Unmanned aerial vehicle capable of cleaning lens

An unmanned aerial vehicle, a clean technology, applied in the field of unmanned aerial vehicles, which can solve the problems such as hindering the normal shooting of the lens, affecting the shooting process, and the lens being easily exposed to rain, dust and grass clippings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

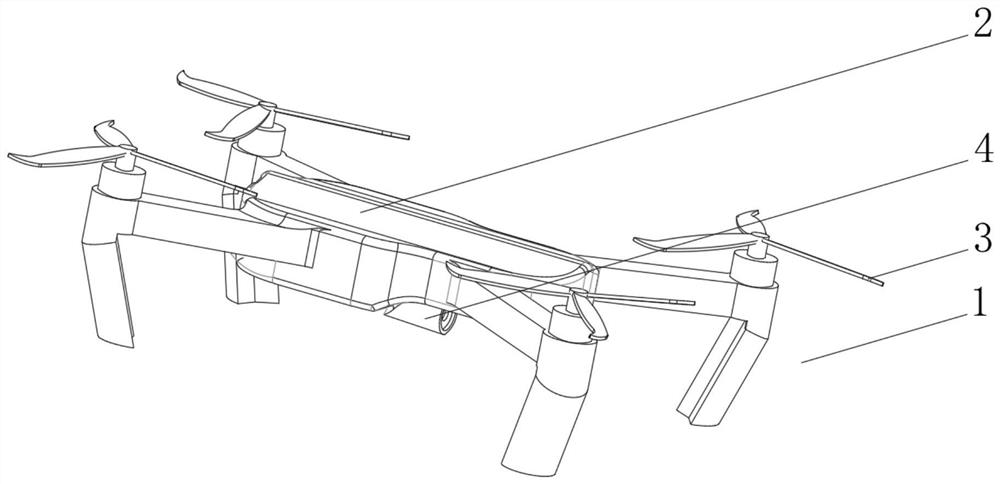

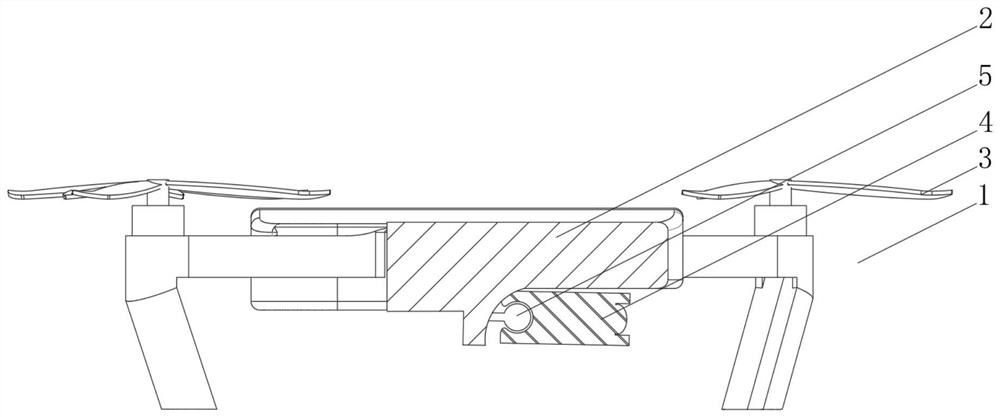

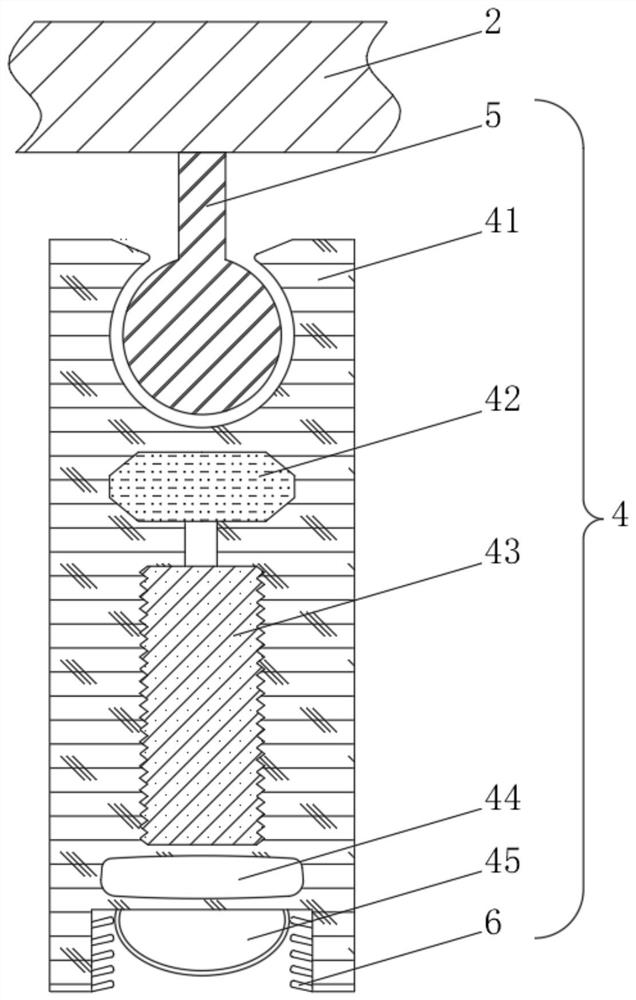

[0042] See Figure 1-4 The present invention provides a technical solution: a cleaner lens-free drone, a cleaner lens-type drone body 1 composed of a body 2, a wing 3, and an imaging mechanism 4, and the top of the body 2 is rotated by the rotating rod Turn the connection with the bottom of the wing 3, the bottom of the body 2 is rotated by the top of the imaging mechanism 4, and the imaging mechanism 4 includes a movable contact plate 41, and the internal fixation of the camera plate 41 is fixedly connected to the microfm 42, the micro blower 42 The bottom portion is connected to the air heater 43 through the gas tube, and the bottom of the air heater 43 communicates with the airbag 44 through the air supply tube, and the inside of the airbag 44 passes through the gas pipe communication with a cleaning mechanism 6, and the bottom portion of the camera plate 41 is fixedly connected to the lens 45. The debug mechanism 5 includes a linkage rod 51, the top portion of the linkage rod 5...

Embodiment 2

[0046] See Figure 1-6 Based on the first example, the present invention provides a technical solution: the cleaning mechanism 6 includes a cleaning block 61, and a gas blowing mechanism 7 is provided outside the cleaning frame 61, and the right side of the cleaning frame 61 passes through the rotary sheet and the camera 41. The internal rotation is connected, and the right side of the cleaning frame 61 is connected to the inside of the airbag 44 through the gas pipe.

[0047] The inside of the cleaning frame 61 is fixedly coupled with the expansion strip 62, and the right side of the cleaning frame 61 is fixedly connected to the push cap 63, the right side of the push blanket 63 is fixed to the inside of the camera plate 41, and the inside of the push 63 is provided with electric telescoping rod 64. The right side of the electric telescoping rod 64 is electrically connected to the external power supply.

[0048] The air blowing mechanism 7 includes the outer casing 71, the outer s...

Embodiment 3

[0052] See Figure 1-8Based on the first and examples of embodiments, the present invention provides a technical solution: the pneumatic mechanism 8 includes a pneumatic bag 81, and the outer side of the air mass 81 is provided with a first inner ring block 82 and a second inner ring block 83. The top portion of the first inner ring 82 is fixed by the bottom of the spring second inner ring block 83, and the bottom of the first inner ring 82 is fixedly connected to the first middle receipt 84, and the bottom of the first middle receipt 84 is fixedly connected. The first air ring 85.

[0053] The top of the second inner ring 83 is fixedly coupled with the second middle receipt 86, and the top of the second hinge 86 is fixedly connected to the second air ring 87, and the bottom of the first air ring 85 is fixed to the internal block 74. Connecting, the bottom of the second gas ring 87 is fixed to the inner portion of the outer block 73, and the outer side of the first middle receiving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com