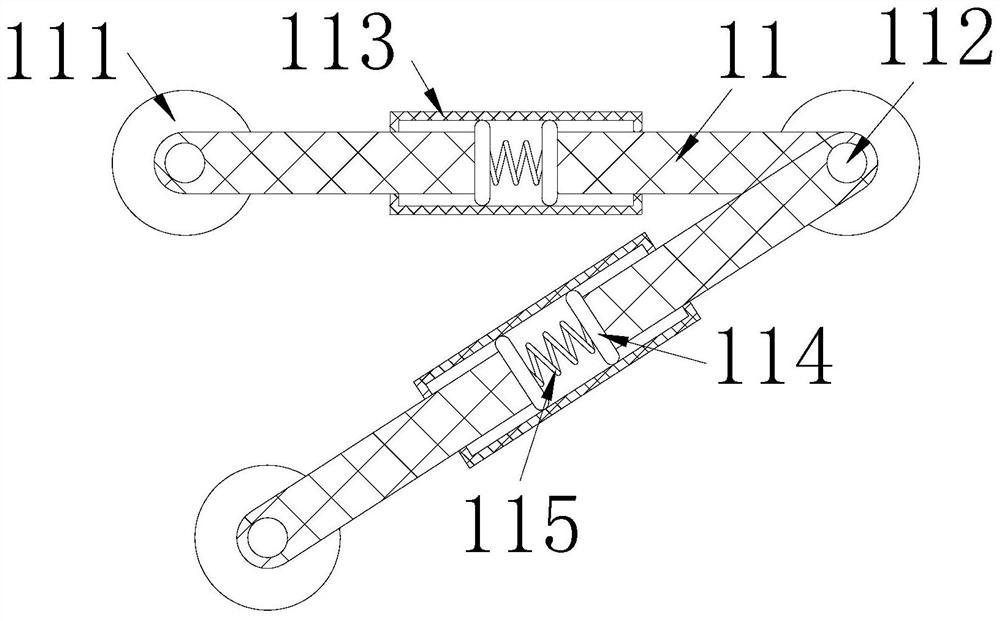

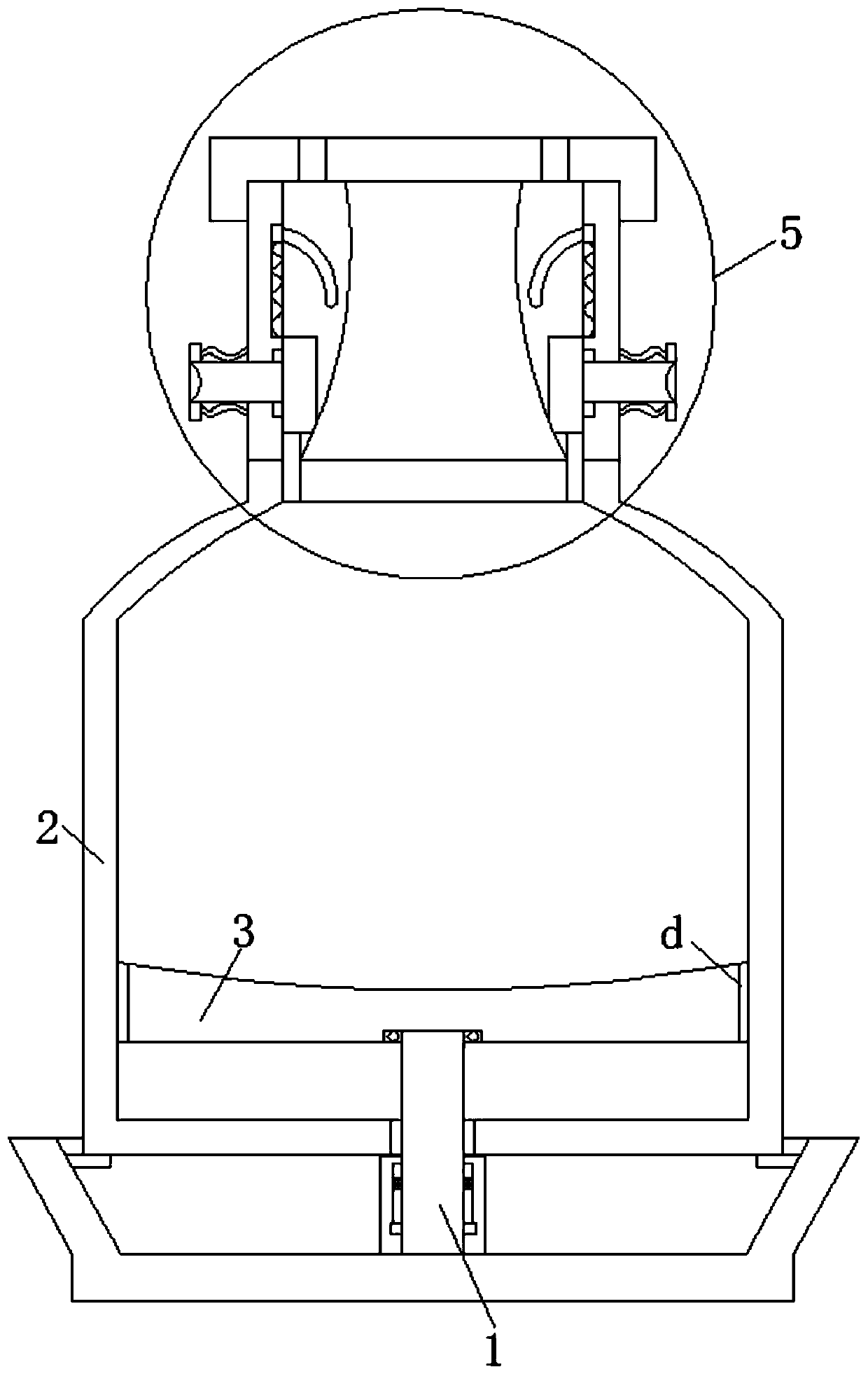

Intelligent building security device

InactiveCN111741197AEasy to wipeAvoid wipingTelevision system detailsTransmission systemsEngineeringStructural engineering

The invention discloses an intelligent building security device. The device structurally comprises a fixed cover, a camera, a fixed column and a mounting base, the top of the fixed cover is welded atthe bottom of the fixed column; the camera is mounted below the fixed cover in a matching manner; the fixed column is welded with the left side of the mounting base. The beneficial effects of the device are that: bluetooth control enables the telescopic rod to extend and pushes the limiting plate to move downwards; the two ends of the limiting plate downwards extrude the traction plate, so that the bent traction plate is gradually straightened; therefore, the positioning cover is pushed to descend, so that the camera descends to a height accessible to a tentacle; dust on the surface of the camera can be wiped conveniently; the condition that the camera can be wiped only by climbing a herringbone ladder is avoided; consequently, unnecessary trouble is avoided, when the camera is wiped, theouter surface of the camera is rubbed with the scraping plate by manually rotating the camera, so that dust on the outer surface of the camera is wiped by the brushes, the dust on the surface of the camera can be wiped cleanly by the arc-shaped brushes on the two sides, and a picture shot by the camera is prevented from being influenced by dust residues.

Owner:成都柏阳林商贸有限公司

Pen water bottle for teaching

The invention provides an ink bottle for teaching. The ink bottle for teaching comprises a bottle bottom raising mechanism, an ink bottle body, a concave raising sealing body, an ink bottle opening ring, a finger-pressing wiping-free mechanism, a concave ventilating bottle cap, an arc-shaped supporting shrinkage body, a ventilating cavity, a sealing outer thread body and a sealing inner thread ring, wherein the upper surface of the concave raising sealing body is concave. The invention relates to the field of stationery. By the ink bottle for teaching, pollution of the bottle body by ink can be relieved and even avoided, ink can also be prevented from polluting hands and clothes of people, thus, the ink bottle can be recycled, waste is avoided, the using method is simple, a follow-up wiping process is omitted, and the problems that an existing ink bottle is too simple in structure, ink easily pollutes various portions such as a table top, fingers and clothes, the ink bottle brings lotsof troubles for a user, after the ink bottle is used repeatedly, a bottle body can be stained with quite thick pigment, most of people may directly throw away the bottle body, and waste is caused aresolved.

Owner:浙江森创服装股份有限公司

IOT-based intelligent lighting equipment

InactiveCN110425469AAvoid wipingIncrease brightnessLighting elementsInsect catchers and killersIntelligent lightingPest control

The invention provides IOT-based intelligent lighting equipment. The IOT-based intelligent lighting equipment comprises a wiping ring, moth-killing lamps, a pest control grid pipe, arc-shaped acceptance discs, an insulating adjustment plate and an electric push rod; a cylindrical lighting lamp is arranged at the bottom of a circular clamping plate in a clamping manner; furthermore, the wiping ringsleeves the upper end outside the lighting lamp; furthermore, a sponge ring is arranged on the inner ring of the wiping ring; a lower insulating plate is connected below an upper insulating plate through two sets of opposite guide rods; furthermore, the two sets of opposite moth-killing lamps are also arranged between the upper insulating plate and the lower insulating plate; the insulating adjustment plate is arranged between the upper insulating plate and the lower insulating plate; the outer end of the wiping ring is connected onto the insulating adjustment plate through a connecting rod;and the two sets of arc-shaped acceptance discs are also arranged outside the lower insulating plate in a clamping manner. The electric push rod drives the insulating adjustment plate to move downwardly; therefore, the wiping ring and the sponge ring move synchronously and downwardly, so that the outside surface of the lighting lamp is wiped; the brightness of the lighting lamp is improved; the moth-killing lamps and the pest control grid pipe can be started; and thus, insects and mosquitoes can be lured and killed.

Owner:张晓卫

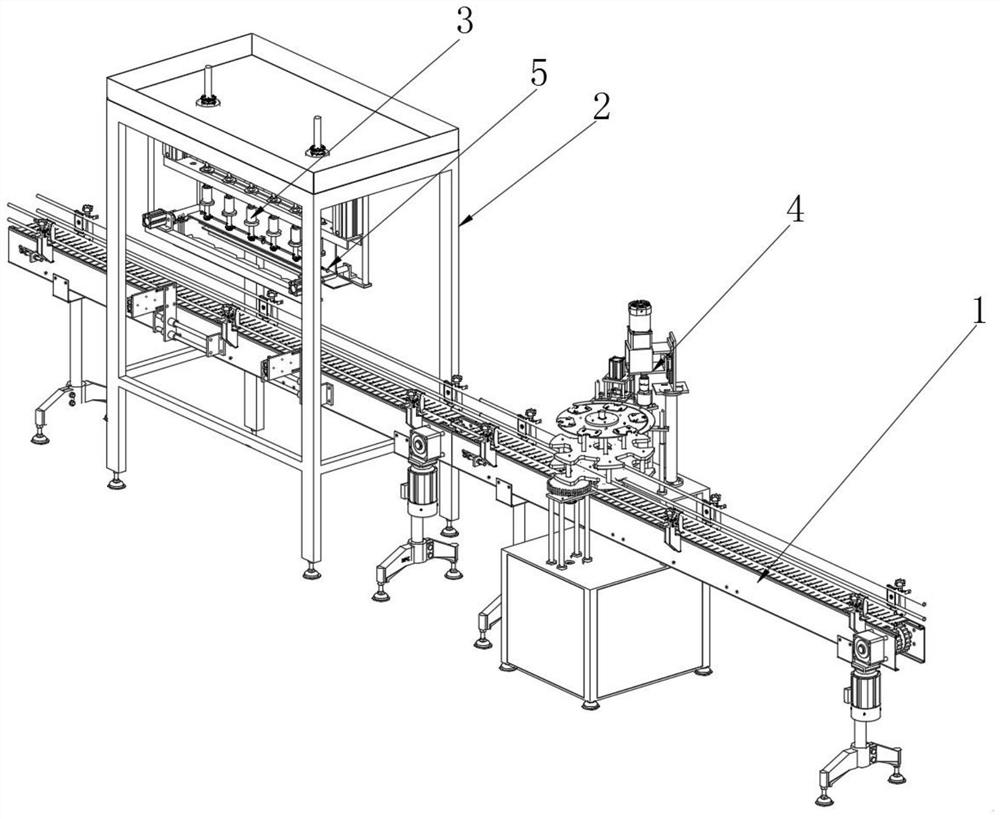

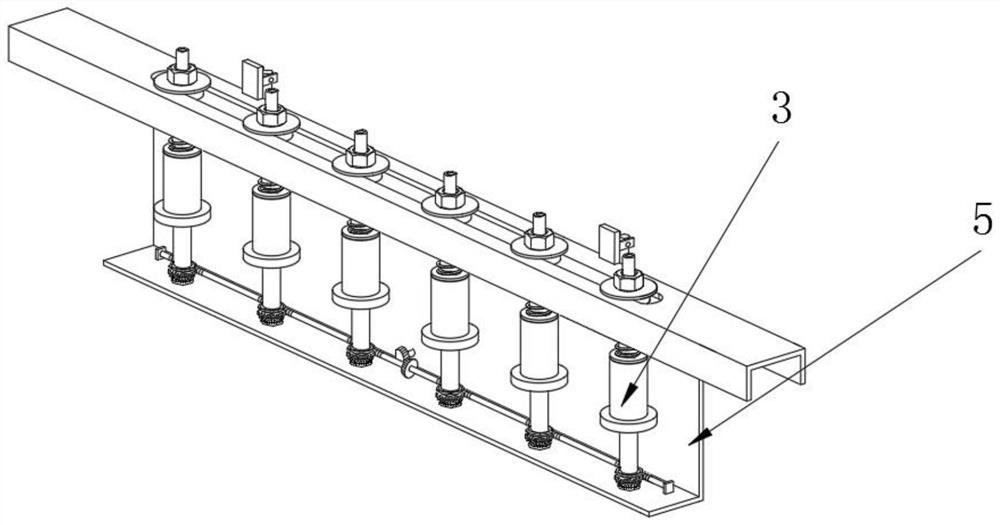

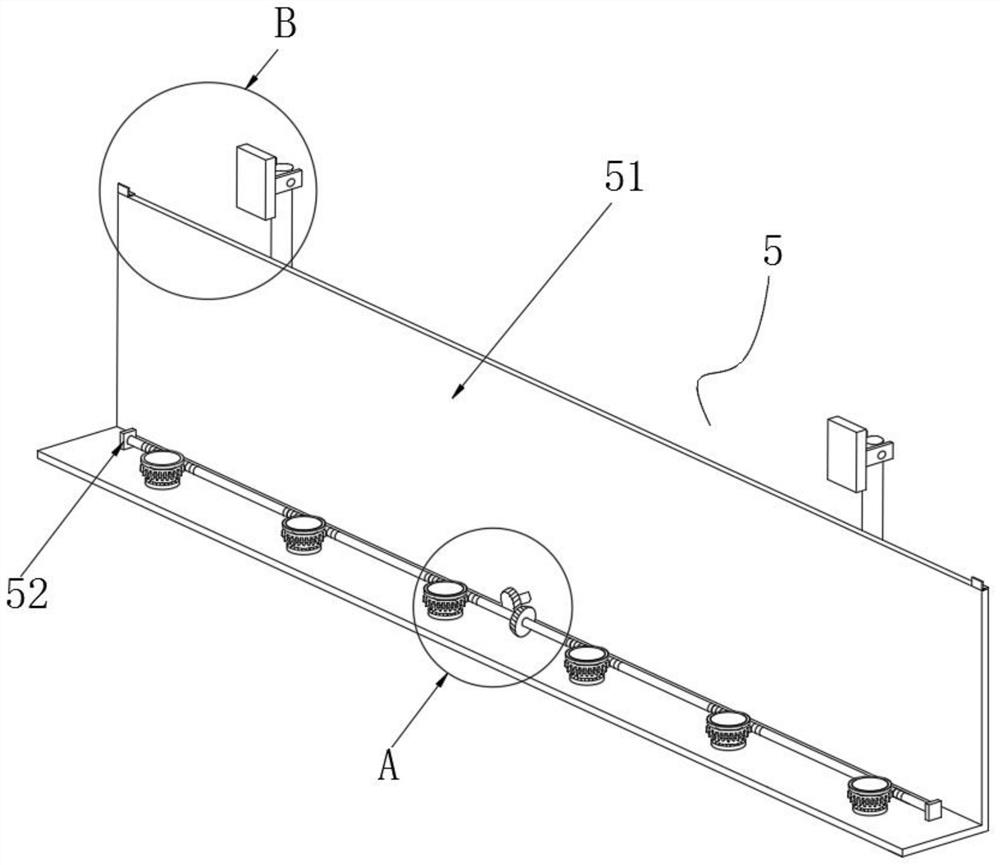

Feeding system of cosmetic glass bottle production line

ActiveCN113479835AAvoid wipingIncrease frictionThreaded caps applicationSynchronising machinesSpray nozzleInternal cavity

The invention discloses a feeding system of a cosmetic glass bottle production line. An automatic liquid wiping device comprises a mounting plate and a fixing plate, hinges are symmetrically and fixedly connected to the top of the mounting plate, a first servo motor is fixedly connected to an inner cavity of a protective shell, hydraulic cylinders are symmetrically and rotationally connected to opposite inner cavities of a rotating component in a sleeving manner, a first bevel gear is fixedly connected to one end of the first servo motor, fixing blocks are symmetrically and fixedly connected to the two sides of the top of the mounting plate, worms are rotationally connected to the opposite sides of the fixing blocks in a sleeving mode, second bevel gears are fixedly connected to the surfaces of the worms in a sleeving mode, and rotating mechanisms are symmetrically and fixedly arranged at the top of the mounting plate. The invention relates to the technical field of cosmetic production processes. The problems that due to the fact that residual cosmetic liquid exists at an end opening of a liquid spraying nozzle after the liquid spraying nozzle sprays liquid, the cosmetic liquid possibly drips on a conveying mechanism when a cosmetic glass bottle is not in place, and the liquid possibly drips on the ground along with movement of the conveying mechanism are solved.

Owner:安徽金冠玻璃有限责任公司

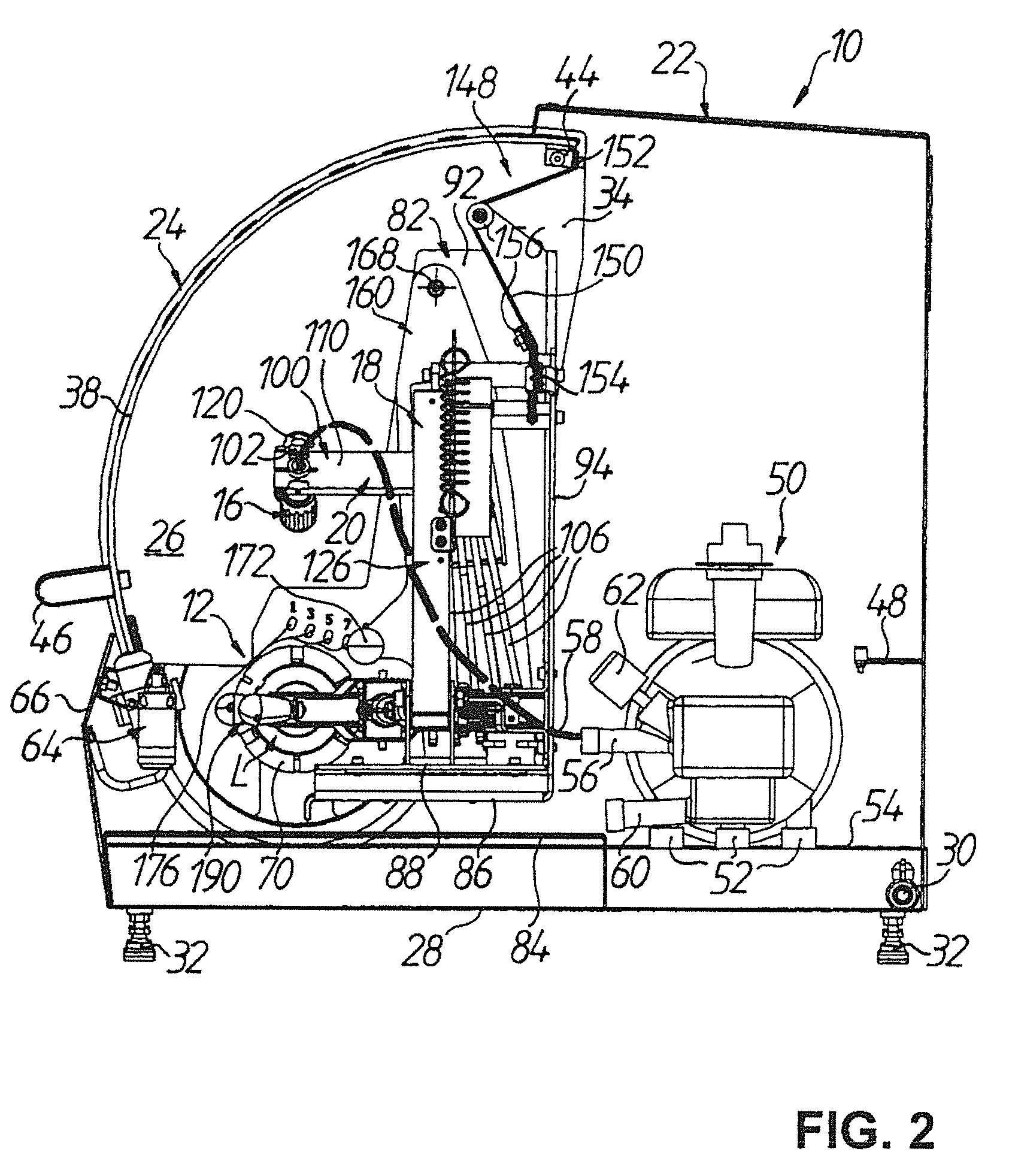

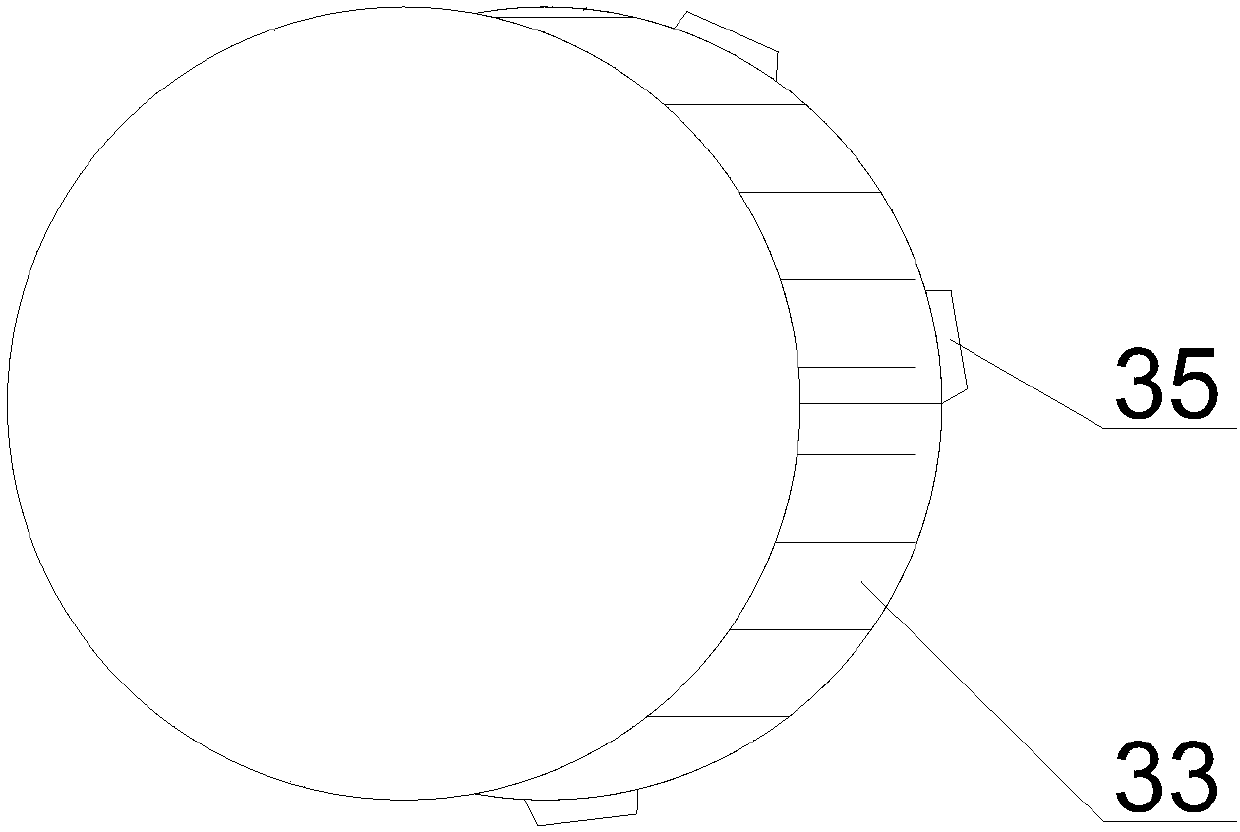

Device for deblocking optical workpieces, in particular eyeglass lenses

ActiveUS9120196B2Deblock the workpiece significantly more quicklyEasy to handleLamination ancillary operationsOptical surface grinding machinesRotational axisEyeglass lenses

A device for deblocking optical workpieces, having a first moving device for rotating a workpiece, which is blocked on a blocking piece, about a workpiece rotational axis and a nozzle for dispensing a pressurized stream in a direction that is essentially transverse to the workpiece rotational axis onto a point of incidence in an edge region between the blocking piece and the workpiece. The device also has a second moving device for generating a relative movement between the nozzle and the workpiece. The second moving device has a nozzle guiding portion on which the nozzle is mounted and by which the nozzle can be positioned with respect to the blocking piece in a cam-controlled manner in order to aim the pressurized stream towards the point of incidence in a defined manner.

Owner:SATISLOH AG

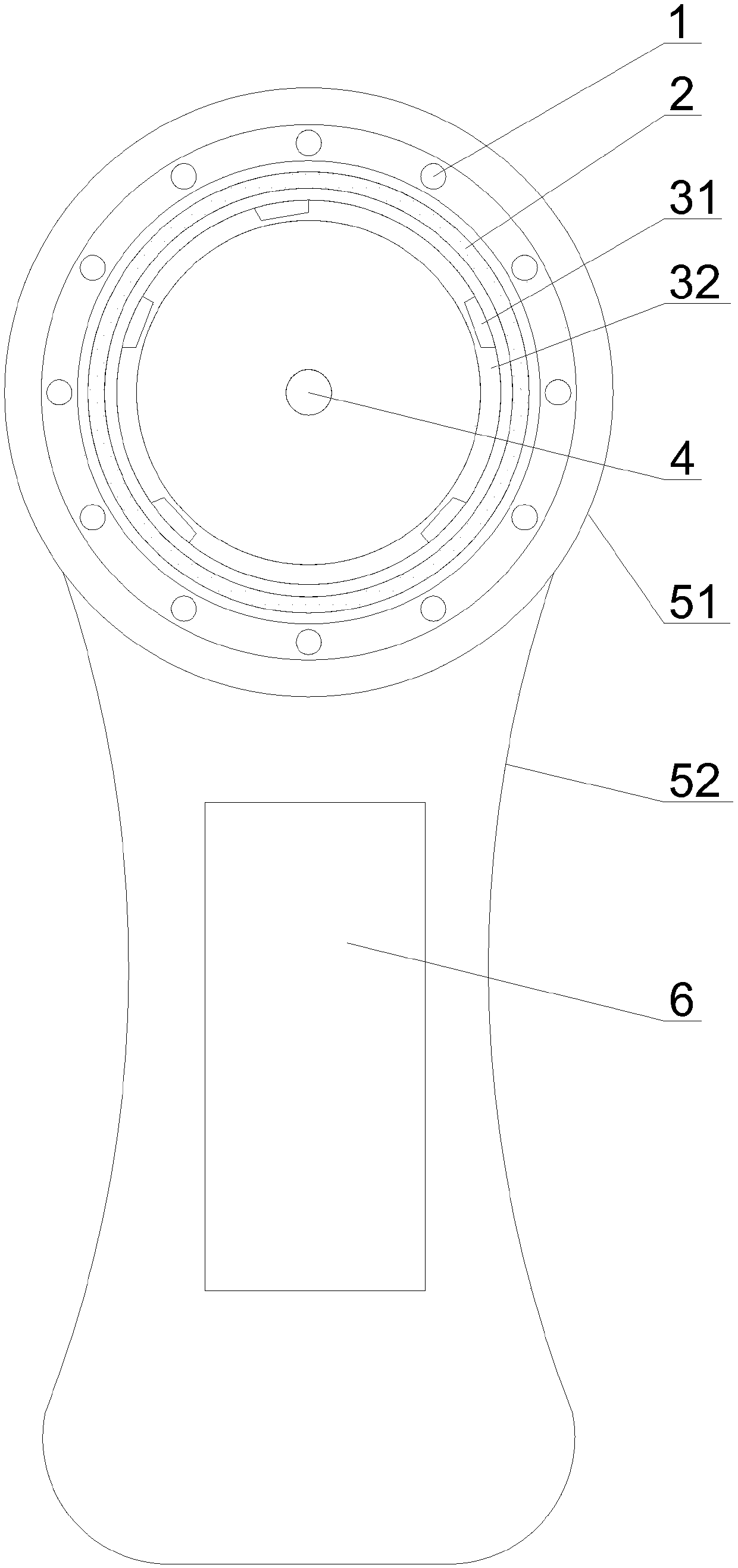

Multifunctional skin care instrument

InactiveCN108014005AEasy to useImprove skin cleansing effectElectrotherapyBrush bodiesControl systemSkin surface

The invention discloses a multifunctional skin care instrument. The instrument comprises a shell, the shell comprises an upper shell body and a lower shell body, and the upper shell body is arranged on the upper portion of the lower shell body; the upper shell body is provided with anion spray orifices, a mounting groove for installing a face washing brush or massage balls, water absorption holesfor absorbing water drops on skin and LED red and blue light for changing the skin cell structure from inside to outside; a waterproof-level touch display screen is arranged on the lower shell body; awater absorption system, a control system and a battery system are arranged in the shell; the control system comprises a controller, a red and blue light generator, a vibration motor, an anion generator and a wireless connection module for being connected with a mobile terminal. The skin is cleaned through the face washing brush, the moisture of the skin is kept through the anion spray orifices,and redundant water drops on the skin surface are mildly absorbed through the water absorption holes; the skin is further cared through the massage balls and the LED red and blue light, the multifunctional skin care instrument is more convenient to use, and the cleaning and skin care effects are improved.

Owner:苏州希尔盖森新材料有限公司

Coupling agent cleaning device

The invention discloses a couplant cleaning device, which comprises an arc-shaped recycling box. The scraper scrapes off the couplant on the skin of a human body with a hand-held handle, and the scraped couplant enters the arc-shaped recycling box and sinks Recycle and store. After scraping, wipe the residual coupling agent with the absorbent cotton at the sealing end of the arc-shaped recycling box. After wiping, remove the non-woven fabric on the scraper and the non-woven fabric on the absorbent cotton. In addition, Absorbent cotton can be washed and cleaned. Pour out the coupling agent in the sinking tank through the opening, open the control valve, and let the disinfectant in the water tank pass through the water spray holes to rinse and disinfect the side wall of the arc-shaped recovery box. The couplant removing device of this structure can avoid waste of paper, can be reused, and saves resources.

Owner:夏国昌

Automatic detecting and labeling device for household electrical waste product

ActiveCN109647737ARealize automatic controlRealize automatic weighingSortingStampingElastic componentWaste product

The invention relates to the technical field of electrical appliance processing and discloses an automatic detecting and labeling device for a household electrical waste product. The automatic detecting and labeling device comprises a rack, wherein a conveying mechanism and a weighing mechanism are arranged on the rack; the weighing mechanism comprises a weighing table; telescopic rods connected with the weighing table are fixedly connected onto the rack; an elastic component is connected between the weighing table and the rack; a jacking mechanism capable of conveying the household electricalwaste product is arranged on the rack below the weighing table; a through hole used for the penetration of the jacking mechanism is formed in the weighing table; gear teeth are arranged on one telescopic rod; a first gear is rotationally connected onto the rack; the telescopic rod is meshed with the first gear through the gear teeth; a second gear is coaxially connected with the first gear; a transmission rod capable of being meshed with the second gear is slidably connected onto the rack; and a marking block used for marking the household electrical waste product is fixedly arranged on the transmission rod. By the adoption of the automatic detecting and labeling device disclosed by the invention, the problem that in the prior art, the detecting and labeling process is low in efficiency and prone to error can be solved.

Owner:CHONGQING ZHONGTIAN ELECTRONICS WASTE TREATMENT

Cleaning device for water conservancy machinery

InactiveCN108927369AEasy to integrateEasy to cleanCleaning using liquidsArchitectural engineeringElectric machinery

The invention discloses a cleaning device for water conservancy machinery in the technical field of water conservancy machinery cleaning. The inner wall of a cleaning tank body is provided with annular support blocks, and a support plate is arranged on the tops of the annular support blocks; the top of the support plate is provided with fixing devices, and the bottom center of the support plate isprovided with a rotating shaft; the bottom of the rotating shaft penetrates the bottom of the cleaning tank body and is connected to the upper output end of a driving motor, and an inner cavity of the cleaning tank body is provided with a waste water tank; the left side of the bottom of the inner cavity of the cleaning tank body is provided with a water tank, and the right side of the bottom of the inner cavity of the cleaning tank body is provided with a mixing tank; parts are double cleaned with alkali aqueous solutions and water, and the cleaning effect is better; meanwhile, the support plate is driven by the driving motor to rotate during cleaning, so that all positions of the parts are cleaned more thoroughly; meanwhile, the remaining water on the parts are thrown away, and subsequent wiping and drying are avoided; and the cleaning efficiency is improved.

Owner:扬州市金阳光铸造有限公司

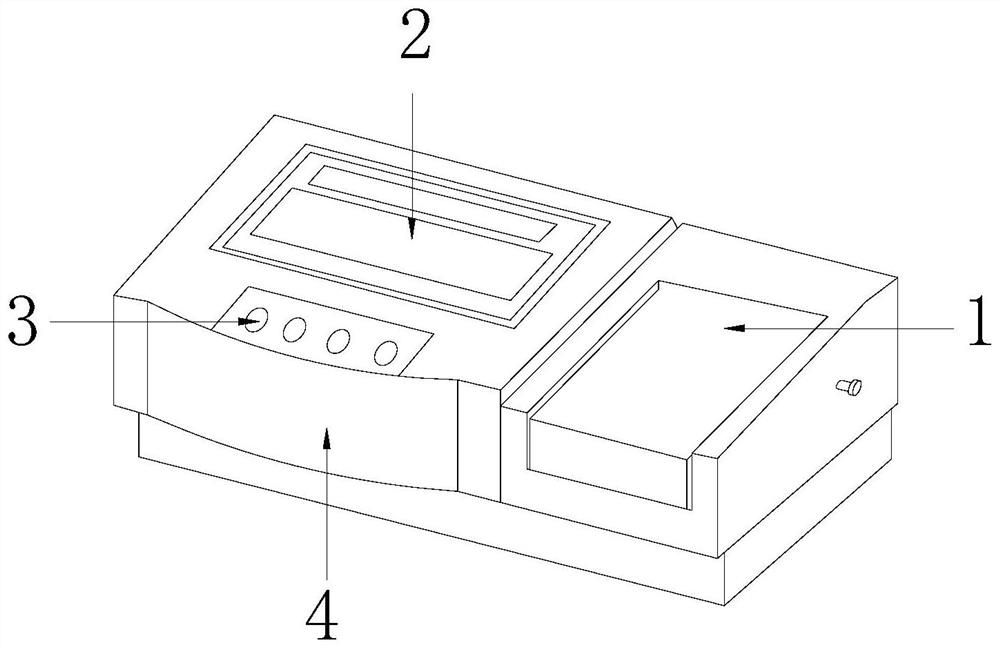

Intelligent food safety detection analyzer

InactiveCN113484243AAvoid hard-to-remove situationsAvoid wipingMaterial analysis by observing effect on chemical indicatorDrying solid materials without heatCuvetteFood safety

The invention discloses an intelligent food safety detection analyzer. The intelligent food safety detection analyzer structurally comprises a detection module, a display panel, a control button and an analyzer body, the intelligent food safety detection analyzer has the beneficial effects that the arranged wiping sleeve block is matched with the lifting mechanism, a cuvette is in contact with the wiping sleeve block and water attached to the surface of the cuvette is scraped off and wiped off in the process of replacing a detection sample, repeated wiping operation of detection personnel is avoided, the workload of the detection personnel is reduced, meanwhile, after detection is finished, the cuvette is moved upwards through the lifting mechanism, so that the situation that the cuvette is difficult to take out when a detection sample is replaced is avoided; a water scraping block is matched with a wiping plate, a detector vertically inserts the cuvette along the detection groove, the water scraping block clings to the surface of the cuvette to scrape off water, and then the cuvette is wiped by the wiping plate, so that the detected surface of the cuvette is kept clean, and the condition of influencing detection data is avoided.

Owner:许雪霞

An easy-to-clean mirror

The invention discloses a mirror convenient to scrub. The mirror is composed of a glass mirror piece, a mirror handle and a mirror frame. The mirror is characterized by further comprising a scrubbing device which is composed of a scrubbing brush, a belt and three guiding wheels, the scrubbing brush is fixed to one end of the belt, bristles of the scrubbing brush closely attach to the glass mirror piece, the axes of the three guiding wheels are arranged in a triangular shape, and the belt can slide along the guiding wheels. The mirror convenient to scrub is simple in structure and convenient to operate, the guiding wheel structure is ingeniously applied, and the scrubbing brush is directly installed in the mirror to serve as one of mirror functional structures; by means of ingenious belt and guiding wheel connection, the scrubbing problem of the mirror is effectively solved; in addition, the bristles in the scrubbing brush are cotton bristles, scrubbing such as tissue scrubbing can be effectively avoided, and the problem that the mirror is scratched due to defects of scrubbing materials is effectively avoided.

Owner:佛山瀚镜智能科技有限公司

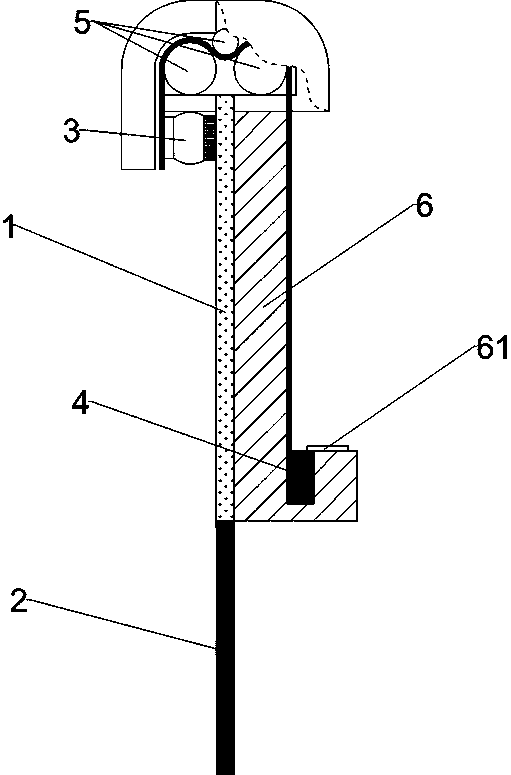

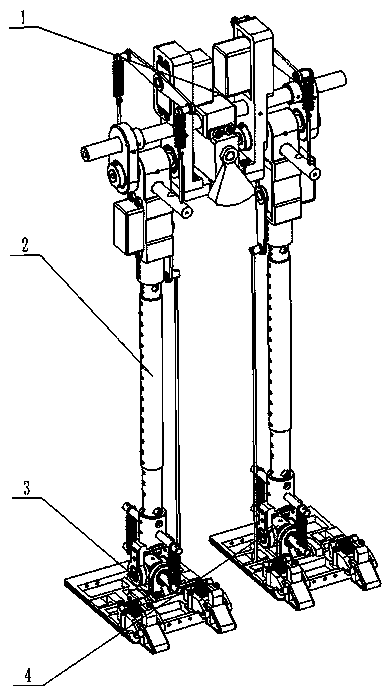

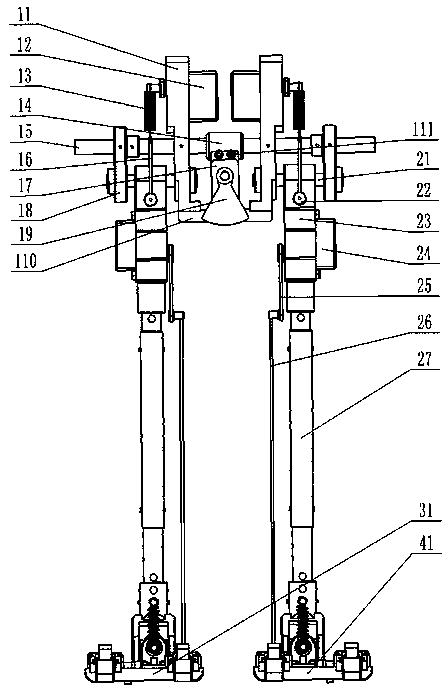

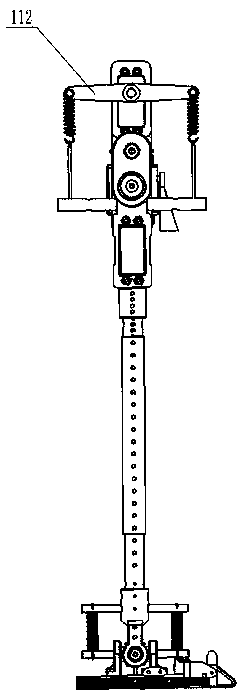

Kneeless underactuated bionic biped walking machine with auxiliary side swing mechanism

ActiveCN108482510BGait Switches NaturallyAvoid wipingVehiclesPhysical medicine and rehabilitationSagittal plane

Owner:JILIN UNIV

Vertical ultrasonic bottle washing machine capable of stably feeding and discharging

PendingCN114798583AStable supportEasy to cleanNon-rotating vibration suppressionDrying solid materials without heatProcess engineeringWash bottle

The invention discloses a vertical ultrasonic bottle washing machine capable of stably loading and unloading, which belongs to the technical field of ultrasonic bottle washing and comprises a bottle washing machine main body, a bottle conveyor belt, a bottle protection cover and a main body support pile. By combining the bottle conveying belt, the bottle protection cover, the bottle input groove, the bottle inner guide plate, the rotating groove, the rotating shaft, the quantitative input rolling shaft, the bottle cleaning box, the ultrasonic oscillation equipment, the vertical drain pipe frame and the bottle centralized input pipeline, the problem that in the using process of an existing bottle cleaning machine, the bottle cleaning efficiency is high is solved conveniently; according to the bottle washing machine, the problems that bottles needing to be washed cannot be stably and quantitatively input into equipment for washing, so that the bottles are always input into the equipment during washing, and the washing effect on the bottles is reduced are solved. Bottles needing to be cleaned can be stably and quantitatively input into the equipment to be cleaned, so that the equipment can stably feed and discharge materials, and the cleaning effect on the bottles is improved.

Owner:浙江润和生物科技有限公司

High-precision and high-strength ceramic hand mold and preparation method thereof

ActiveCN114213109AImprove thermal stabilityIncrease usageDischarging arrangementCoatingsParaffin waxHeat stability

The invention discloses a high-precision and high-strength ceramic hand mold and a preparation method thereof.White corundum and alpha alumina powder are adopted as raw materials for manufacturing the hand mold, although the cost of the raw materials is relatively high, a forming mold is made of polyurethane and paraffin, and therefore the links of wiping and fettling after a plaster mold is formed are avoided; the raw materials are all raw materials subjected to high-temperature treatment, and after the product is sintered, the shrinkage is almost zero, so that the sintering precision of the product can be effectively guaranteed; meanwhile, the heat stability of the raw materials is extremely high, the repeated extremely cold and extremely hot phenomenon in the glove production process can be effectively resisted, and the use frequency of the ceramic hand mold is greatly increased; according to the preparation method, the links such as wiping and fettling in the production process of a traditional clay ceramic hand mold are eliminated, and the production efficiency and the manual error of the product are greatly improved.

Owner:LIAONING SILICATE RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com