Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

617 results about "Gold foil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for manufacturing an electromagnetic interference shielding metallic foil cladded plastic product

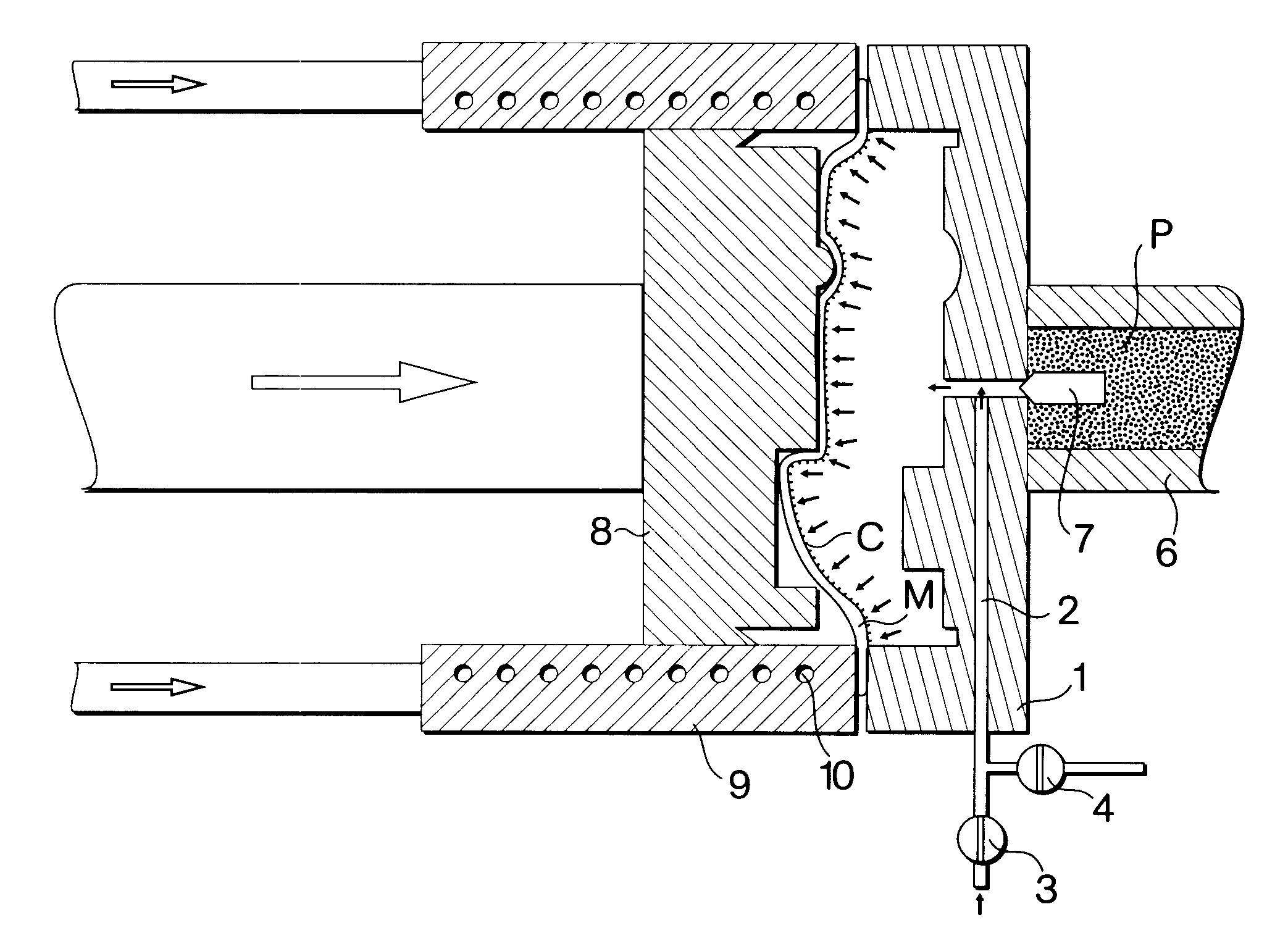

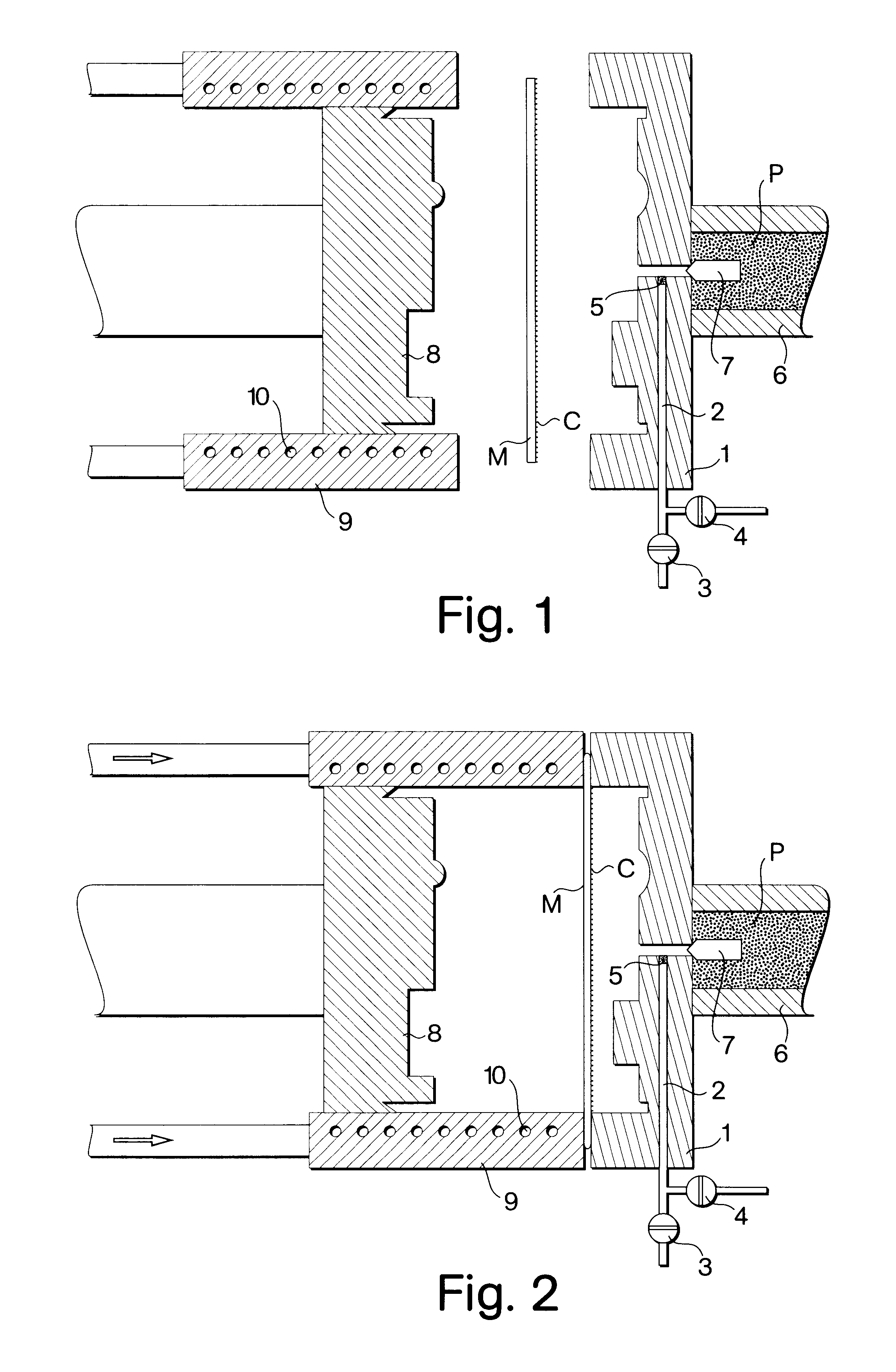

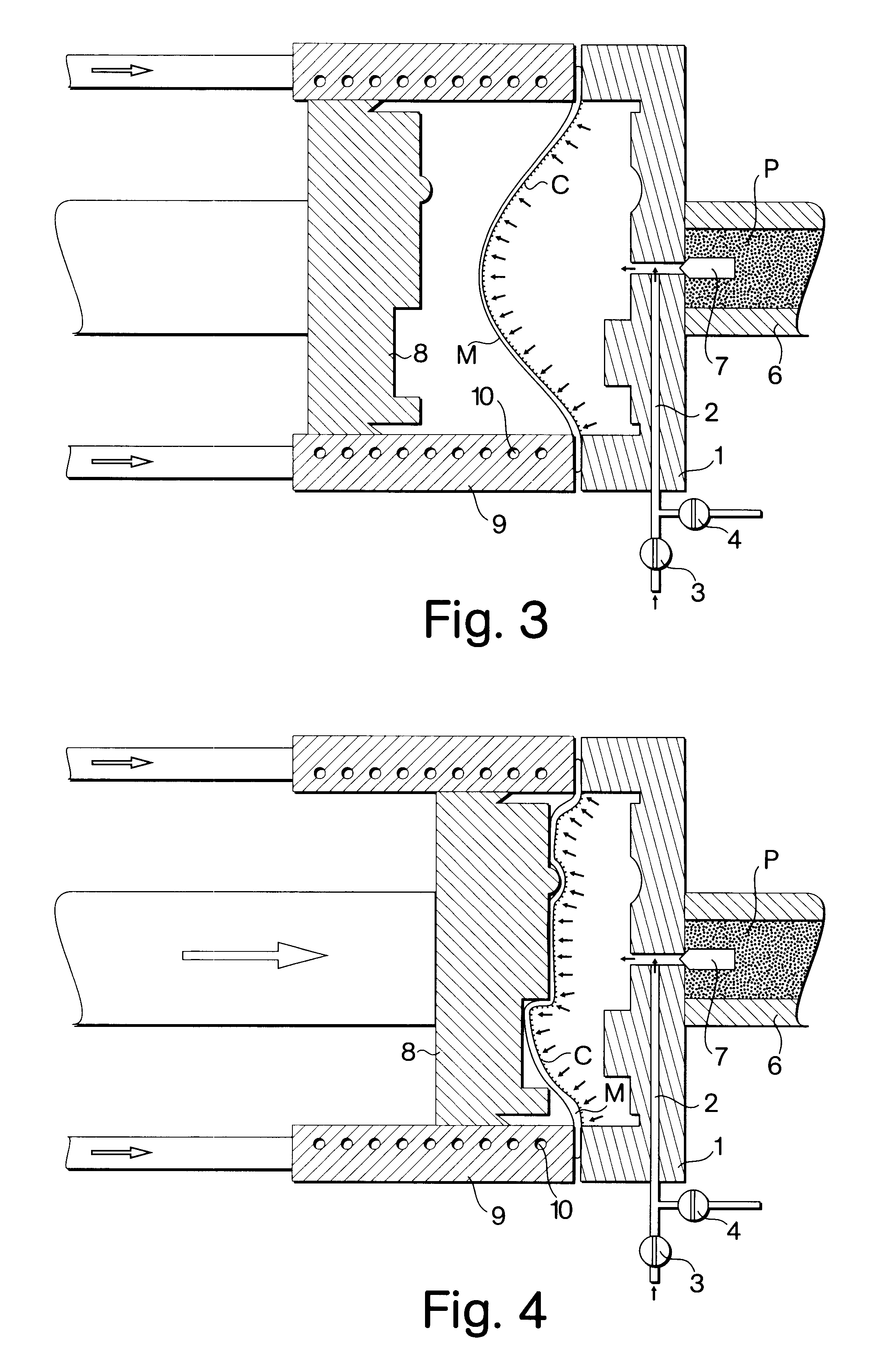

The present invention provides a process and apparatus for manufacturing an electromagnetic interference shielding metallic foil cladded plastic product. The process comprises (a) coating one side of a superplastic alloy plate with a coupling agent or a hot melt adhesive; (b) placing the coupling agent- or hot melt adhesive-coated superplastic alloy plate in a mold, and superplastically forming the superplastic alloy plate to a superplastic alloy foil with a predetermined shape, such that another side of the superplastic alloy foil is attached to the mold and the coupling agent- or hot melt adhesive-coated side of the superplastic alloy foil is spaced apart from the mold to form a mold cavity, wherein an injection machine is attached to the mold cavity, and wherein the injection machine is capable of injecting softened plastic into the mold cavity; (c) introducing softened plastic from the injection machine to the mold cavity, such that plastic adheres on the coupling agent- or hot melt adhesive-coated side of the superplastic alloy foil, and an electromagnetic interference shielding metallic foil cladded plastic product is formed; and (d) removing the plastic product from the mold. The final metallic plastic product can not only have as intricate a shape as an ordinary plastic product, but also has a shielding effectiveness as high as an ordinary metallic shield.

Owner:NAT SCI COUNCIL

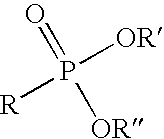

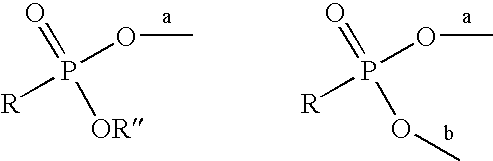

Composite structure with organophosphonate adherent layer and method of preparing

The present invention provides an article comprising: a substrate having a surface and comprising electrodeposited copper foil or copper alloy foil; an adherent layer serving to promote adhesion, comprising at least one organophosphonate or salt thereof covalently bound to the surface; and a functional layer, comprising at least one polymer bound to the adherent layer. The present invention further provides devices comprising a heat source or electronic component and the article described above, wherein the heat source is in thermal contact with the substrate and the electronic component is in electrical contact with the substrate.Also provided is a method of producing the above-described article.

Owner:ACULON

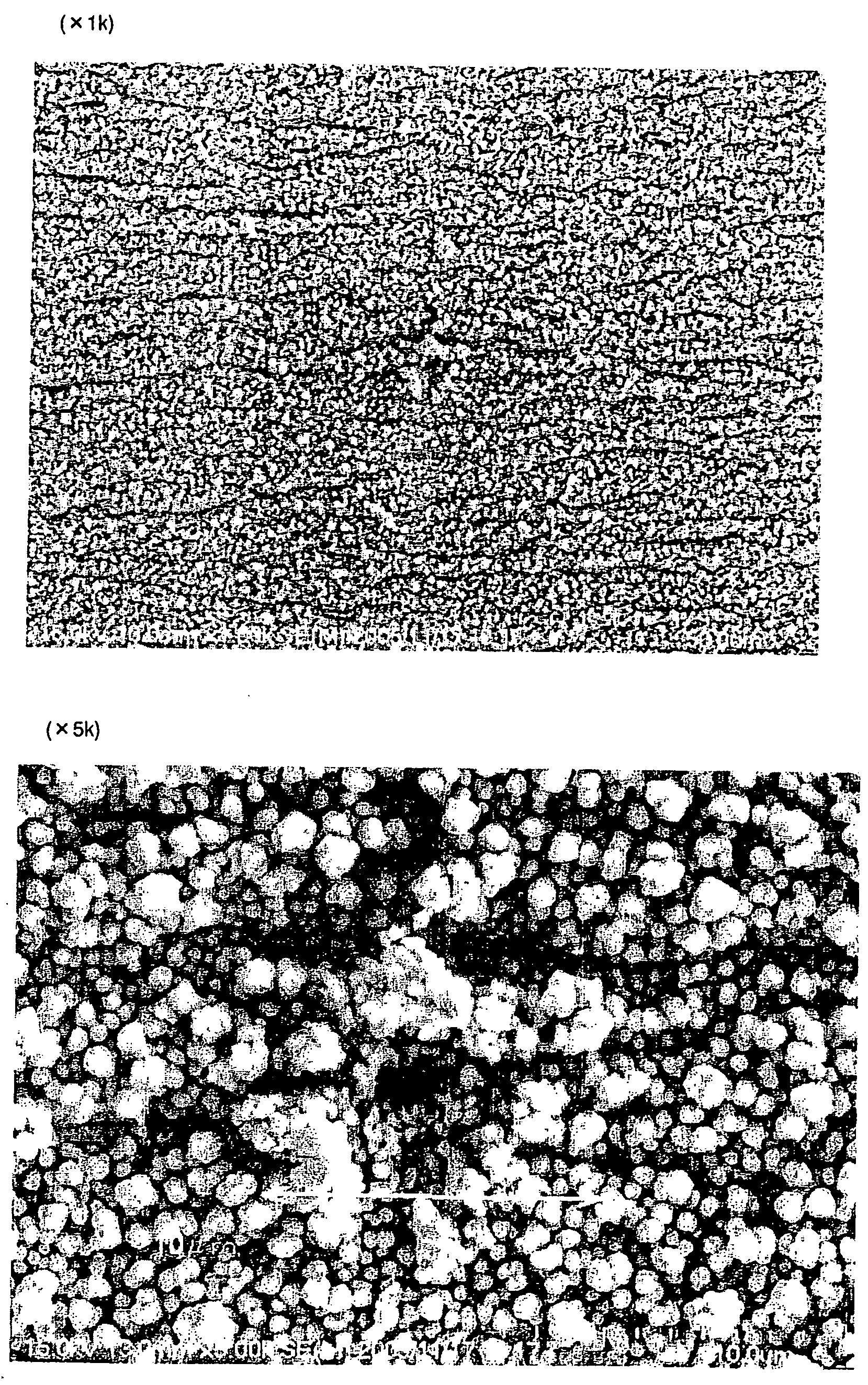

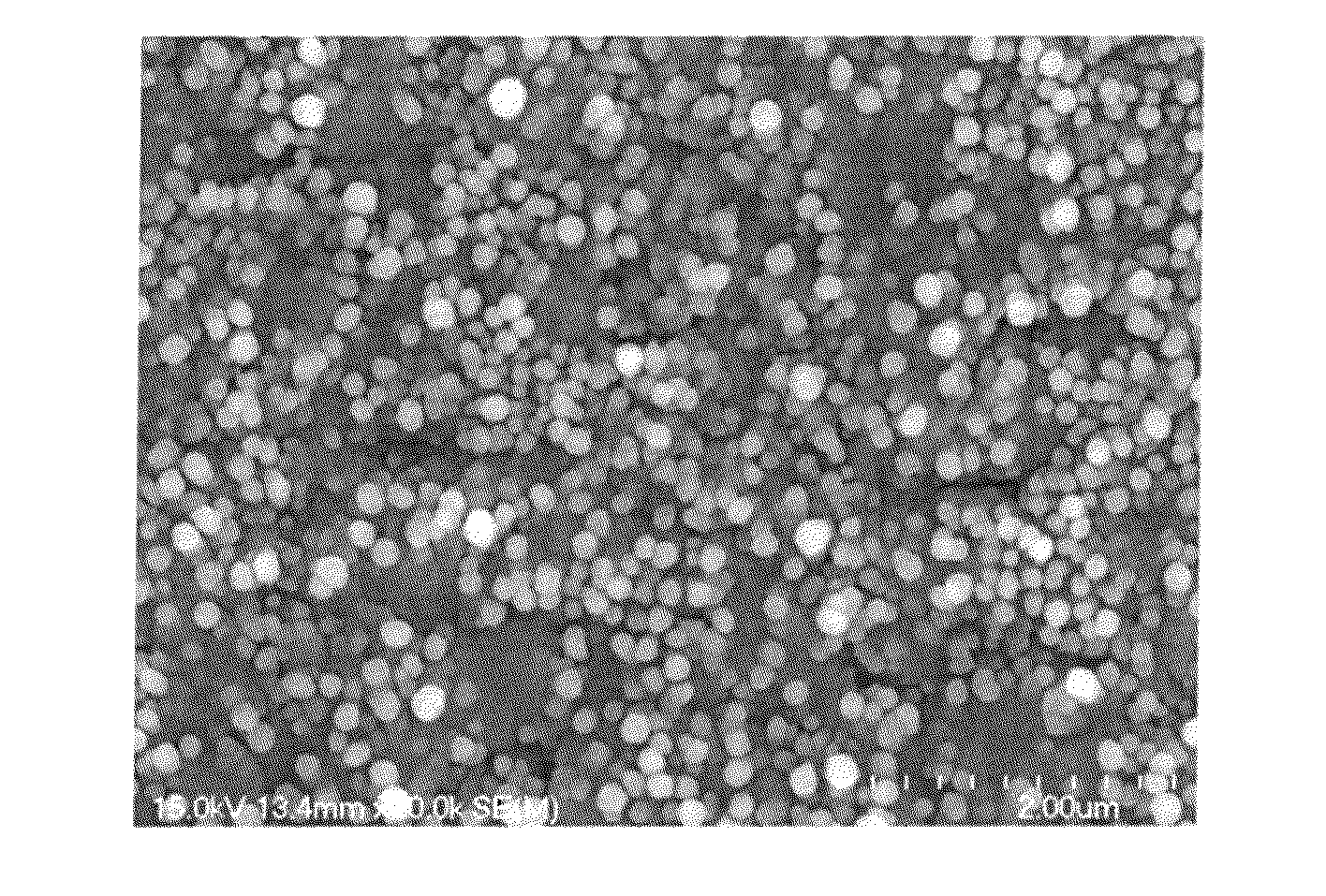

Rolled Copper or Copper Alloy Foil with Roughened Surface and Method of Roughening Rolled Copper or Copper Alloy Foil

ActiveUS20090162685A1Improve featuresInhibition formationPrinted circuit aspectsPrinted circuit manufactureTin platingCopper sulfate

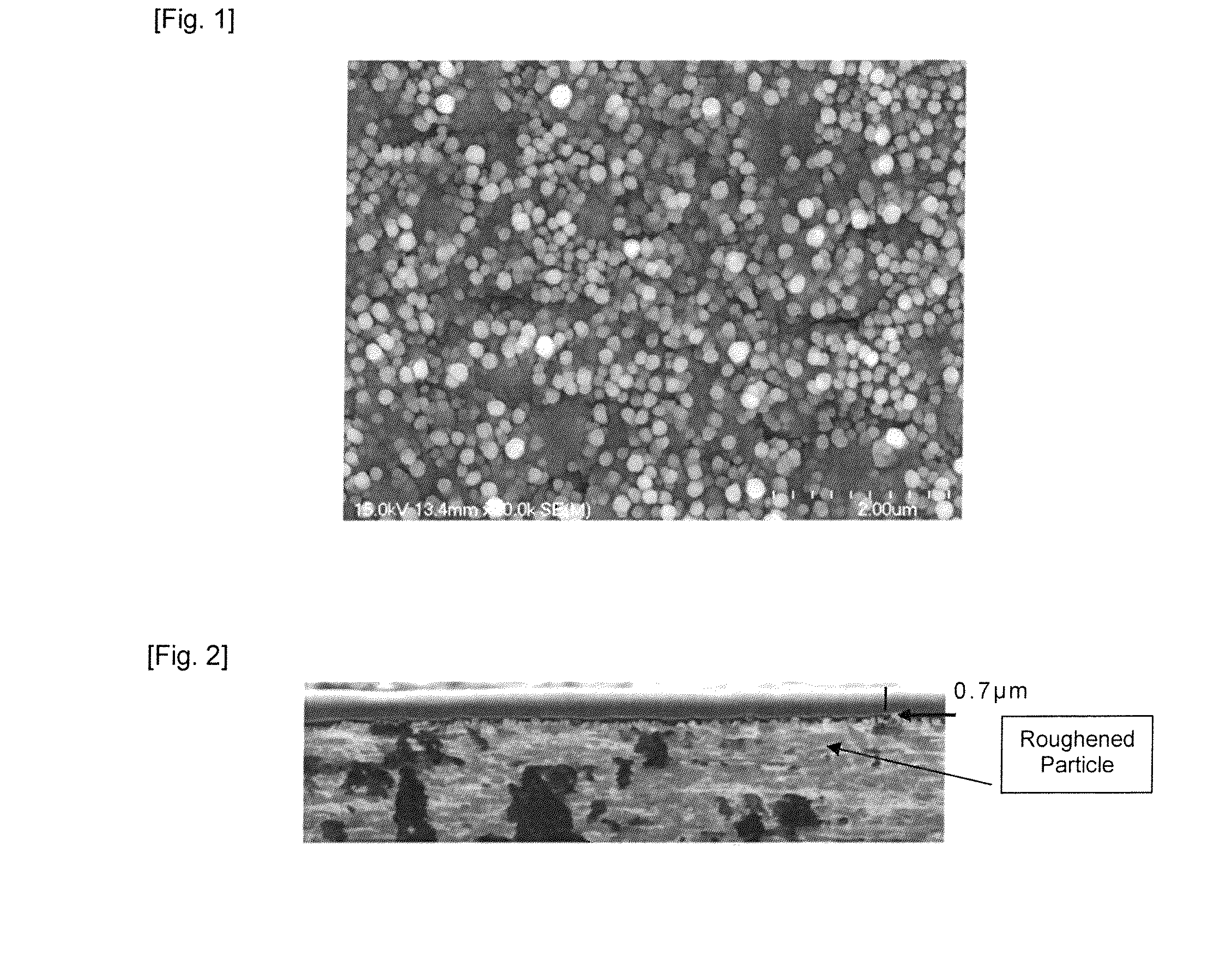

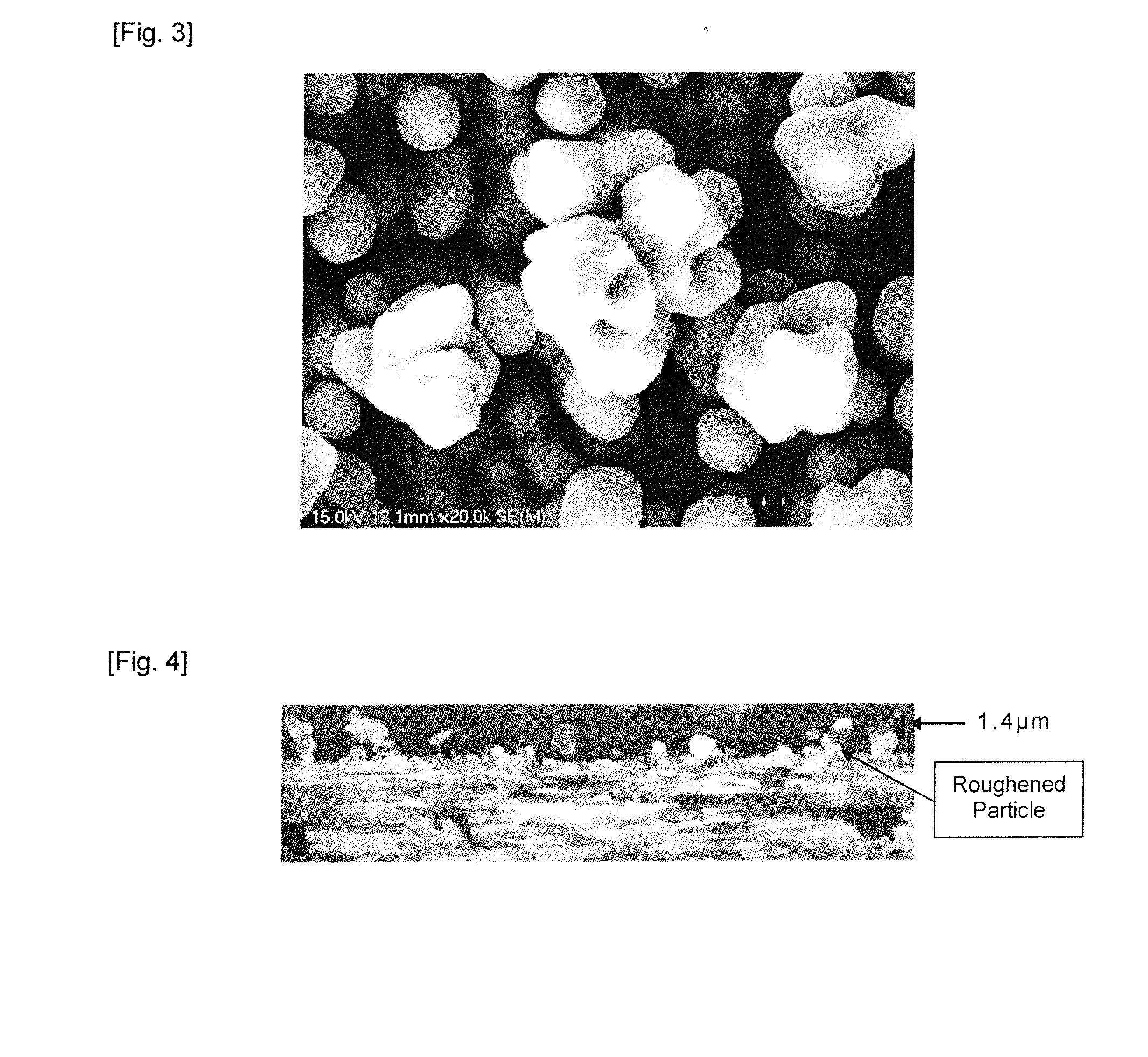

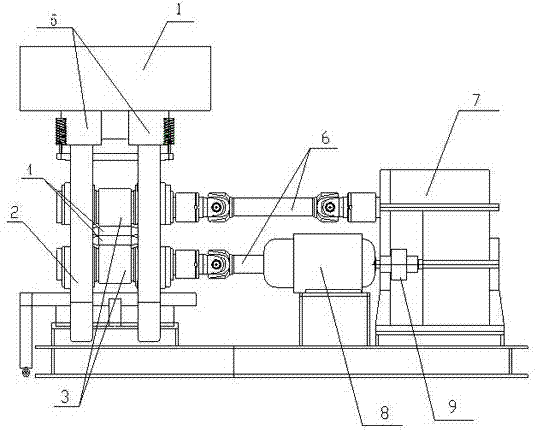

Provided is a rolled copper or copper alloy foil having a roughened surface formed of fine copper particles, obtained by subjecting a rolled copper or copper alloy foil to roughening plating with a plating bath containing copper sulfate (Cu equivalent of 1 to 50 g / L), 1 to 150 g / L of sulfuric acid, and one or more additives selected among sodium octyl sulfate, sodium decyl sulfate, and sodium dodecyl sulfate under the conditions of a temperature of 20 to 50° C. and a current density of 10 to 100 A / dm2. The provided rolled copper or copper alloy foil subject to roughening is reduced in craters which are obvious defects unique to rolled copper or copper alloy foils having a roughened surface, has high strength, adhesive strength with the resin layer, acid resistance and anti-tin plating solution properties, high peel strength, favorable etching properties and gloss level, and also suits for use in producing a flexible printed wiring board capable of bearing a fine wiring pattern. Additionally provided is a method of roughening the rolled copper or copper alloy foil.

Owner:JX NIPPON MINING& METALS CORP

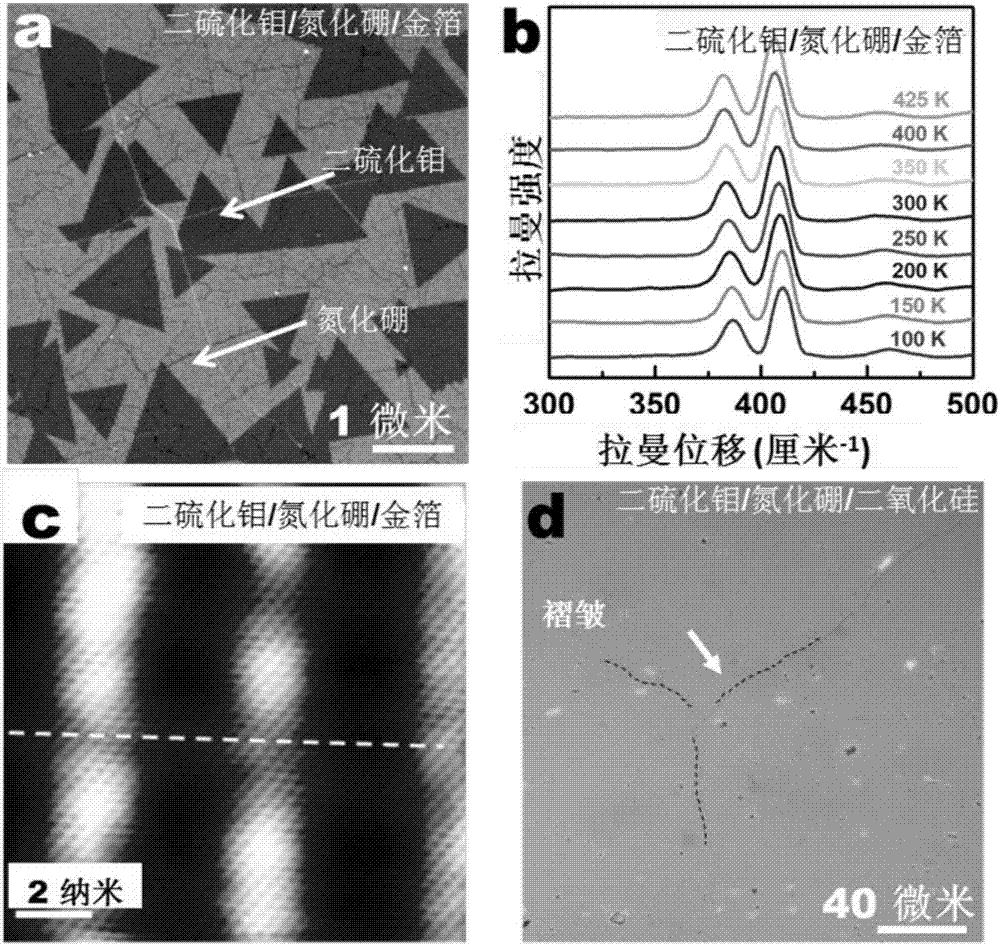

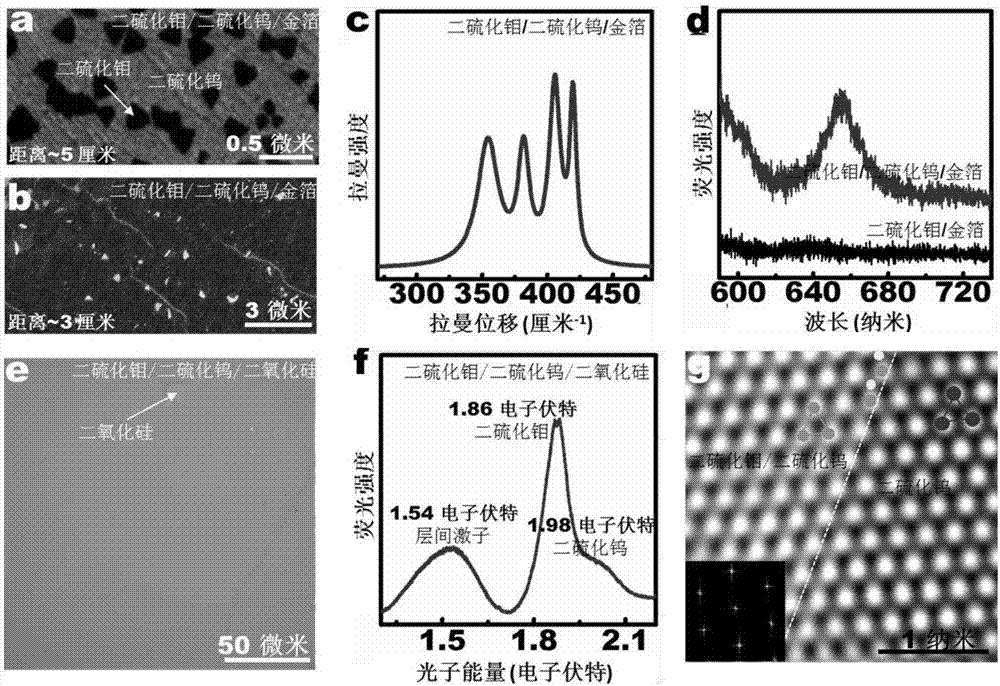

Method for preparing transition metal chalcogenide/two-dimensional layered material interlayer heterogeneous structure through two-step chemical vapor deposition method

InactiveCN107447200AAchieve epitaxial growthAvoid pollutionChemical vapor deposition coatingChemical vapor depositionGold foil

The invention discloses a method for preparing a transition metal chalcogenide / two-dimensional layered material interlayer heterogeneous structure through a two-step chemical vapor deposition method. The method comprises the following steps that (1) gold foil is cleaned and subjected to high-temperature pre-annealing treatment; (2) the annealed gold foil is placed in a high-temperature tube furnace, a two-dimensional layered material is grown on the gold foil through the low-pressure chemical vapor deposition method, and a two-dimensional layered material / gold foil sample is obtained after the temperature is lowered to the room temperature; (3) the two-dimensional layered material / gold foil sample is put into a second high-temperature tube furnace, and powdered sulfur, molybdenum oxides and the two-dimensional layered material / gold foil are sequentially arranged according to the order from the upstream portion to the downstream portion; (4) argon and hydrogen are pumped into a reaction chamber, and molybdenum disulfide is grown; and (5) after growing of molybdenum disulfide is finished, the molybdenum disulfide / two-dimensional layered material interlayer heterogeneous structure on the gold foil is obtained.

Owner:PEKING UNIV

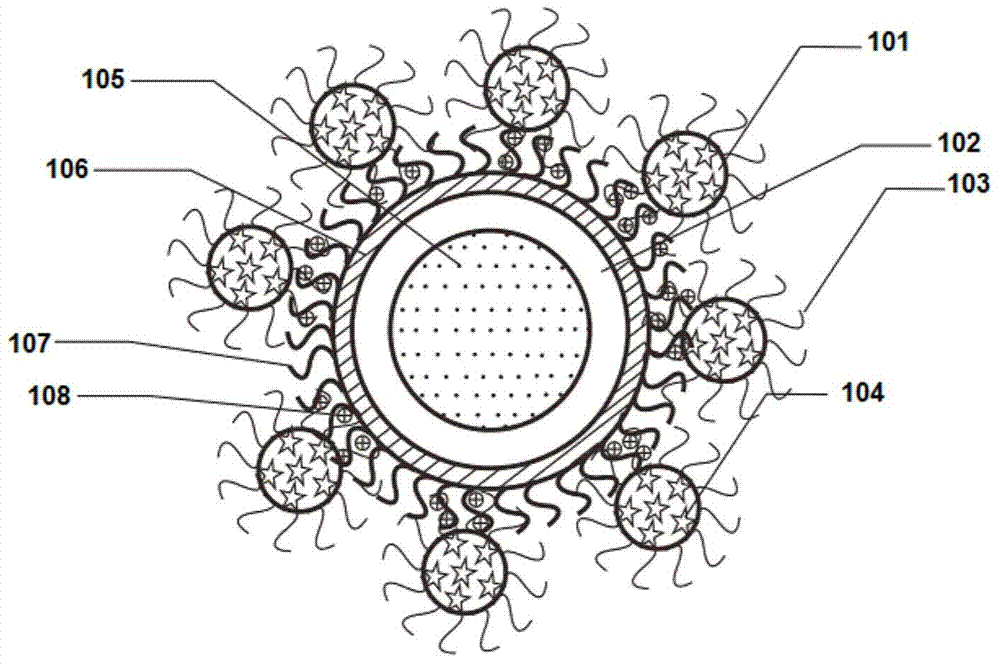

Double-ion response type SERS (Surface Enhanced Raman Scattering) probe and preparation method thereof

InactiveCN103616367AEasy to separatePlay a role in purifying the environmentRaman scatteringNanotechnologyResponse typeSilicon dioxide

The invention discloses a double-ion response type SERS (Surface Enhanced Raman Scattering) probe and a preparation method thereof. The probe comprises two nano particles with independent core-shell structures, wherein a carrier nano particle comprises four layers of core-shell structures; the four layers of core-shell structures are as follows: the innermost layer is made of Fe3O4 magnetic nano balls, a layer of silicon dioxide is coated outside the innermost layer, the second-outer layer is a gold foil shell layer, and the outermost layer is an oligonucleotide coating layer; an object nano particle comprises two layers of core-shell structure; the two layers of core-shell structure are as follows: the inner core is made of Raman molecule marked gold nano-balls, and a shell is an oligonucleotide coating layer. Due to the adoption of a specific base sequence in the oligonucleotide coating layer, the identify and SERS trace detection on two metal ions, namely silver / mercury, in an environment solution can be performed at the same time; furthermore, under the action of an external magnetic field, the probe and the obtained silver / mercury ions can be rapidly separated from an initial environment solution system, and therefore, the function of purifying the environment is realized.

Owner:SOUTHEAST UNIV

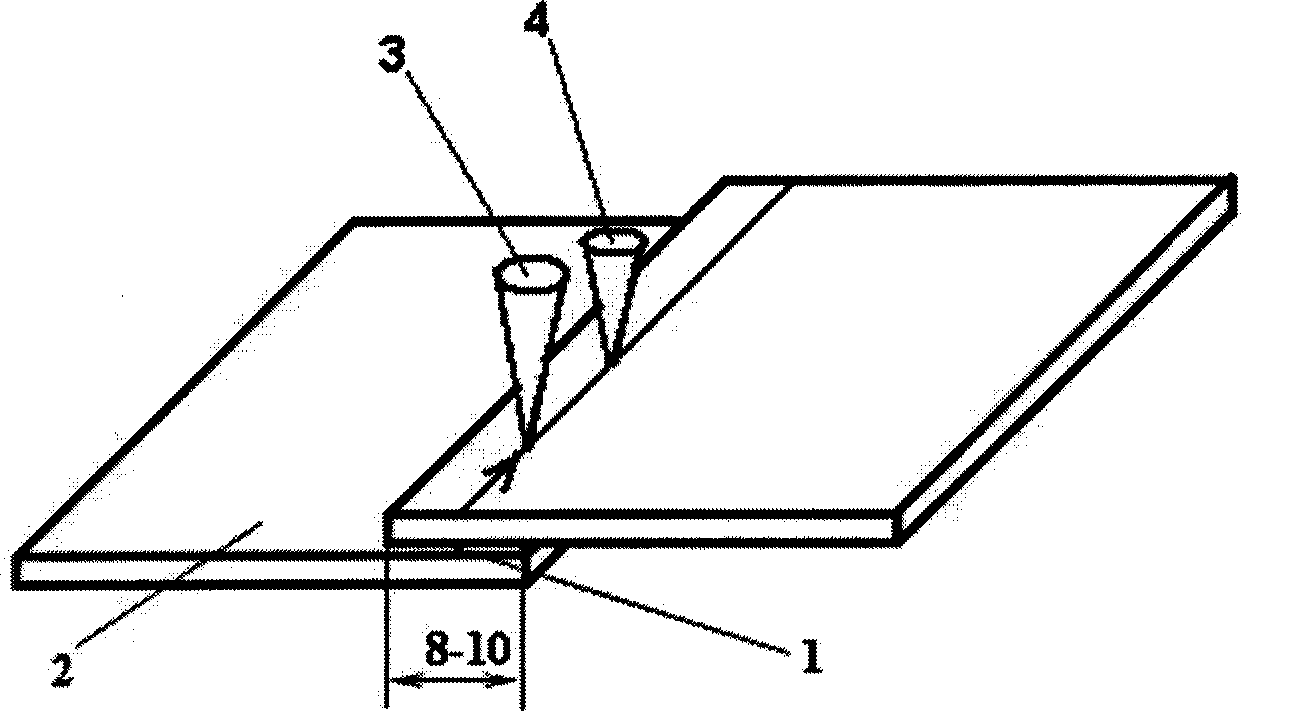

Galvanized steel sheet lap-over laser welding method

InactiveCN101508058AReduce manufacturing costImprove welding qualityWelding/soldering/cutting articlesMetal working apparatusAlloyWeld seam

The invention discloses a laser welding method for lapping galvanized steel sheets, which comprises: placing a Al-Sn alloy foil containing 35 to 45 weight percent of Sn between faying surfaces of the steel sheets; and utilizing two laser beams of which the power is respectively from 2 to 3KW and from 3 to 4KW to weld welding seams, wherein the space of the laser beams is between 20 and 50mm and the welding speed is between 4 and 8m / min. The method has low production cost and stable welding quality; and the strength of the obtained welding seams is greater than that of base metal, no welding spatter exists on the surface, and the corrosion resistance of the welding seams is more than three times higher than that of by a sweeping-out method. The method can be used for laser welding of lapped welding seams of DP series, TRIP series and HSLA series hot galvanized steel sheets, and realizes high efficiency, low pollution and low waste material of welding production.

Owner:HUAZHONG UNIV OF SCI & TECH

Low-temperature hot stamping hot melt adhesive for alumite and preparation method thereof

ActiveCN103468174ALow softening temperatureReduce adhesionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesHot stampingNitrocellulose

The invention provides low-temperature hot stamping hot melt adhesive for alumite and a preparation method of the low-temperature hot stamping hot melt adhesive. In the existing alumite rotary gold stamping process, heat transfer hot stamping temperatures are all within the range of 120 DEG C to 200 DEG C, if the temperature of a gold stamping plate is too high, energy consumption in the gold stamping process is increased, alumite hot stamping foil or printing materials can deform by being heated, and then hot stamping is inaccurate. The low-temperature hot stamping hot melt adhesive is prepared from the following raw materials, by weight, 1-6 parts of chloroethylene-vinyl acetate resin, 1-10 parts of terpene resin, 1-10 parts of acrylic ester, 1-5 parts of nitrocellulose, 1-5 parts of fumed silica, 20-70 parts of ethyl acetate, 10-50 parts of ethyl alcohol and 1-5 parts of propyl acetate. The low-temperature hot stamping hot melt adhesive is low in softening temperature and high in adhesive power, heat transfer hot stamping temperatures are within the range of 85 DEG C to 100 DEG C, energy consumption can be remarkably reduced, the problems that the gold stamping foil or the printing materials easily deform by being heated by high-temperature hot stamping, so that waste caused by inaccurate hot stamping is generated are solved.

Owner:云南玉溪东魅包装材料有限公司

Method for manufacturing radio frequency tags with hot and cold stamping technology

ActiveCN102339402AWide range of useFast hot stampingAntenna supports/mountingsRadiating elements structural formsHot stampingInsulation layer

The invention discloses a manufacturing method of radio frequency tags, and the radio frequency tags are manufactured with a hot and cold stamping technology; the process method has the steps that: polyvinyl chloride (PVC), polypropylene (PP), polyethylene terephthalate (PET), paper, plastics and the like are adopted as base materials, and electro-metal stamping foils are stamped on the base materials by a stamping machine through a hot stamping or cold stamping technology, then waste is discharged from other parts of the metal foils, and antenna patterns are obtained; and if coil antennas are to be manufactured, insulation layers need to be paved on coils, the electro-metal stamping foils are stamped on the insulation layers and are connected with the ends of the antennas to form bridges, i.e. radio frequency antennas. Finally, chips are reversely pasted on the antenna bridges, coated and packaged, and radio frequency tags are obtained. A traditional radio frequency tag process has the disadvantages of too high cost, complicated process, long production time, certain pollution to the environment and the like, and the method for manufacturing radio frequency tags with the hot and cold stamping technology can effectively reduce the radio frequency tag manufacturing cost, simplify the complicated process, and meet the market demand for the low-cost radio frequency tags.

Owner:哈尔滨大东方新材料科技股份有限公司

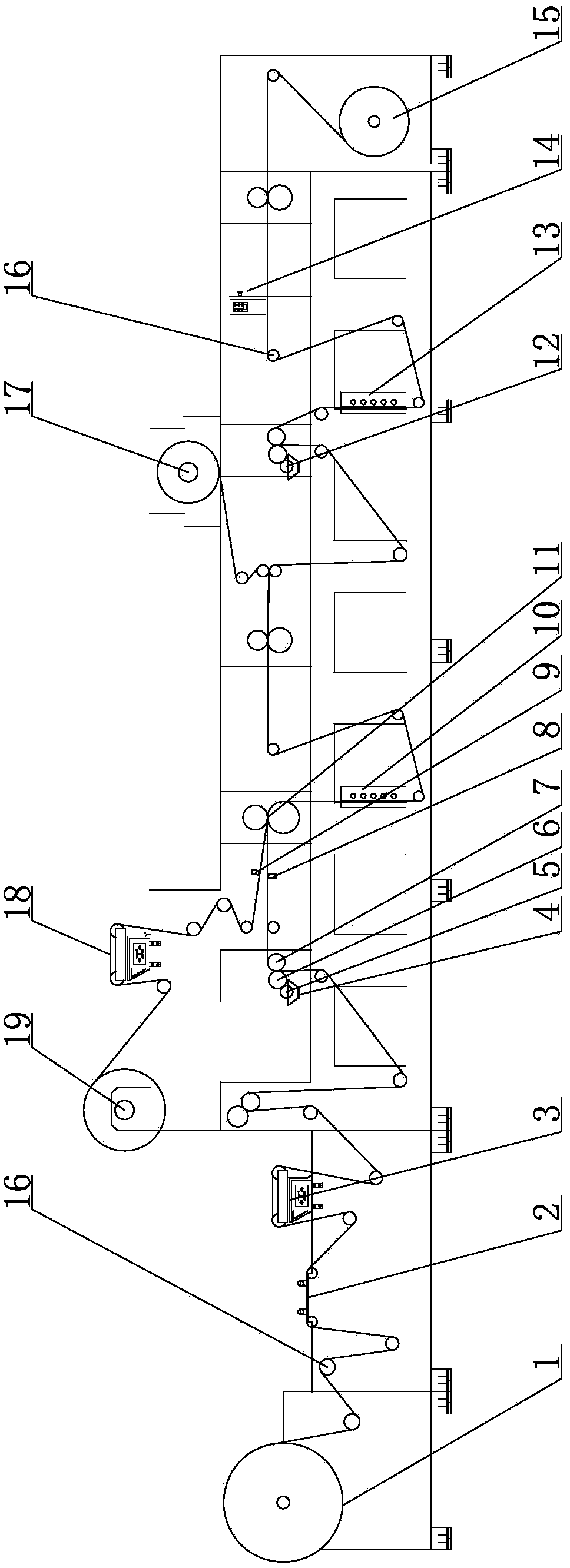

Method and device for triple-corresponding positioning compounding of anti-counterfeit printing

ActiveCN103818135AReduce processing stepsIncrease productivityPattern printingBronze printingMaterial consumptionHot stamping

The invention relates to a method for triple-corresponding positioning compounding of anti-counterfeit printing. The method comprises the following steps: printing patterns on a flexible printing machine; printing first identifying markers on two sides of each plate, thereby obtaining an anti-counterfeit identified coiled material; printing second identifying markers on the two sides of each plate of a gold blocking foil roll; finally, putting the printed anti-counterfeit identified coiled material, the gold blocking foil roll and a hot stamping plate on a triple-corresponding positioning compounding device for performing triple-corresponding combined positioning printing, thereby once finishing the hot stamping and cover ink printing of the anti-counterfeit identified coiled material. Meanwhile, the invention relates to the triple-corresponding positioning compounding device which comprises a hot stamping system, a gold blocking foil roll correcting system and a cover ink printing system. According to the invention, the processing procedure is reduced and the production efficiency is increased; the hot stamping efficiency is increased and the hot stamping speed can reach 50 meters per minute; the efficiency of the cover ink printing is increased and the bottleneck problem of ink scraping of cover scrape is thoroughly solved; the manpower is saved, the material consumption is reduced and the environmental protection is benefited.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

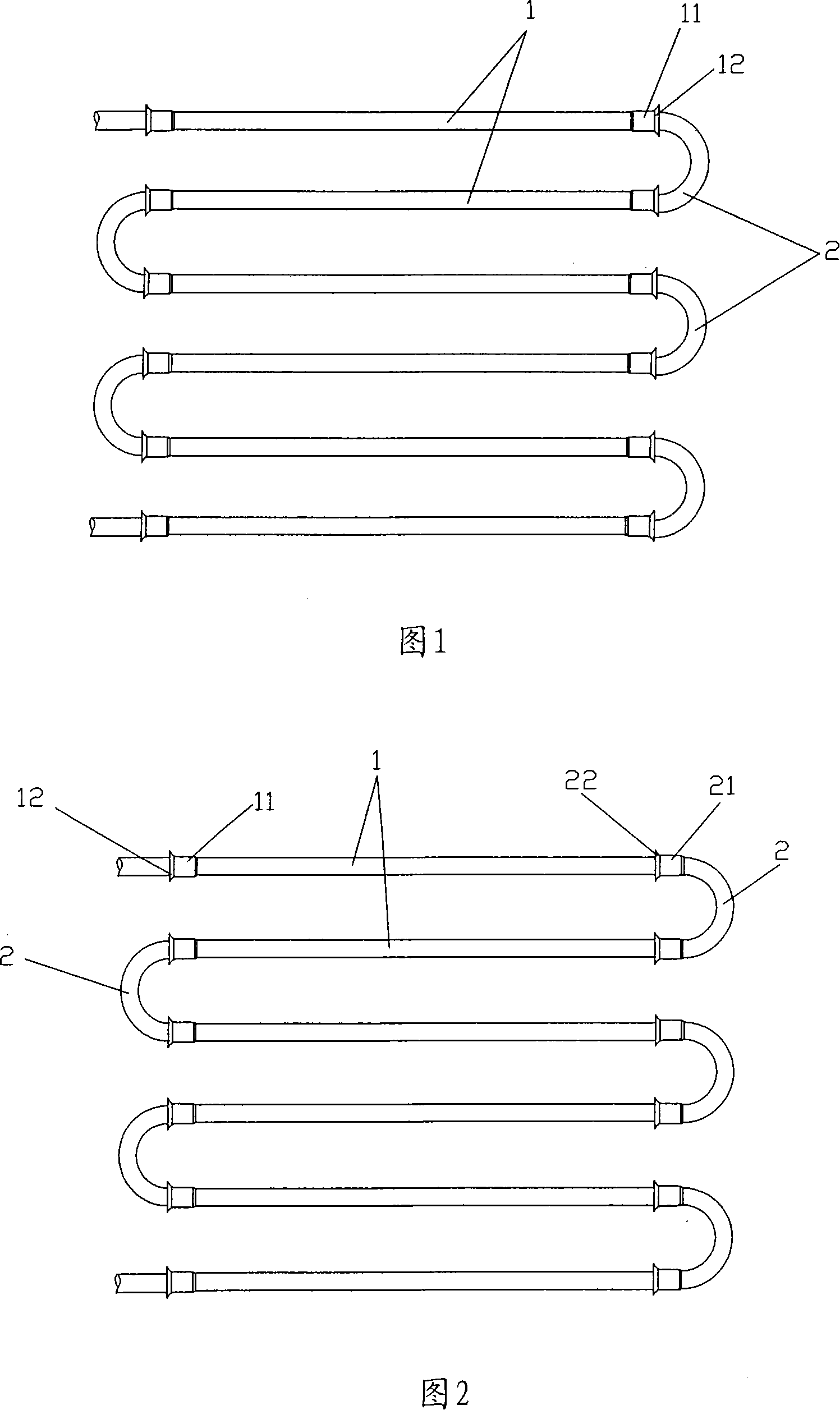

Heat-exchanging non-corrosive steel alloy foil coil and its manufacture method

InactiveCN101149236ADesign scienceReasonable structureSoldering apparatusTubular elementsAlloyCopper coil

This invention is a heat transferring stainless steel alloy foil coil and its production method. The coil is welded by stainless alloy foil straight pipe and bended pipe. The thickness of the straight pipe wall is 0.02mm-0.3mm, while the thickness of the bended pipe wall is 0.15-0.45mm. The production method includes: material prepare, bended pipe production, bended pipe or straight pipe end making and welding. This invention has reasonable structure and easy technique. The chlorine anion resistant capability of the said coil is higher than 100ppm and increases more than 50% times than that of the copper materials. The strength increases one time. The ductility is nearly the same as that of the copper materials. The heat power is higher than that of the existing heat transferring copper coil. All of its heat superconductivity is suitable for various kinds of condensers and evaporators. This invention can be used on various kinds of air conditioners and refrigerating equipments.

Owner:陈卫东

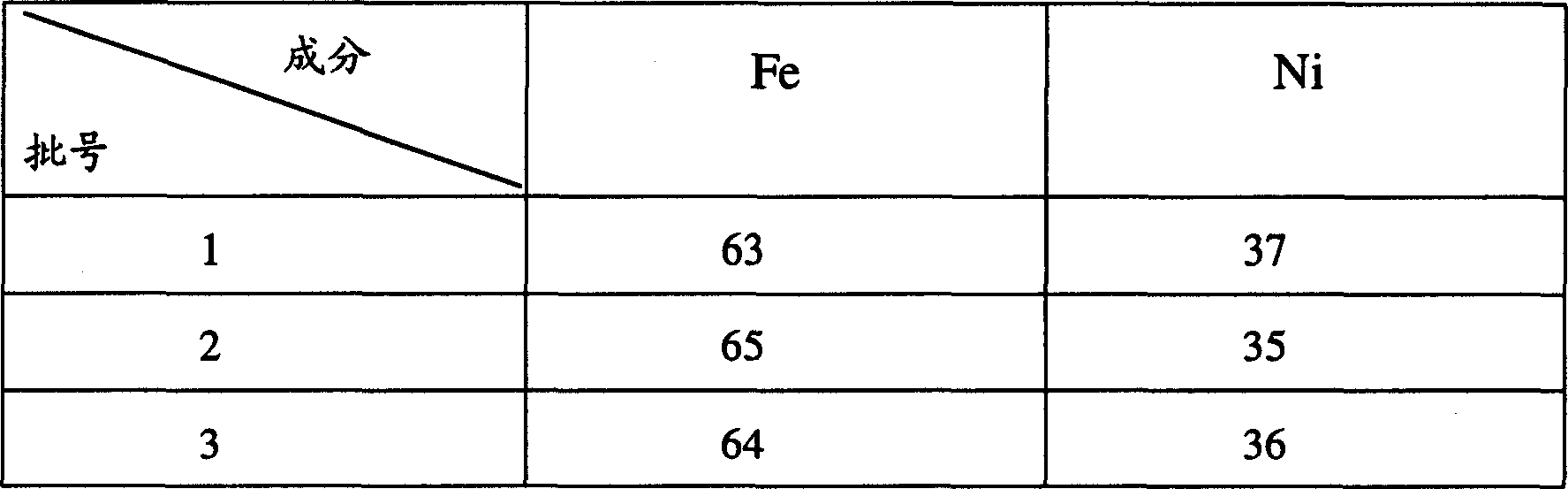

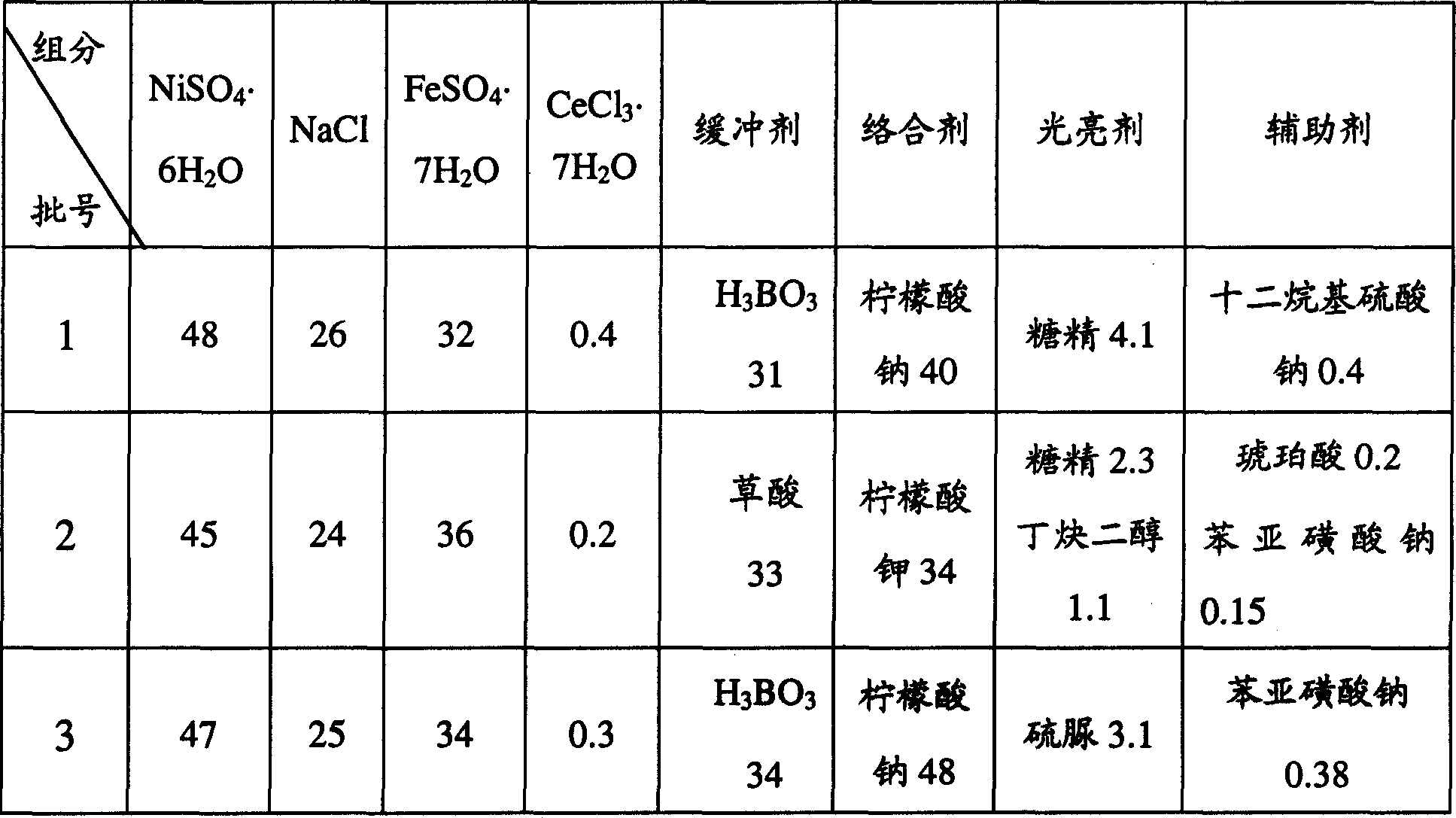

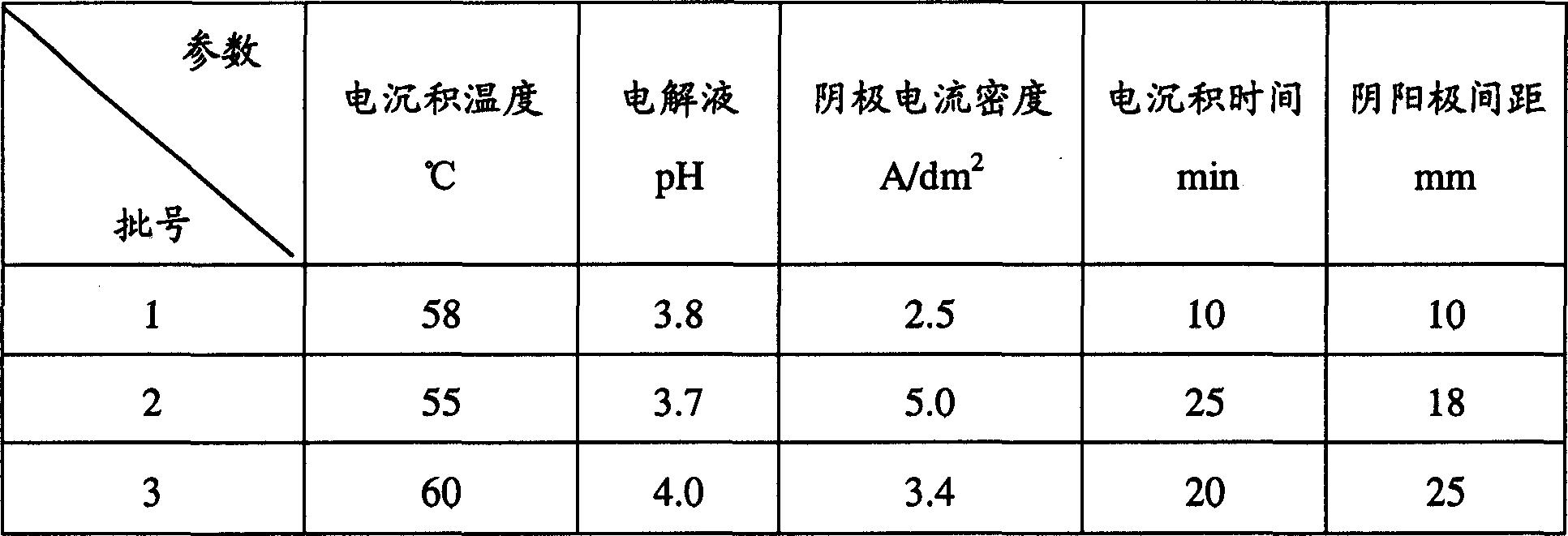

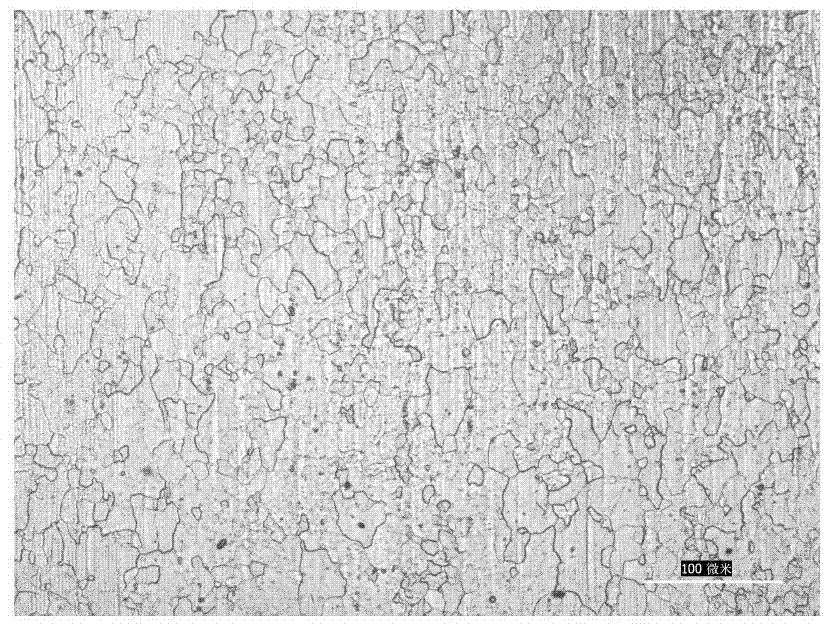

Process for preparing invor alloy foil

InactiveCN1793433AFlat and bright appearanceDense tissueElectroforming processesVolumetric Mass DensityAlloy

The invention relates to a Invar alloy foil manufacturing method. It belongs to precious alloy field. The Invar alloy is Fe-Ni alloy with 35-37% (wt%) nickel. The manufacturing method is electro deposition. Electrolyte is sulfate system with low metal salt density. Buffer, complexing agent, brightener, auxiliary, and 304 stainless steel, Ir2; the distance of cathode and anode is 10-30mm; the electro deposition time is 5-50min. and it includes the following steps: putting cathode in electroplating solution; electrifying direct current for curtain time; depositing Invar alloy on the cathode; taking it out; cleaning; drying; peeling off the formed Fe-Ni alloy layer to form Invar alloy foil.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Heat conduction electromagnetic shielding composite material and preparation method thereof

ActiveCN109881038AImproved vertical thermal conductivityFlexibleMagnetic/electric field screeningSynthetic resin layered productsElectromagnetic shieldingCopper foil

The invention discloses a heat conduction electromagnetic shielding composite material. The heat conduction electromagnetic shielding composite material is characterized by comprising a polymer matrixcomposite material and a heat conduction electromagnetic shielding membrane framework with a vertical orientation structure inlaid in the polymer matrix composite material; the heat conduction electromagnetic shielding membrane framework is parallel to the extension direction of the polymer matrix composite material; the heat conduction electromagnetic shielding membrane framework is made of oneor more composite membrane of gold foil, silver foil, copper foil, nickel foil, aluminum foil, iron foil, titanium foil, zinc foil, chromium foil, cobalt foil, a stainless steel plate and metal alloy;and the thickness of the heat conduction electromagnetic shielding membrane framework is 0.01mm to 0.2mm. The heat conduction electromagnetic shielding composite material is low in cost, simple in structure, simple and convenient to manufacture, easy to produce and capable of being used as a thermal interface material and an electromagnetic shielding material of an electronic device.

Owner:SHENZHEN INST OF ADVANCED TECH

Hydrographics transfer printing digital anti-counterfeit stained paper and printing method thereof

The invention relates to hydrographics transfer printing digital anti-counterfeit stained paper and a printing method thereof. The method comprises the following steps: 1, a pattern is manufactured; 2, a film is manufactured; 3, a printing screen printing plate is manufactured; 4, non-stamping characters and pattern are printed; 5, anti-counterfeit characters and pattern are printed, and a two-dimension code and an anti-counterfeit number are subjected to jet printing; 6, isolating resin is used for coating; 7, gold stamping bottom ink is used for coating; UV (ultraviolet) resin is used; characters and patterns of different colours are subjected to screen printing on the same body paper according to a method that the same colour is printed once, so that UV printing ink is formed; and the UV printing ink is subjected to light curing under LED (Light Emitting Diode) irradiation; 8, transfer printing gold stamping is carried out; a selected hot gold foil is subjected to transfer printing on the UV printing ink obtained in the step 6 by a stamping machine to obtain stamping characters and patterns of different colours; and 9, a tearable cover adhesive film is used for coating. The hydrographics transfer printing digital anti-counterfeit stained paper has an excellent anti-counterfeit effect, and can be widely applied to packaging boxes of various cosmetics, articles of everyday use, cigarettes, wine, food and the like; and meanwhile, the procurement cost in the prior art is reduced, and the identification is facilitated.

Owner:安徽江南春包装科技有限公司

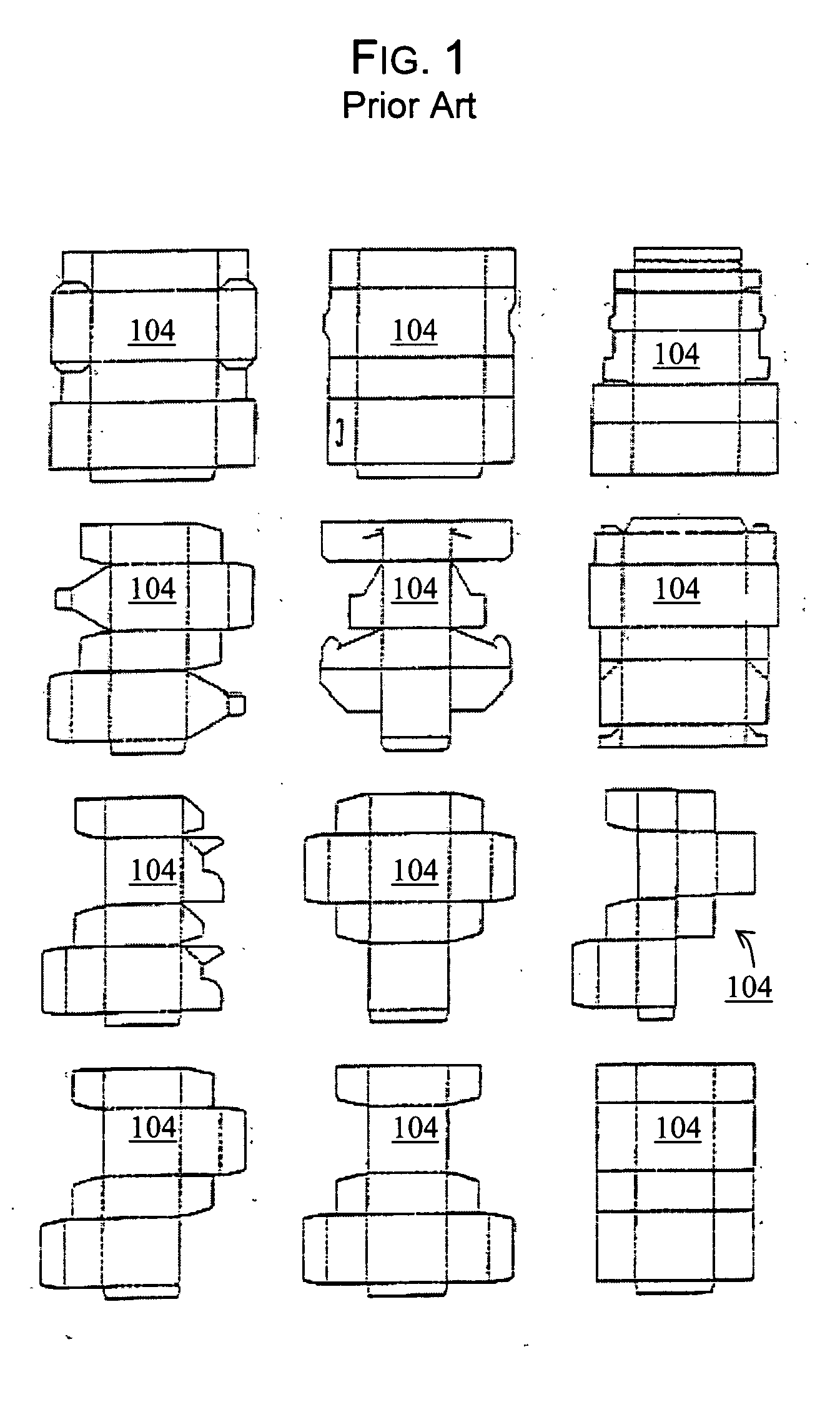

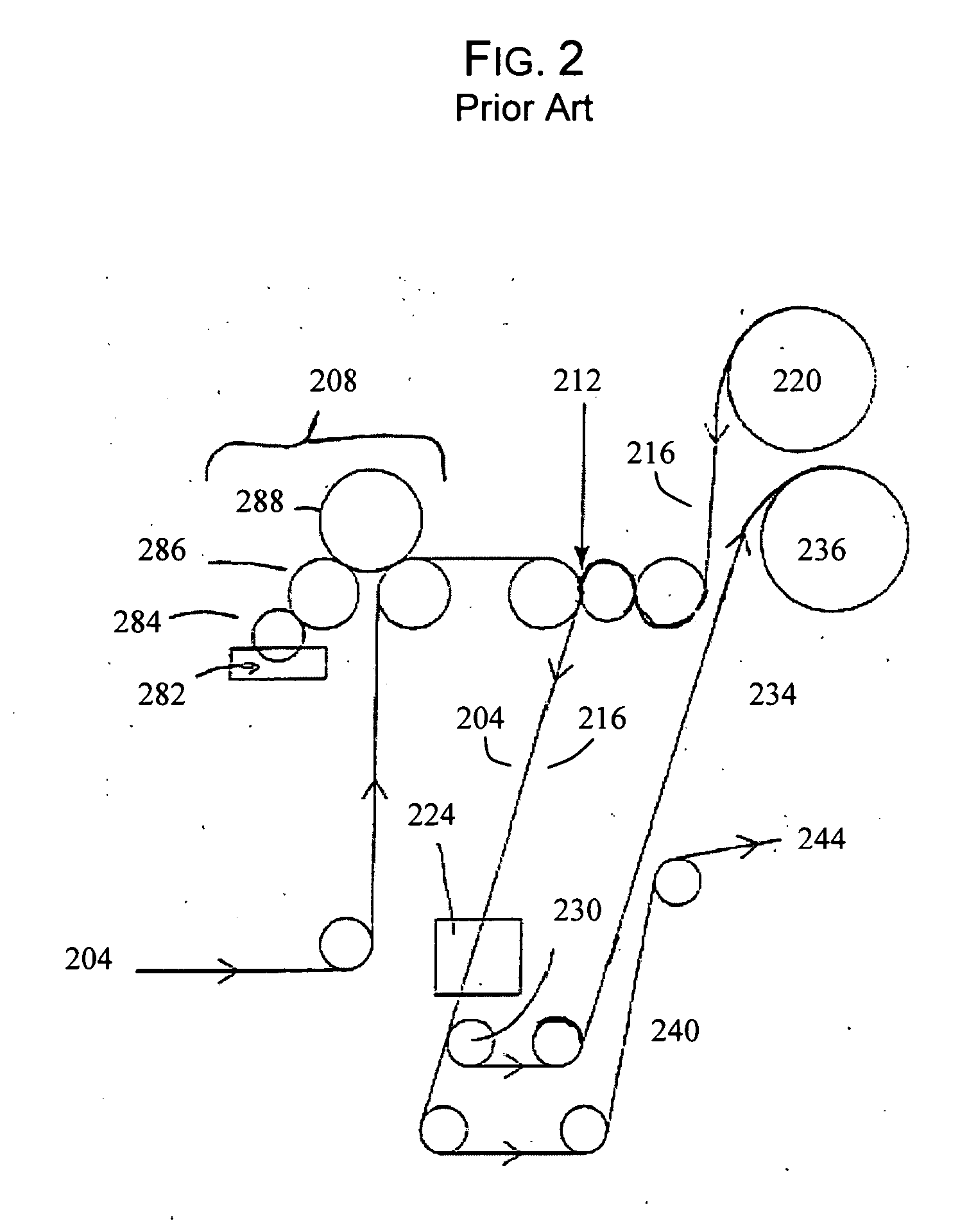

High speed microwave susceptor pattern application

The disclosure for High-Speed Microwave Susceptor Pattern Application discusses various methods for applying microwave susceptor material from a foil web to packaging, particularly food packaging such as folded carton flats. Typically, the microwave susceptor is applied in a pattern rather than uniformly to the packaging. The application can be done at high speeds using a modified form of cold foil printing or hot-stamp foil printing. The application can be done using hot-stamp sheet fed equipment to make use of legacy equipment. This abstract is intended to help those conducting a patent search for relevant disclosures and not intended as a limit on the scope of the claims.

Owner:HALIFAX SCOTT

Nickel-based interlayer material suitable for instantaneous liquid phase diffusion welding

InactiveCN101966629AHigh strengthImprove toughnessWelding/cutting media/materialsSoldering mediaHeat-affected zoneChemical composition

The invention discloses a nickel-based interlayer material suitable for instantaneous liquid phase diffusion welding. The material is characterized by comprising the following chemical elements in percentage by weight: 4.3 to 7 percent of Si, 3 to 8 percent B and the balance of nickel. The melting point temperature of a quickly solidified Ni-B-Si alloy foil belt with thickness of 30 microns is 950 to 1,050 DEG C; the material is suitable for instantaneous liquid phase diffusion welding among low-alloy steel, stainless steel and low-alloy steel / stainless steel composite materials, has high strength of seams and heat affected zones, good toughness and wide application, and is simple and convenient to manufacture; and the tensile strength Rm is 620MPa, the bent shaft diameter D is 6t, and no crack is produced when bending 180 degrees.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

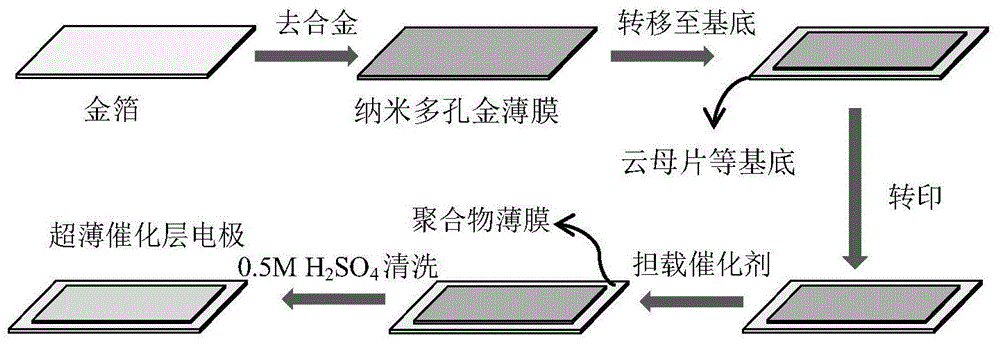

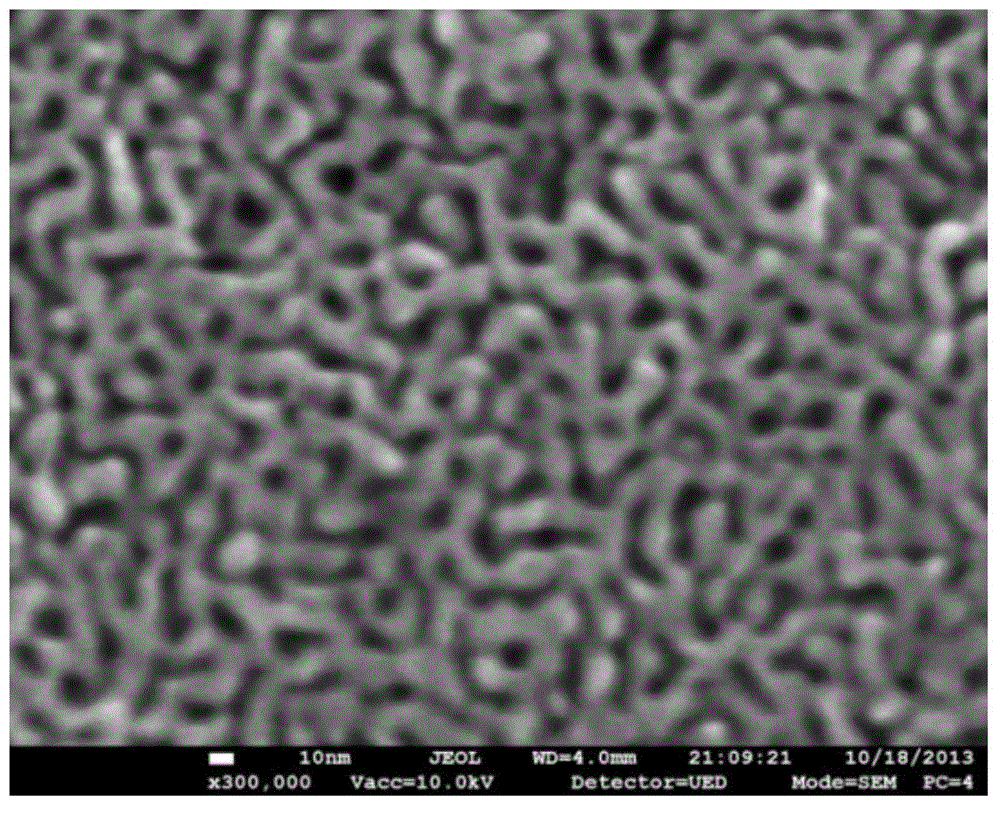

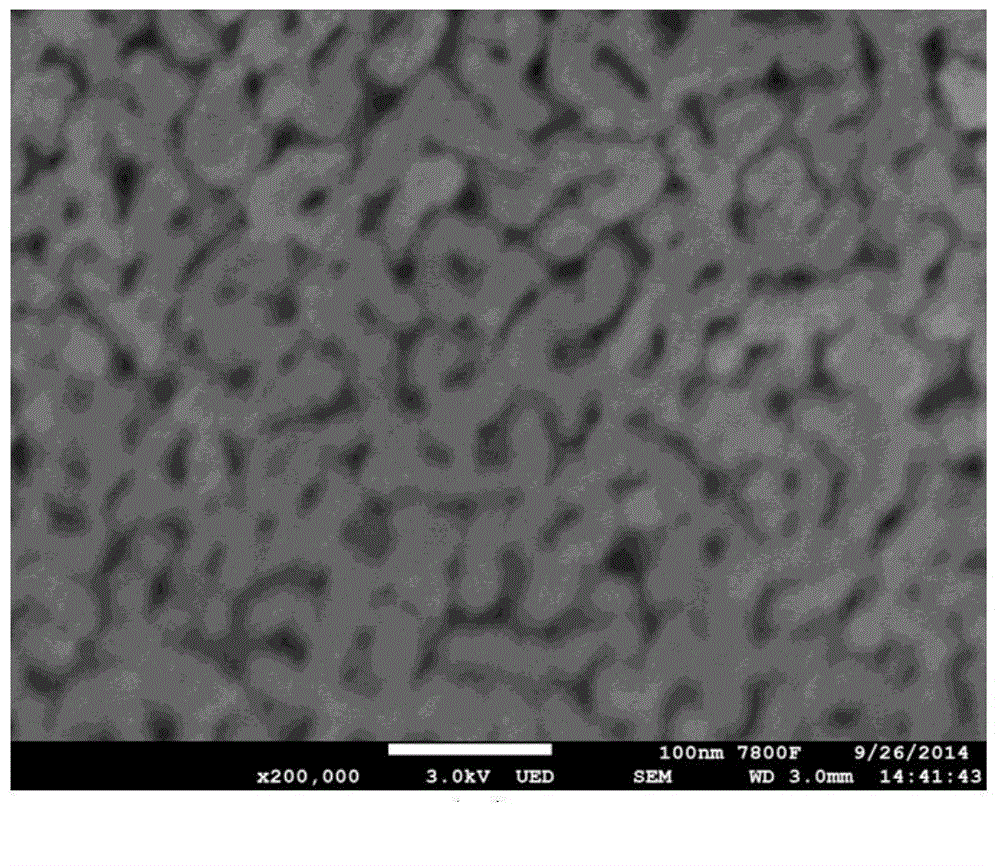

Structure of ultrathin membrane electrode for SPE water electrolysis and preparation and application of structure

ActiveCN105734606ALow resolutionGood dispersionCellsCell electrodesElectrochemical responseElectrolysis

The invention provides a structure of an ultrathin membrane electrode for SPE water electrolysis and a preparation method of the structure. The preparation method comprises the steps that firstly, a gold foil is adopted as a raw material, an dealloy method is adopted for obtaining a nano porous gold thin membrane, and then the thin membrane is transfer-printed to an ion exchange membrane; and the nano porous gold thin membrane is adopted as a supporting layer to carry a catalyst, and the ultrathin membrane electrode is manufactured. The manufactured membrane electrode has the beneficial effects of being small in catalyst carrying amount, high in utilization rate, easy to amplify and the like. The manufactured membrane electrode can be used for a water electrolysis pool, a regenerative fuel cell and other electrochemical reactors.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

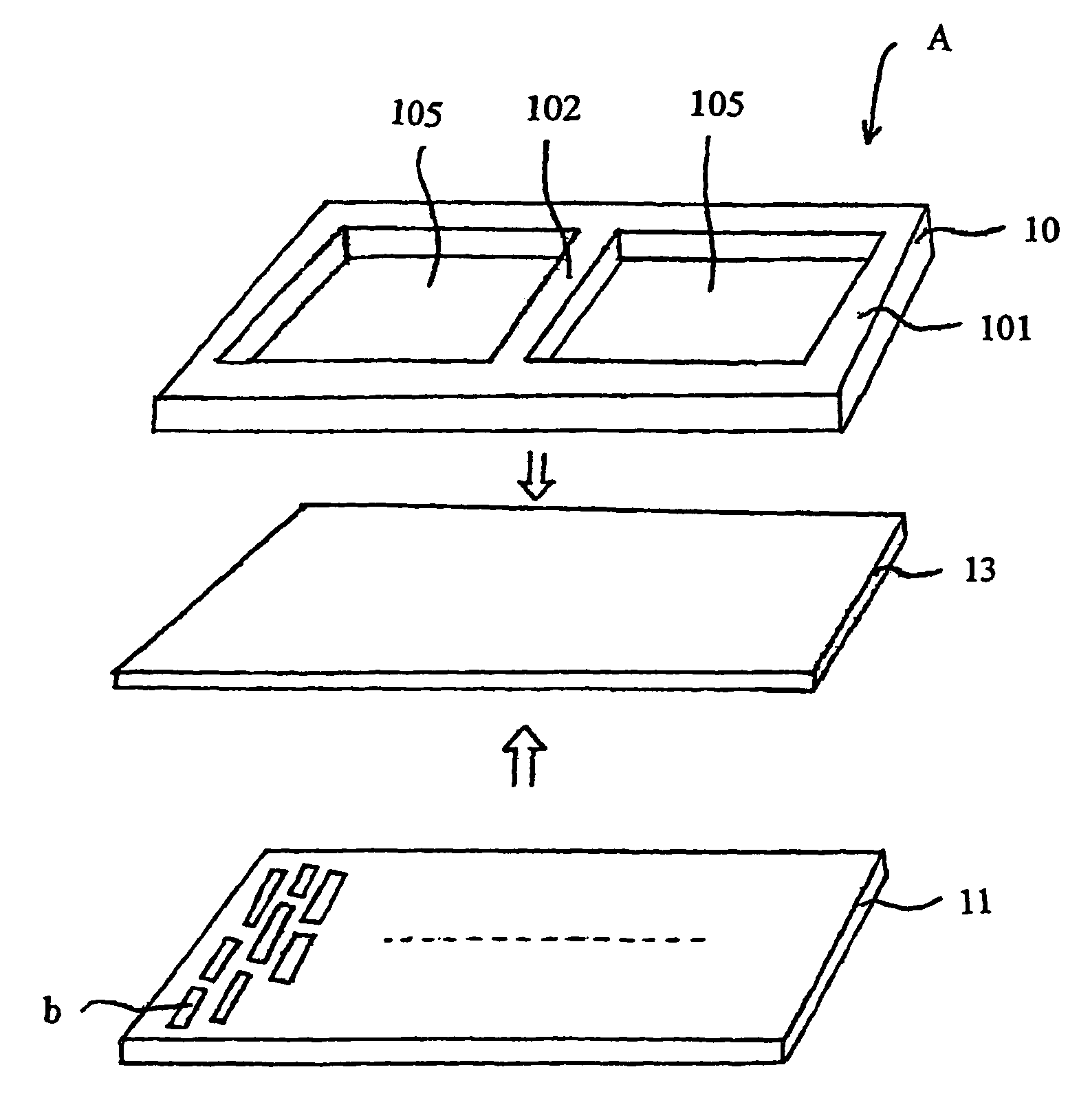

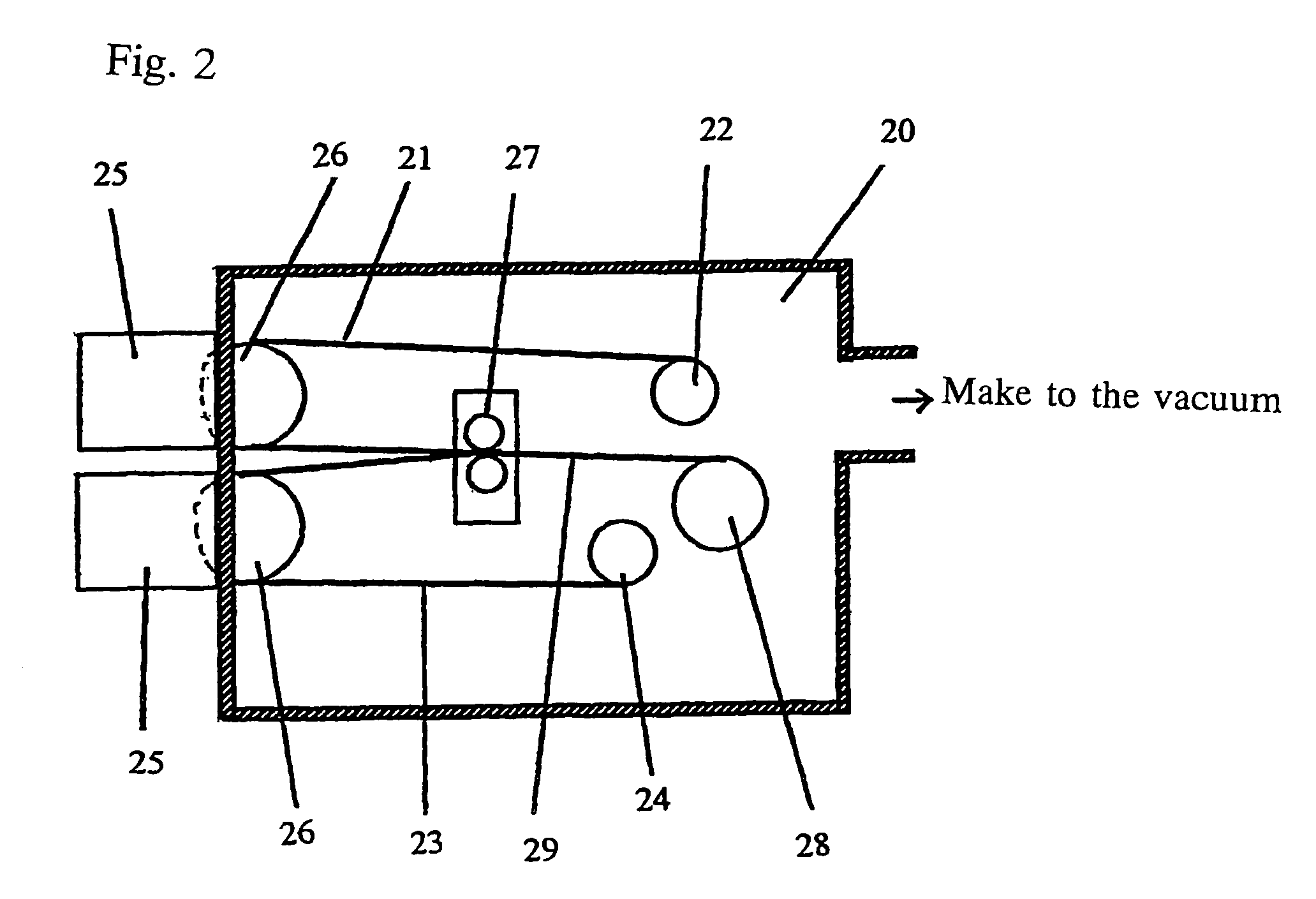

Gas separating unit and method for manufacturing the same

InactiveUS7033641B2Increase the effective areaIncrease volumeMembranesSemi-permeable membranesHydrogenMetallurgy

A method for manufacturing a gas separating unit which comprises laminating a metal plate on a material capable of separating a hydrogen gas (palladium alloy foil) by cladding, etching selectively a central portion of a cut clad plate (K) using an etching solution, to thereby expose an underlying palladium alloy foil layer, and providing a metal supporting plate on the other side of the palladium alloy foil layer. The method allows the manufacture of a gas separating unit having an enhanced effective area of a material capable of separating a hydrogen gas and is excellent in the handlability of a material capable of separating a hydrogen gas during manufacturing.

Owner:TOYO KOHAN CO LTD

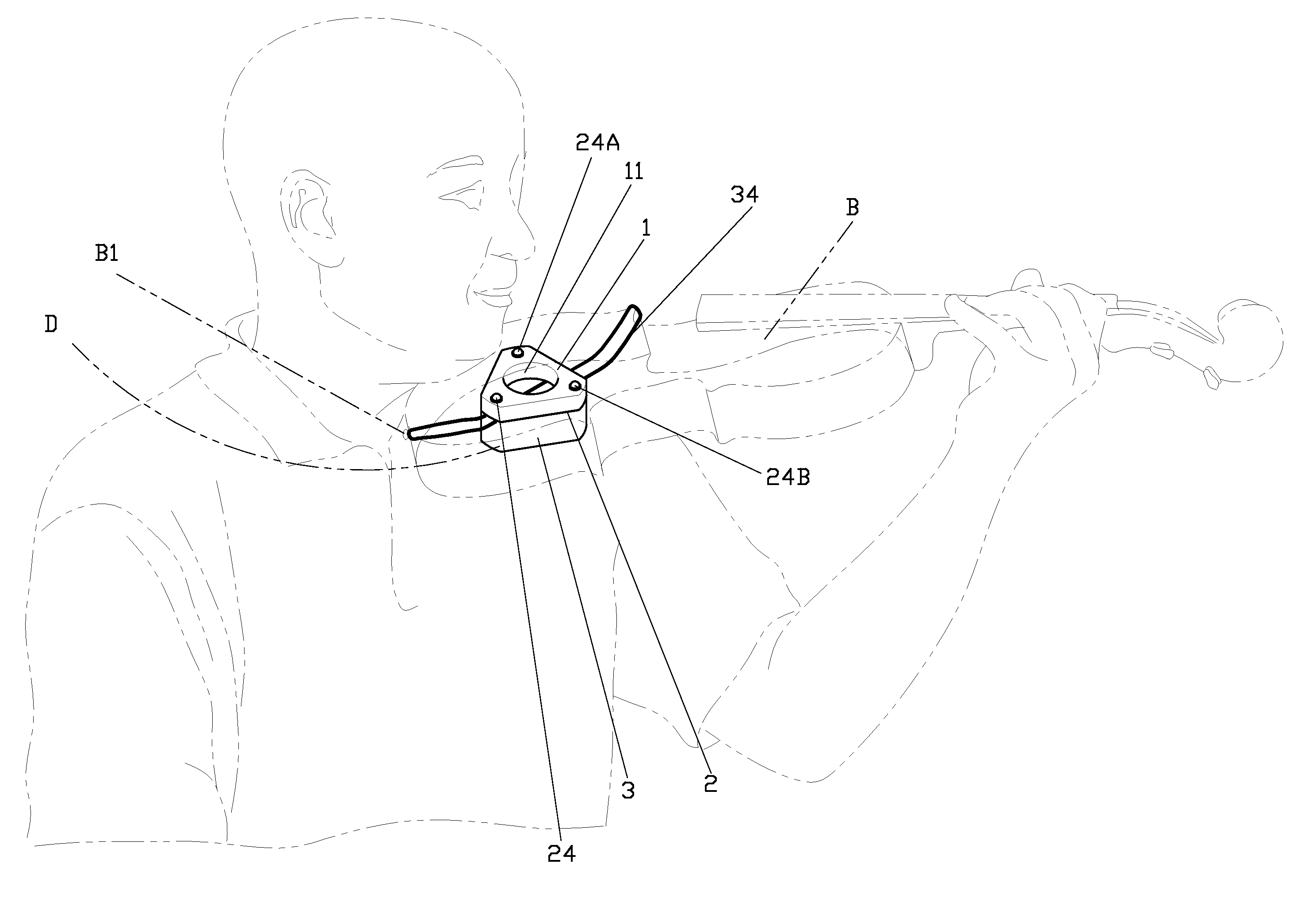

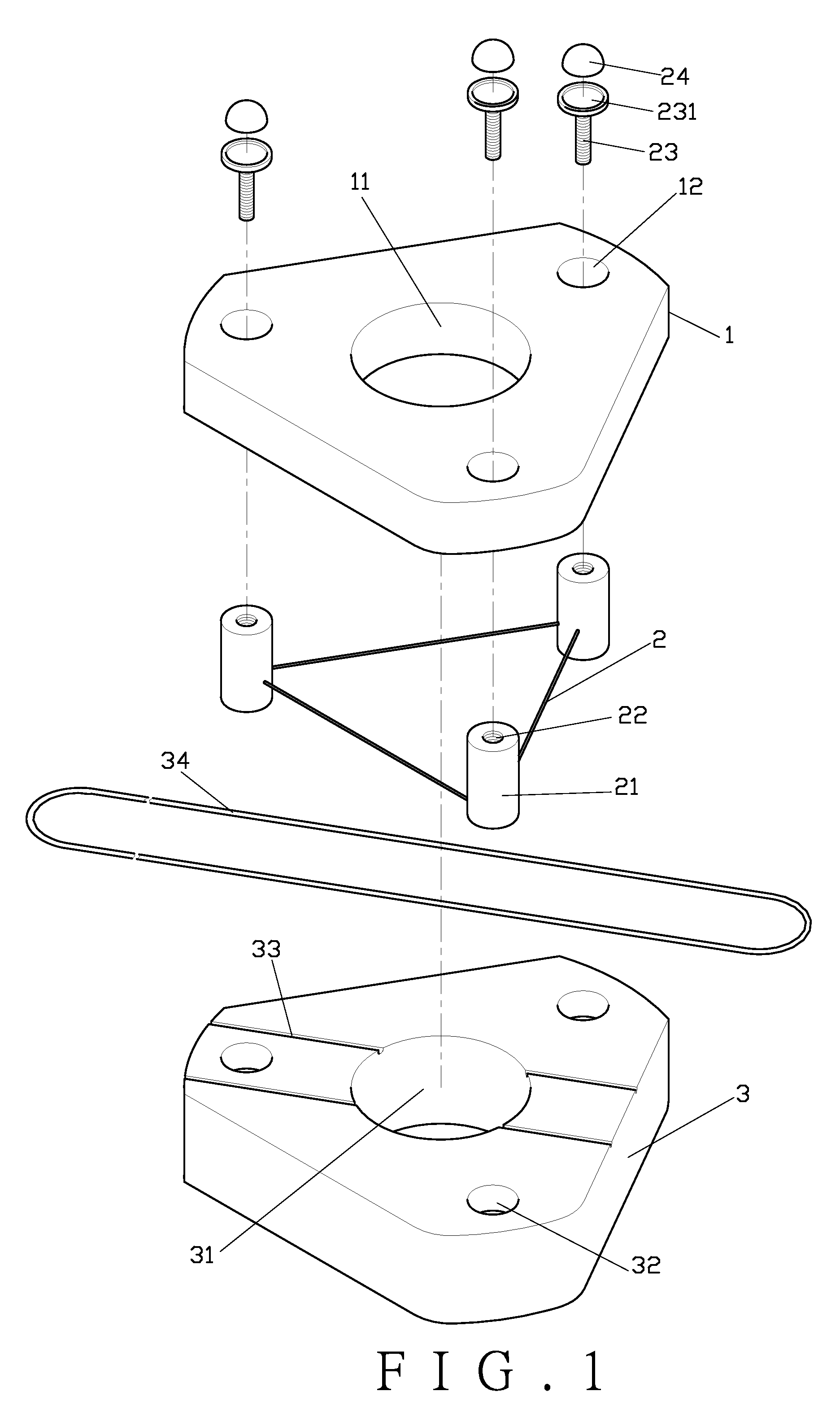

Viola/violin shoulder rest

Owner:TWU HWEI MING

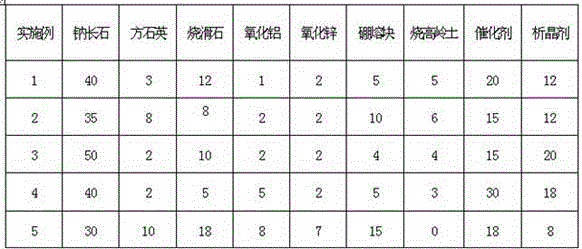

Aventurine metallic luster glaze and preparation method thereof

The invention relates to aventurine metallic luster glaze and a preparation method thereof.The aventurine glaze is prepared from, by weight, the raw materials of 30-50 parts of albite, 2-10 parts of cristobalite, 5-18 parts of calcined talc, 2-8 parts of aluminium oxide, 2-7 parts of zinc oxide, 4-15 parts of boron frit, 0-6 parts of calcined kaolin, 15-30 parts of catalyst, and 8-20 parts of crystallization agent.The preparation method of the aventurine metallic luster glaze comprises the steps that the raw materials are evenly mixed in proportion to obtain the total dry material, water is added in a certain proportion to be mixed, glaze slip with the concentration of 325-335g / 200ml is obtained, and the glaze slip with the granularity smaller than or equal to 10 microns is controlled to range from 50% to 55%.By means of reasonable adjustment of the firing process system and optimization of chemical composition of the formula, during later condensation after high-temperature firing, many micro ferric oxide crystalline granules are separated out from the glaze of the aventurine glaze produced in the invention, and many isolated flake-shaped single crystals sparkling like small gold foils are formed, so that an aventurine metallic glaze effect is shown.

Owner:HUIDA SANITARY WARE

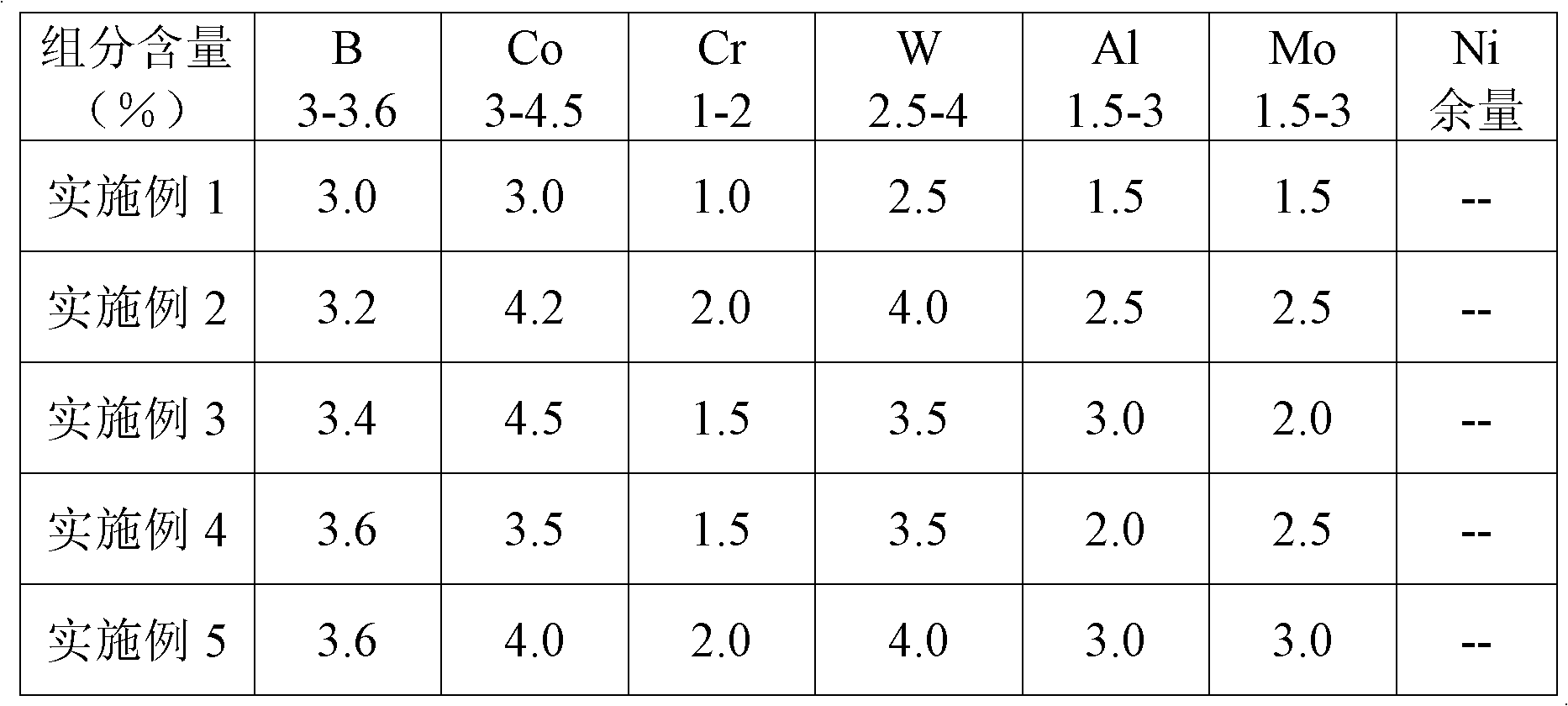

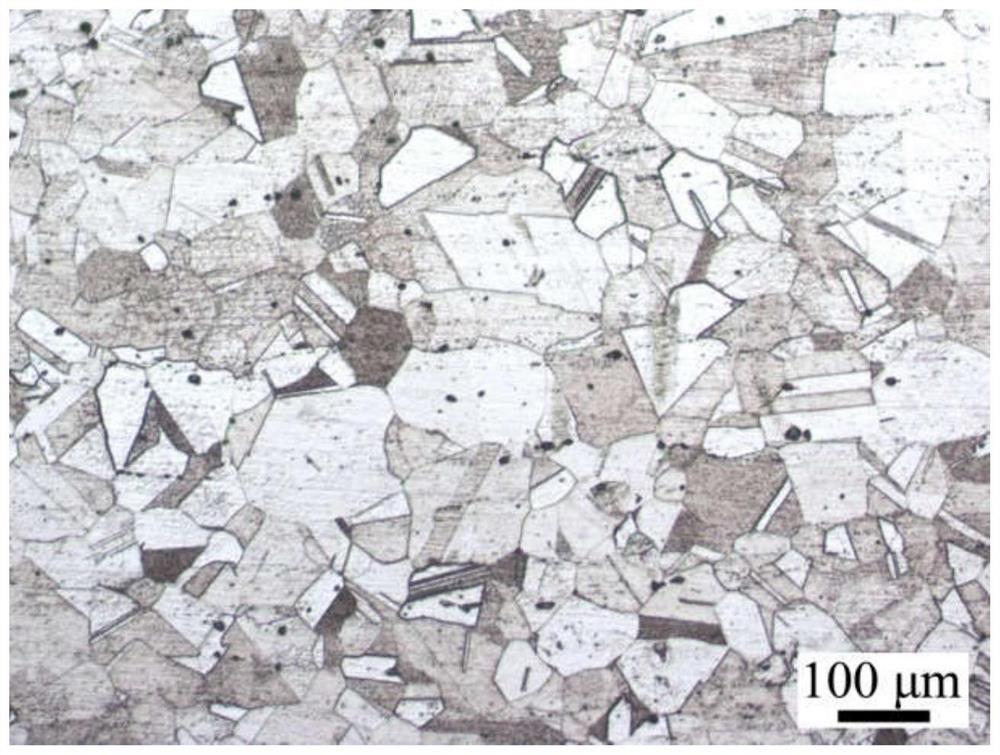

Interlayer alloy of DD6 nickel-based single crystal high temperature alloy used for transient liquid phase (TLP) bonding and preparation method thereof

The invention discloses an interlayer alloy of a DD6 nickel-based single crystal high temperature alloy used for transient liquid phase (TLP) bonding. The interlayer alloy comprises the following components by atom percent: 3%-3.6% of B, 3%-4.5% of Co, 1%-2% of Cr, 2.5%-4% of W, 1.5%-3% of Al, 1.5%-3% of Mo and the balance of Ni, wherein the sum of the atom percents is 100%. The invention also discloses a preparation method of an interlayer alloy foil material. The preparation method comprises the following steps: performing step smelting and using a single-roller rapid solidification device to prepare the interlayer alloy foil material. The interlayer alloy disclosed by the invention has good flexibility and is convenient to process and assemble; when being welded, the interlayer alloy can be well matched with the DD6 nickel-based single crystal high temperature alloy and the brazed joint has a single crystal appearance and structure; and the preparation method of the interlayer alloy foil material has a simple process and low production cost.

Owner:XIAN UNIV OF TECH

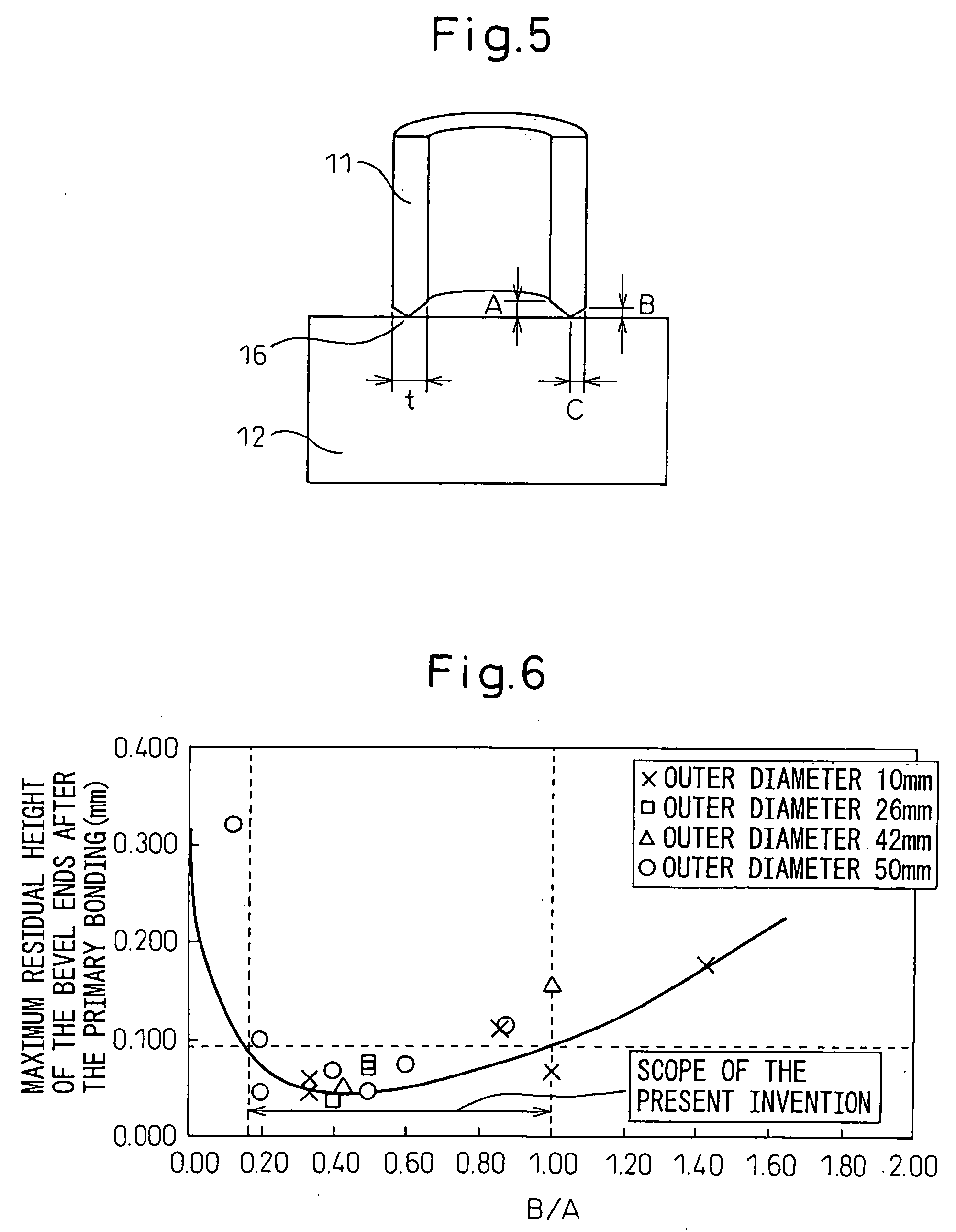

Liquid phase diffusion welding method for metallic machine part and metallic machine part

ActiveUS20060163321A1Improve joint qualityShorten bonding timeCamsValve arrangementsProduction rateElectrical resistance and conductance

A liquid phase diffusion bonding method for a metal machine part superior in the quality of the joint and the productivity enabling the bonding time to be shortened, achieving homogenization of the bonding structure and improving the tensile strength, fatigue strength, and joint quality and reliability. This liquid phase diffusion bonding method of a metal machine part is characterized interposing an amorphous alloy foil for liquid phase diffusion bonding at bevel faces of metal materials, performing primary bonding by melt bonding said amorphous alloy foil and said metal material by resistance welding to form a joint, then performing secondary bonding by liquid phase diffusion bonding by reheating said joint to at least the melting point of said amorphous alloy foil, then holding it there to complete the solidification process of said joint.

Owner:NIPPON STEEL CORP +1

Rolling method of magnesium or magnesium alloy foils

The invention provides a rolling method of magnesium or magnesium alloy foils. According to the rolling method, firstly, magnesium or magnesium alloy thin plates are rolled into thin plates with the thickness being 0.3mm to be used as foil blanks. The foil blanks are cut into sheets with the same dimension, the sheets are cleanly cleaned, two surfaces of each sheet are coated with polyethylene solution, and a plurality of foil blanks are overlapped and are covered by aluminum plates to obtain overlapped rolling bags. The overlapped rolling bags are subjected to multi-step crossed rolling by a magnesium alloy block type warm rolling and cold rolling method, after the preset thickness is reached, covering edges are cut, and the foils are separated. The thickness of produced magnesium or magnesium alloy foils is very coincident, for example, 0.05mm pure magnesium foils meet the requirement of certain loudspeaker vibrating diaphragms. A block type rolling method of the magnesium or magnesium alloy overlapped rolling bags is characterized in that the production arrangement is flexible, and the method is suitable for producing plate belt materials with lower yield and variable variety specifications. The method has the advantages that the production rate and the qualified rate are higher, the cost is low, the equipment is simple, and the investment is low.

Owner:山西银光华盛镁业股份有限公司

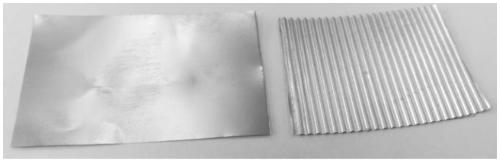

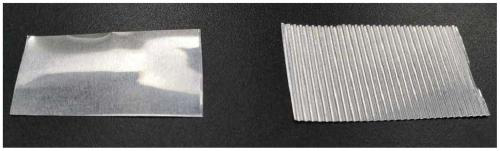

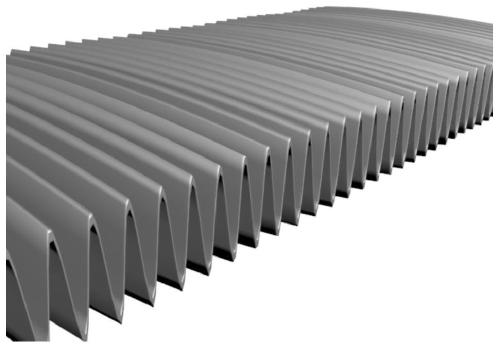

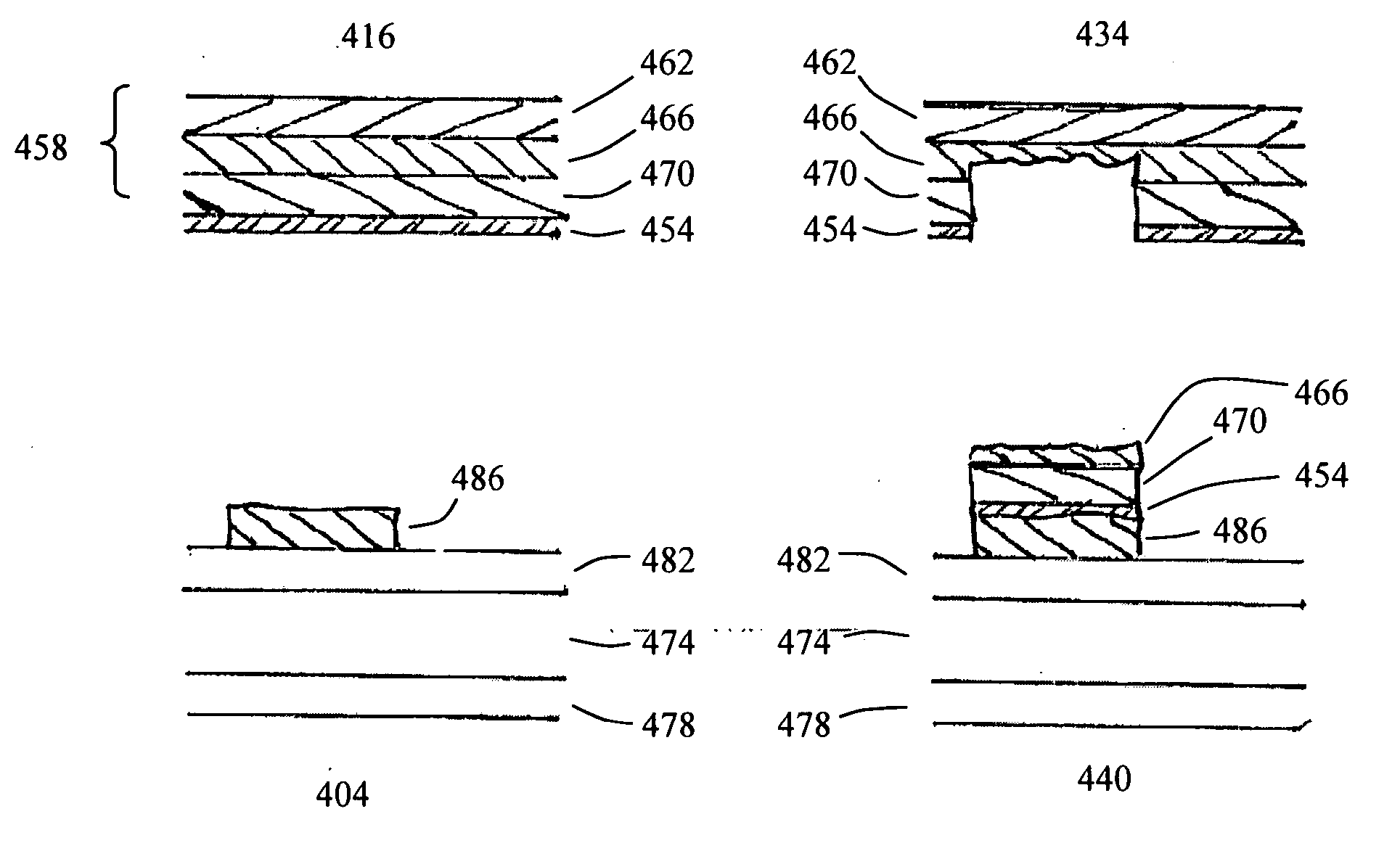

High-strength and high-toughness nickel-base high-temperature alloy foil and preparation method thereof

ActiveCN111850348AHigh strengthImprove high temperature mechanical propertiesChemical elementOxidation resistant

The invention discloses high-strength and high-toughness nickel-based high-temperature alloy foil and a preparation method thereof, and belongs to the technical field of nickel-based high-temperaturealloy materials. The foil comprises the following chemical elements of, by mass, 0.01-0.05% of C, 16-18% of Cr, 4-6% of Al, 3-7% of Fe, 0.001-0.02% of Y, 0.01-0.8% of Ti, 0.05-2% of Mn, 0.001-0.03% ofCe, 0.001-0.8% of Si, 0.001-0.01% of B, less than or equal to 0.20% of W, less than or equal to 0.10% of Co, less than or equal to 0.10% of Mo, less than or equal to 0.03% of Zr, and the balance Ni and inevitable impurities. The nickel-based high-temperature alloy foil for a honeycomb sealing structure can service at 980 DEG C or below with low density, low linear expansion coefficient, high temperature wear resistance, high temperature corrosion resistance, oxidation resistance, high strength, high toughness, easiness in processing and molding and easiness in welding, and the problems of long process flow, low yield and poor surface quality and plate shape of the finished product foil of an existing nickel-based high-temperature alloy foil are solved.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

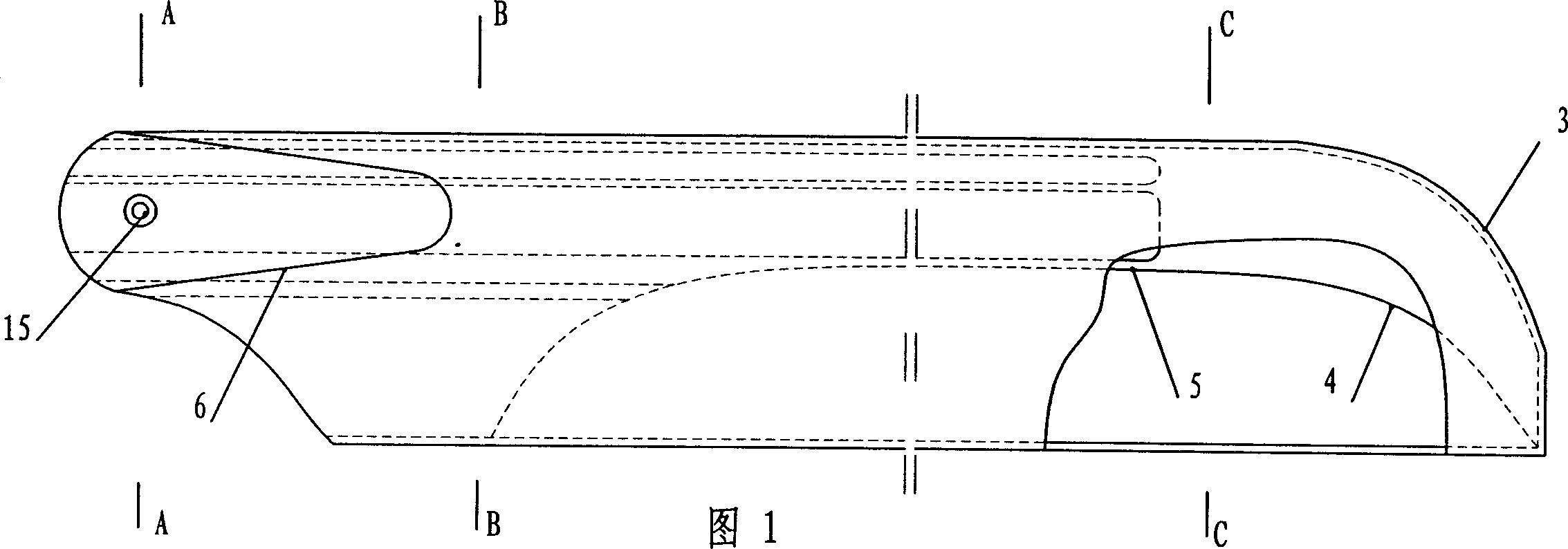

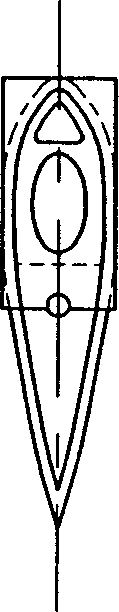

Rotary wing of simulation helicopter and its making process and curing mold

InactiveCN1846824AImprove residual strengthGood damage toleranceToy aircraftsGlass fiberCarbon fibers

The present invention relates to rotary wing of simulation helicopter and its making process and curing mold. The rotary wing includes carcass and covering, and the covering includes at least one closed reinforcing layer of reinforcing material carbon fiber, aramid fiber, polyethylene fiber, titanium foil and / or glass fiber. The making process includes making carcass, making covering and pressing to integrate the carcass the covering. The curing mold is one combined mold including upper mold and lower mold and with notch, positioning lobe and dovetail groove. The technology of the present invention may be used in making various kinds of simulation flyers.

Owner:王云松

Preparation method of ultrathin Ta-W alloy foil

The invention provides a preparation method of ultrathin Ta-W alloy foil, and belongs to the technical field of Ta-W alloy machining. The preparation method includes the steps that cyclic operation of alloy billet prepared through a powder metallurgy method, cold rolling cogging, and cold rolling and vacuum annealing, 3-5 micrometer foil annealing, and the like. The thickness of the prepared foil can reach 3-5 micrometers. The preparation method is simple in process, the prepared foil is high in precision, and compared with pure Ta foil and other Ta-W alloy foil, the ultrathin Ta-W alloy foil has the advantages of being high in strength, good in surface quality, and the like. The prepared Ta-(5.0-7.5 wt%)W alloy foil with the thickness of 3-5 micrometers is suitable for high-power microwave tubes, traveling wave tubes, and other vacuum devices of electronic components, aerospace, and other industries. The preparation method has great significance on achieving high-power high-performance microwave tube localization, improving microwave tube using performance, prolonging service life, and the like.

Owner:CENT SOUTH UNIV

Copper foil for negative electrode current collector of secondary battery

InactiveUS20130011734A1Reduce variationImprove adhesionElectrode manufacturing processesElectrolytic inorganic material coatingCopper foilCurrent collector

Provided is a copper foil for a negative electrode current collector of secondary battery, wherein: roughening treatment is performed to both front and rear surfaces of a rolled copper alloy foil; an average surface roughness Ra of both the front and rear surfaces based on laser microscope measurement is 0.04 to 0.20 μm; and the ratio of surface area factor is within a range of 1.0<(C) / (C′)<1.1, when a three-dimensional surface area upon measuring the roughened surfaces with a laser microscope is (A), a two-dimensional area as a projected area upon measuring the three-dimensional surface area is (B), and a calculated value of (A) / (B) is expressed in (C), and when a three-dimensional surface area upon measuring the surfaces of a non-roughened rolled copper or copper alloy foil with a laser microscope is (A′), a two-dimensional area as a projected area upon measuring the three-dimensional surface area is (B′), and a calculated value of (A′) / (B′) is expressed in (C′). This invention aims to provide a copper foil for a negative electrode current collector of a secondary battery in which the adhesiveness of the secondary battery active material is superior, and which can reduce the variation in the area weight of the secondary battery active material, and has superior weather resistance and thermal resistance.

Owner:JX NIPPON MINING& METALS CORP

Four-roller finishing mill

The invention relates to a four-roller finishing mill, and belongs to the technical field of metallurgical machines. The four-roller finishing mill comprises a rack, a motor, a composite gear box, two universal joint shafts and two supporting rollers arranged in parallel, the composite gear box is connected with the motor through a coupling, one ends of the two universal joint shafts are connected with the composite gear box, and the supporting rollers are connected with the other ends of the universal joint shafts. Two work rollers are arranged between the two supporting rollers. A feeding press plate is arranged between the work rollers. A pressing-down device is arranged on the upper portion of the rack, and comprises a pressing-down motor, a worm gear and a worm. The worm is fixed to the rack through a nut. A pressure sensor is arranged at the bottom of the worm. The output end of the pressure sensor is connected with a control system. The worm gear is connected with a rotary encoder. The output end of the rotary encoder is connected to the control system. Through the four-roller finishing mill, the rolling of 0.005mm fold foil which can be achieved previously by multi-roller mills with 12 rollers or 20 rollers can be achieved, energy is greatly saved, and the operation is simplified.

Owner:XINGHUA MAIDA MACHINERY

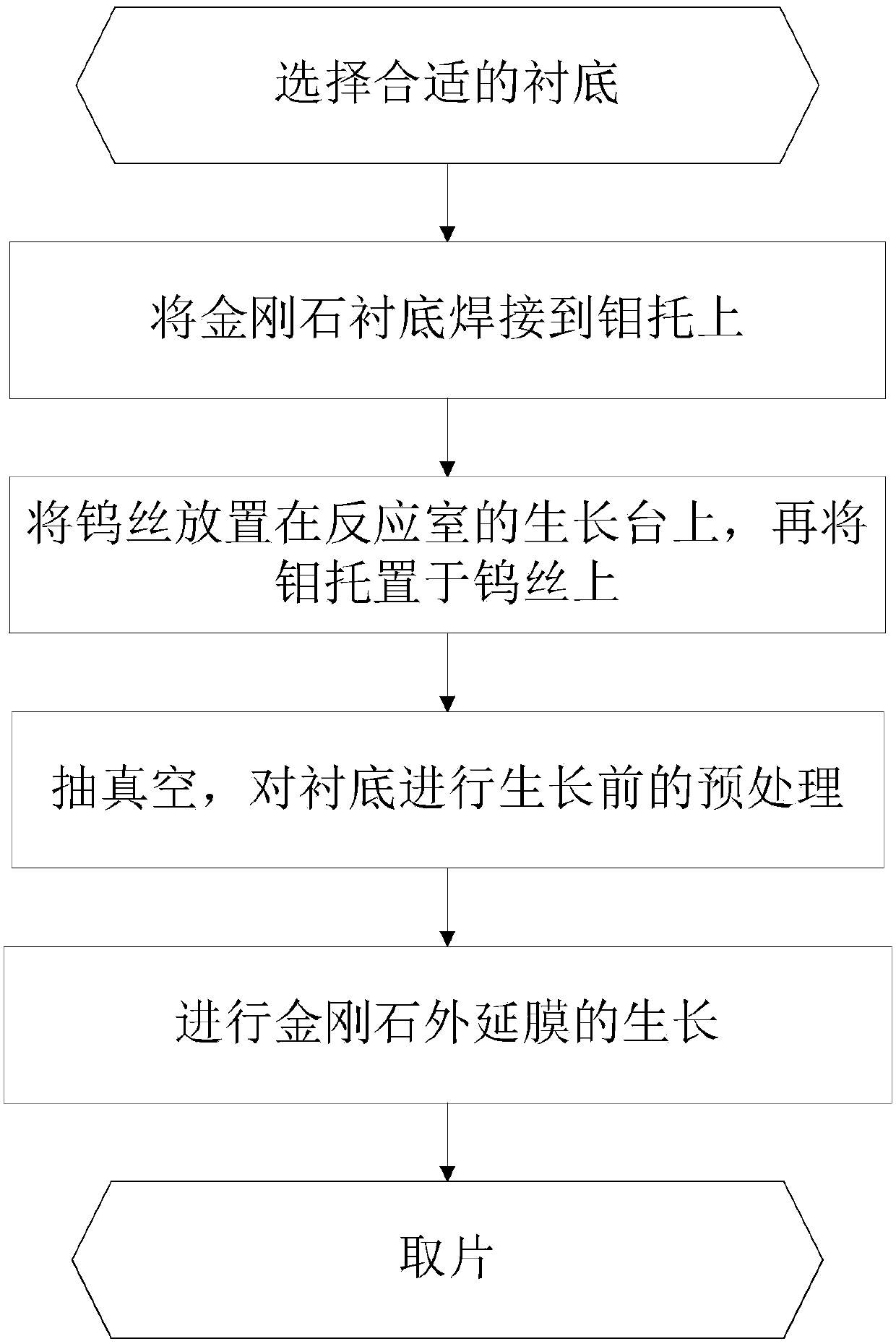

Diameter enlarging growth method of monocrystal diamond

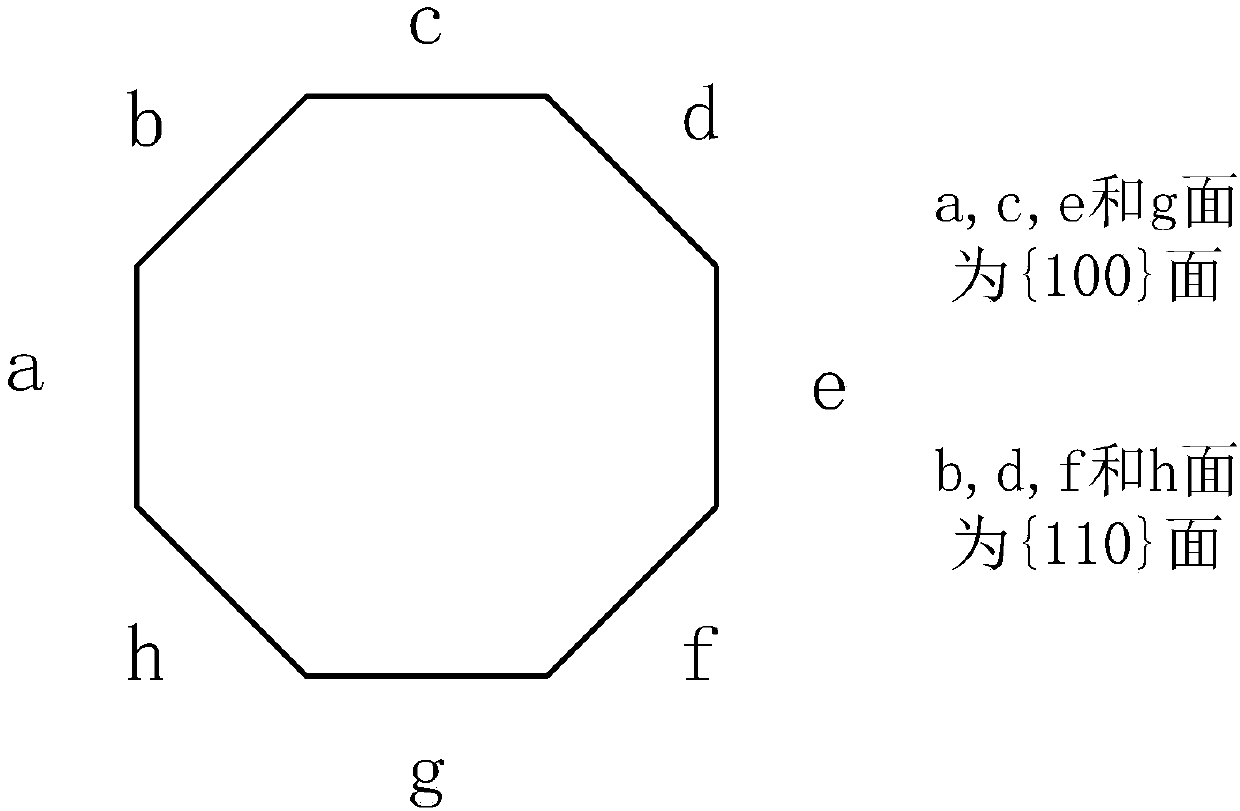

ActiveCN107675249AReduce polycrystalline contentEffective diameter expansionPolycrystalline material growthFrom chemically reactive gasesSingle crystalField-effect transistor

The invention discloses a diameter enlarging growth method of monocrystal diamond. The diameter enlarging growth method of monocrystal diamond comprises following steps: 1, an octagonal high temperature high pressure diamond substrate is selected, wherein the side surfaces of the octagonal high temperature high pressure diamond substrate are designed to be alternatively arranged {100} crystal faces and {110} crystal faces; 2, a molybdenum support is introduced into a reaction chamber, a piece of gold foil is placed on the molybdenum support, the octagonal high temperature high pressure diamondsubstrate is placed on the molybdenum support, the reaction chamber is vacuumized, the octagonal high temperature high pressure diamond substrate is heated in the reaction chamber until the gold foilis melted, and then the octagonal high temperature high pressure diamond substrate is welded onto the molybdenum support; 3, tungsten filaments are placed on a growth platform in the reaction chamber, and the molybdenum support welded with the octagonal high temperature high pressure diamond substrate is placed on the tungsten filaments for surface defect and injury etching pretreatment; and 4, the pressure, the temperature, microwave frequency, methane concentration, and growth time in the reaction chamber are controlled, so that growth of monocrystal diamond epitaxial film with a thicknessranging from 0.5 to 2.5mm on the octagonal high temperature high pressure diamond substrate obtained via pretreatment is realized. The diameter enlarging growth method is capable of reducing the content of polycrystal in the monocrystal diamond epitaxial film, and ensuring diameter enlarging effectiveness, and can be used for manufacturing of diamond field effect transistors.

Owner:湖州中芯半导体科技有限公司

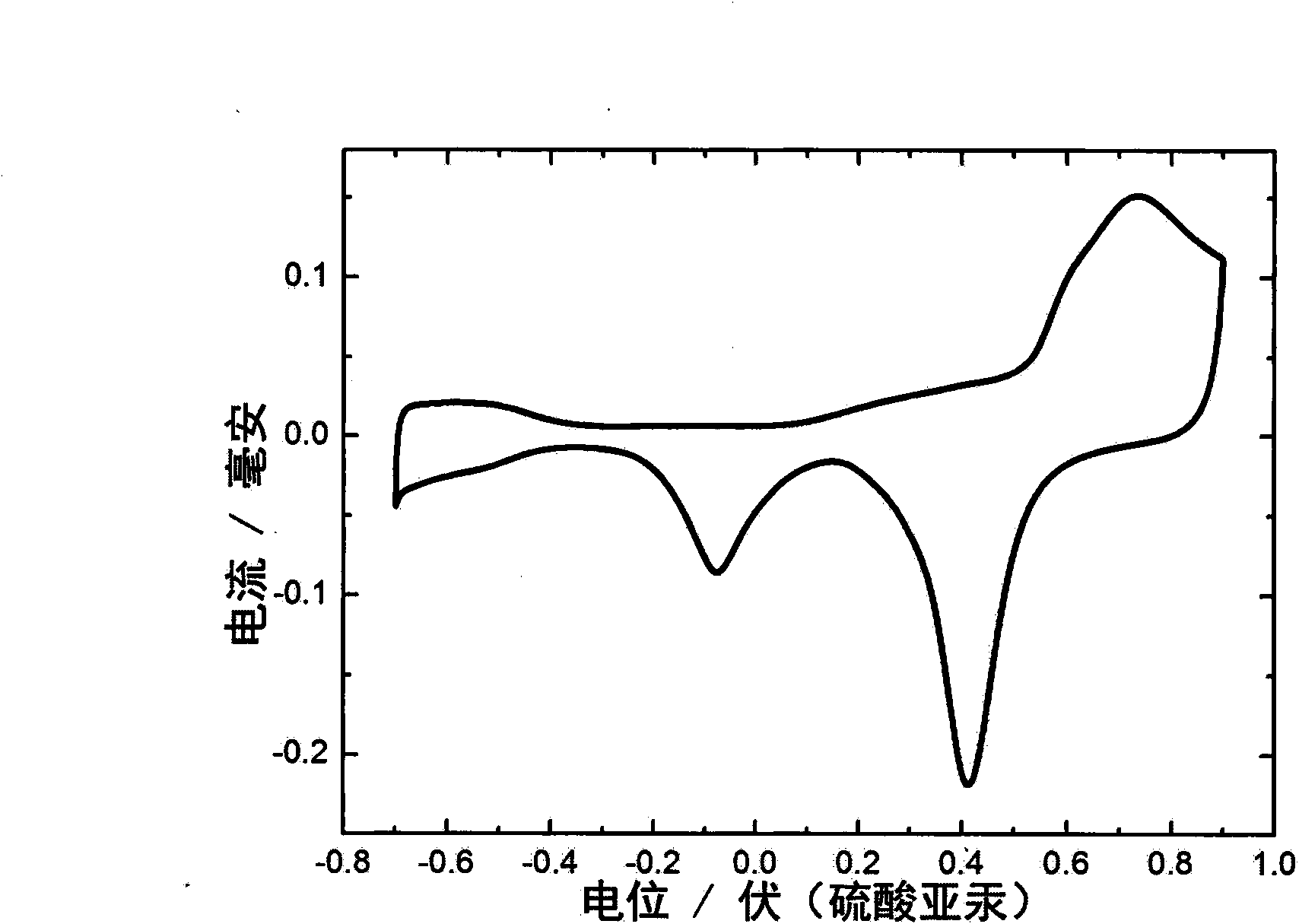

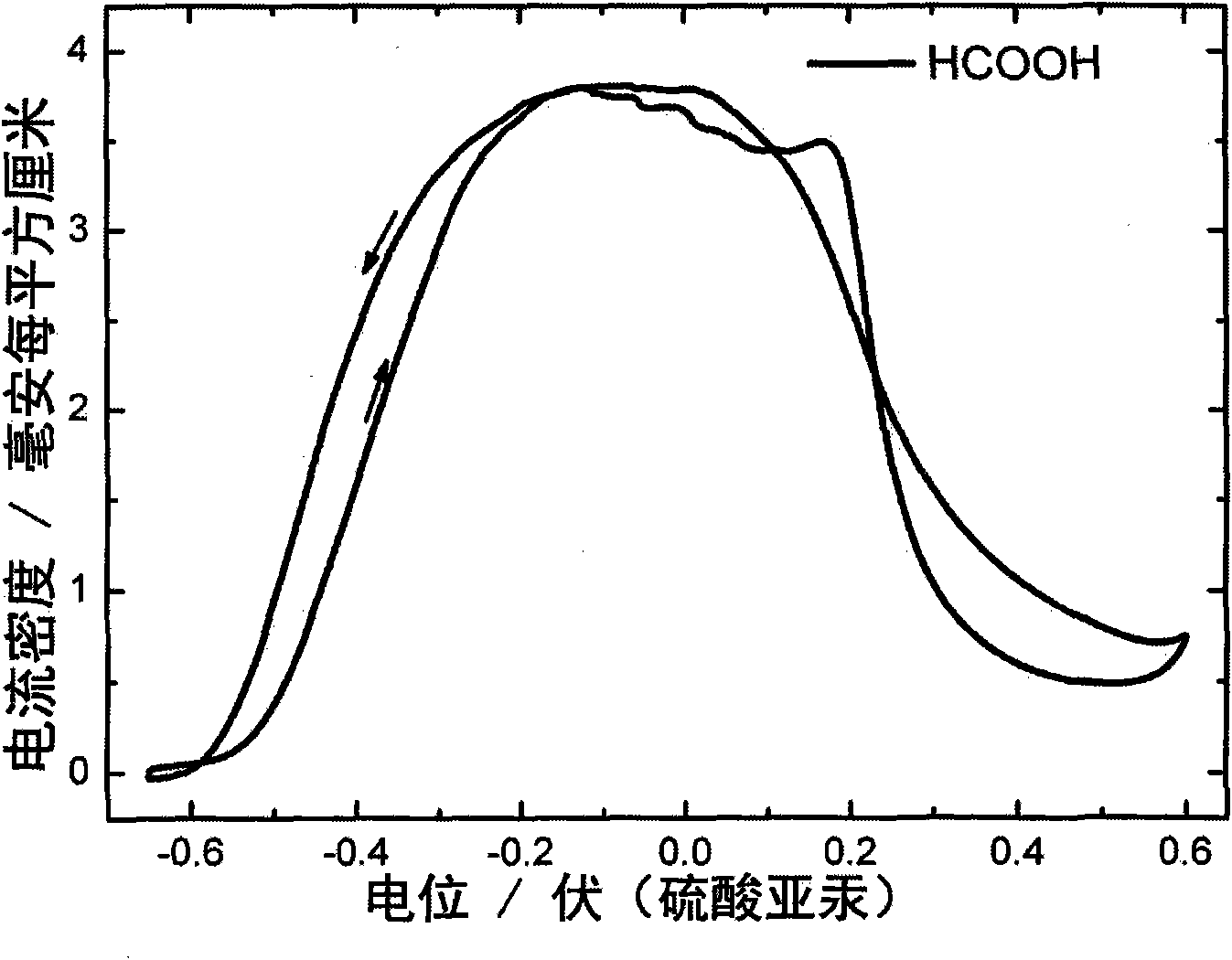

Nano porous alloy fuel battery catalyst and preparation method thereof

InactiveCN101997123AReduce cleaningReduce manufacturing costCell electrodesCatalyst activation/preparationPlatinumFuel cells

The invention discloses a nano porous alloy fuel battery catalyst and a preparation method thereof. The method is simple and convenient, and directly prepares nano porous alloy fuel battery catalyst by gold-silver alloy foils and inert metal irons. The nano porous alloy fuel battery catalyst has good catalytic activity to oxidize formic acid, contains little platinum, has high poisoning resistance and stability, and is suitable for the field of fuel battery catalyzing.

Owner:济南美高纳米材料有限公司 +1

Nuisance free special microelement additive for bastard halibut and pleuronectid and its production process

InactiveCN1836546ALow costPromote growthAnimal feeding stuffAccessory food factorsManganeseInorganic compound

The trace element feed additive for sea water left-eyed flounder and right-eyed flounder has the effective components comprising Fe 23000-50000 mg / kg, Mn 4000-8000 mg / kg, Zn 25000-48000 mg / kg, Cu 2000-5000 mg / kg, Co 200-400 mg / kg, Se 100-200 mg / kg and I 50-130 mg / kg; and carrier of natural Chinese medicinal stone in the weight range of 60-80 %. Its compounding process includes calculating the added amount of organic chelates and inorganic compounds based on the required ratio of trace elements and their contents in organic chelate or inorganic compound; mixing through stirring in stainless steel stirrer and packing in gold foil bag. The trace element feed additive has obvious growth promoting effect on sea water left-eyed flounder and right-eyed flounder and less water environment pollution.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com