Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Shorten bonding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

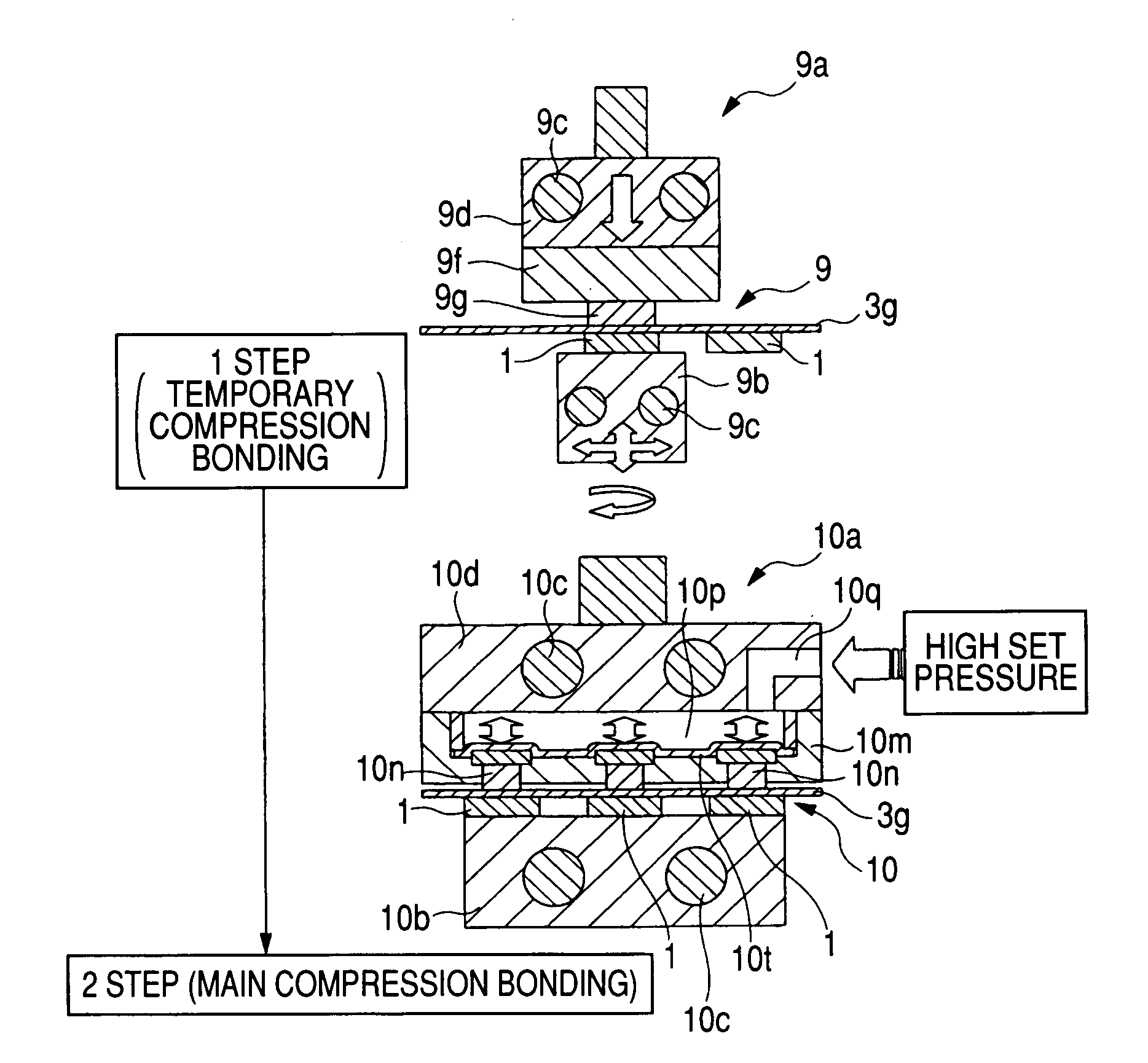

Fabrication method of semiconductor integrated circuit device

InactiveUS20050061856A1Improve productivityImprove bonding qualitySemiconductor/solid-state device detailsSolid-state devicesProduction rateSemiconductor chip

Productivity is to be improved in assembling a semiconductor integrated circuit device. A matrix substrate is provided and semiconductor chips are disposed on a first heating stage, and then the matrix substrate is disposed above the semiconductor chips on the first heating stage. Subsequently, the semiconductor chips and the matrix substrate are bonded to each other temporarily by thermocompression bonding, while heating the chips directly by the first heating stage. Thereafter, the temporarily bonded matrix substrate is disposed on a second heating stage adjacent to the first heating stage, and then, on the second heating stages, the semiconductor chips are thermocompression-bonded to the matrix substrate, while being heated directly by the second heating stage.

Owner:RENESAS ELECTRONICS CORP +1

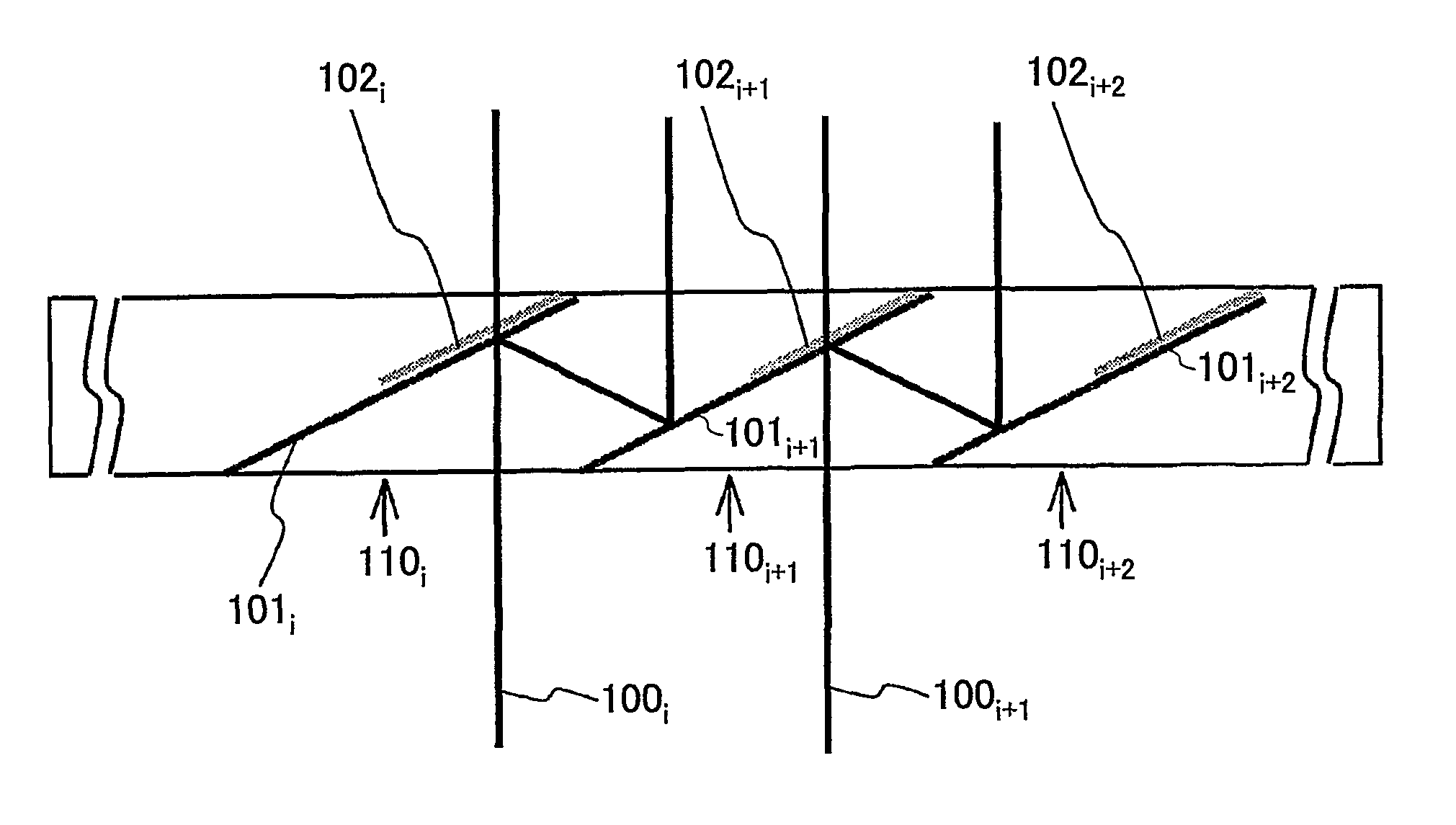

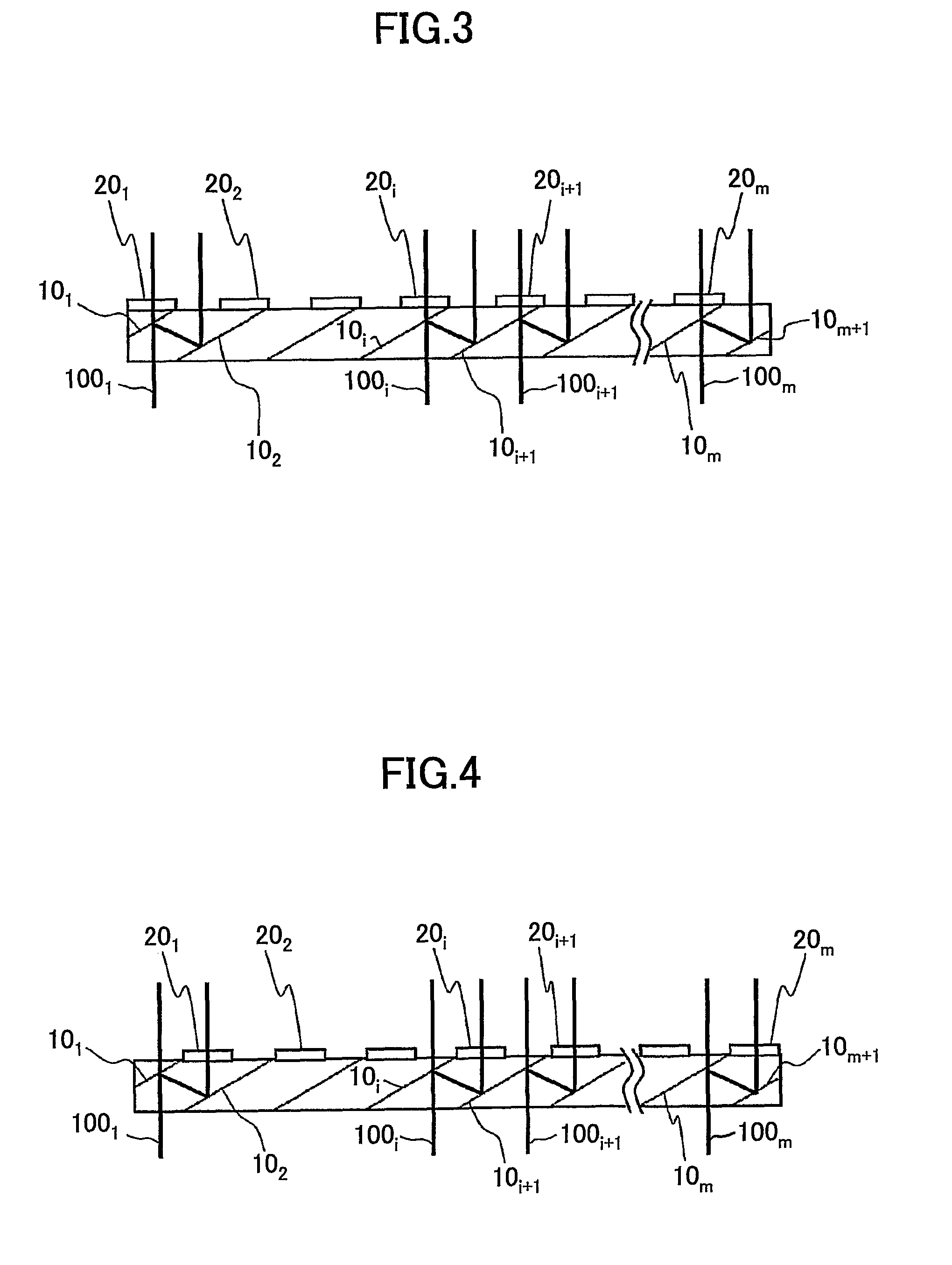

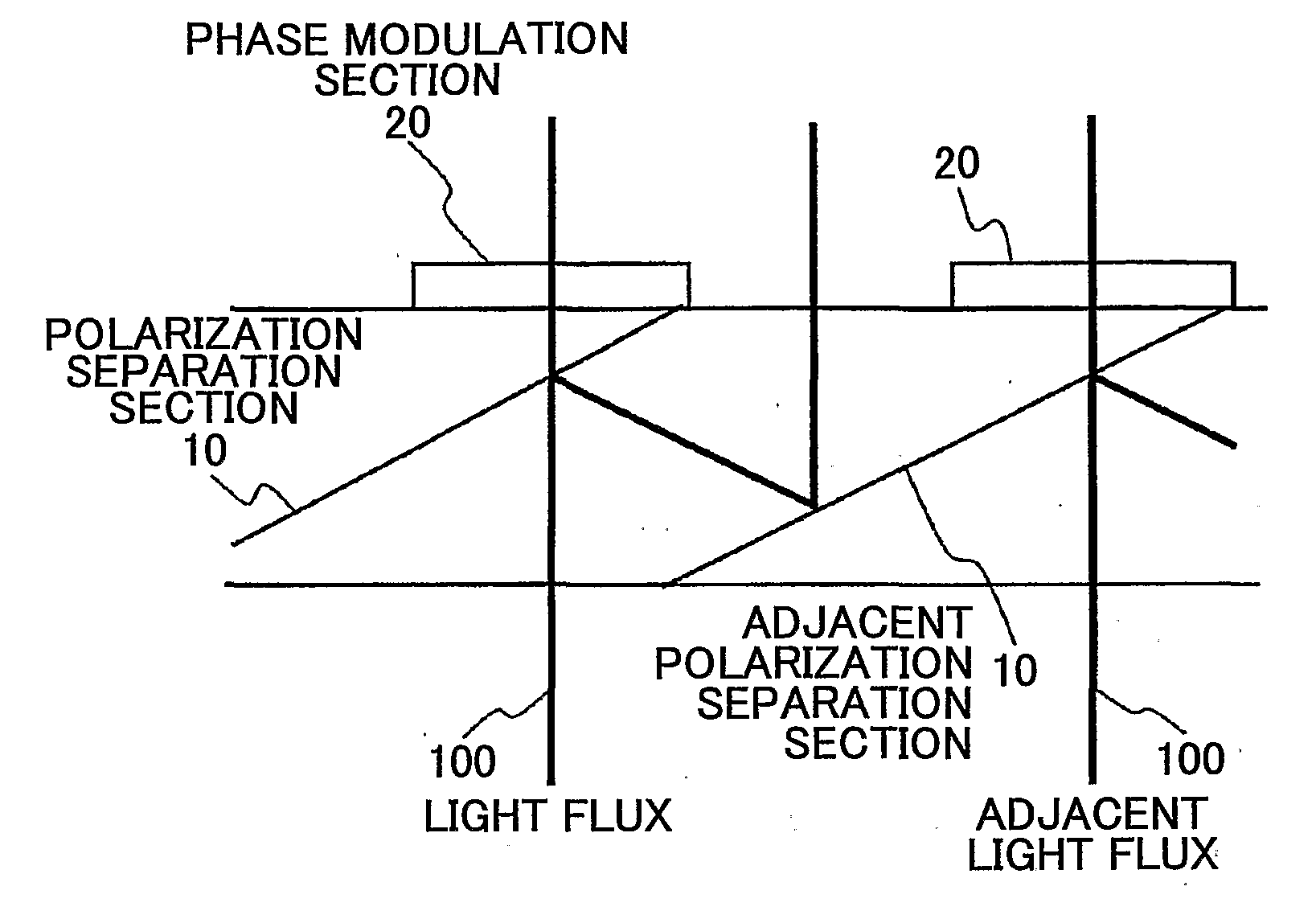

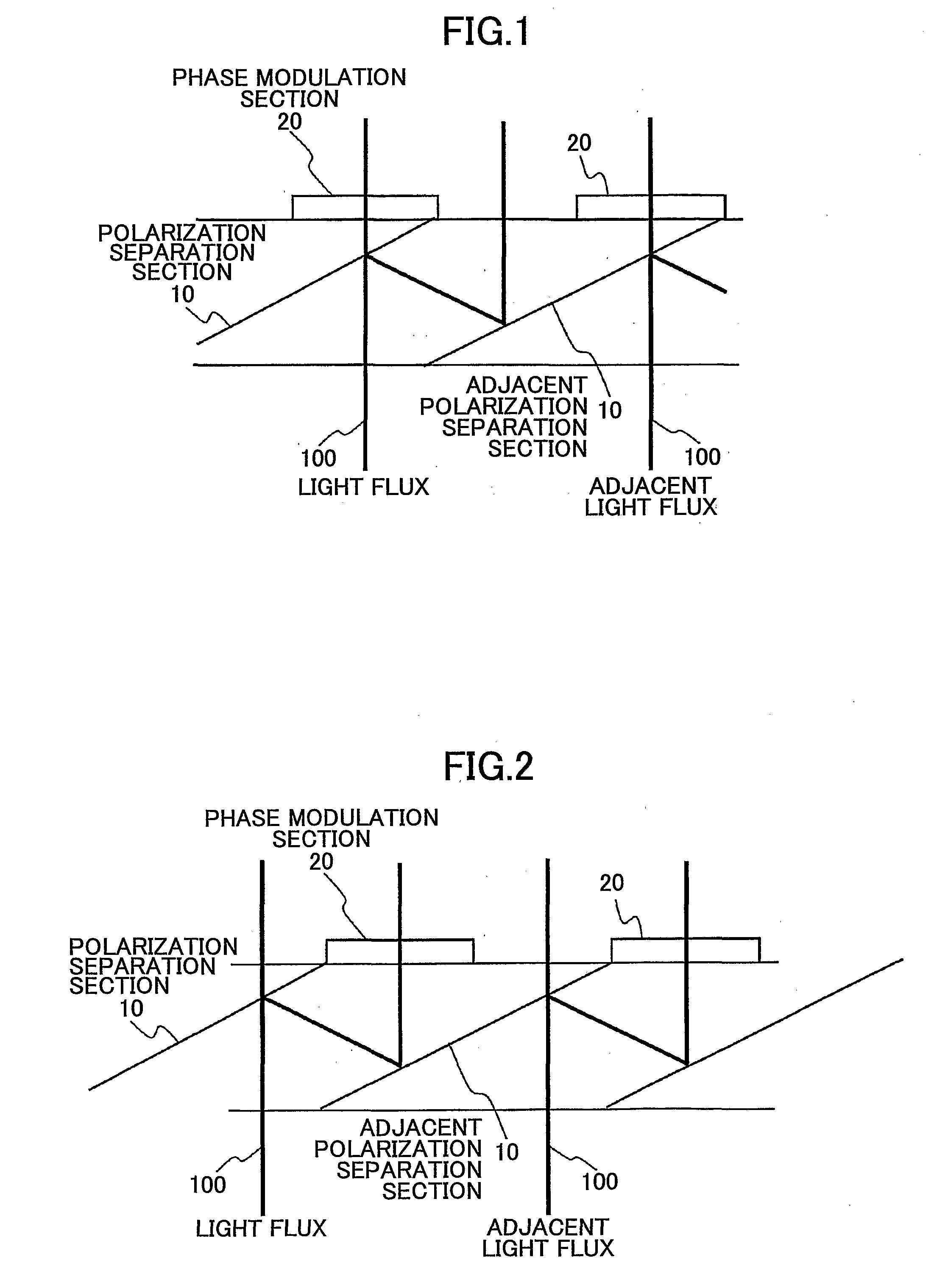

Polarization conversion element, polarization conversion optical system and image projecting apparatus

InactiveUS7995275B2Reduce in quantityImprove productivityTelevision system detailsProjectorsLight fluxLight beam

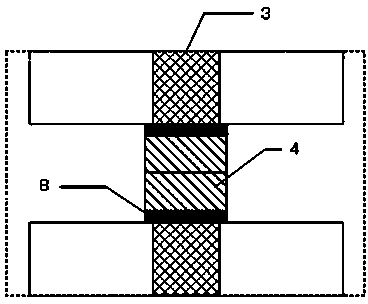

A polarization conversion element having plural polarization separation sections and plural phase modulation sections is disclosed. A light flux is separated into transmission light (P polarization) and reflection light (S polarization) by being input to a polarization separation section. The reflection light reflected at the polarization separation section is output in the same direction as that of the transmission light by being reflected again at an adjacent polarization separation section at a different position from a position where a light flux is input to the adjacent polarization separation section. The phase modulation section is disposed on an optical path of the transmission light or the reflection light and output light becomes the same polarization.

Owner:RICOH KK

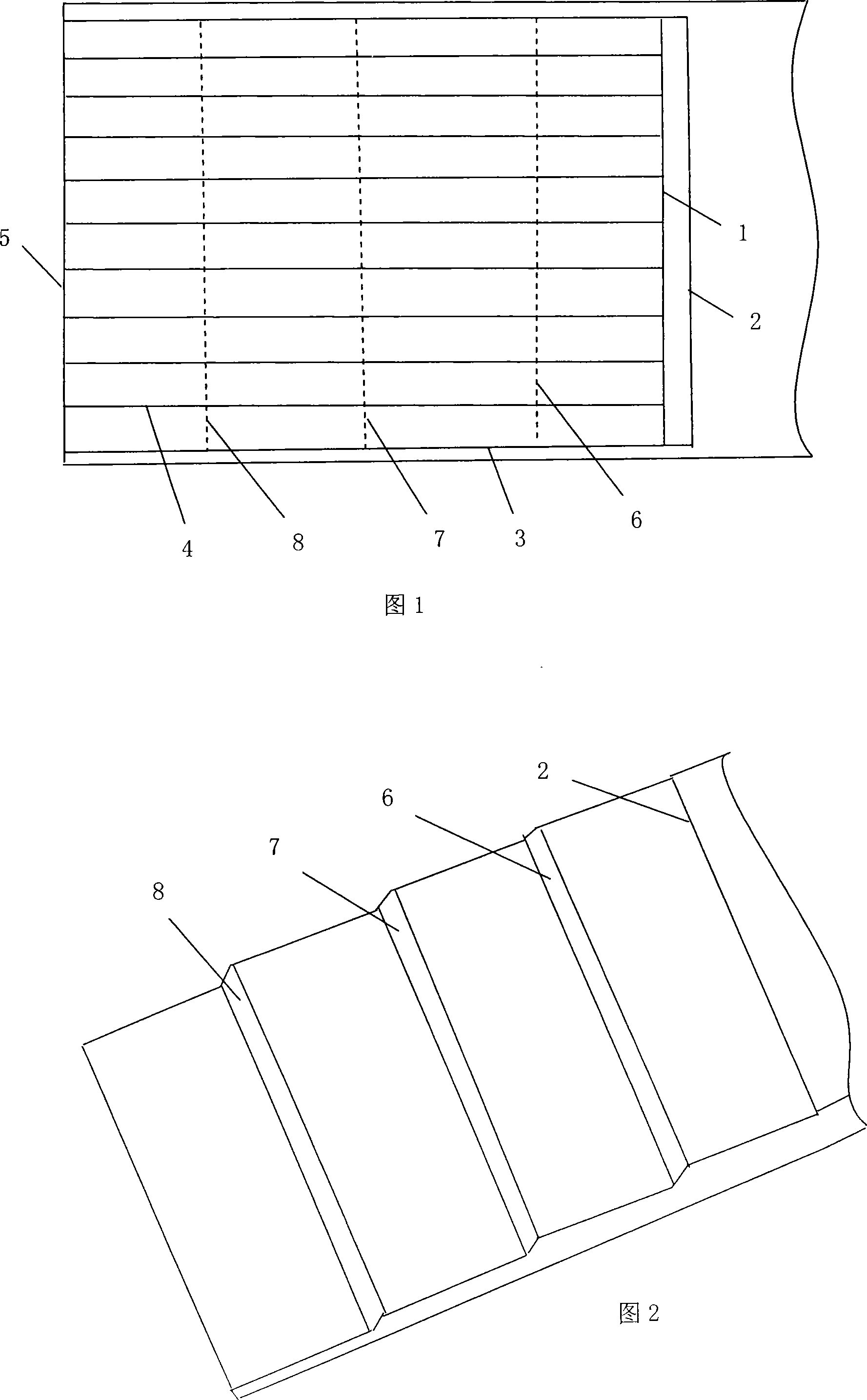

Method for gluing conveyer belt joint

InactiveCN101205961AShorten bonding timeExtended service lifeBelt fasteningsEngineeringUltimate tensile strength

The invention provides a glue joint method of conveying belt lacer, which comprises the following steps: (1) wiping out line frames of braided fabric layers for glue joint at the head end and tail end of the conveying belt which need cutting off; (2) cutting and stripping the braided fabric layers for glue joint at the head and tail end of the conveying vertically and section by section from inside to end face along marking lines to form two ladder type glue joint faces where the number of the braided fabric layers gradually increases from end face to inside; (3) roughening and cleaning the ladder type glue joint faces; (4) brushing 2 rubber films with equal thickness and uniformity onto each roughened ladder type glue joint faces; (5) drying the ladder type glue joint faces on the two ends of the conveying belt until the two faces are not sticky to hands, sticking the two faces together and compacting; (6) trimming edges; (7) neatening. The invention gets rid of the prior tools for jacking and etc., adds a roughening procedure, and shortens the glue joint time of the conveying belt. The glue joint operation can be completed at a feeding interval of a conveying system with joint strength being greatly improved and the service life of the conveying belt being prolonged.

Owner:YANKUANG LUNAN CHEM FERTILIZER PLANT

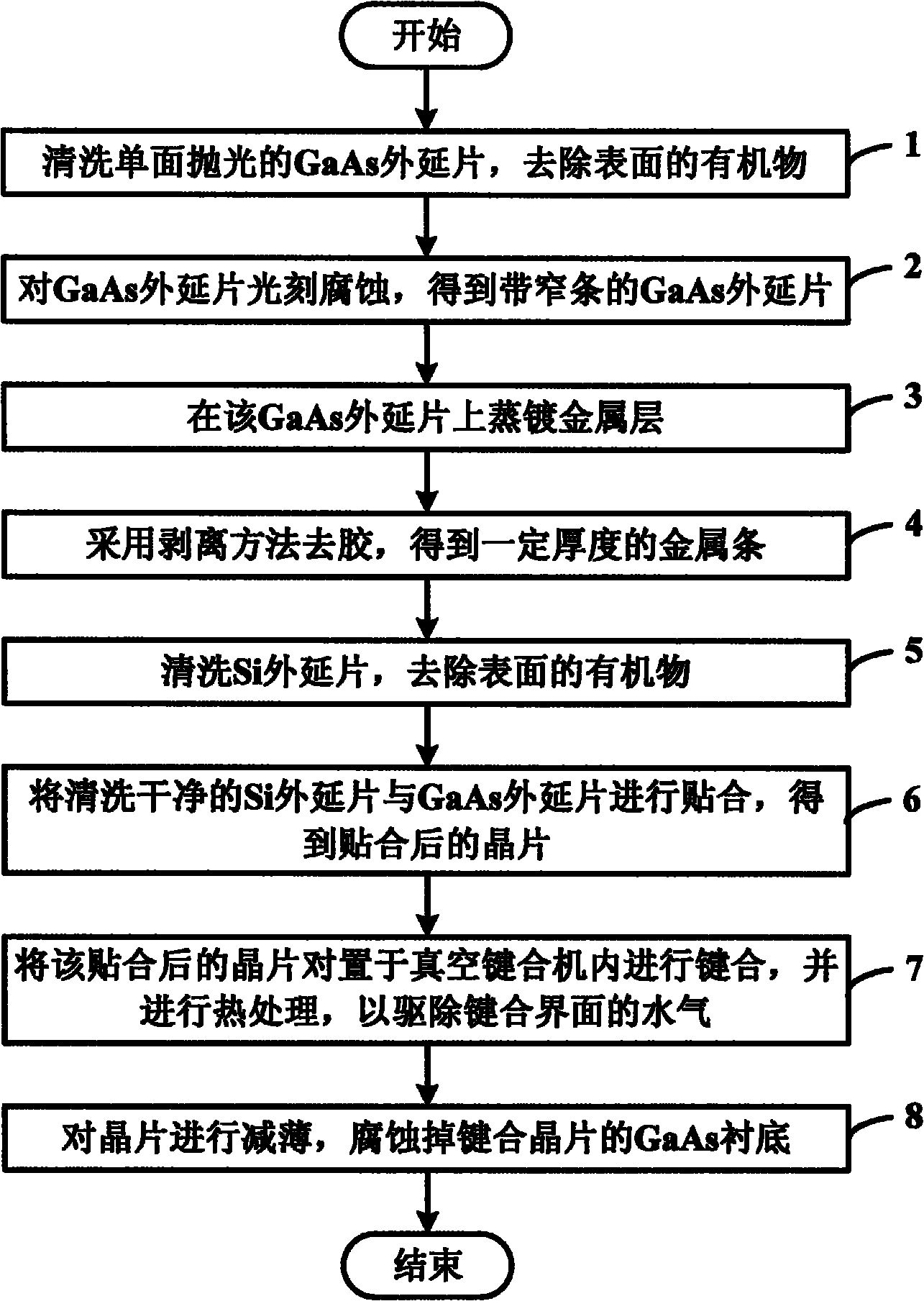

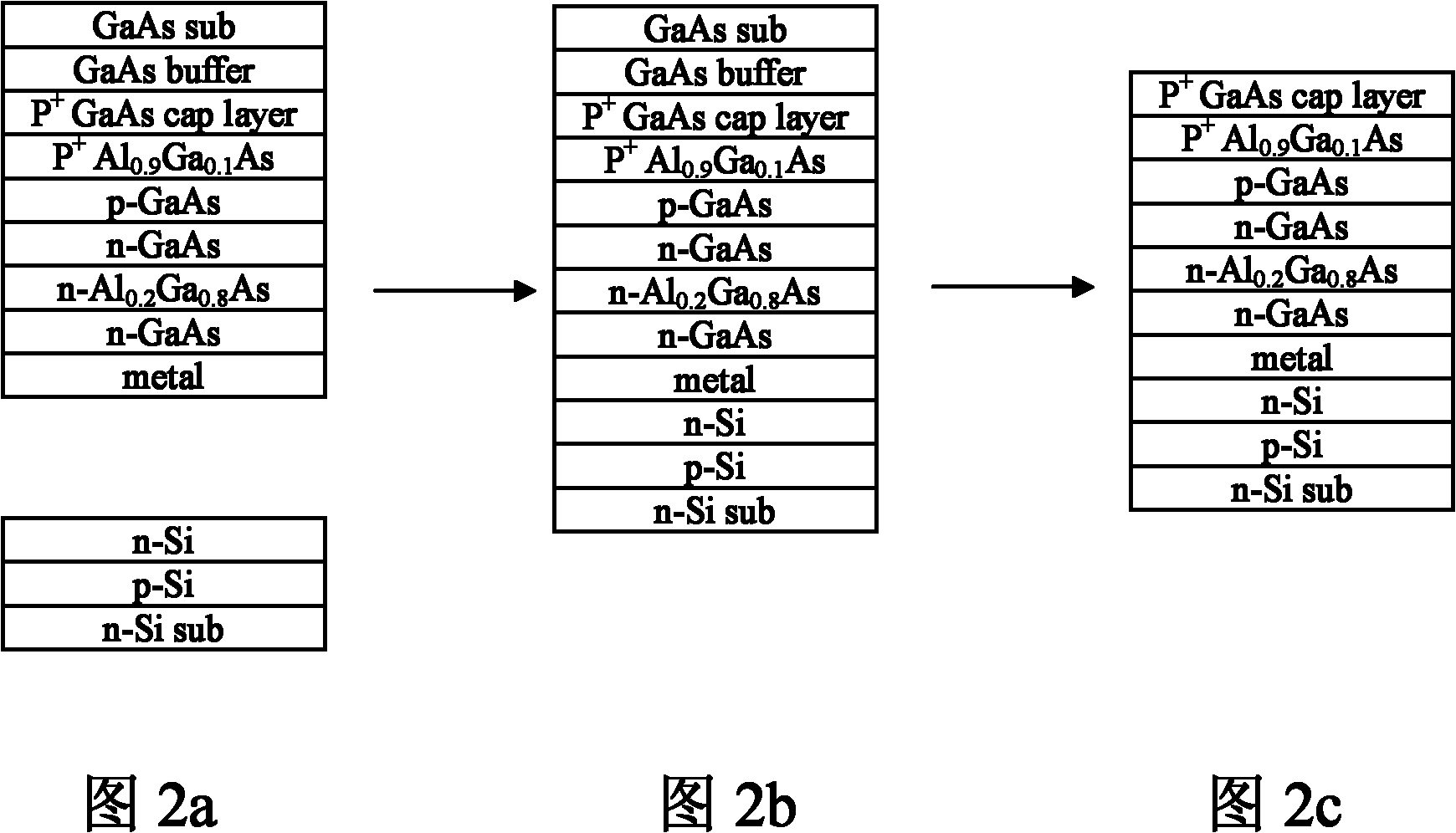

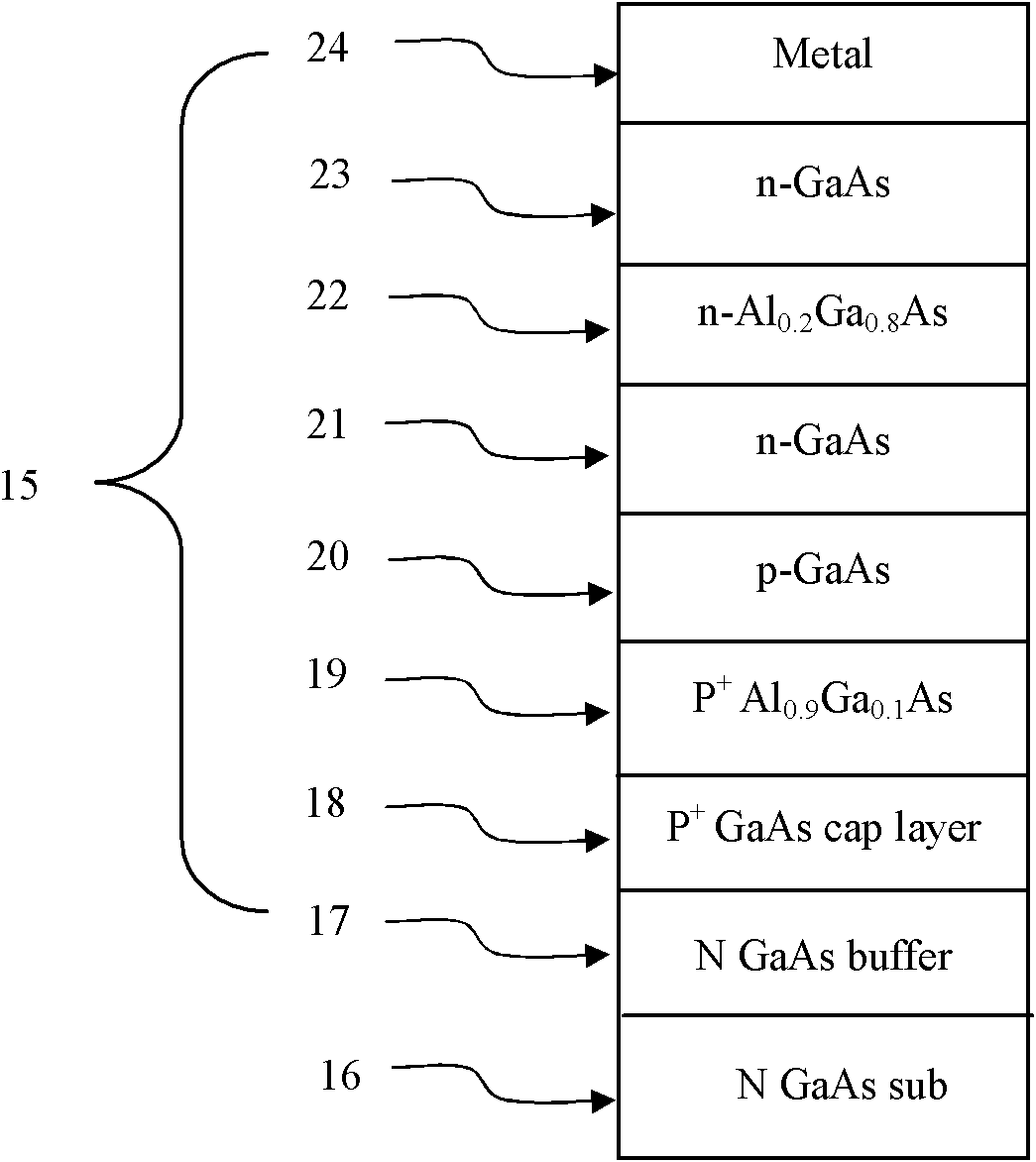

Method for performing low-temperature metal bonding on GaAs and Si

InactiveCN102110594ARealize the structureAchieve bondingFinal product manufactureSemiconductor/solid-state device manufacturingMetal stripsBond interface

The invention discloses a method for performing low-temperature metal bonding on GaAs and Si. The method comprises the following steps of: cleaning a single-side polished GaAs epitaxial wafer to remove organic substances on the surface of the wafer; performing photoresist etching on the GaAs epitaxial wafer to obtain the GaAs epitaxial wafer with a narrow strip; performing evaporation on the GaAs epitaxial wafer to form a metal layer; removing a photoresist by a stripping method to obtain a metal strip with a certain thickness; cleaning a Si epitaxial wafer to remove organic substances on the surface of the wafer; treating the surface of the Si epitaxial wafer by using H2SO4 solution and RCAl solution and attaching the cleaned Si epitaxial wafer to the GaAs epitaxial wafer so as to obtain an attached wafer; oppositely arranging the attached wafer in a vacuum bonding machine for bonding and performing thermal treatment to remove vapor of a bonding interface; and thinning the bound wafer and corroding off the GaAs substrate of the bound wafer. By the method, the low-temperature metal bonding of the GaAs and the Si is realized; and the method can be extended to the bonding between two III-V groups (or materials such as Si, Ge and the like of an IV group).

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

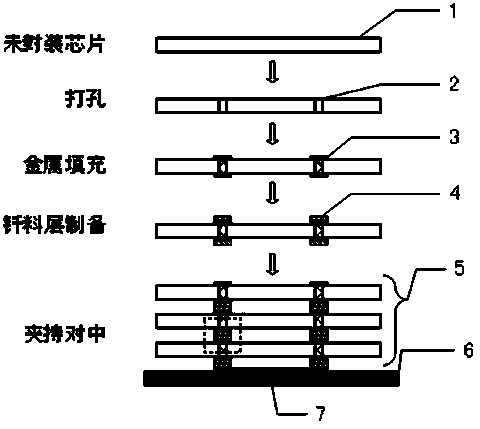

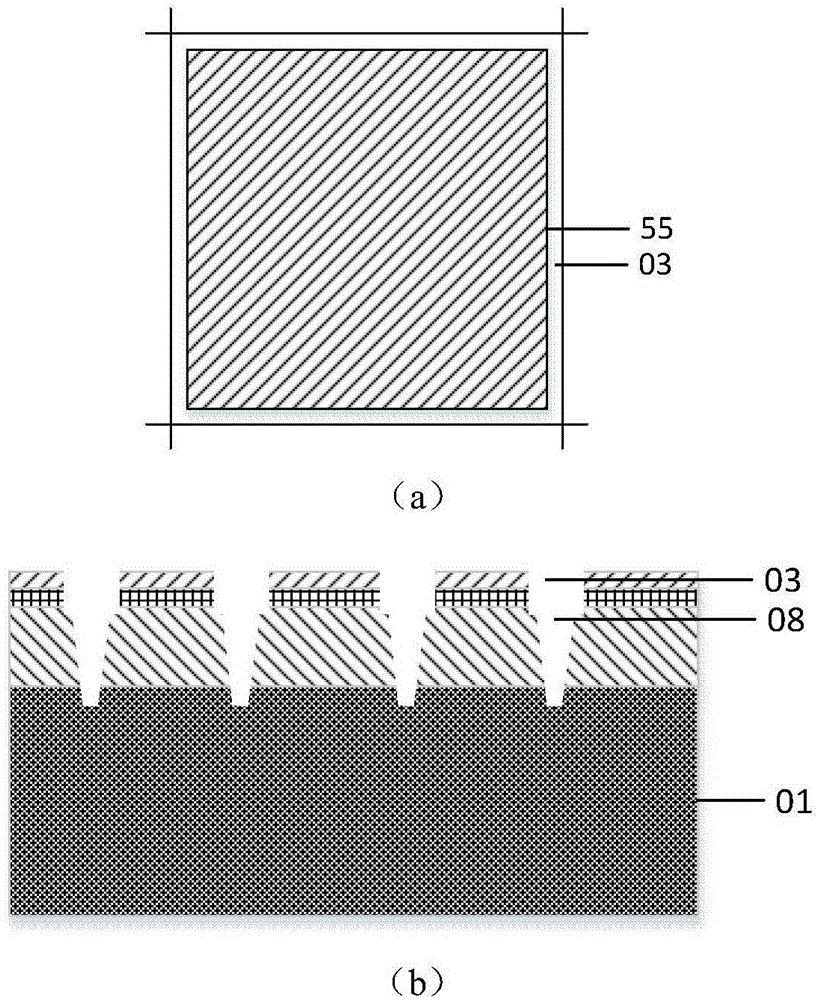

Method for achieving silicon through hole laminated chip interconnection

InactiveCN103972165AQuick bondImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingBonding processEngineering

The invention discloses a method for achieving silicon through hole laminated chip interconnection. The method is used for achieving bonding among multiple layers of stacked silicon through hole chips through the following steps of punching, filling of conductive metal, preparing of a solder layer, clamping and centering, bonding and forming of finished products, wherein in the bonding process, a current joule heat auxiliary bonding technology is adopted for achieving silicon through hole three-dimensional interconnection welding spot bonding. According to the method for achieving three-dimensional packaging and bonding with the assistance of joule heat, under the low temperature and even the normal temperature, fast bonding of full intermetallic compound welding spots can be achieved, and heat damage to a chip is effectively reduced. Under the action of oriented currents, intermetallic compounds in the welding spots are grown preferably and rapidly in an oriented mode, high electrical conductivity and the good comprehensive mechanical property of the welding spots are achieved, and the reliability of the bonding spots is effectively improved. A parallel electrode resistance welding platform is adopted, a hot plate and an ultrasound device are easily integrated, the better bonding effect can be achieved, and the bonding time is shortened.

Owner:HARBIN INST OF TECH

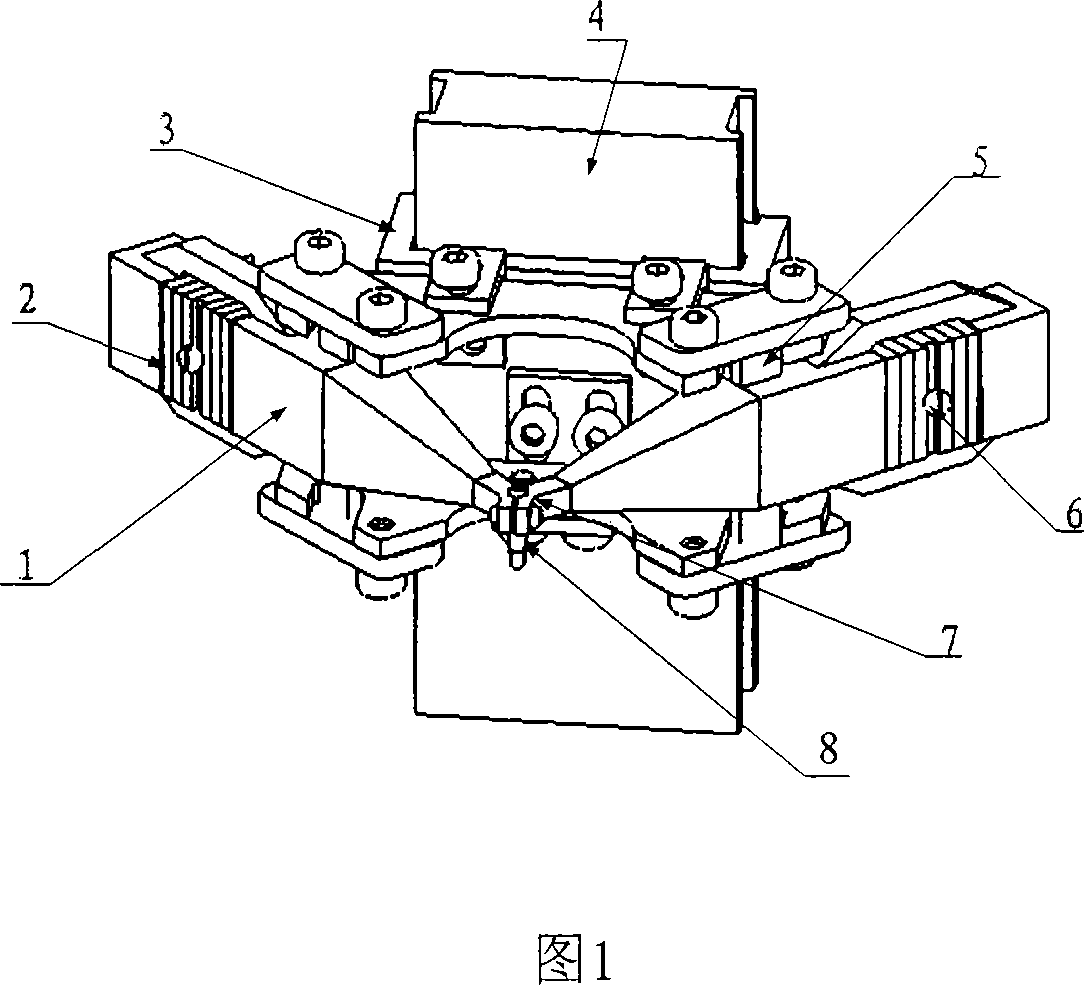

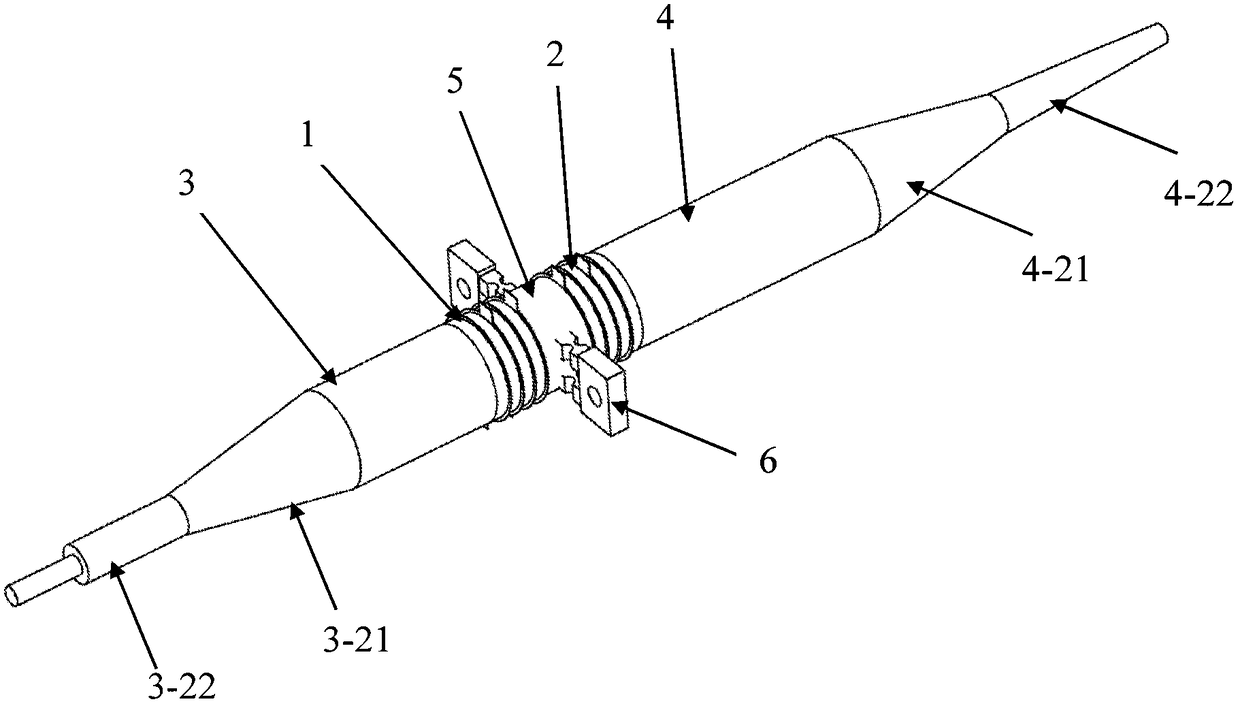

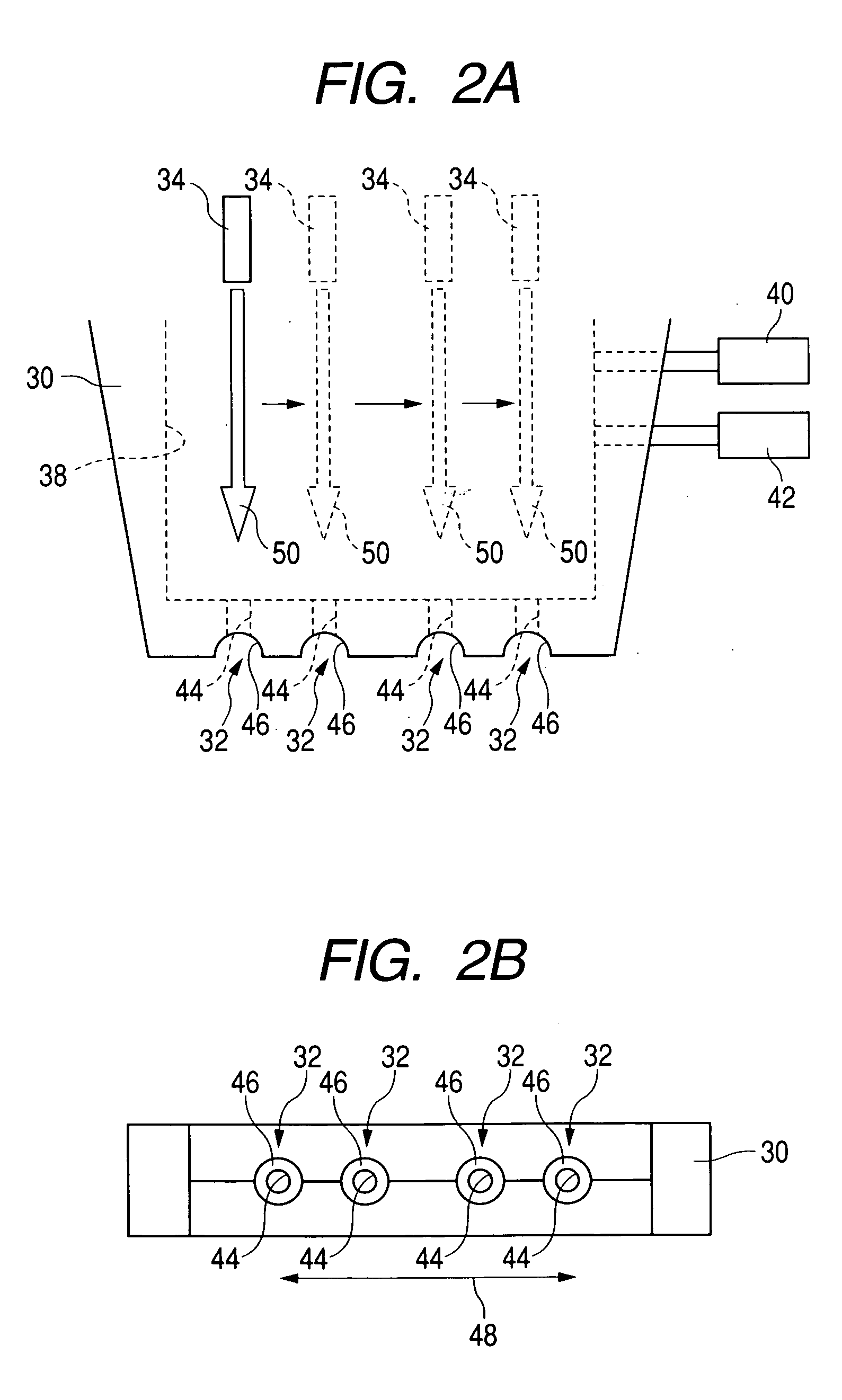

Parallel compound ultrasonic energy transmission device

InactiveCN101053864ALarge coverage areaReduced lateral deflection stiffnessSemiconductor/solid-state device manufacturingMechanical vibrations separationEnergy transferVibration amplitude

The invention provides a parallel connection combined type ultrasonic energy transferring device, which comprises a parallel connection combined type supersonic wave amplitude transformer, a piezoelectricity ultrasonic transducer as well as a working cleaver on front end of the amplitude transformer. Two sets of unidirectional vibration amplitude transformer are rigidly connected with each other on working end, and the parallel connection combined type supersonic wave amplitude transformer is fixed on a movable flatform via an elastic beam. The invention provides a novel parallel connection combined type ultrasonic energy transferring device, which is used to increase lead bond efficiency, wherein, the requirement of increasing supersonic wave lamplitude transformer end cleaver track cover area is satisfied, at the same time, ultrasonic energy density is increased, bond time is reduced, and bond efficiency is increased.

Owner:HARBIN INST OF TECH

Liquid phase diffusion welding method for metallic machine part and metallic machine part

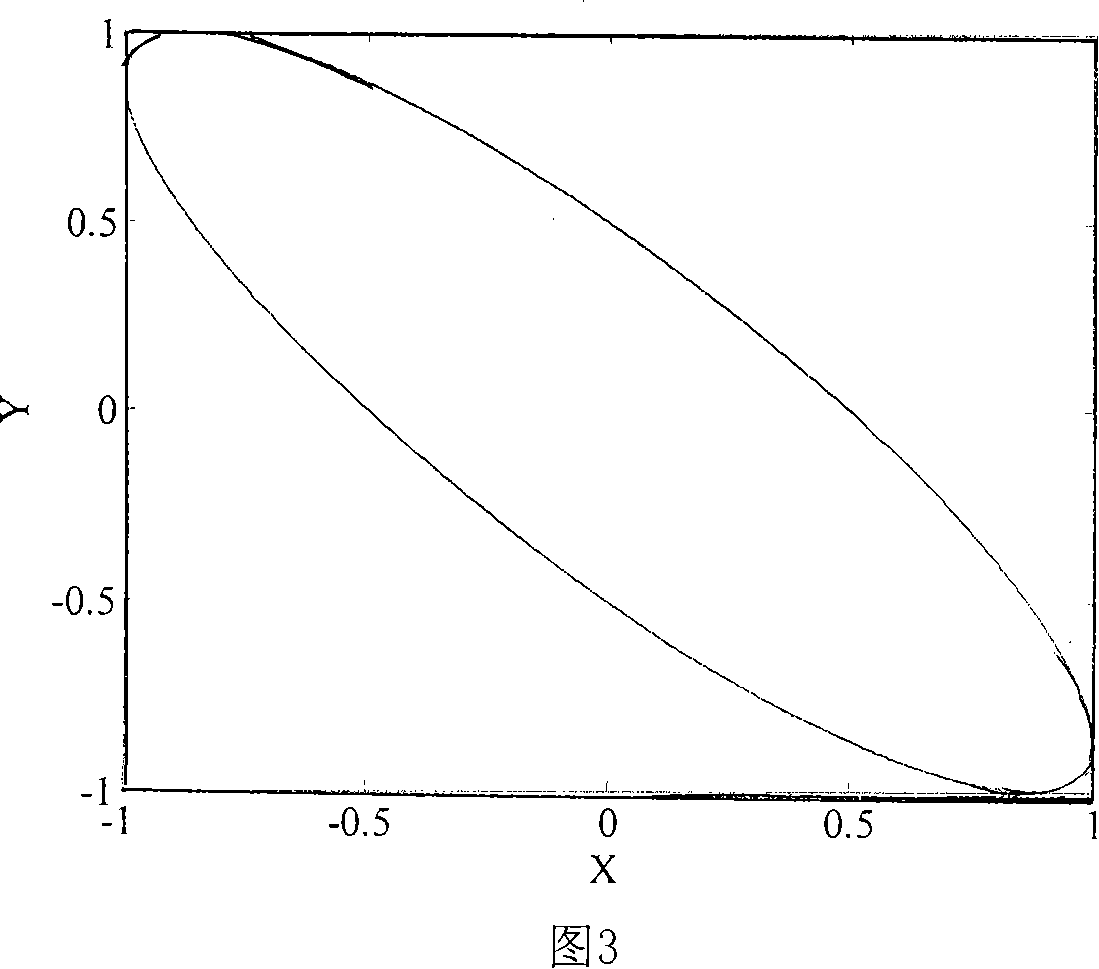

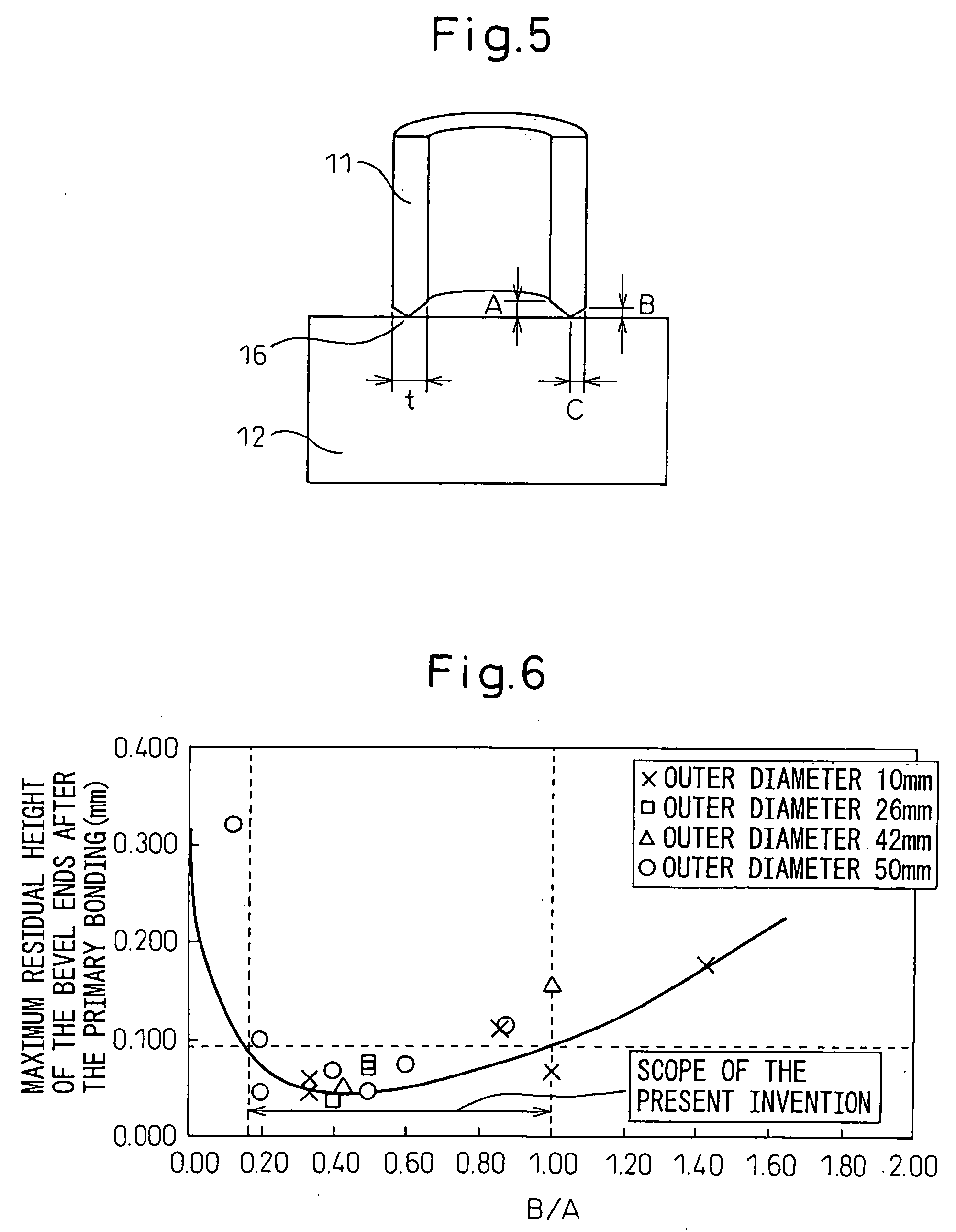

ActiveUS20060163321A1Improve joint qualityShorten bonding timeCamsValve arrangementsProduction rateElectrical resistance and conductance

A liquid phase diffusion bonding method for a metal machine part superior in the quality of the joint and the productivity enabling the bonding time to be shortened, achieving homogenization of the bonding structure and improving the tensile strength, fatigue strength, and joint quality and reliability. This liquid phase diffusion bonding method of a metal machine part is characterized interposing an amorphous alloy foil for liquid phase diffusion bonding at bevel faces of metal materials, performing primary bonding by melt bonding said amorphous alloy foil and said metal material by resistance welding to form a joint, then performing secondary bonding by liquid phase diffusion bonding by reheating said joint to at least the melting point of said amorphous alloy foil, then holding it there to complete the solidification process of said joint.

Owner:NIPPON STEEL CORP +1

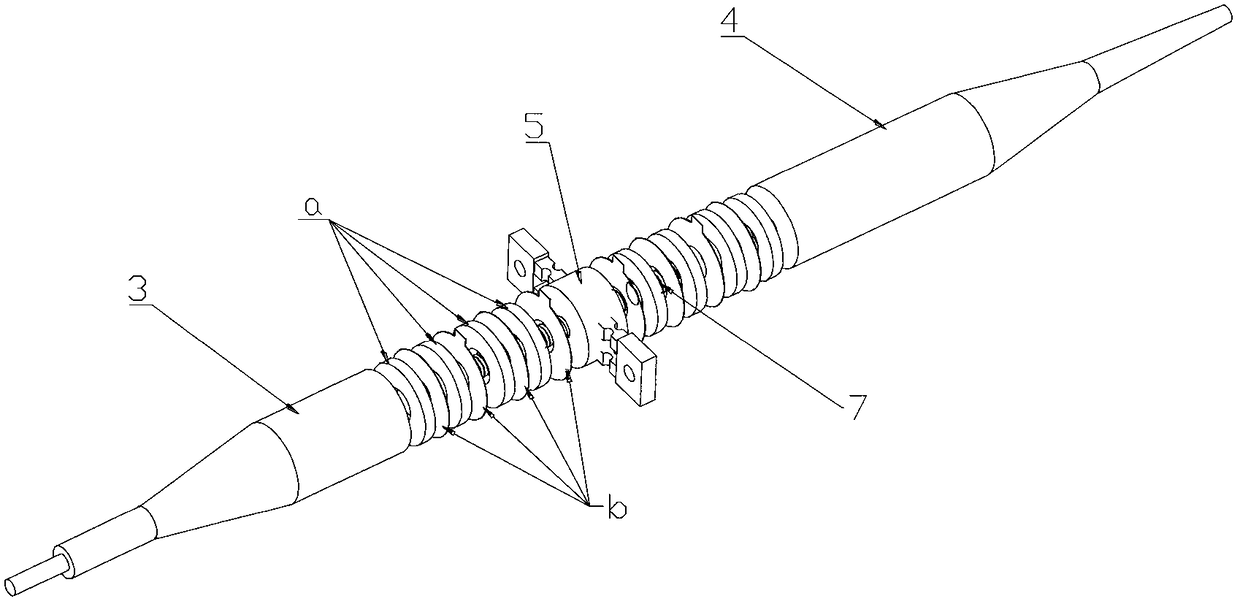

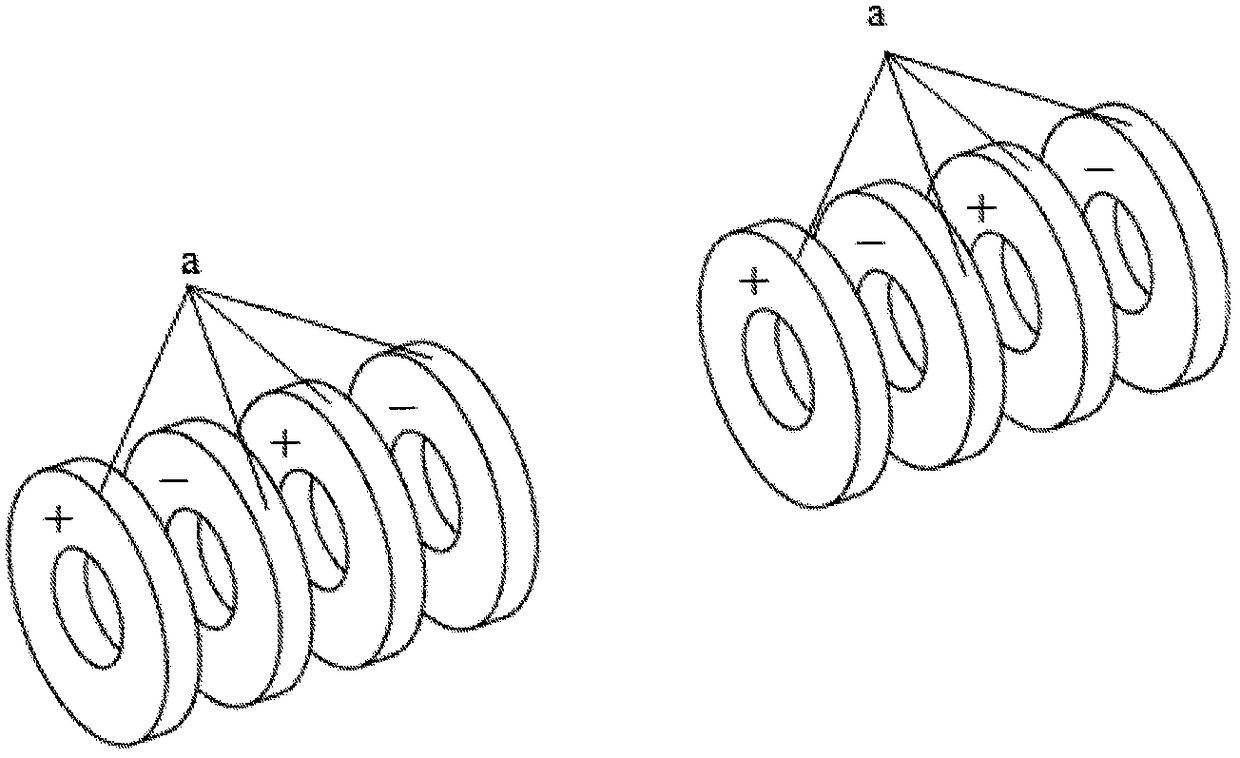

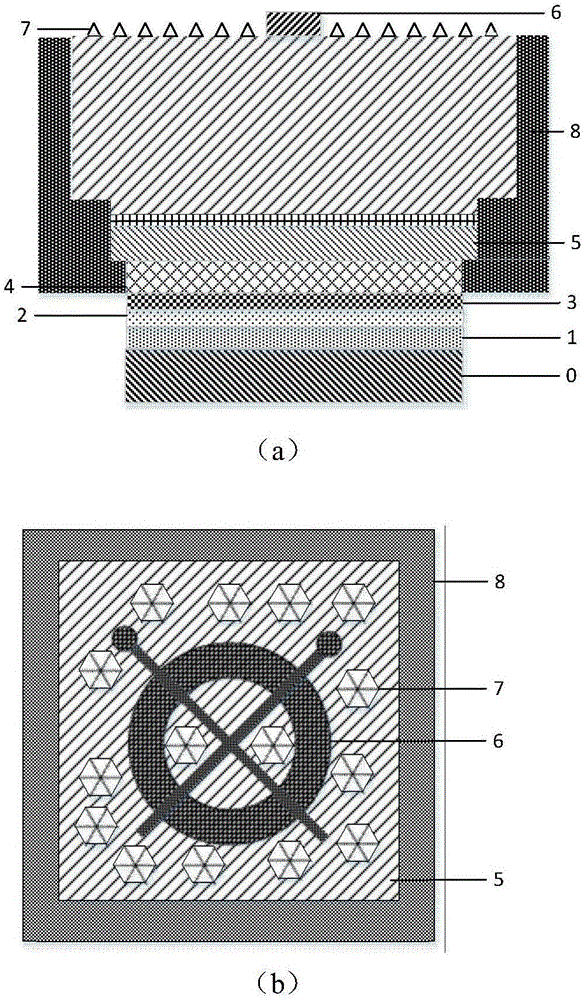

Series composite structure double-frequency multi-amplitude piezoelectric ultrasonic transducer

InactiveCN108176574AReduced service lifeReduce energy consumptionMechanical vibrations separationUltrasonic wire bondingUltrasonic transmission

The invention discloses a series composite structure double-frequency and multi-amplitude piezoelectric ultrasonic transducer applied to a thermal ultrasonic wire bonding and sealing process of an integrated circuit chip. The transducer is composed of two sets of double-ended radiating piezoelectric oscillators and two two-stage mechanical variable-amplitude poles with different amplification factors. The transducer can work at the frequency near the frequency of 60 kHz or 120 kHz and has three driving modes. Under simple harmonic excitation signals with the same frequency, the transducer canobtain multiple amplitude outputs to meet the different requirements of the wire bonding process of the integrated circuit chip and improve the bonding connection efficiency and reliability. Meanwhile, clamping mechanisms of the composite structure ultrasonic transducer adopt flexible flange clamping mechanisms formed by circular arc hinges, the influence of the clamping rack disturbance torque onthe ultrasonic transmission efficiency in the axial ultrasonic transmission process of the variable-amplitude pole can be effectively lowered, and the utilization rate of ultrasonic energy is increased.

Owner:TIANJIN POLYTECHNIC UNIV

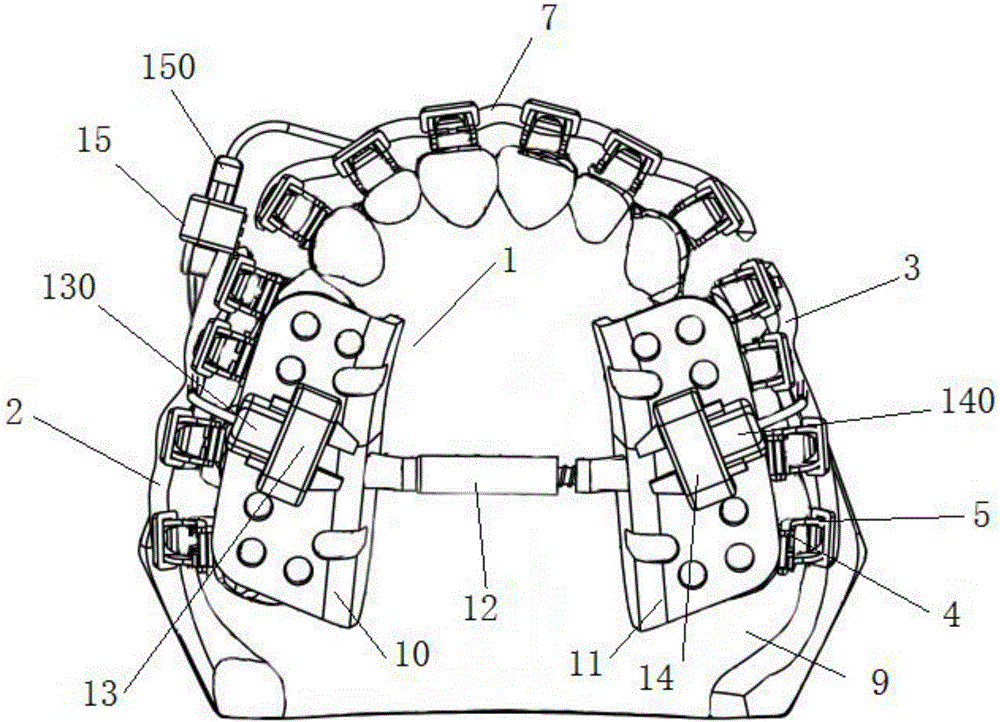

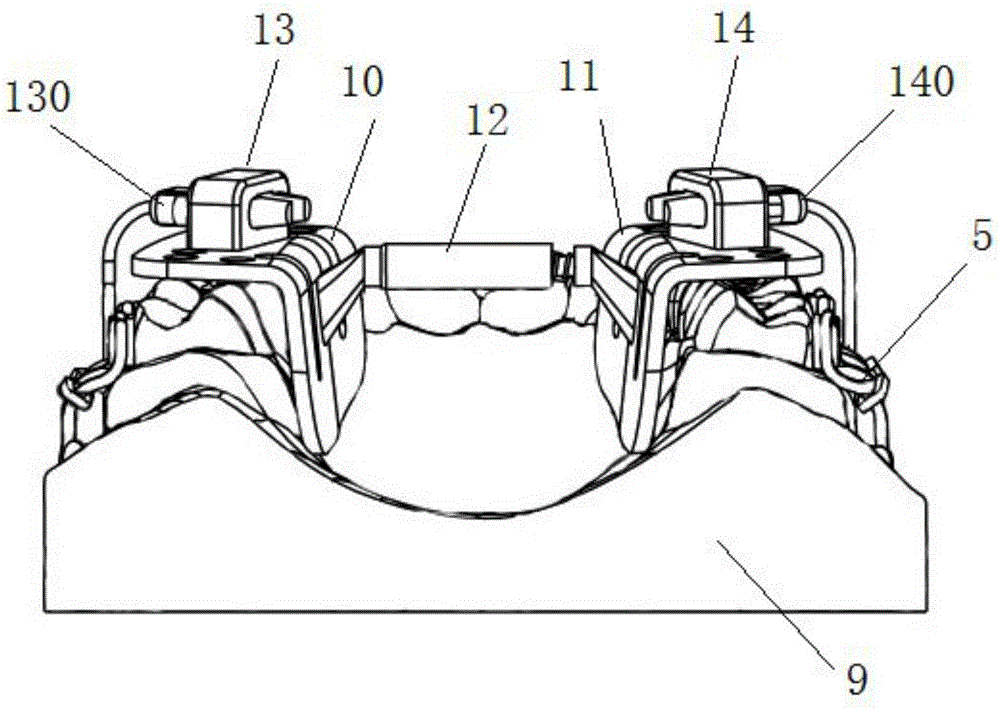

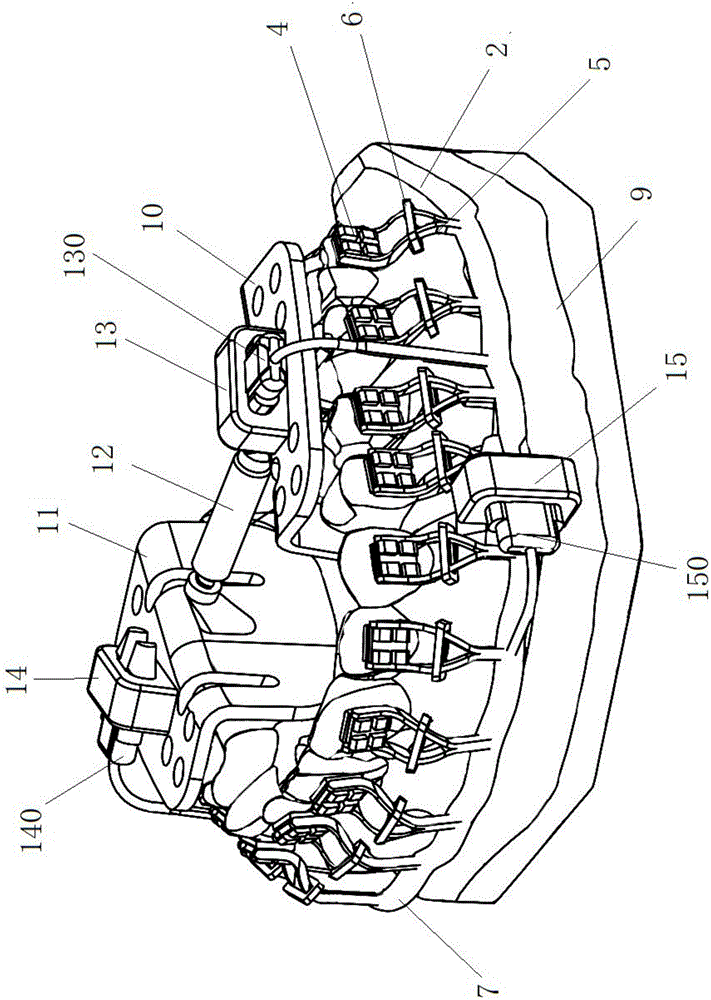

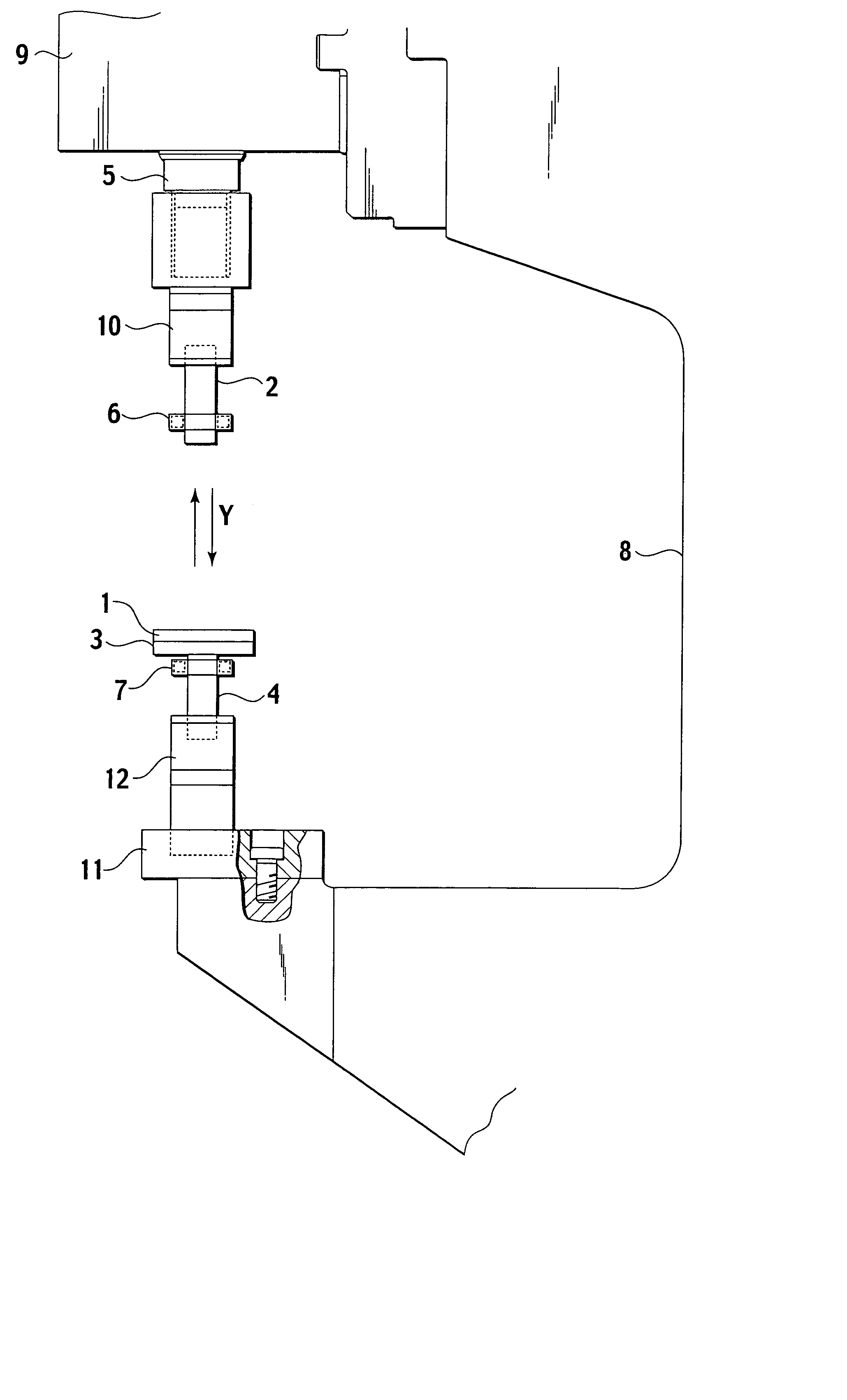

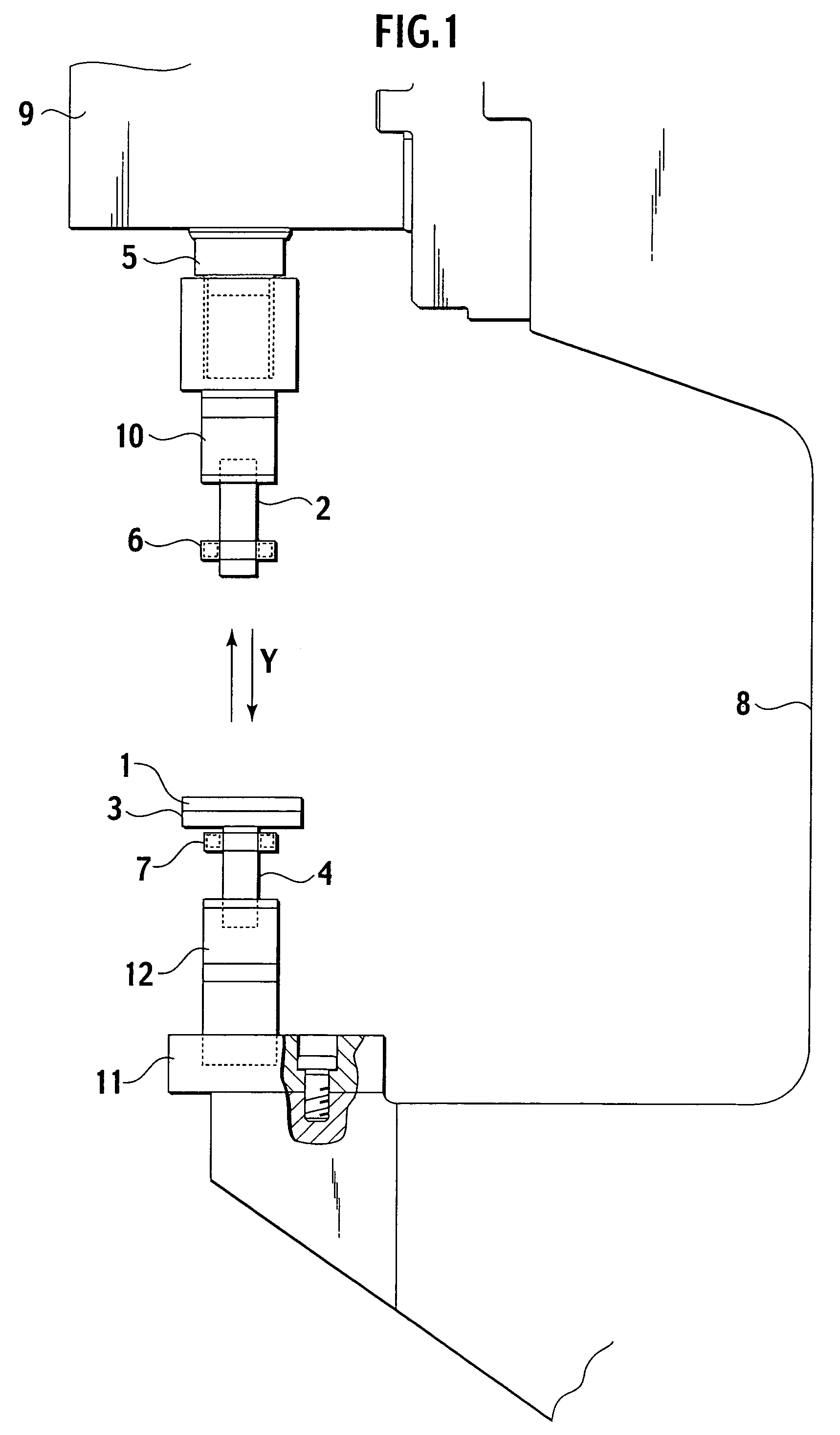

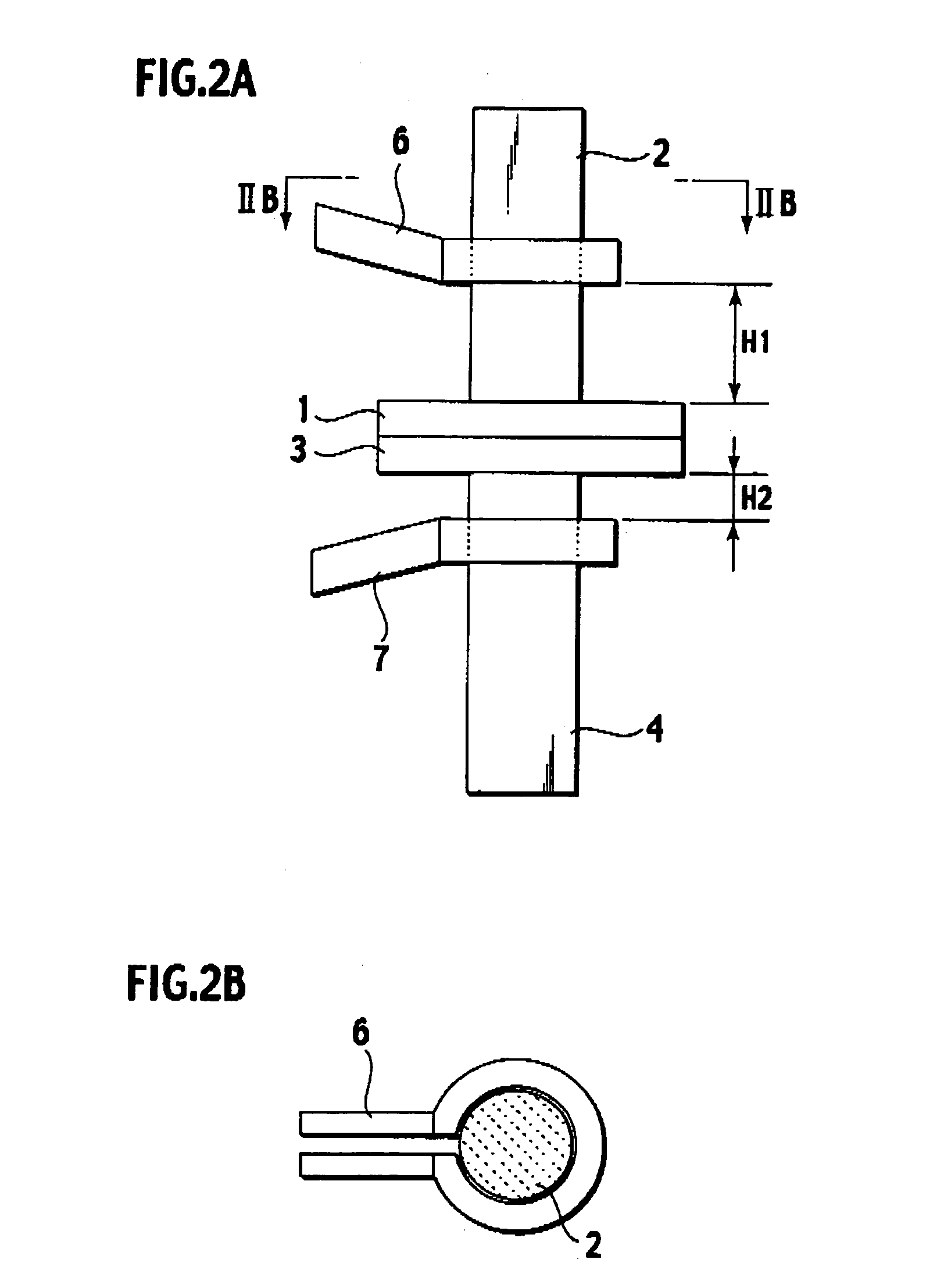

Orthodontic bracket indirect bonding precise positioning system and application method

The invention relates to an orthodontic bracket indirect bonding precise positioning system and an application method. The orthodontic bracket indirect bonding precise positioning system comprises a local positioning tray (1), a rear right tooth transfer arch-shaped rod (2), a rear left tooth transfer arch-shaped rod (3) and a front tooth transfer arch-shaped rod (7). The local positioning tray (1) comprises a first single side positioning local tray body (10) and a second single side positioning local tray body (11) which are symmetrically arranged, and a detachable spring ejecting rod (12) is installed between the first single side positioning local tray body (10) and the second single side positioning local tray body (11). By means of the orthodontic bracket indirect bonding precise positioning system and the application method, a bracket can be more precisely arranged; the bonding time is shortened; a patient feels more comfortable, and an upper bracket for intraoral teeth can be easily and quickly bonded clinically. In addition, healthier human engineering is achieved through indirect bonding, three-dimensional control over the teeth can be conveniently achieved, facial form improvement can be better achieved, and a good correction effect can be obtained.

Owner:赵计林

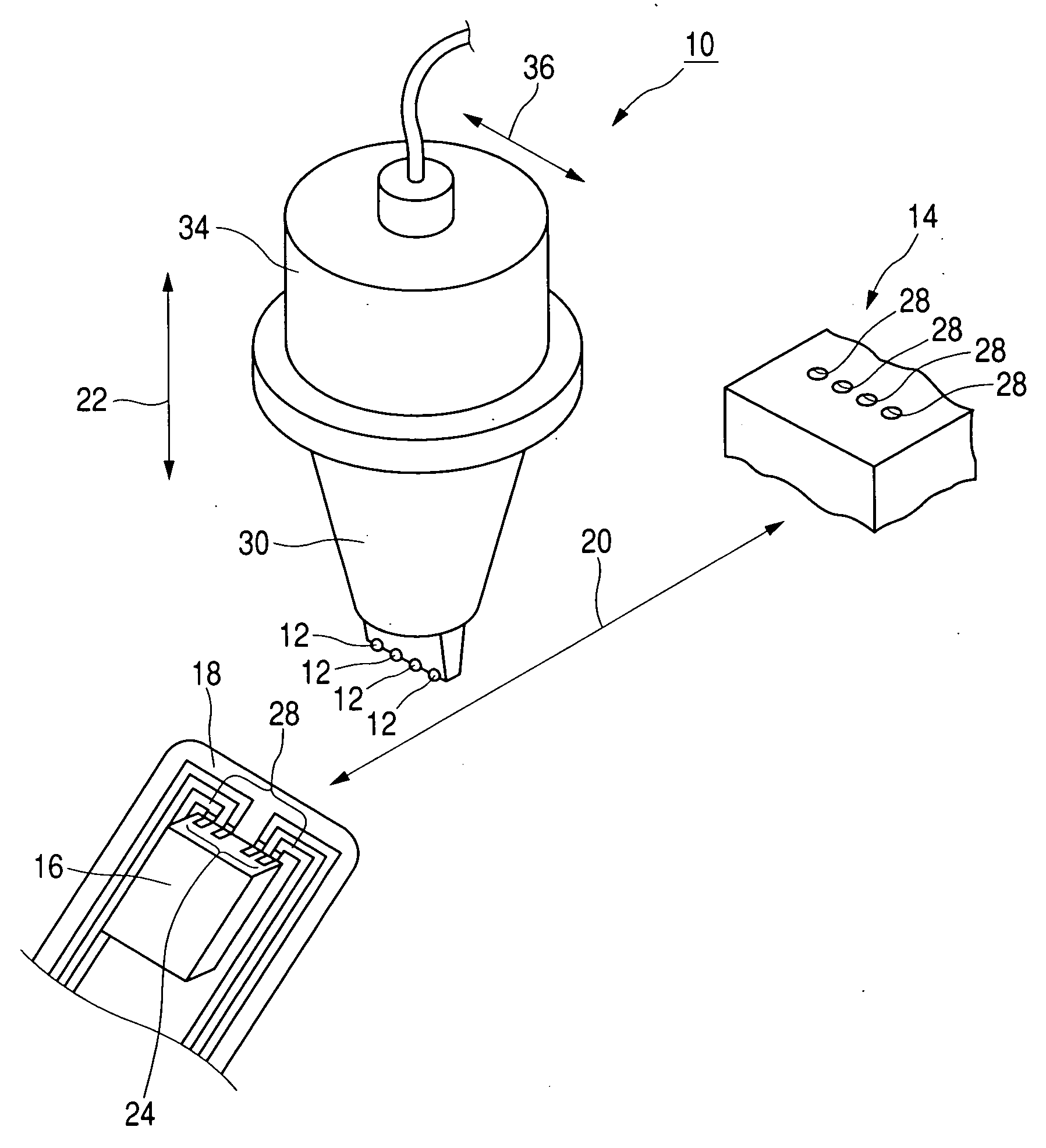

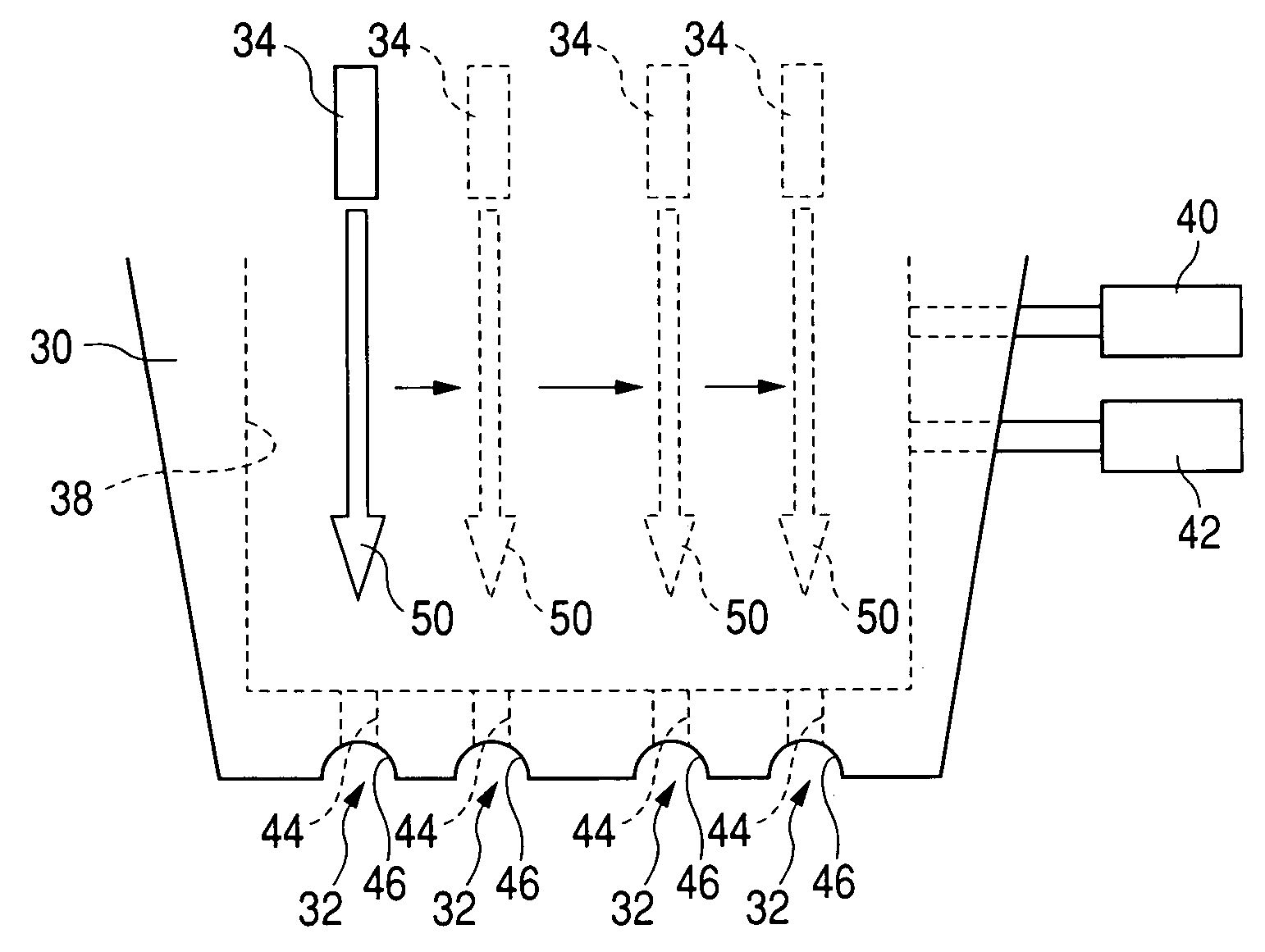

Solder ball bonding method and bonding device

ActiveUS20050051521A1Improve efficiencyPrevent movementPrinted circuit assemblingSolid-state devicesSolder ballEngineering

Provided are a solder ball bonding method and a solder ball bonding device for performing bonding of a plurality of electrode portions formed on objects to be bonded by melting solder balls. The solder balls are suctioned by using a plurality of suction nozzles that follow the electrode portions of the objects to be bonded, and conveyed onto the electrode portions. A laser irradiation portion that is positioned above the suction nozzles is then moved in a direction along which the suction nozzles are arranged, while the solder balls are irradiated with laser light passing through suction openings of the suction nozzles by using the laser irradiation portion. Accordingly, it is possible to melt the plurality of solder balls on the electrode portions by using only a single laser irradiation portion.

Owner:SAE MAGNETICS H K LTD 50

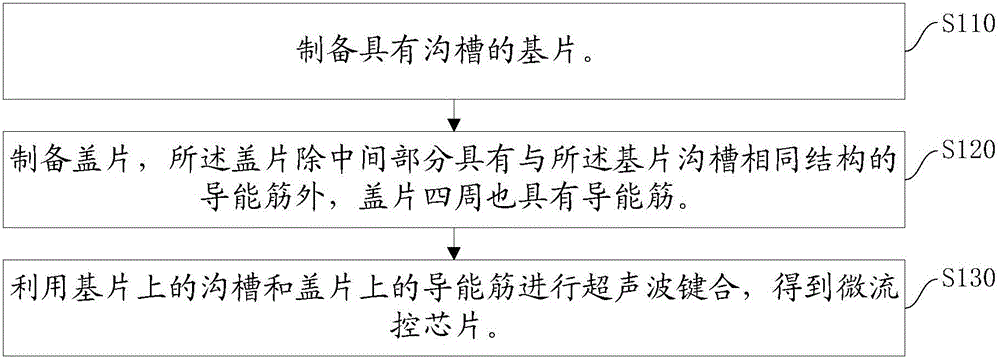

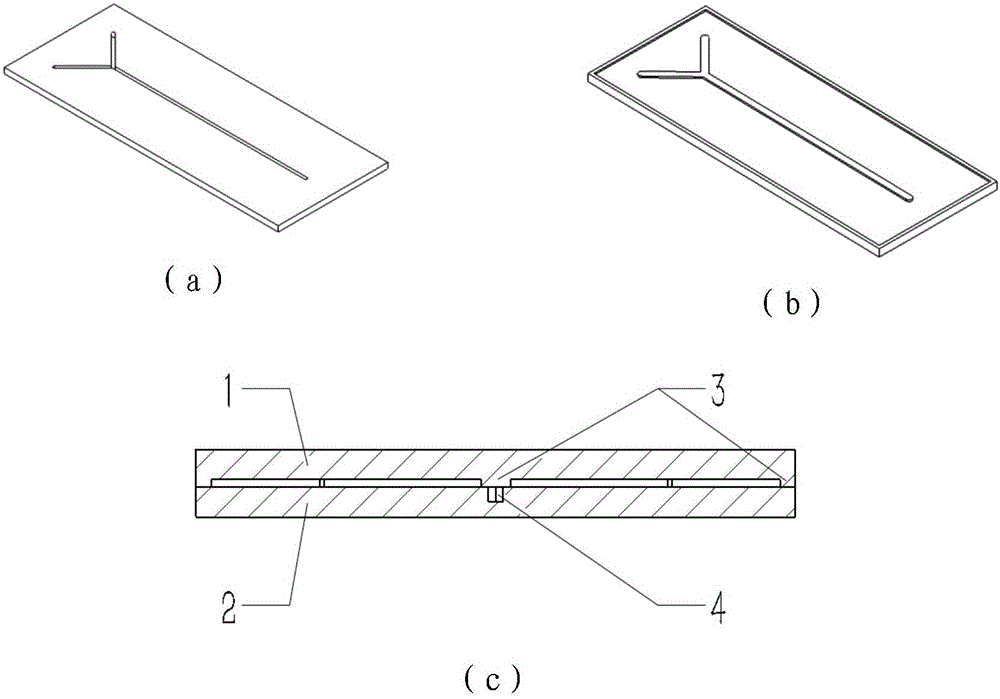

Ultrasonic-bonded micro-fluidic chip and preparation method thereof

InactiveCN105833924ASimple manufacturing processRealize large-scale productionLaboratory glasswaresEngineeringPre treatment

The invention relates to an ultrasonic-bonded micro-fluidic chip and a preparation method thereof. The preparation method comprises the following steps: preparing a substrate with a groove; preparing a cover glass plate, wherein the periphery and the central part of cover glass plate are provided with energy guiding ribs of a same structure with the groove of the substrate; and carrying out ultrasonic bonding in virtue of the groove on the substrate and the energy guiding ribs on the cover glass plate so as to obtain the micro-fluidic chip. According to the invention, a targeted cover glass plate structure is designed on the basis of the characteristic size of the substrate, so a making process for a chip injection mould is greatly simplified and production efficiency is improved; mediums like an adhesive are not needed in the process of packaging, so pollution is not produced; connection surfaces are in fusion connection, so bonding strength is high; moreover, before ultrasonic bonding, pre-treatment is not needed, so preparation time is shortened, bonding time in the aspect of bonding technological parameters is reduced, a packaging speed is fast, continuous automatic production can be realized, and thus, large-scale production of the polymer chip is realized.

Owner:北京同方华光系统工程有限公司

Polarization Conversion Element,Polarization Conversion Optical System And Image Projecting Apparatus

InactiveUS20080278690A1Reduce in quantityImprove productivityTelevision system detailsProjectorsLight fluxLight beam

A polarization conversion element having plural polarization separation sections and plural phase modulation sections is disclosed. A light flux is separated into transmission light (P polarization) and reflection light (S polarization) by being input to a polarization separation section. The reflection light reflected at the polarization separation section is output in the same direction as that of the transmission light by being reflected again at an adjacent polarization separation section at a different position from a position where a light flux is input to the adjacent polarization separation section. The phase modulation section is disposed on an optical path of the transmission light or the reflection light and output light becomes the same polarization.

Owner:RICOH KK

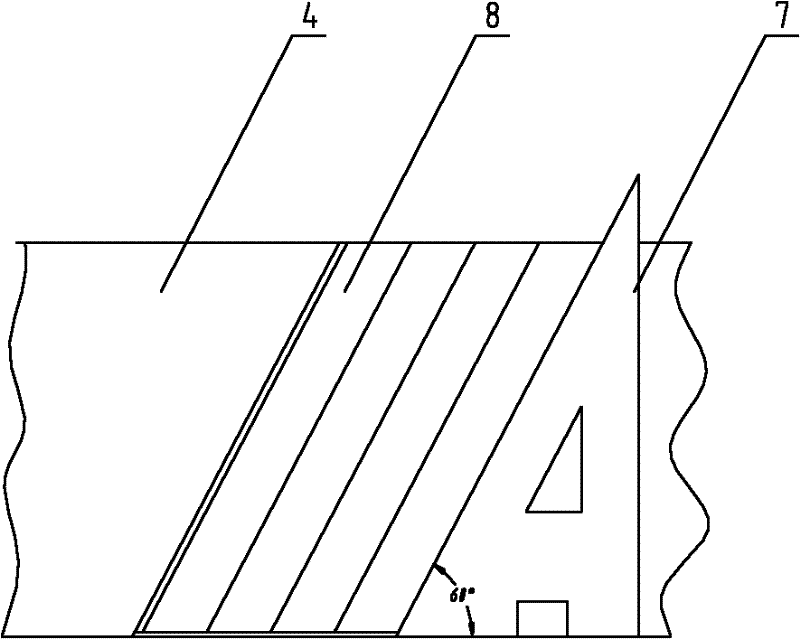

Vulcanization bonding process by template method for conveying belt

The invention relates to a vulcanization bonding process by a template method for conveying belts, which comprises: cutting a cloth layer and a glue layer of a belt joint part into symmetric gradient according to a certain form and angle, smearing rubber cement for bonding, then heating for a certain time to perform a vulcanization reaction at a certain pressure and temperature so as to allow rawrubber to become vulcanized rubber and provide the joint with optimal bonding strength. The invention introduces a bold innovation based on the original thermal bonding process, establishes a new process of lineation cutting and peeling for vulcanization bonding template; the process greatly shortens the bonding time; the new cutting and bonding process for the vulcanization bonding template method is safe, simple and rapid, saves human and material resources, improves working efficiency, increases the quality by 15-20%, and fills a gap in belt vulcanization bonding technology.

Owner:TIANJIN JINBIN PETROCHEM EQUIP

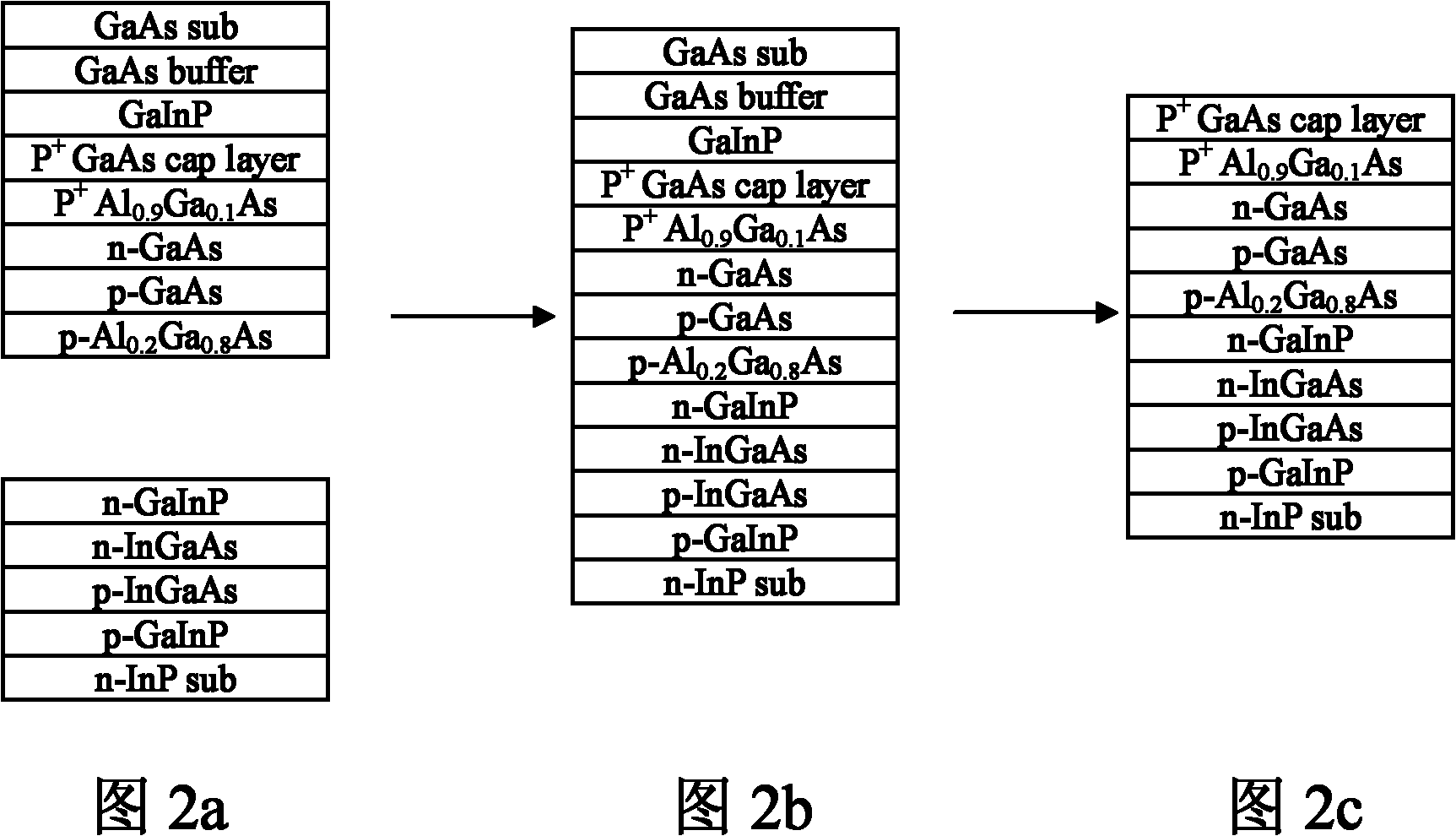

Method for performing low-temperature metal bonding on InGaAs and GaAs

ActiveCN102110595AHigh repeatabilityShorten bonding timeFinal product manufactureSemiconductor/solid-state device manufacturingPhotoresistThermal treatment

The invention discloses a method for performing low-temperature metal bonding on InGaAs and GaAs. The method comprises the following steps of: cleaning a single-side polished InGaAs epitaxial wafer to remove organic substances on the surface of the wafer; performing evaporation on the cleaned InGaAs epitaxial wafer to form a metal layer; performing photoresist etching on the InGaAs epitaxial wafer to obtain the InGaAs epitaxial wafer with a narrow metal strip; removing a photoresist on the surface of the InGaAs epitaxial wafer by plasma etching; cleaning a GaAs epitaxial wafer to remove organic substances on the surface of the wafer; attaching the cleaned GaAs epitaxial wafer to the InGaAs epitaxial wafer which is subjected to the plasma etching so as to obtain an attached wafer; oppositely arranging the attached wafer in a vacuum bonding machine for bonding and performing thermal treatment to remove vapor of a bonding interface; and thinning the bound wafer and corroding off the GaAs substrate of the bound wafer. By the method, the low-temperature metal bonding of the InGaAs and the GaAs is realized.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

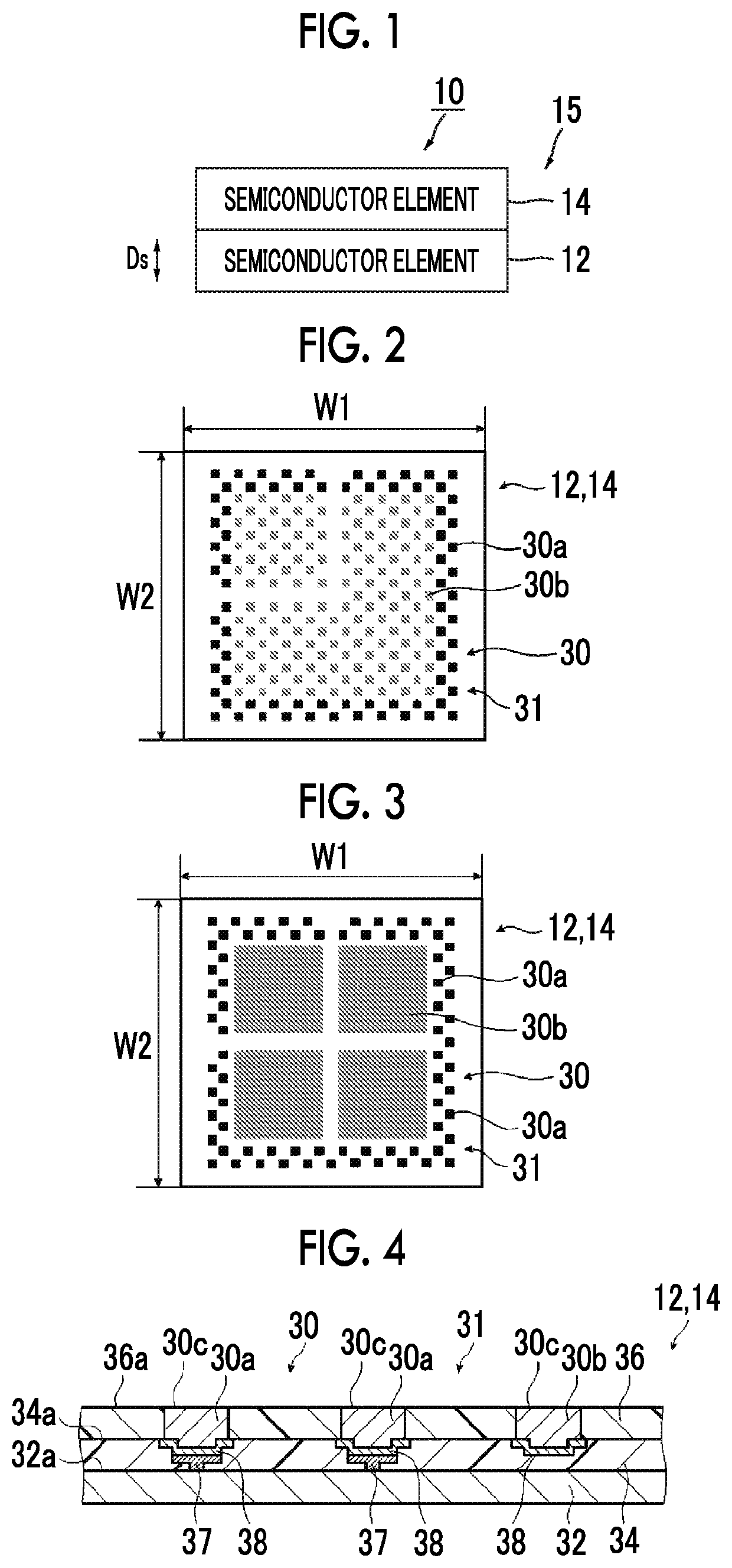

Stacked device, stacked structure, and method of manufacturing stacked device

ActiveUS20190363068A1Bonding strengthImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesElectricityEngineering

A stacked device includes a stacked structure in which a plurality of semiconductors are electrically connected to each other, the semiconductor includes a surface on which a plurality of terminals are provided, the plurality of terminals include a terminal that bonds and electrically connects the semiconductors to each other and a terminal that bonds the semiconductors to each other and does not electrically connect the semiconductors to each other, an area ratio of the plurality of terminals on the surface of the semiconductor is 40% or higher, and an area ratio of the terminals that bond and electrically connect the semiconductors to each other among the plurality of terminals is lower than 50%.

Owner:FUJIFILM CORP

Solder ball bonding method and bonding device

ActiveUS7164097B2Improve efficiencyPrevent movementPrinted circuit assemblingSolid-state devicesSolder ballLaser light

Provided are a solder ball bonding method and a solder ball bonding device for performing bonding of a plurality of electrode portions formed on objects to be bonded by melting solder balls. The solder balls are suctioned by using a plurality of suction nozzles that follow the electrode portions of the objects to be bonded, and conveyed onto the electrode portions. A laser irradiation portion that is positioned above the suction nozzles is then moved in a direction along which the suction nozzles are arranged, while the solder balls are irradiated with laser light passing through suction openings of the suction nozzles by using the laser irradiation portion. Accordingly, it is possible to melt the plurality of solder balls on the electrode portions by using only a single laser irradiation portion.

Owner:SAE MAGNETICS H K LTD 50

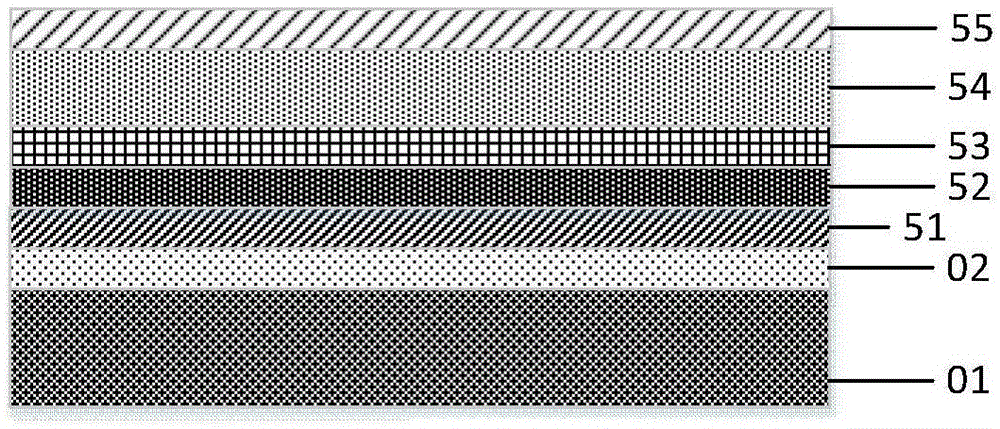

Thin-film structure light-emitting diode (LED) chip based on silver-based metal bonding and preparation method of thin-film structure LED chip

ActiveCN105047788AAvoid damageShorten bonding timeSemiconductor devicesHeat conductingRetention time

The invention discloses a thin-film structure light-emitting diode (LED) chip based on silver-based metal bonding and a preparation method of the thin-film structure LED chip. AgCuIn alloy is adopted as a bonding metal layer, so that the bonding temperature is reduced and the retention time is shortened; AgCuIn bonding can be finished at relatively low bonding temperature and bonding pressure; the bonding time is shortened; reduction of the injuries to the photoelectric property of an LED epitaxial layer in the bonding process is facilitated; by a bonding metal layer of the AgCuIn alloy, the cavity phenomenon in the bonding process is removed; stress release of the LED epitaxial layer is facilitated; the AgCuIn bonding is high in mechanical property and has good conductivity and heat-conducting property; prolonging of the service life of the LED chip is facilitated; with the AgCuIn as bonding metal, the manufacturing cost of the vertical structure LED chip is greatly reduced; and marketing development of the vertical structure LED chip is facilitated.

Owner:PEKING UNIV +1

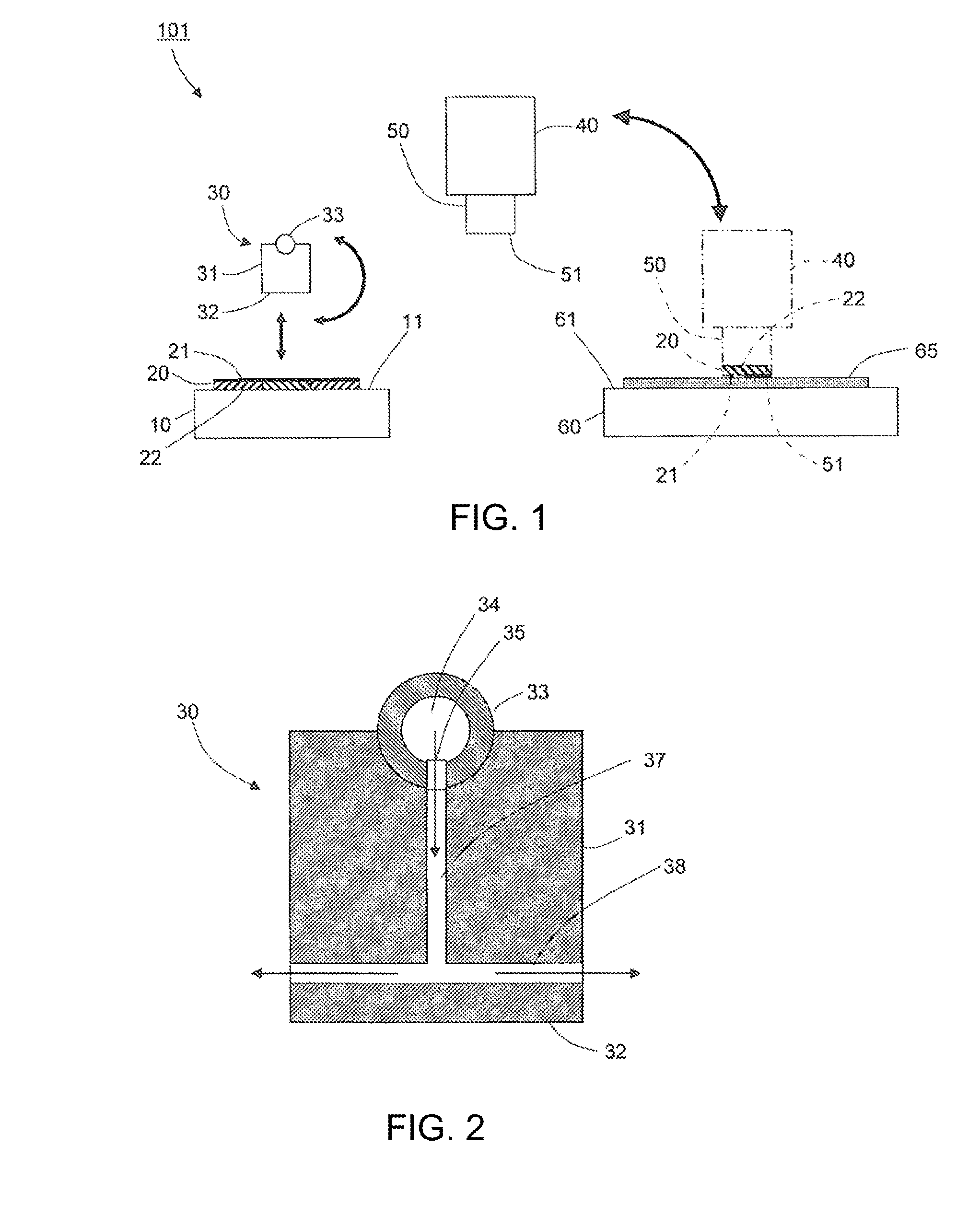

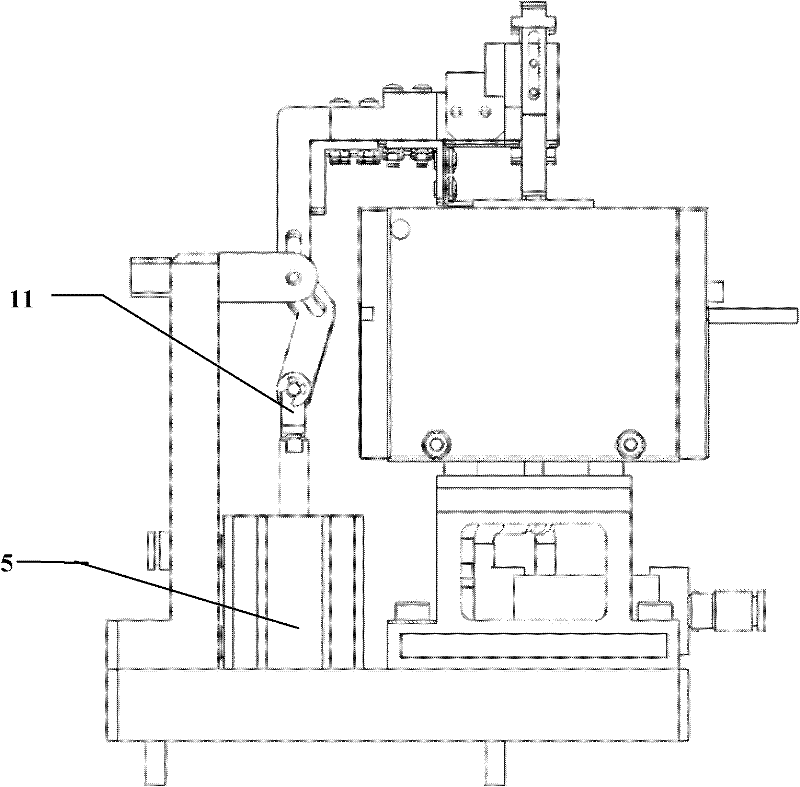

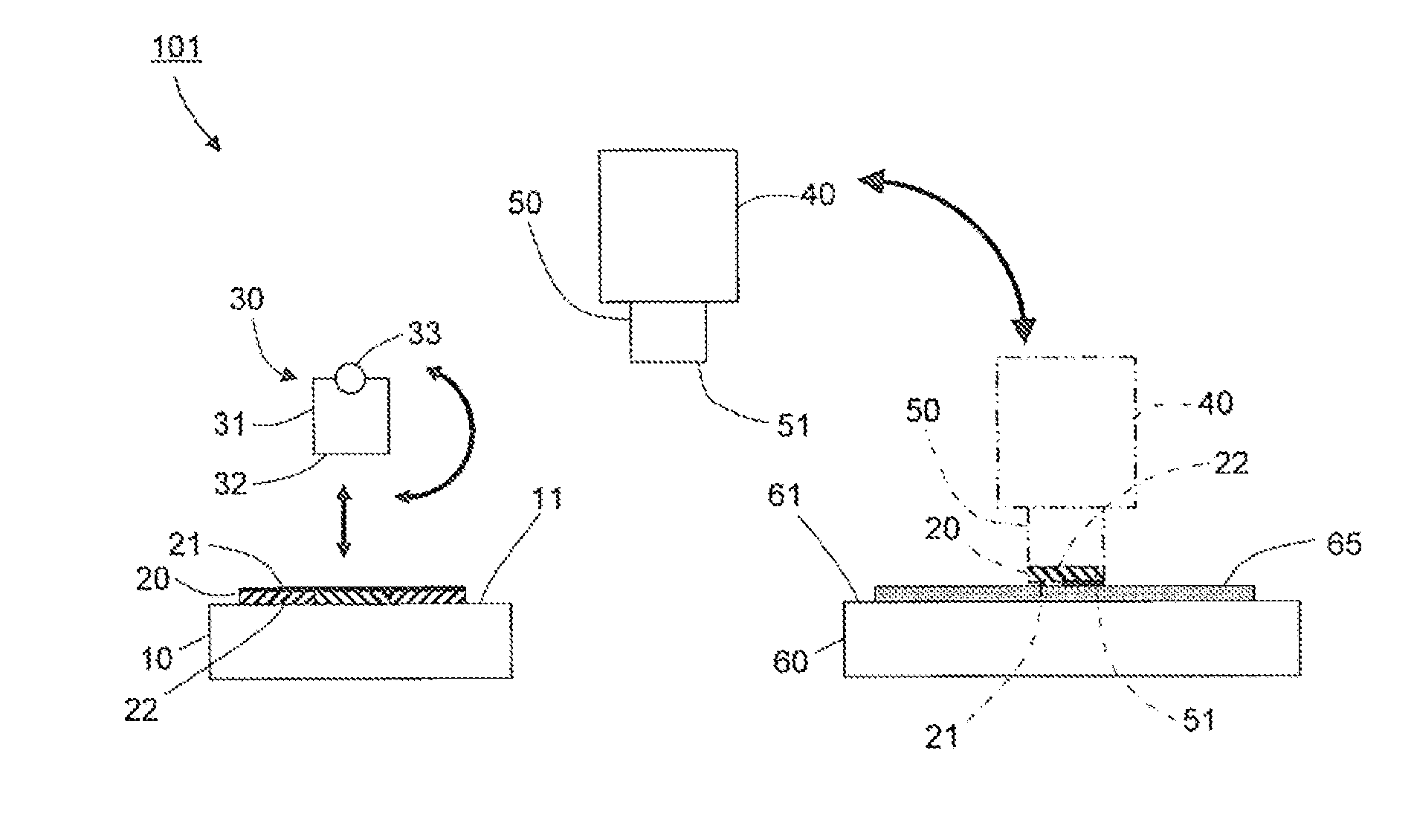

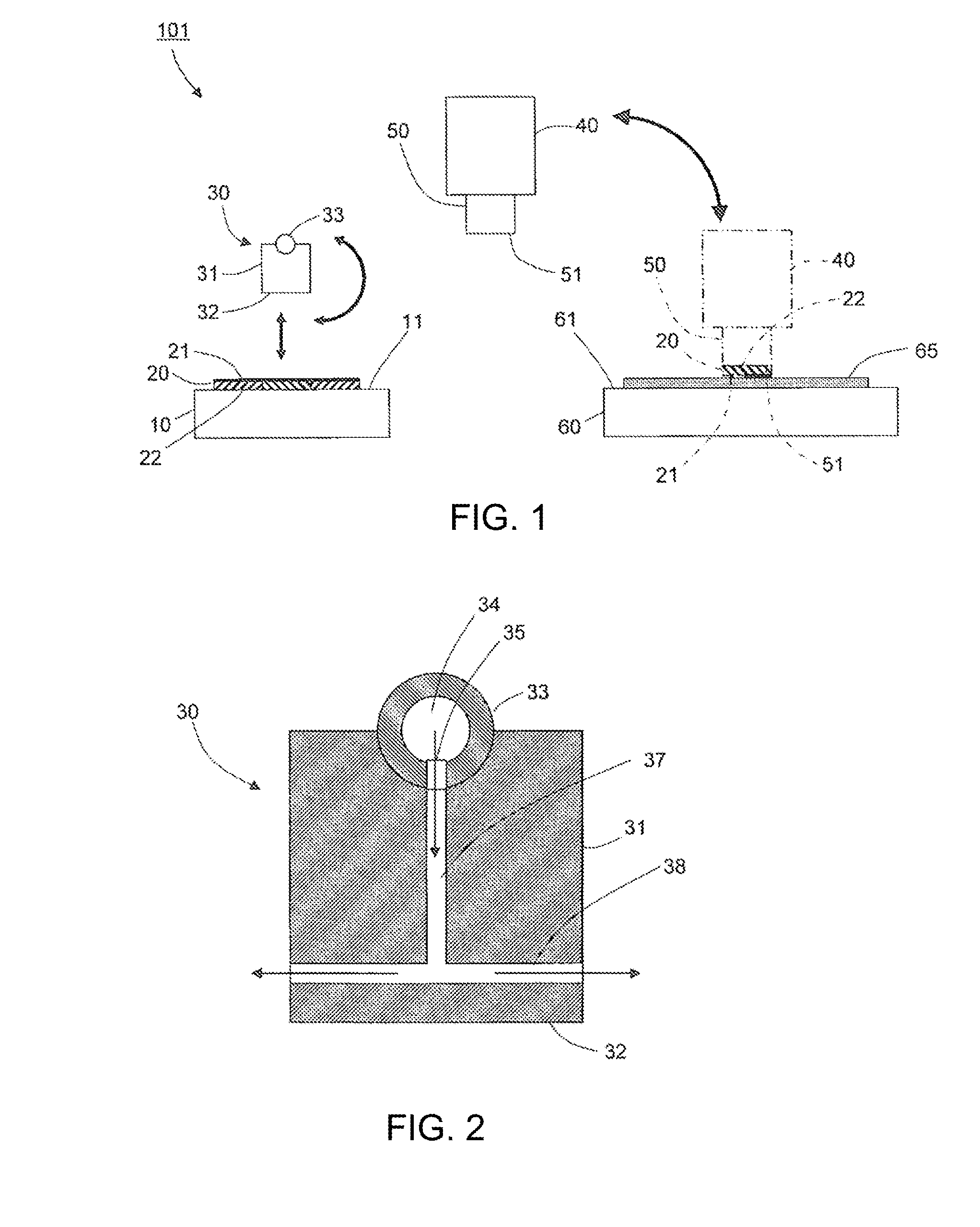

Flip chip bonder and flip chip bonding method

ActiveUS20150380381A1Quality improvementShorten bonding timeSemiconductor/solid-state device detailsSolid-state devicesEngineeringCooling channel

Provided is a flip chip bonder including: a pickup flipping collet configured to flip a chip; and a bonding tool configured to receive the chip flipped with the pickup flipping collet from the pickup flipping collet and to bond the received chip to a circuit board. The pickup flipping collet includes a cooling channel through which cooling air flows to cool the pickup flipping collet. Thus, bonding time can be reduced without lowering bonding quality.

Owner:SHINKAWA CO LTD

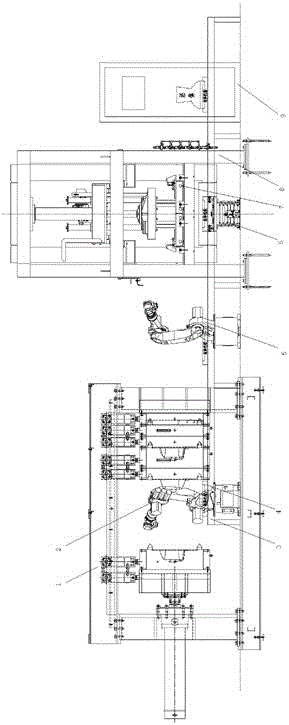

Combined type high-pressure forming system for fully-automatic lifting type in-mould ring-stuck water closet

ActiveCN105818261AHigh water contentHigh water content, high regularity of green body bondingCeramic shaping plantsEngineeringHigh pressure

The invention discloses a combined type high-pressure forming system for a fully-automatic lifting type in-mould ring-stuck water closet. The combined type high-pressure forming system comprises a water closet ring high-pressure former, a ring de-molding robot, a green body conveying line, a green body conveying and bonding support plate, a mud applying robot, a bonding lifter, a water closet body side mould opening-closing machine, a water closet body high-pressure former and an automatic electrical control system, wherein under the control of the electrical control system, the water closet ring high-pressure former and the water closet body high-pressure former automatically complete green body slip-casting, green body automatic de-molding, automatic conveying, automatic bonding and automatic side mould opening separately, so that a finished product green body is automatically conveyed to the tail end of a forming unit. According to the combined type high-pressure forming system, the labor intensity of a worker is greatly relieved, the bonding time is shortened, and the production efficiency is greatly improved; the labor intensity of the worker is effectively relieved, the forming period of the finished product green body is shortened, and the formation of occupational diseases of staff is reduced; and the green body drying time and green body trimming workload are reduced as a result of high regularity of green body bonding, and degree of contamination on the environment is reduced.

Owner:TANGSHAN HEXIANG INDAL

Liquid phase diffusion bonding method for dissimilar metal sheets and liquid phase diffusion bonding apparatus for the same

InactiveUS7119309B2Shorten bonding timeHigh bonding strengthHigh frequency current welding apparatusWelding/soldering/cutting articlesAlloyMaterials science

A liquid phase diffusion bonding method for dissimilar metal sheets by allowing a galvanized steel sheet and an aluminum alloy sheet to come into close contact with each other and pressing both sheets by using a first mold of a liquid phase diffusion bonding apparatus and a second mold of the same; and heating the sheets at approximately the same heat-up rate and at approximately the same temperature to perform liquid phase diffusion bonding of the sheets by using induction heat generated by applying high frequency currents to a first high frequency induction heating coil provided on the first mold and a second high frequency induction heating coil provided on the second mold. The first high frequency induction heating coil and the second high frequency induction heating coil are positioned to sandwich the sheets at predetermined distances from the sheets, respectively.

Owner:NISSAN MOTOR CO LTD +1

Indium antimonide (InSb) wafer and silicon (Si) wafer bonding method

InactiveCN103199156ASimple processPracticalFinal product manufactureSemiconductor devicesOrganic solventWafering

The invention provides an indium antimonide (InSb) wafer and silicon (Si) wafer bonding method. The method includes a first step of carrying out high-temperature ultrasonic boiling and washing in organic solvent on an InSb wafer and a Si wafer which are respectively polished on at least one side and then using deionized water to wash the InSb wafer and the Si wafer, a second step of placing the Si wafer into acid solution for boiling and washing and then using the deionized water to wash, a third step of placing the Si wafer into alkali solution for boiling and washing and then using the deionized water to wash, and a fourth step of enabling the polished surface of the InSb wafer and the polished surface of the Si wafer to face inwards, carrying out laminating, then placing the two laminated wafers into a vacuum bonding machine and carrying out heat treatment to complete bonding of the InSb wafer and the Si wafer. The InSb wafer and Si wafer bonding method is simple in process and has strong practicality.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

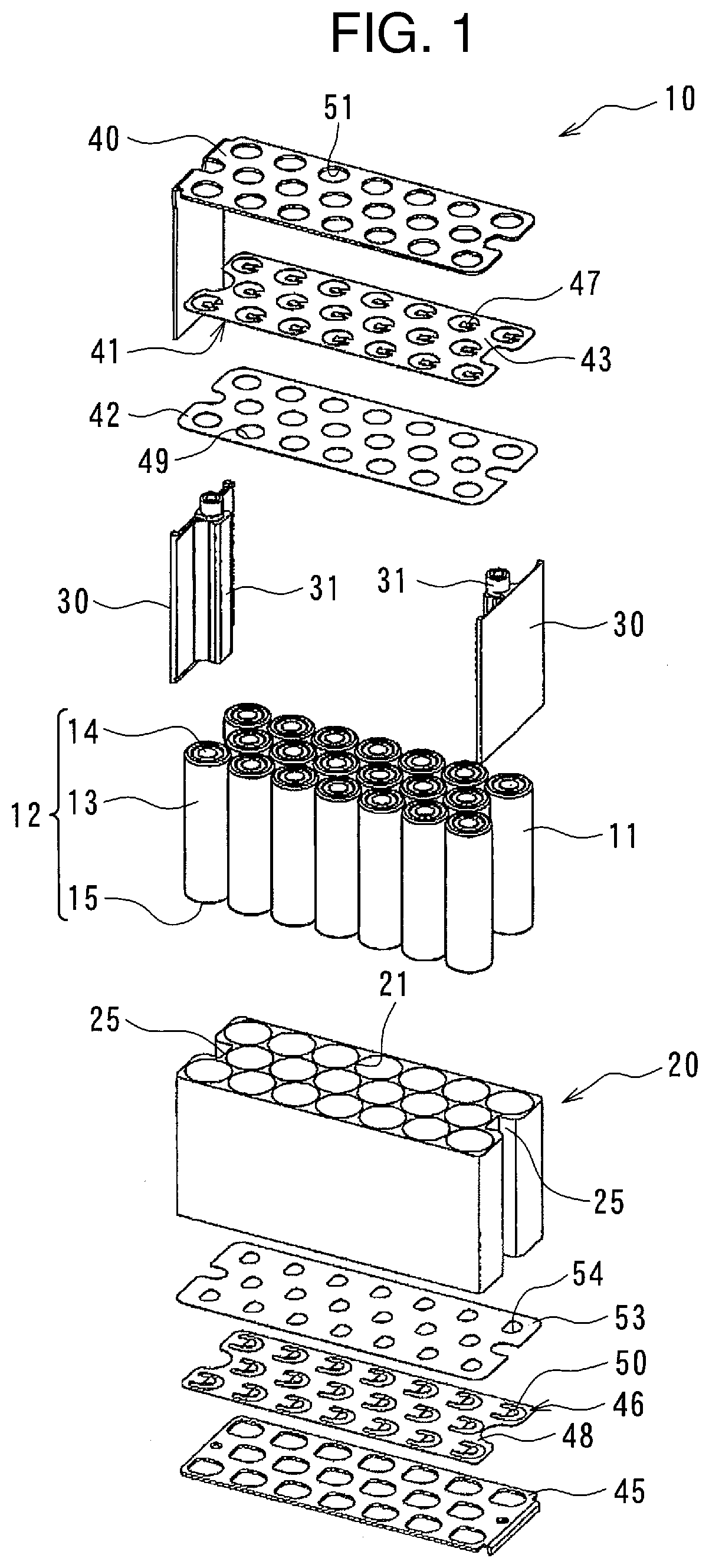

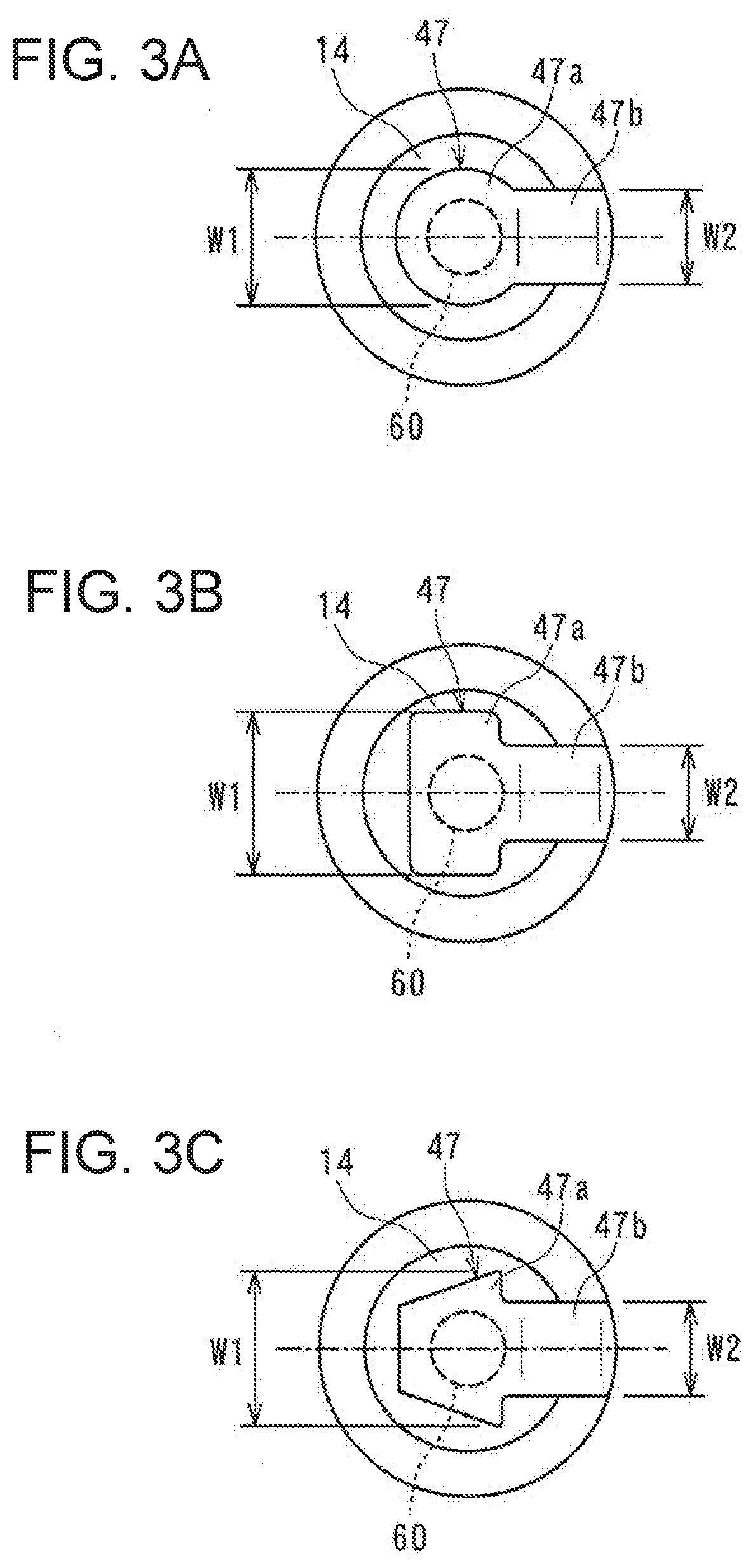

Battery module and method for manufacturing same

InactiveUS20190363318A1Shorten bonding timeImprove reliabilitySmall-sized cells cases/jacketsLarge-sized cells cases/jacketsSurface roughnessEngineering

A battery module includes a plurality of battery cells each having a terminal, and a lead plate having a lead part each of which is joined to the terminal of each of the battery cells to electrically connect the battery cells to each other. The lead part includes an aluminum thin plate having aluminum purity higher than or equal to 99.0%. Surface roughness Ra of a joining surface of the lead part to the terminal is less than or equal to 10 μm. The lead part is electrically connected to the terminal by solid-phase bonding.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Heating and pressing device for anodic bonding of long glass cylinders

ActiveCN102295268AGuaranteed power-up effectImprove bonding efficiencyDecorative surface effectsChemical vapor deposition coatingEngineeringSelf adaptive

The invention discloses a heating imposing electric device of long glass column anodic bonding. The device provided by the invention comprises adaptive pressure heads, a heating stage, heating pipes integrated inside the heating stage, heating blocks disposed on the heating stage, ceramic blocks installed on the heating blocks, a pedestal and a cylinder installed on the pedestal. The adaptive pressure heads comprise connecting rods, insulation blocks connected with the connecting rods, pressure head bases, pressure heads installed in the pressure head bases, glass column imposing electric reeds installed on the pressure head bases, and silicon chip imposing electric reeds installed on the insulation blocks. The adaptive pressure heads are connected with the cylinder through the connecting rods. The glass column imposing electric reeds contain two and the two glass column imposing electric reeds respectively clamp the two sides of the glass column. By the adoption of an imposing electric mode by clamping the two sides of the glass column, the imposing electric effect can be guaranteed, and the bonding efficiency is also greatly raised. In addition, the bonding time can be shortened and the imposing electric height is convenient to adjust if the glass column is long.

Owner:LINYI YIQUN PACKAGING PROD CO LTD

Manufacturing technology of digitized orthodontic guide plate

ActiveCN106388954AResolve discomfortSolve the painAdditive manufacturing apparatusOthrodonticsWaxManufacturing technology

The invention relates to the technical field of dental orthodontic bracket positioning production, in particular to a manufacturing technology of a digitized orthodontic guide plate. The manufacturing technology comprises the following steps of 1 model taking; 2 finishing; 3 scanning; 4 tooth arranging; 5 bracket position setting, wherein a bracket is arranged according to the tooth radian obtained after tooth arranging and a tooth body cross positioning method; 6 guide plate frame designing, wherein a guide plate frame is designed according to the shape of an occlusal surface of a tooth model, the width of the guide plate frame is 10 mm, the height is 5 mm, and the length is consistent with the dental arch radian; 7 3D printing of the model, wherein the designed model is output and printed into a resin model; 8 guide plate manufacturing, wherein the printed model is installed into the bracket according to the tooth positions and fixed through light wax; 9 light curing, wherein the surface of the guide plate is pressed to be smooth through light wax, and then the guide plate is put into a light curing machine to be subjected to hardening treatment; 10 brightener applying. The manufacturing technology is simple, the bracket position is very accurate, operation and control are convenient, and the time that a doctor performs adhesion in an oral cavity is shortened by 70%.

Owner:东莞定远陶齿制品有限公司

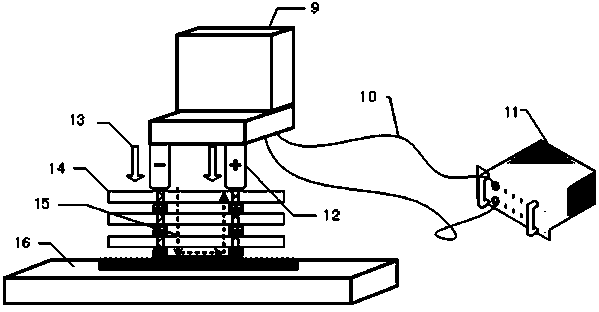

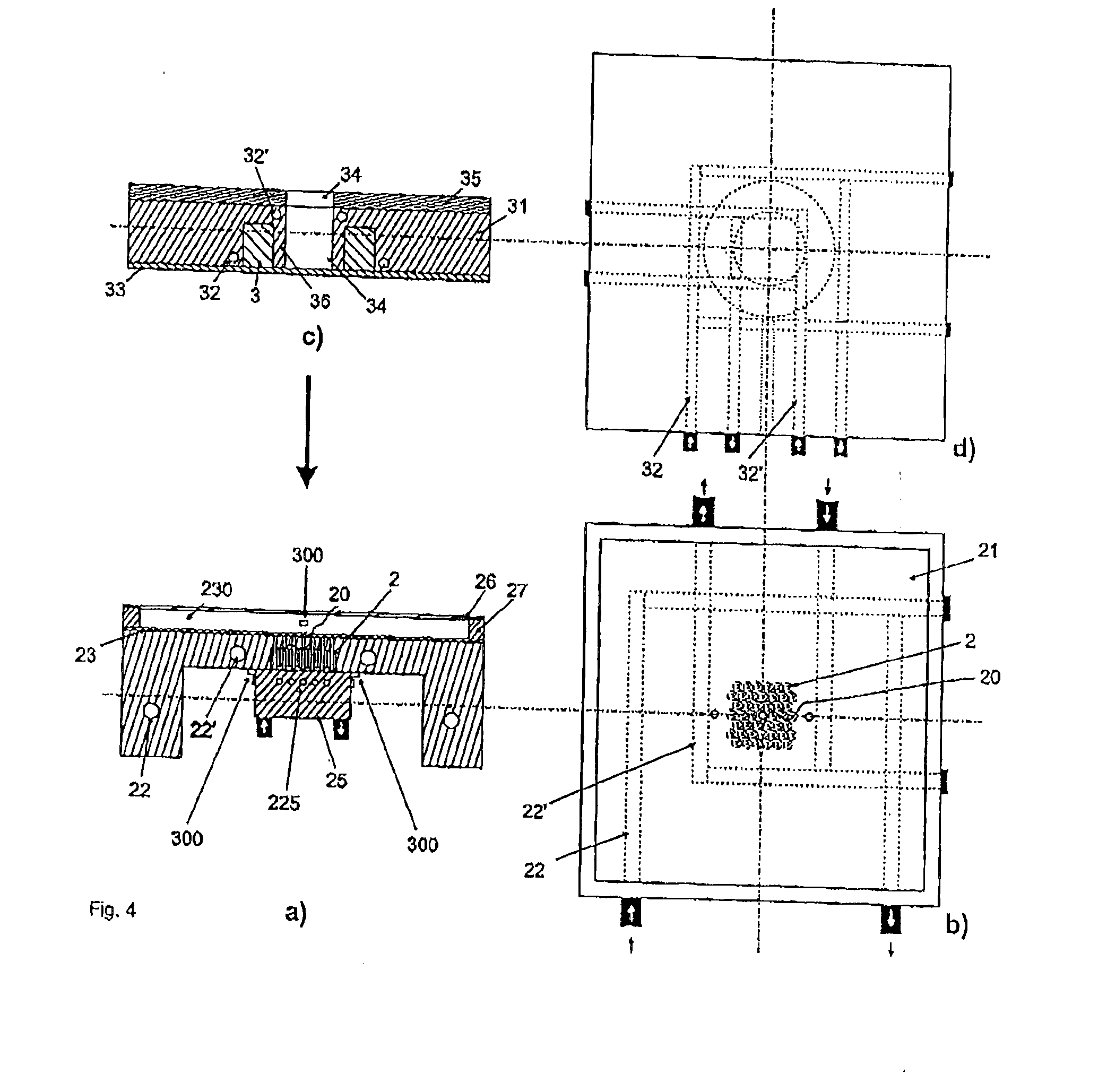

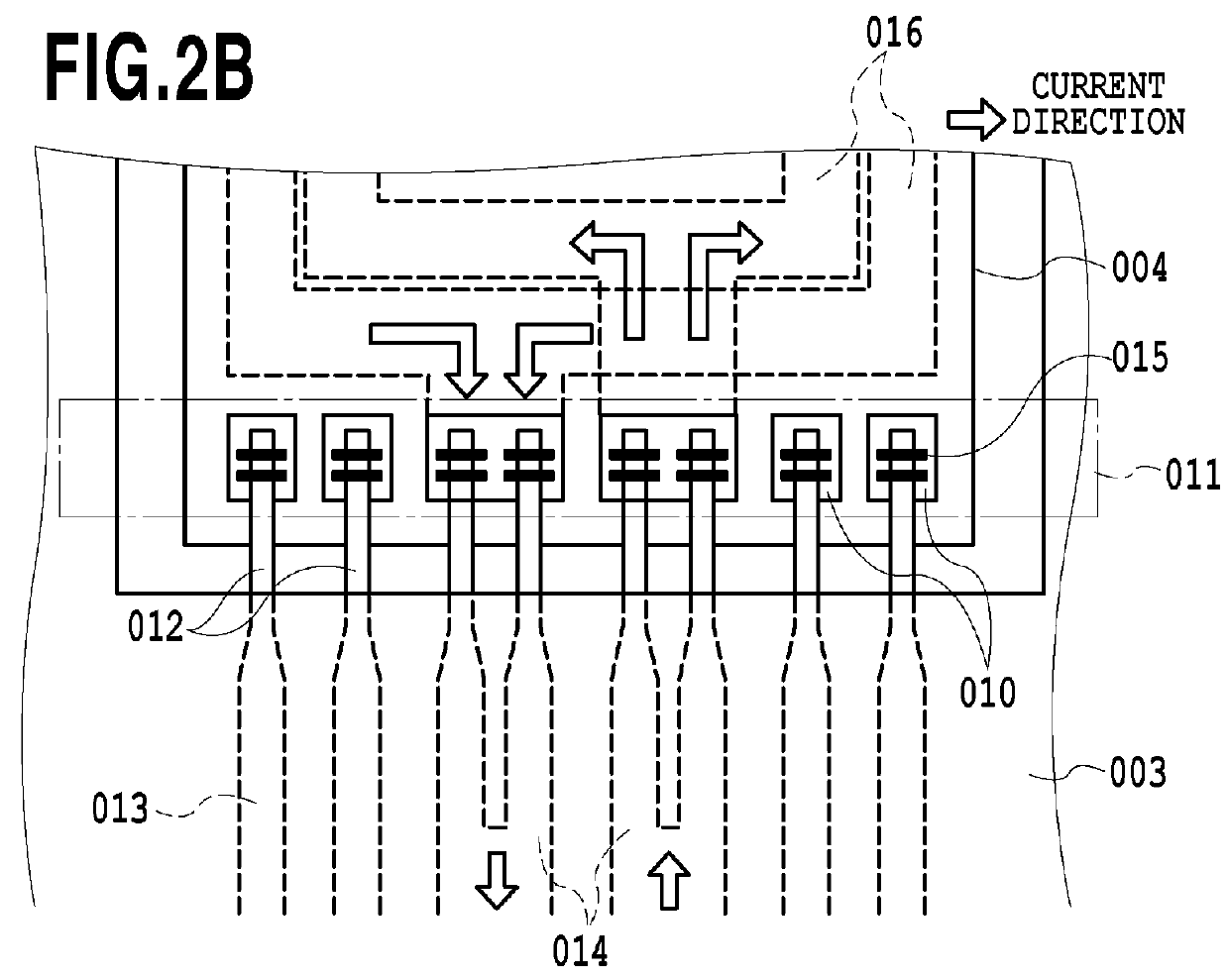

Apparatus For Increasing The Reaction Efficiency, Especially The Binding Efficiency, Between Molecules And Molecular Moieties

InactiveUS20090325822A1Improve efficiencyIncrease frequencyTransportation and packagingMixersMicroscope slideControl manner

An apparatus for enhancing the contact frequency between two reactants capable of binding to one another, preferably between an analyzer molecule and an analyte molecule, especially for enhancing the binding effectiveness in bioanalysis arrays with the aid of micro- or nanomagnetic particles (75) set in motion in a controlled manner in the fluid reaction medium by means of magnetic fields generated by variably feedable electromagnets (3, 2, 20) arranged on both sides of the reaction fluid film. On one side of a reaction fluid film, especially of a microscope slide (4) comprising the reactants (63), the reaction liquid (70) comprising the reactants (73) and preferably a glass plate (5) covering the microbioanalysis array (6), is arranged close to a two-dimensional matrix (20) having a multitude of miniature or millimagnetic coils (2) feedable individually with magnetization current of variable strength and / or voltage as a function of time—corresponding to a time-dependent variable magnetization pattern desired in each case—and, on the other side of the reaction vessel, especially the microscope slide (4) with the (micro)bioanalysis array (6), in whose vicinity is positioned only one magnetic coil (3) likewise feedable with variable magnetization current and whose magnetic field permeates the entire reaction vessel, especially the microbioanalysis array (6).

Owner:AIT AUSTRIAN INST OF TECH +1

Die bonding device of single-sided polisher

The invention discloses a die bonding device of a single-sided polisher. The device comprises a ceramic disk, the upper surface of the ceramic disk is glued with a remaining disk on which a plurality of work-piece holes matched with the sizes and shapes of work-pieces are formed, the work-pieces are embedded into the remaining disk through the work-piece holes, the remaining disk 1 is made from either an epoxy resin glass plate or a blue steel disc, and is directly, firmly and flatly glued with the ceramic disc 2. By adopting the technical scheme provided by the invention, the defects of cushion absorbing and wax pasting can be prevented; furthermore, the work-pieces can be convenient and quick to be placed in the work-piece holes of the remaining disk, and the work-pieces are fixed and reliable, therefore the triviality of wax pasting and the inconsistency defects of the thickness of a wax layer can be saved, the gluing time can be greatly reduced, and the processing precision can be improved; furthermore, the die bonding device is wide in range of application and high in interchangeability.

Owner:SUZHOU HRT ELECTRONICS EQUIP TECH

Liquid ejection head

Provided is a liquid ejection head that makes it possible to achieve both of the stability of bonding and the shortening of a bonding time when bonding an electrical wiring substrate where thick leads applied with large current and thin leads applied with small current are mixed and a printing element substrate. For this purpose, the electrical wiring substrate includes wiring lines having different widths, and each of the wiring lines of the electric wiring substrate and a connecting terminal of the printing element substrate are connected by inner leads whose number corresponds to width of the wiring line.

Owner:CANON KK

Durable flexible circuit board for transparent display board and assembling method thereof

ActiveUS20180146549A1Reduce the differenceLine connection is stablePrinted circuit assemblingCircuit optical detailsFlexible circuitsControl signal

Owner:G SMATT

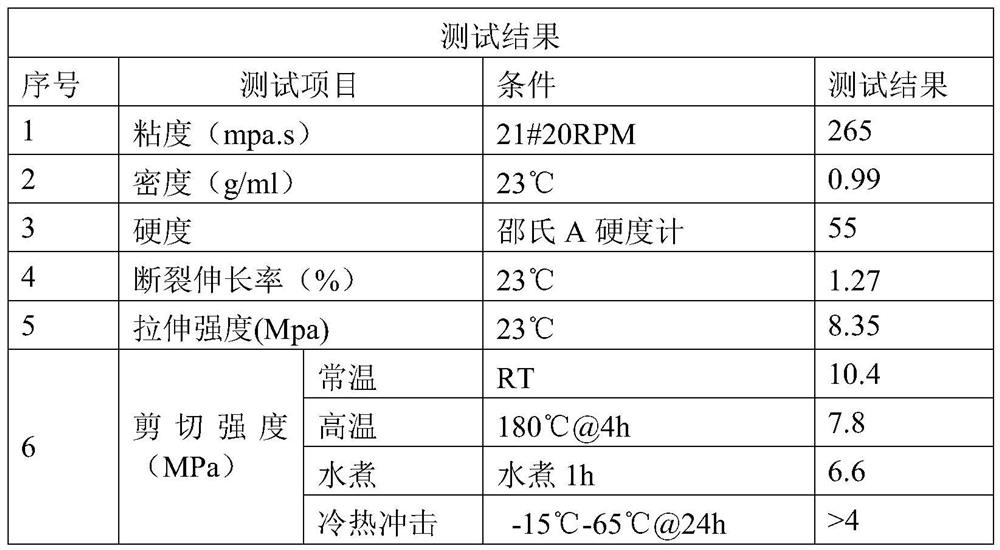

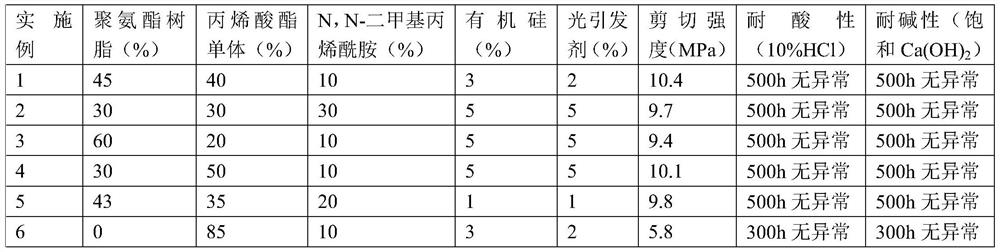

Glass adhesive and preparation method thereof

InactiveCN113683988AImprove heat resistanceReduce surface tensionGraft polymer adhesivesPolymer scienceAcrylic resin

The invention discloses a glass adhesive and a preparation method thereof. The glass adhesive is prepared from the following components in percentage by weight: 30 to 60 percent of polyurethane resin, 20 to 50 percent of an acrylate monomer, 10 to 30 percent of N, N-dimethylacrylamide, 1 to 5 percent of organic silicon and 1 to 5 percent of a photoinitiator. According to the invention, organic silicon with reaction activity is added in a polymerization reaction of acrylic resin, so that the organic silicon is directly grafted on molecular chains of acrylic ester, polyurethane resin and N, N-dimethylacrylamide in the polymerization reaction process, and the organic silane modified acrylic resin with a cross-linked network structure is obtained, so that the bonding performance, the bonding speed, the high temperature resistance, the weather resistance, the acid and alkali resistance and the yellowing resistance of the adhesive are greatly improved; and the N, N-dimethylacrylamide and the acrylate monomer are copolymerized to generate a polymer with a high polymerization degree, and then the adhesive property of the adhesive is further synergistically improved.

Owner:JIANGSU XIUQIANG GLASSWORK CO LTD

Flip chip bonder and flip chip bonding method

ActiveUS9536856B2Quality improvementShorten bonding timeSemiconductor/solid-state device detailsSolid-state devicesEngineeringCooling channel

Provided is a flip chip bonder including: a pickup flipping collet configured to flip a chip; and a bonding tool configured to receive the chip flipped with the pickup flipping collet from the pickup flipping collet and to bond the received chip to a circuit board. The pickup flipping collet includes a cooling channel through which cooling air flows to cool the pickup flipping collet. Thus, bonding time can be reduced without lowering bonding quality.

Owner:SHINKAWA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com