Water-based laser alumite coating without release layer and preparation method thereof

A technology of anodized aluminum and release layer, which is applied in the direction of cellulose coating, polyurea/polyurethane coating, coating, etc., can solve the problems of workers' health damage and environmental pollution, and achieves wide application range, low production process requirements, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

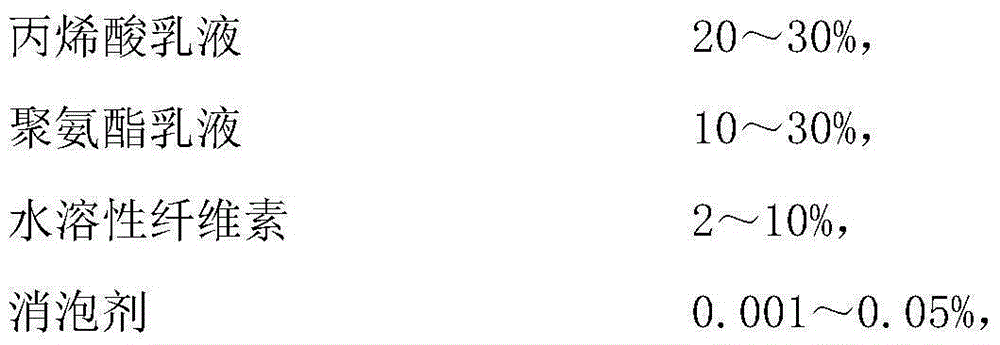

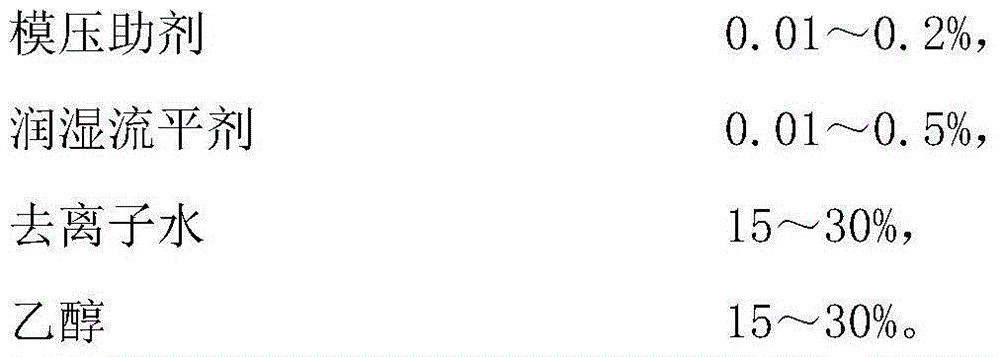

Method used

Image

Examples

Embodiment 1

[0035] This embodiment relates to a water-based laser anodized aluminum coating without a release layer, and its preparation specifically includes the following steps:

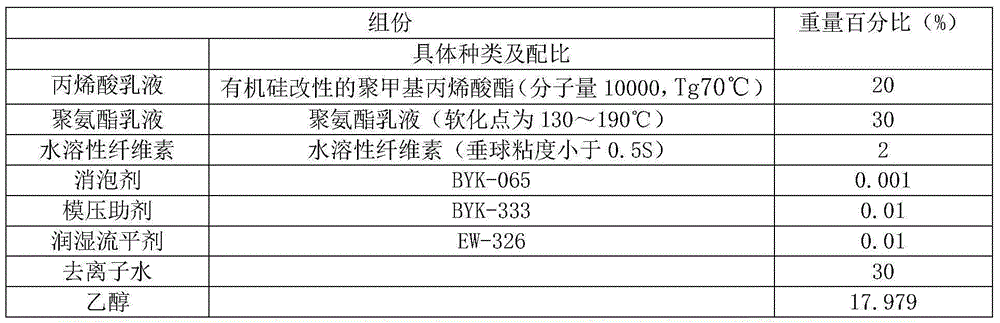

[0036] (1) According to the (weight part) raw material of following table 1 component and content (weight part) raw material is prepared

[0037] Table 1

[0038]

[0039] Add deionized water and ethanol into the reaction kettle, stir at 750-800 rpm, and keep the temperature at 40-80°C;

[0040] Add acrylic emulsion or acrylic mixed emulsion, polyurethane emulsion, and water-soluble cellulose, stir at 1000-1200 rpm, keep the temperature at 40-80°C, and disperse for 20-40 minutes;

[0041] Add defoamer and stir for 5-20 minutes at 750-800 rpm and constant temperature of 40-80°C;

[0042] Add molding aids, stir for 5-20 minutes at 750-800 rpm, constant temperature 40-80°C;

[0043] Add a wetting and leveling agent, stir at 750-800 rpm and a constant temperature of 40-80°C for more than 40 minutes to obtain...

Embodiment 2

[0045] This embodiment relates to a water-based laser anodized aluminum coating without a release layer, and its preparation specifically includes the following steps: prepare the raw materials according to the components and contents in the following table 2 (parts by weight)

[0046] Table 2

[0047]

[0048] Add deionized water and ethanol into the reaction kettle, stir at 750-800 rpm, and keep the temperature at 40-80°C;

[0049] Add acrylic emulsion or acrylic mixed emulsion, polyurethane emulsion, and water-soluble cellulose, stir at 1000-1200 rpm, keep the temperature at 40-80°C, and disperse for 20-40 minutes;

[0050] Add defoamer and stir for 5-20 minutes at 750-800 rpm and constant temperature of 40-80°C;

[0051] Add molding aids, stir for 5-20 minutes at 750-800 rpm, constant temperature 40-80°C;

[0052] Add a wetting and leveling agent, stir at 750-800 rpm and a constant temperature of 40-80°C for more than 40 minutes to obtain the water-based laser anodize...

Embodiment 3

[0054] The present embodiment relates to a water-based laser anodized aluminum coating without a release layer, and its preparation specifically includes the following steps: prepare the raw materials according to the following table 3 components and contents (parts by weight):

[0055] table 3

[0056]

[0057]

[0058] Add deionized water and ethanol into the reaction kettle, stir at 750-800 rpm, and keep the temperature at 40-80°C;

[0059] Add acrylic emulsion or acrylic mixed emulsion, polyurethane emulsion, and water-soluble cellulose, stir at 1000-1200 rpm, keep the temperature at 40-80°C, and disperse for 20-40 minutes;

[0060] Add defoamer and stir for 5-20 minutes at 750-800 rpm and constant temperature of 40-80°C;

[0061] Add molding aids, stir for 5-20 minutes at 750-800 rpm, constant temperature 40-80°C;

[0062]Add a wetting and leveling agent, stir at 750-800 rpm and a constant temperature of 40-80°C for more than 40 minutes to obtain the water-based l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com