Automatic thermoprinting machine and thermoprinting method thereof

A hot stamping machine, automatic technology, applied in the direction of printing machine, transfer printing, rotary printing machine, etc., can solve the problems of slow heating and cooling speed of hot stamping roller, uneven heating of film, complicated transmission mechanism, etc., and achieve improvement Hot stamping effect, simple structure and reduced operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

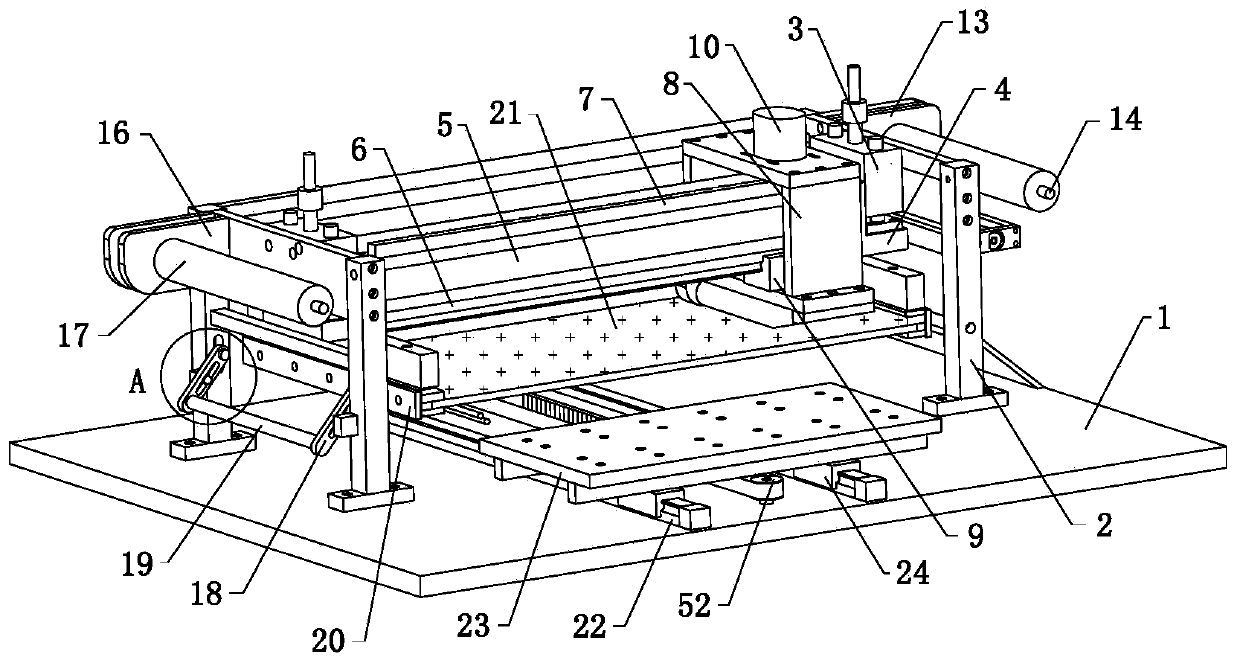

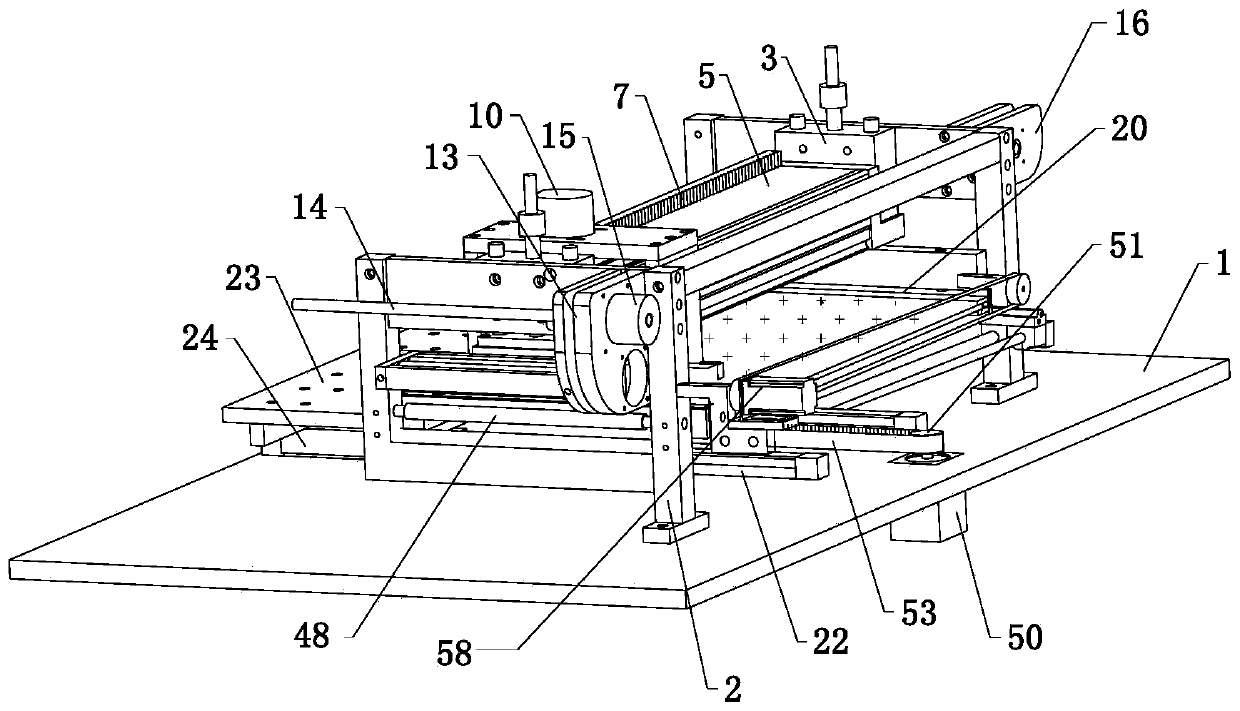

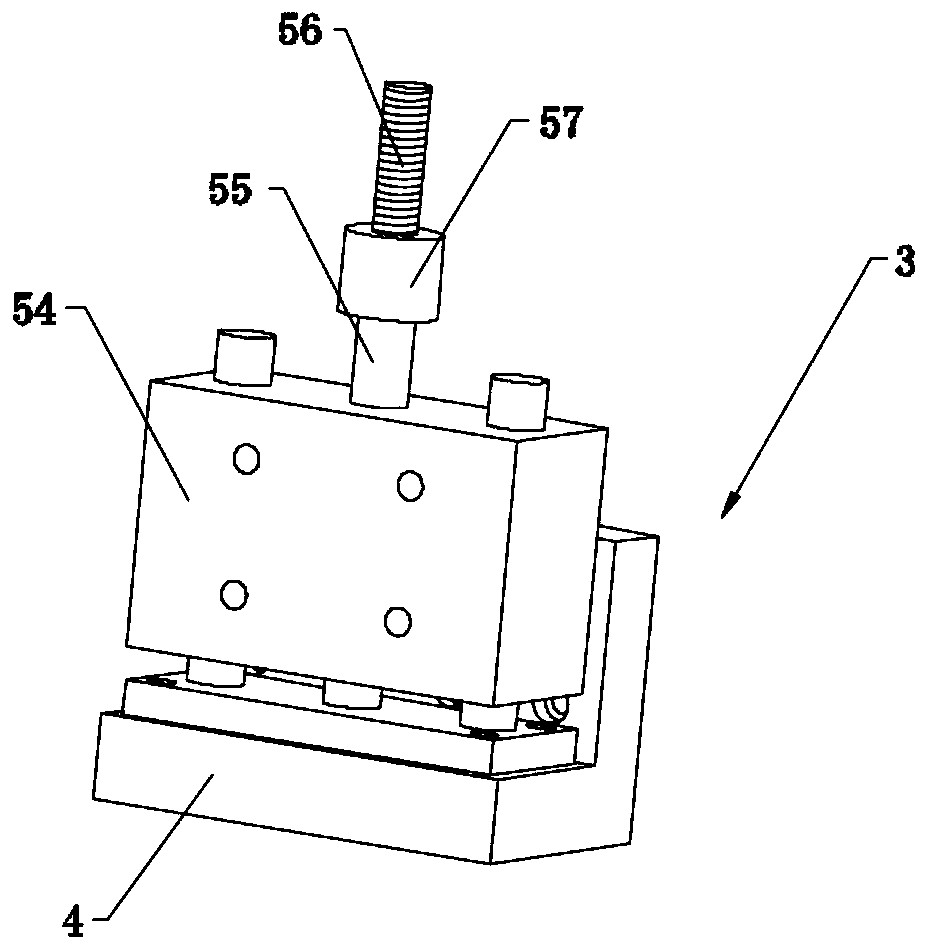

[0044] Embodiment: a kind of automatic hot stamping machine, constitutes as Figure 1-2 As shown, including workbench 1, the top of workbench 1 is provided with frame 2, and the inner side of two ends of frame 2 is symmetrically provided with telescopic driver 3, and the end of each telescopic driver 3 is provided with lifting plate 4, two A crossbeam 5 is provided between the lifting plates 4, and a transmission roller mechanism is arranged on the crossbeam 5; a heating sheet holder 20 is provided at the bottom of the two lifting plates 4, and a heating sheet holder 20 is provided at the middle of the heating sheet holder 20 and is located below the transmission roller mechanism. Silica gel heating plate 21; Be provided with the membrane transmission mechanism that is fixed on the frame 2 below the beam 5; Also be provided with the feeding mechanism that is vertically arranged with membrane transmission mechanism on the described workbench 1; The demoulding mechanism 58 for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com