Combined type high-pressure forming system for fully-automatic lifting type in-mould ring-stuck water closet

A technology of high-pressure molding and high-pressure molding machines, applied in ceramic molding machines, ceramic molding workshops, manufacturing tools, etc., can solve the problems of harsh operating environment and low production efficiency, reduce environmental pollution, improve production efficiency, and reduce occupational diseases of personnel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

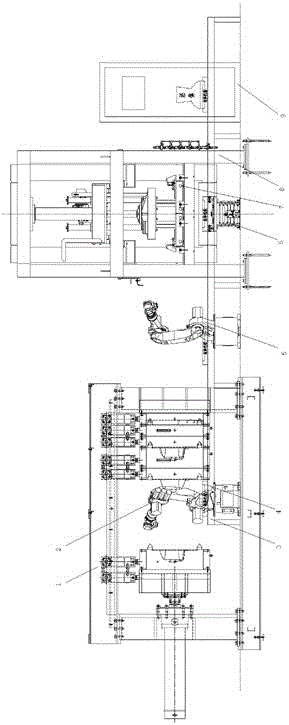

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] See attached Figure 1-4 , this combined automatic lifting type in-mold sticky ring seat toilet high-pressure forming system, including toilet ring high-pressure molding machine 1, ring stripping robot 2, green body conveying line 3, green body conveying and bonding pallet 4, Mud-applying robot 5, bonding elevator 6, toilet body side model opening and closing machine 7, toilet body high-pressure molding machine 8, automatic electrical control system 9, compression lifting frame 10, lifting cylinder 11, synchronous wire rope 12, mold opening support Frame 13, reversing wheel 14, catch plate 15, gas-liquid conversion cylinder 16, wire rope fixed plate 17, track 18. Under the control of the electrical control system, the high-pressure forming machine for the toilet ring and the high-pressure forming machine for the toilet body automatically complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com