High-precision and high-strength ceramic hand mold and preparation method thereof

A high-strength, high-precision technology, applied in ceramic molding machines, clay preparation devices, chemical instruments and methods, etc., can solve the problems of affecting the dimensional accuracy of gloves, multiple trimming and wiping, and complicated production processes, and improve production. Efficiency and artificial error, resistance to repeated extreme cold and extreme heat, strong thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

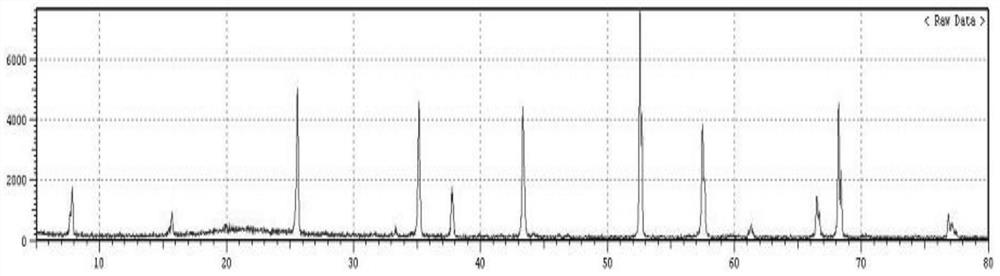

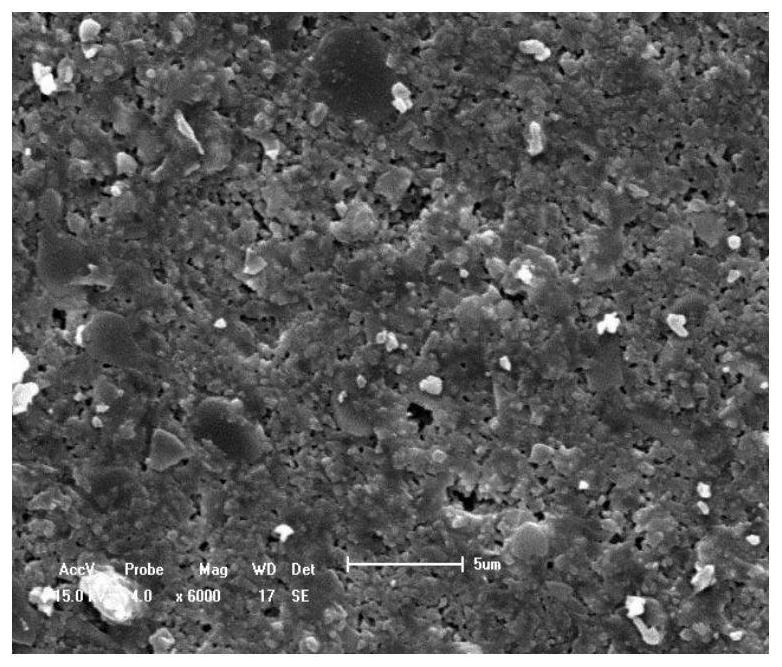

[0033] A high-precision, high-strength ceramic hand mold is specifically prepared according to the following method:

[0034] a) Mixing of main ingredients: by weight, take 20 parts of 20-50 mesh white corundum powder, 30 parts of 120 mesh white corundum powder, 25 parts of 5 μm α-alumina powder, 21 parts of 0.5 μm α-alumina powder, and 4 parts of high aluminate cement 2 parts, sent to the non-gravity mixing equipment, start mixing for 10 minutes, after mixing the raw materials evenly, add 0.8 parts of sodium polyacrylate and 7 parts of water, start mixing for 15 minutes, and wait for the raw materials to form a paste-like slurry before use;

[0035] b) Vacuum stirring and defoaming: send the paste slurry into a vacuum mixer, start vacuum stirring, the vacuum degree needs to reach -0.09Mpa, and the vacuum stirring time is 15 minutes. After removing the air bubbles in the paste slurry, seal it for storage. stand-by;

[0036] c) Mold opening: the mold is divided into an inner c...

Embodiment 2

[0044] A high-precision, high-strength ceramic hand mold is specifically prepared according to the following method:

[0045] a) Mixing of main ingredients: by weight, take 23 parts of 20-50 mesh white corundum powder, 27 parts of 120 mesh white corundum powder, 30 parts of 5 μm α-alumina powder, 12 parts of 0.5 μm α-alumina powder, and 8 parts of high aluminate cement 1 part, put it into the gravity-free mixing equipment, start mixing for 15 minutes, mix the raw materials evenly, add 1 part of sodium polyacrylate and 7 parts of water, start mixing for 15 minutes, and wait for the raw materials to form a paste-like slurry before use;

[0046] b) Vacuum stirring and defoaming: send the paste slurry into a vacuum mixer, start vacuum stirring, the vacuum degree needs to reach -0.09Mpa, and the vacuum stirring time is 20 minutes. After removing the air bubbles in the paste slurry, seal it for storage. stand-by;

[0047] c) Mold opening: The mold is divided into an inner core and ...

Embodiment 3

[0055] A high-precision, high-strength ceramic hand mold is specifically prepared according to the following method:

[0056] a) Mixing of main ingredients: by weight, take 27 parts of 20-50 mesh white corundum powder, 23 parts of 120 mesh white corundum powder, 35 parts of 5 μm α-alumina powder, 3 parts of 0.5 μm α-alumina powder, 12 parts of high aluminate cement 1.2 parts of sodium polyacrylate and 7 parts of water, and then start mixing for 15 minutes. After the raw materials form a paste-like slurry, it is ready to use;

[0057] b) Vacuum stirring and defoaming: send the paste slurry into a vacuum mixer, start vacuum stirring, the vacuum degree needs to reach -0.09Mpa, and the vacuum stirring time is 30 minutes. After removing the air bubbles in the paste slurry, seal it for storage. stand-by;

[0058] c) Mold opening: The mold is divided into an inner core and a jacket according to the structure, wherein the jacket mold is made of polyurethane material, and the inner co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com