Ultrasonic-bonded micro-fluidic chip and preparation method thereof

A microfluidic chip and ultrasonic technology, which is applied in the field of biological science micro-total analysis systems, can solve the problems of difficult cleaning, collapse of chip microchannels, and unfavorable mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

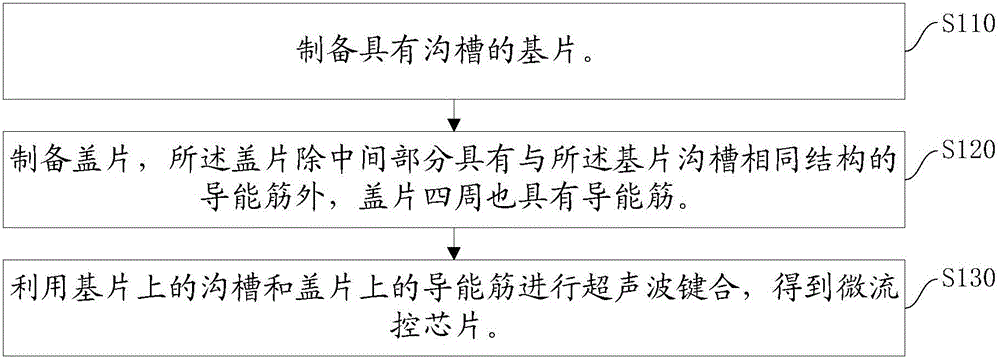

[0027] figure 1 The flow chart of the method for preparing an ultrasonically bonded microfluidic chip provided in Example 1 of the present invention, as shown in figure 1 As shown, the method includes:

[0028] S110, preparing a substrate with grooves.

[0029] Specifically, design the characteristic size and structure of the required substrate, and use the photolithography mask technology to manufacture the corresponding substrate, that is, make the photolithography master mold with the required groove through SU-8 photoresist photolithography, After a layer of conductive layer is sputtered by magnetron, the nickel brief injection mold is made by electroforming process, and finally the substrate is injected by a disc injection molding machine.

[0030] Specifically, the material of the substrate is a thermoplastic polymer. For example, polymethylmethacrylate (polymethylmethacrylate, PMMA), polycarbonate (Polycarbonate, PC), cycloolefin polymer (Cyclo-olefin polymer, COP) a...

Embodiment 2

[0042] A method for preparing a PMMA ultrasonically bonded microfluidic chip, the steps are as follows:

[0043] 1. The specification of the PMMA substrate is 37.5*25*0.6mm, and the substrate with cross-shaped grooves is produced by using photolithography mask technology, such as figure 2 (a) shown. Wherein, the groove width and depth are both 100 μm.

[0044] 2. The specification of the PMMA cover sheet is 37.5*25*0.6mm. The photolithographic mask technology is used to make the cover sheet with cross-shaped energy directors, such as figure 2 (b) shown. The cross-shaped energy director and figure 2 Corresponding to the position of the cross-shaped groove in (a), the width of the cross-shaped energy director is 200 μm, and the thickness is 50 μm. In addition, there are also energy-directing ribs around the cover sheet, and the width of the energy-directing ribs around the cover sheet is 100 μm.

[0045] 3. Fix the substrate and cover sheet with fixtures, align the groov...

Embodiment 3

[0047] A method for preparing a PC ultrasonically bonded microfluidic chip, the steps are as follows:

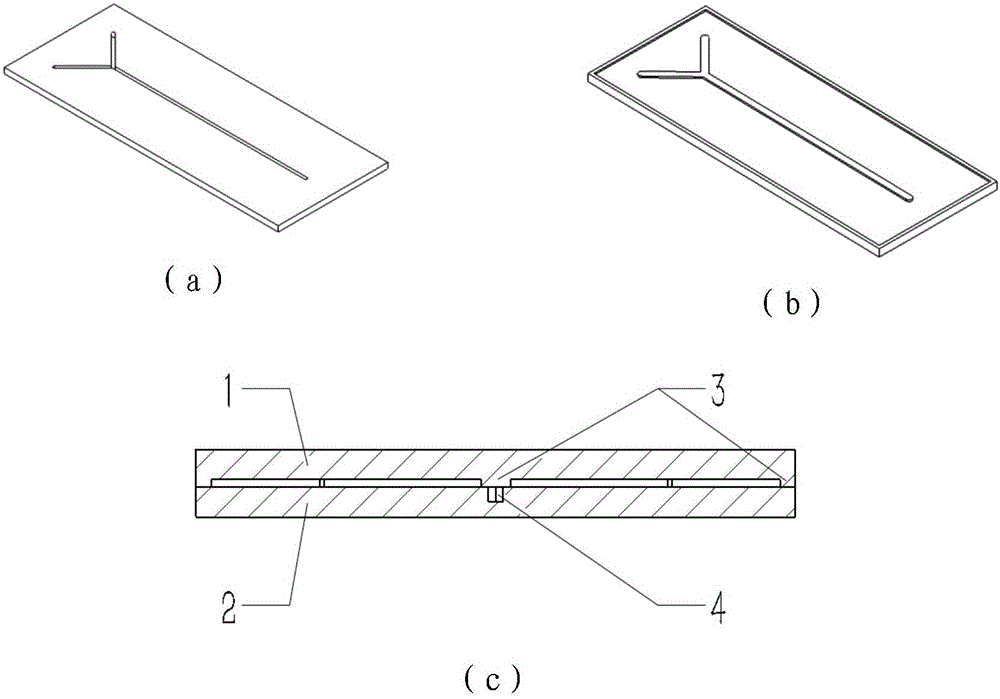

[0048] 1. The specification of the PC substrate is 45*37*0.6mm, and the substrate with Y-shaped grooves is produced by photolithography mask technology, such as image 3 (a) shown. Wherein, the groove width and depth are both 150 μm.

[0049] 2. The specification of the PC cover sheet is 45*37*0.6mm, and the photolithography mask technology is used to make the cover sheet with Y-shaped energy guiding ribs, such as image 3 (b) shown. The Y-shaped energy director and image 3 Corresponding to the position of the Y-shaped groove in (a), the cross-shaped energy director has a width of 250um and a thickness of 50μm. In addition, there are also energy-directing ribs around the cover sheet, and the width of the energy-directing ribs around the cover sheet is 100 μm.

[0050] 3. Fix the substrate and cover sheet with fixtures, align the grooves on the substrate with the energy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com