Vertical ultrasonic bottle washing machine capable of stably feeding and discharging

A bottle washing machine and ultrasonic technology, which is applied in the field of ultrasonic bottle washing, can solve the problems of reducing the cleaning effect of the bottle, increasing the workflow, and the time required to achieve the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

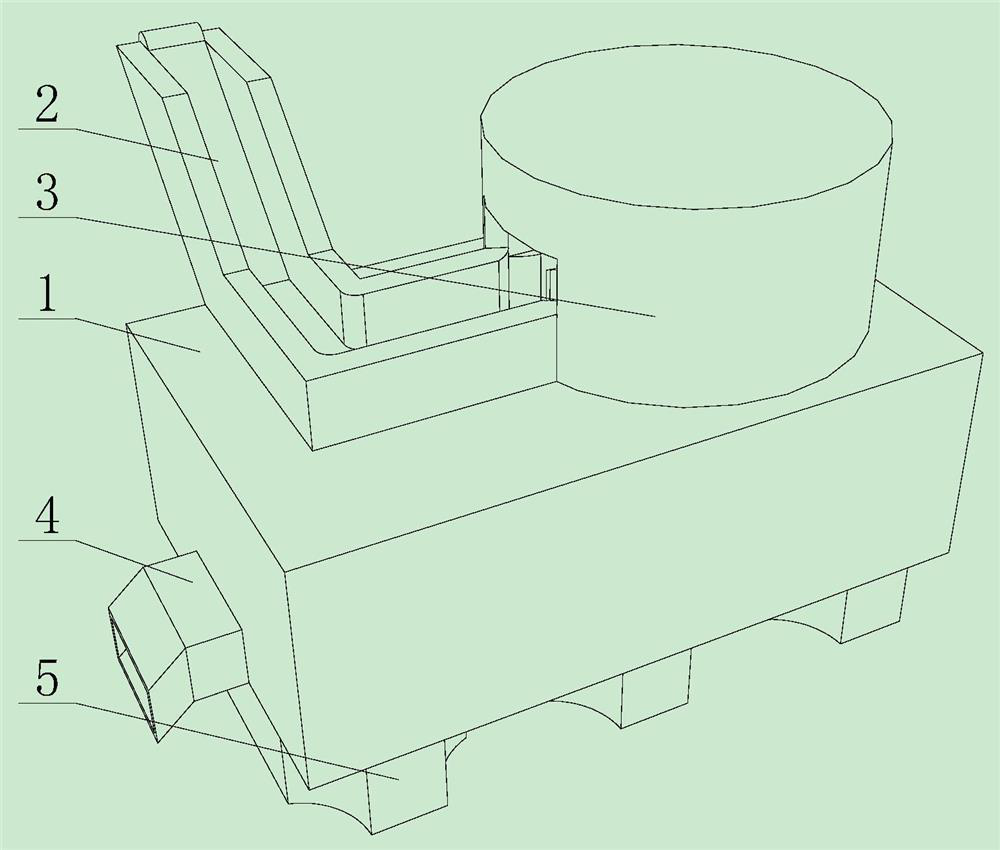

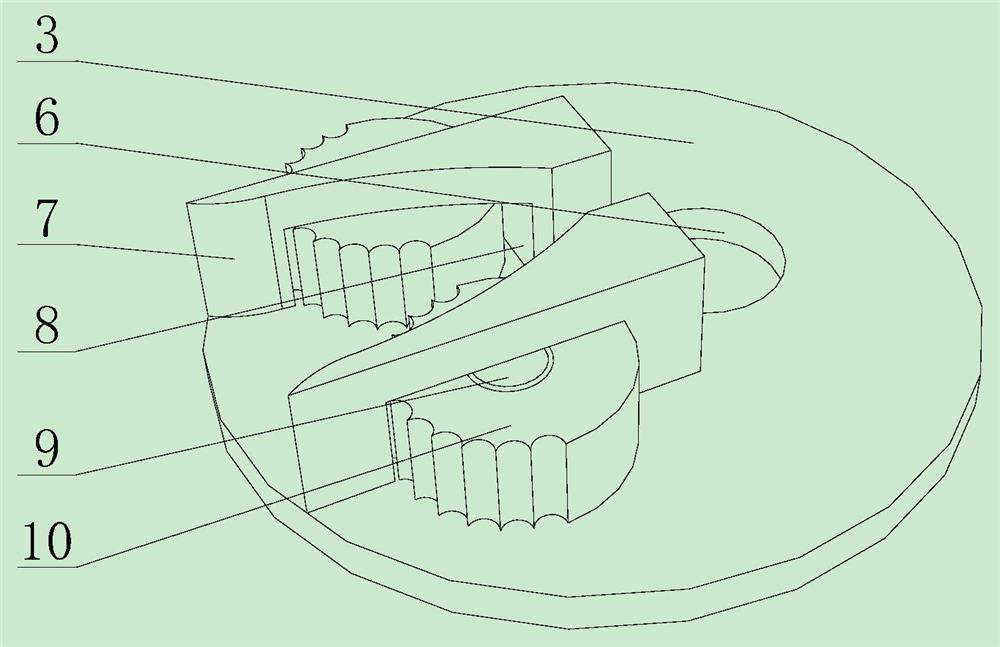

[0035] like figure 1 - Image 6 As shown, the present invention provides a vertical ultrasonic bottle washing machine that can stably load and unload materials, including a bottle washing machine main body 1, a bottle container conveyor belt 2, a bottle container protective cover 3 and a main body support pile 5, and the bottle washing machine main body 1 A bottle conveyor belt 2 is provided on the top of the bottle washer, and a bottle protector 3 is provided on the top of the bottle washer main body 1 and located on the right side of the bottle conveyor belt 2. The bottom of the bottle washer main body 1 is provided with a main body support pile 5. The bottom end of the inner wall of the bottle protector 3 is provided with a quantitative input roller 10. The quantitative input roller 10 is used to input the bottles to be cleaned according to the number of grooves above, and quantitatively control the number of bottles. 1. It is electrically connected to an external power su...

Embodiment 2

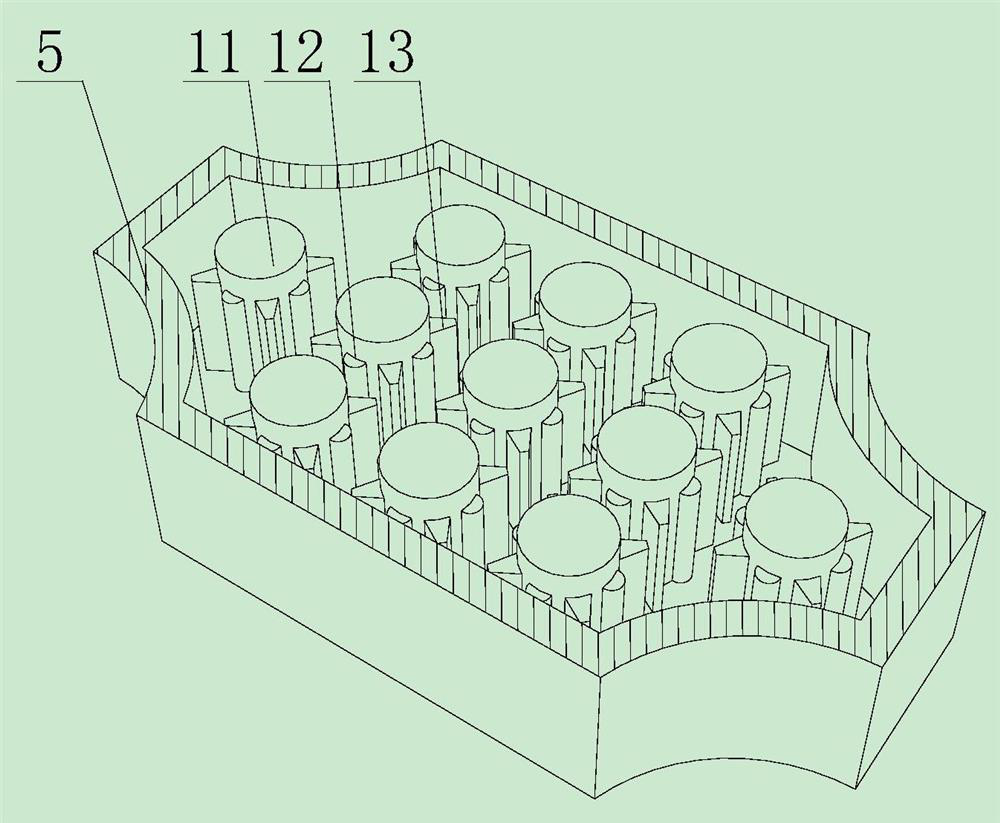

[0042] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the upper and lower ends of the damping cylinder 11 are fixedly installed on the inner wall of the main body support pile 5, and the surface of the damping cylinder 11 is provided with half arcs around it. Support column 12, the inner side of the half-arc support column 12 is fixedly installed around the surface of the shock-absorbing cylinder 11, and the upper and lower ends of the half-arc support column 12 are fixedly installed on the inner wall of the main body support pile 5, and the surface of the main body support pile 5 is surrounded by and A rectangular supporting plate 13 is arranged on the inner side of the half-arc supporting column 12 , the inner side of the rectangular supporting plate 13 is fixedly installed around the surface of the shock-absorbing cylinder 11 , and the upper and lower ends of the rectangular supporting plate 13 are fixedly instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com