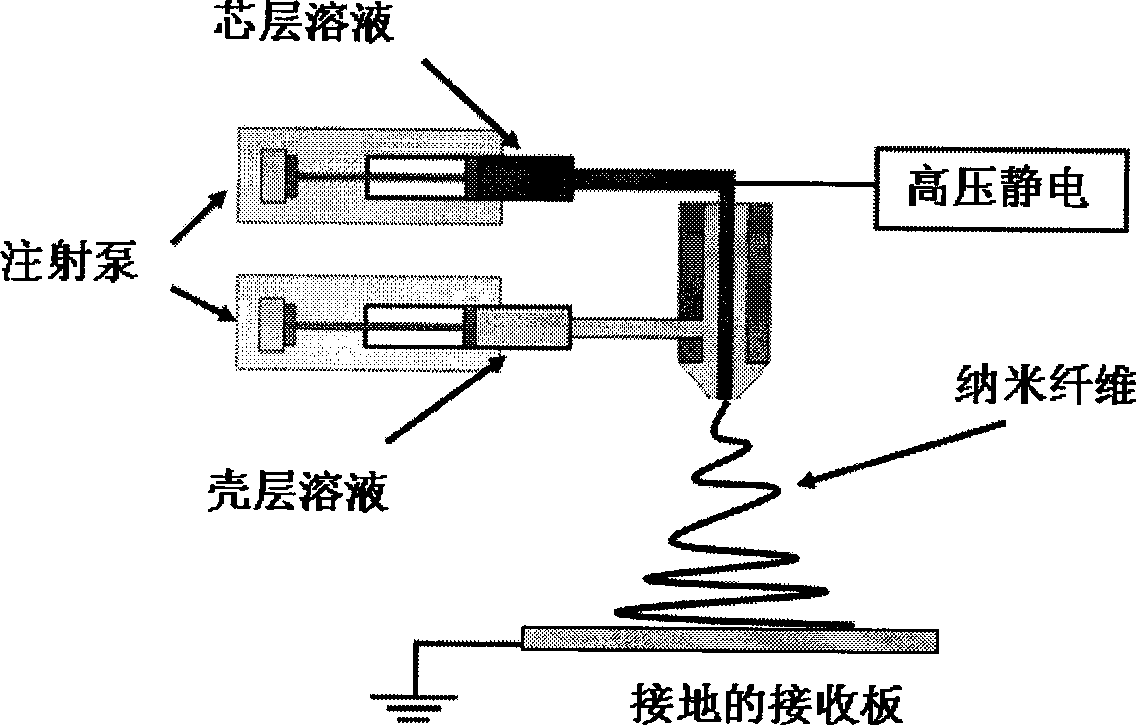

Method for producing shell-core structure medicament nano-fibre with coaxial electrostatic spinning technology

A technology of coaxial electrospinning and nanofibers, which is applied in the direction of spinning solution preparation, drug delivery, fiber treatment, etc., to meet the needs of tissue regeneration or patients, with low cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 0.3g of gelatin, 0.3g of bovine serum albumin and 0.01mg of VEGF with an electronic balance, and dissolve them in 10ml of ultrapure water at the same time under sterile conditions, stir and oscillate to dissolve completely to obtain a core layer solution;

[0028] Weigh 0.8g poly(lactic acid-caprolactone) P(LLA-CL)[50:50] and 0.01g heparin with an electronic balance, dissolve them together in 10ml of trifluoroethanol, stir and oscillate until completely dissolved, and obtain the shell solution;

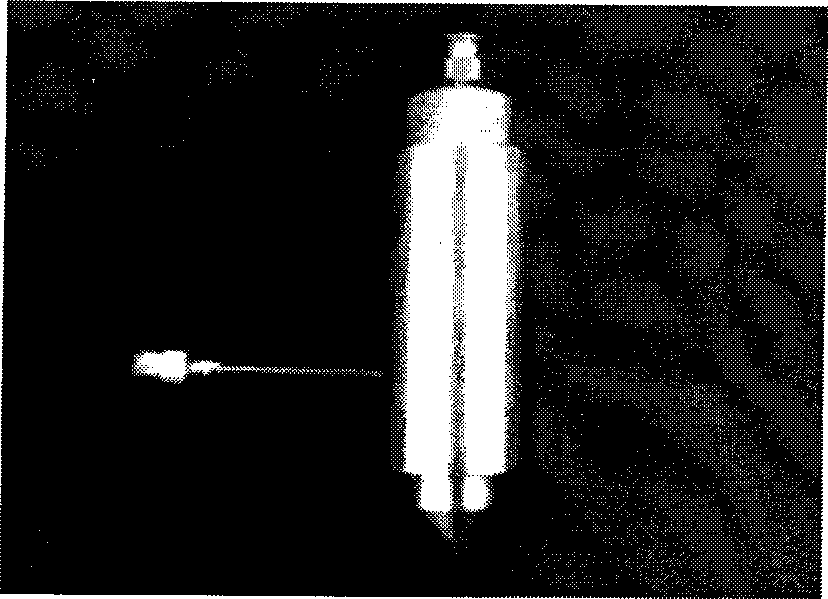

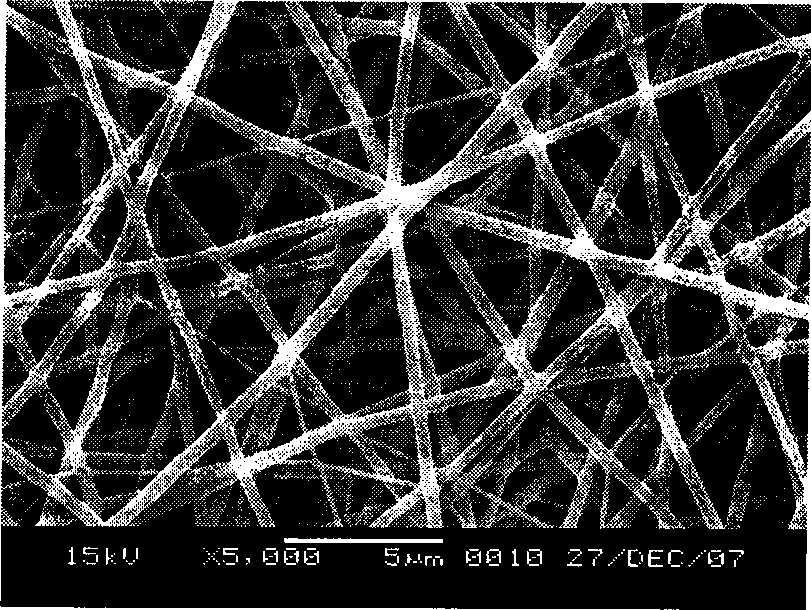

[0029] For coaxial electrospinning, set the flow rate of the core layer solution to 0.2ml / h, the diameter of the spinneret to be 0.9mm, the flow rate of the shell solution to 1.0ml / h, and the diameter of the spinneret to be 1.2mm; 12 cm, and spinning; obtain "shell-core" structure nanofibers with a diameter of about 650 nm, wherein the core layer is about 100 nm.

Embodiment 2

[0031] Weigh 0.1g doxorubicin with an electronic balance, dissolve it in 10ml ultrapure water, stir and oscillate to dissolve completely to obtain a core layer solution;

[0032] Weigh 0.8g poly(lactic acid-caprolactone) P(LLA-CL)[50:50] and 0.05g paclitaxel respectively with an electronic balance, dissolve them together in 10ml of trifluoroethanol, stir and oscillate until completely dissolved, and obtain the shell solution;

[0033] For coaxial electrospinning, set the flow rate of the core layer solution to 0.4ml / h, the diameter of the spinneret to be 0.9mm, the flow rate of the shell solution to 1.0ml / h, and the diameter of the spinneret to be 1.2mm; 12 cm, and spinning; obtain a "shell-core" structure nanofiber with a diameter of about 500 nm, wherein the core layer is about 150 nm.

Embodiment 3

[0035] Weigh 0.3g tetracycline hydrochloride with an electronic balance, and dissolve it in 10ml ultrapure water under sterile conditions, stir and oscillate to dissolve completely to obtain a core layer solution;

[0036] Weigh 0.6g poly-L-lactic acid PLLA and 0.2g griseofulvin respectively with an electronic balance, dissolve them together in 10ml of chloroform, stir and oscillate until completely dissolved, and obtain a shell solution;

[0037] For coaxial electrospinning, set the flow rate of the core layer solution to 0.2ml / h, the diameter of the spinneret to be 0.9mm, the flow rate of the shell solution to 0.8ml / h, and the diameter of the spinneret to be 1.2mm; 12 cm, and spinning; obtain "shell-core" structure nanofibers with a diameter of about 800 nm, wherein the core layer is about 180 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com