Glass adhesive and preparation method thereof

A technology for adhesives and glass, applied in the direction of adhesives, adhesive types, grafted polymer adhesives, etc., can solve problems such as low impact strength and peel strength, poor water resistance and re-peelability, and slow polymerization speed , to achieve the effect of improving the bonding performance, improving the adhesion, and firming the chemical bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a glass adhesive, which is made of the following components in weight percentage: 45% polyurethane resin, 40% acrylate monomer, 10% N,N-dimethylacrylamide, 3% Silicone, 2% photoinitiator.

[0034] The polyurethane resin is bisphenol A polyurethane resin; the acrylate monomer is methyl methacrylate; the organosilicon is γ-mercaptopropyltrimethoxysilane; the photoinitiator is α-hydroxycyclohexyl Benzophenone.

[0035] The preparation method of described a kind of glass glue, comprises the steps:

[0036] S1. Under the protection of nitrogen, add 5% N,N-dimethylacrylamide to the polyurethane resin in the above weight percentage, and heat and stir at 75°C until the polyurethane resin is completely dissolved and then set aside;

[0037]S2. Dissolve the acrylate monomer and photoinitiator in the above weight percent with the remaining 5% of N,N-dimethylacrylamide, add silicone at the same time, heat and stir at 95°C until completely dissolved, then ...

Embodiment 2-11

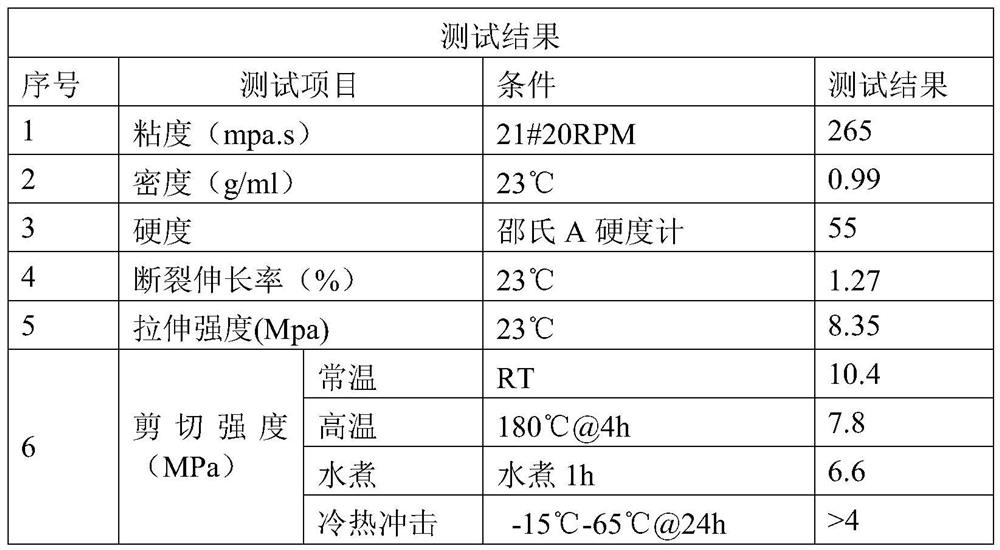

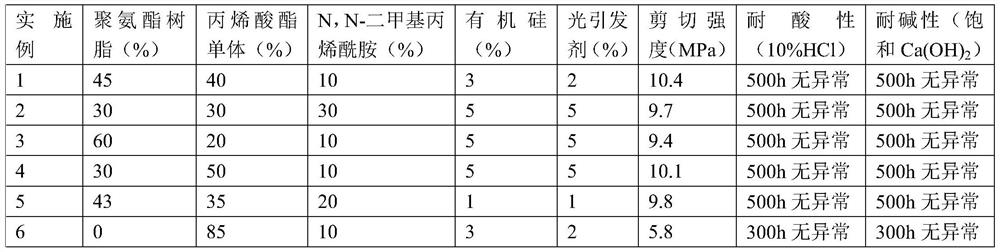

[0043] Embodiment 2-11 provides a glass adhesive. Compared with Embodiment 1, the difference is that the weight ratio of each component is changed, and the rest are the same as Embodiment 1, and will not be repeated here. The specific experiment The parameters and results are shown in the table below.

[0044]

[0045]

[0046] Comparing the results of Examples 1 to 5 in the table, it can be seen that the glass adhesive provided by the present invention has good adhesion and acid and alkali resistance. Simultaneously comparing the results of Examples 1 to 5 with Examples 6 to 9, it can be known that the present invention prepares silicone-modified polyurethane resin base by participating in the copolymerization reaction of silicone monomers containing polymerizable double bonds with acrylate monomers and polyurethane resins. It combines the excellent heat resistance, low surface energy and normal temperature curability of silicone with the cohesiveness of polyurethane re...

Embodiment 12-17

[0050] Embodiments 12-17 provide a glass adhesive. Compared with Embodiment 1, the difference is that the type of the acrylate monomer is changed, and the rest are the same as Embodiment 1, and will not be repeated here. The experimental parameters and results are shown in the table below:

[0051]

[0052] Comparing the results of Example 1 and Examples 12-17, it can be seen that the type of acrylate monomer will have a more significant impact on the bond strength of the prepared adhesive, but under the conditions of each dosage ratio defined in the present invention , The prepared adhesives all have high corrosion resistance (20% acid and alkali) performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com