Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

181 results about "Sequence diagram" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A sequence diagram shows object interactions arranged in time sequence. It depicts the objects and classes involved in the scenario and the sequence of messages exchanged between the objects needed to carry out the functionality of the scenario. Sequence diagrams are typically associated with use case realizations in the Logical View of the system under development. Sequence diagrams are sometimes called event diagrams or event scenarios.

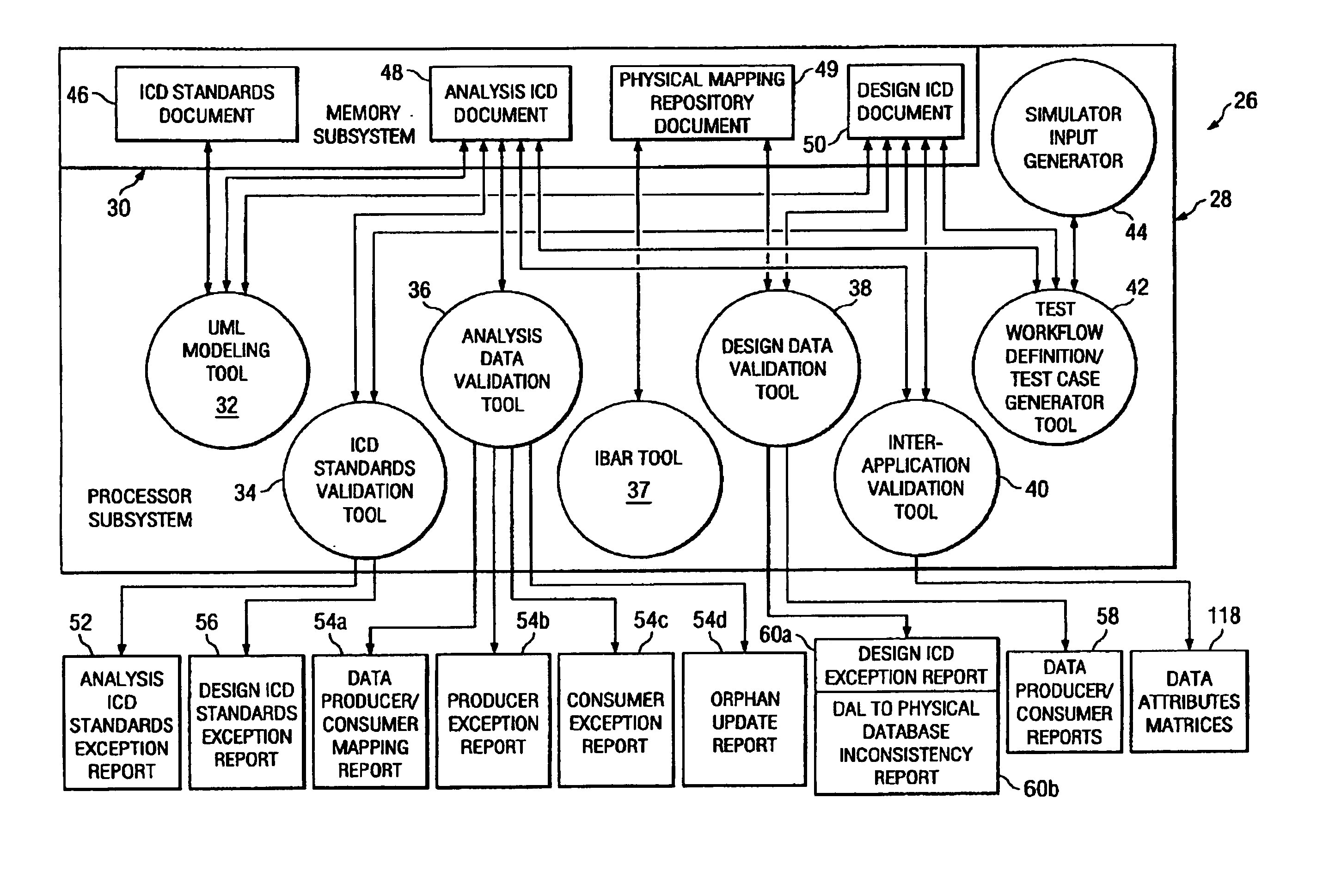

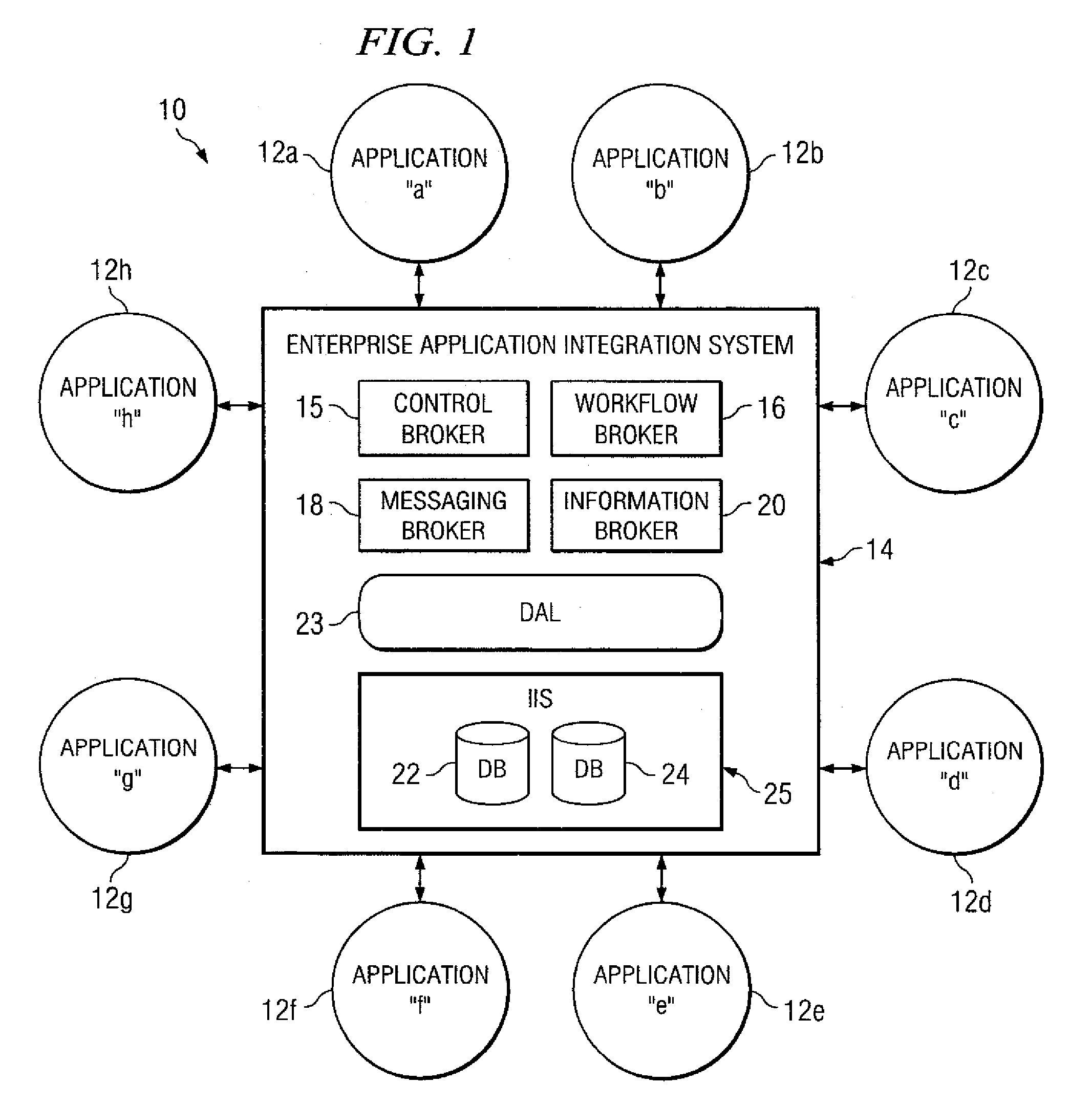

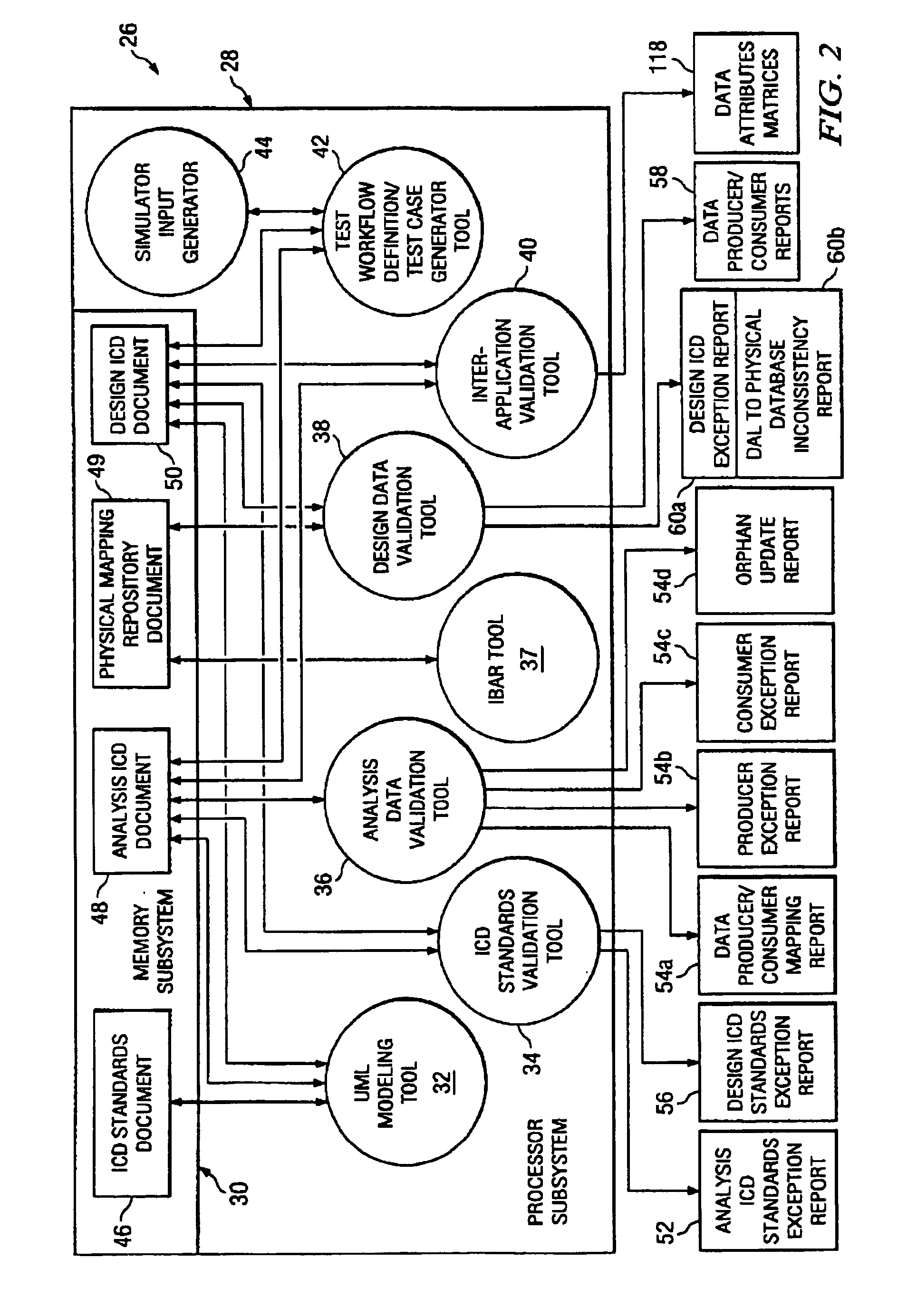

Design data validation tool for use in enterprise architecture modeling

InactiveUS7203929B1Requirement analysisSpecific program execution arrangementsData validationSequence diagram

A selected scenario of a design ICD document for an integrated enterprise is validated by examining each IDL call of each sequence diagram forming part of the selected scenario. A list of data attributes contained in one or more of the IDL calls are generated and each IDL call associated therewith is generated. A physical location to which each such IDL call is mapped is then associated with the IDL call. By analyzing the IDL calls and associated physical locations on a data attribute-by-data attribute basis, inconsistencies in the physical mapping of the data attributes to the databases forming an IIS for the integrated enterprise may be identified and subsequently corrected.

Owner:SPRINT CORPORATION

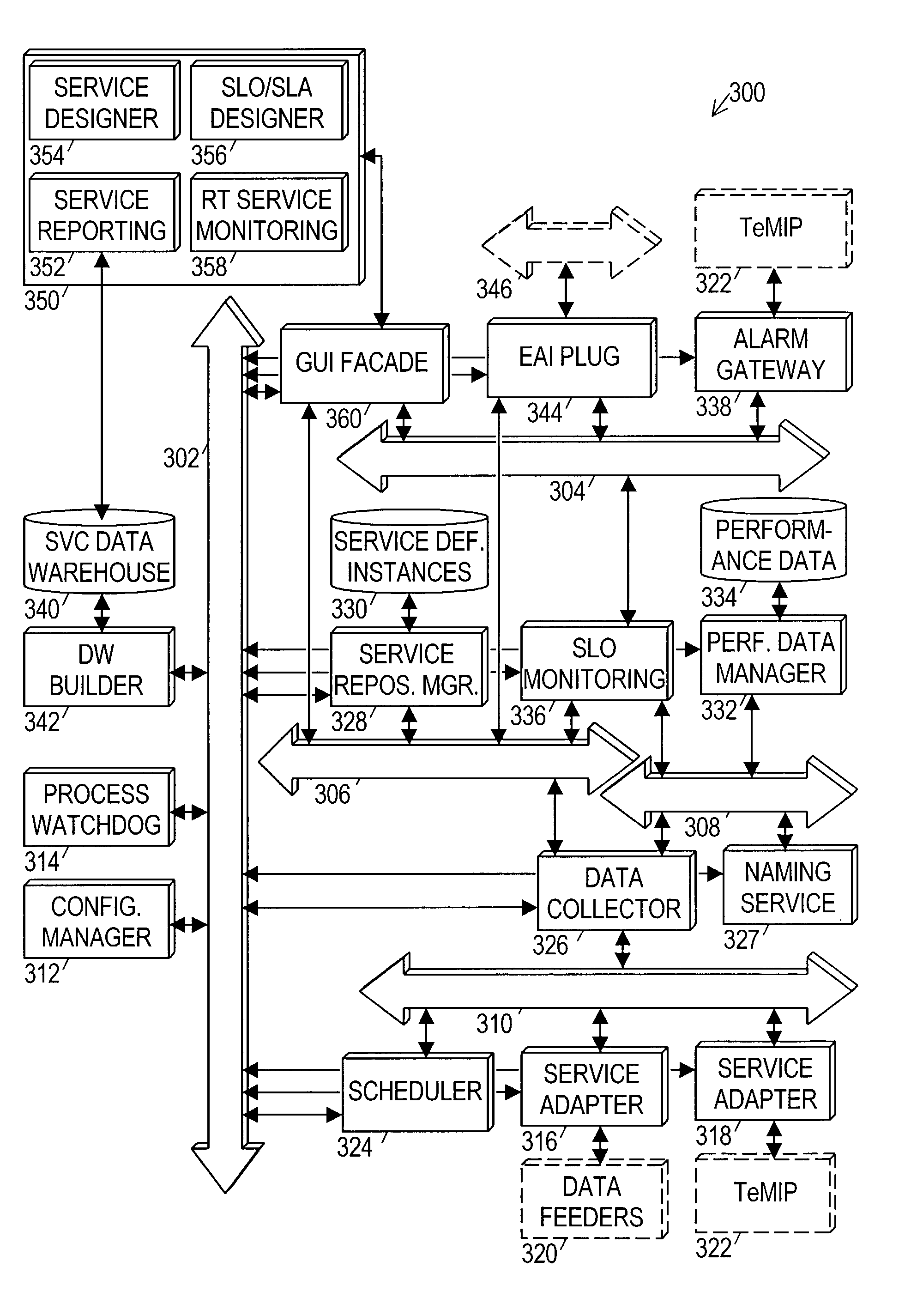

UML representation of parameter calculation expressions for service monitoring

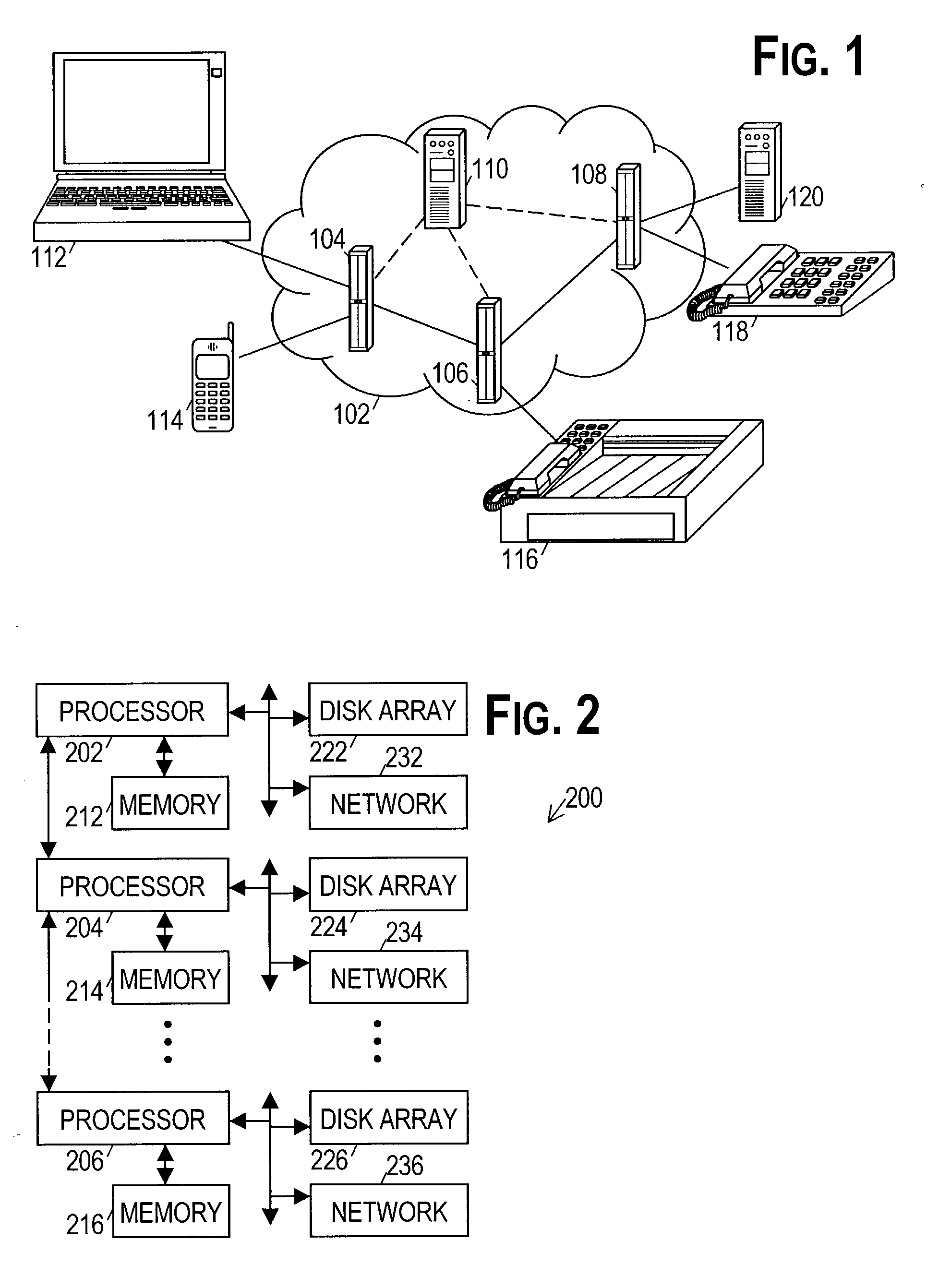

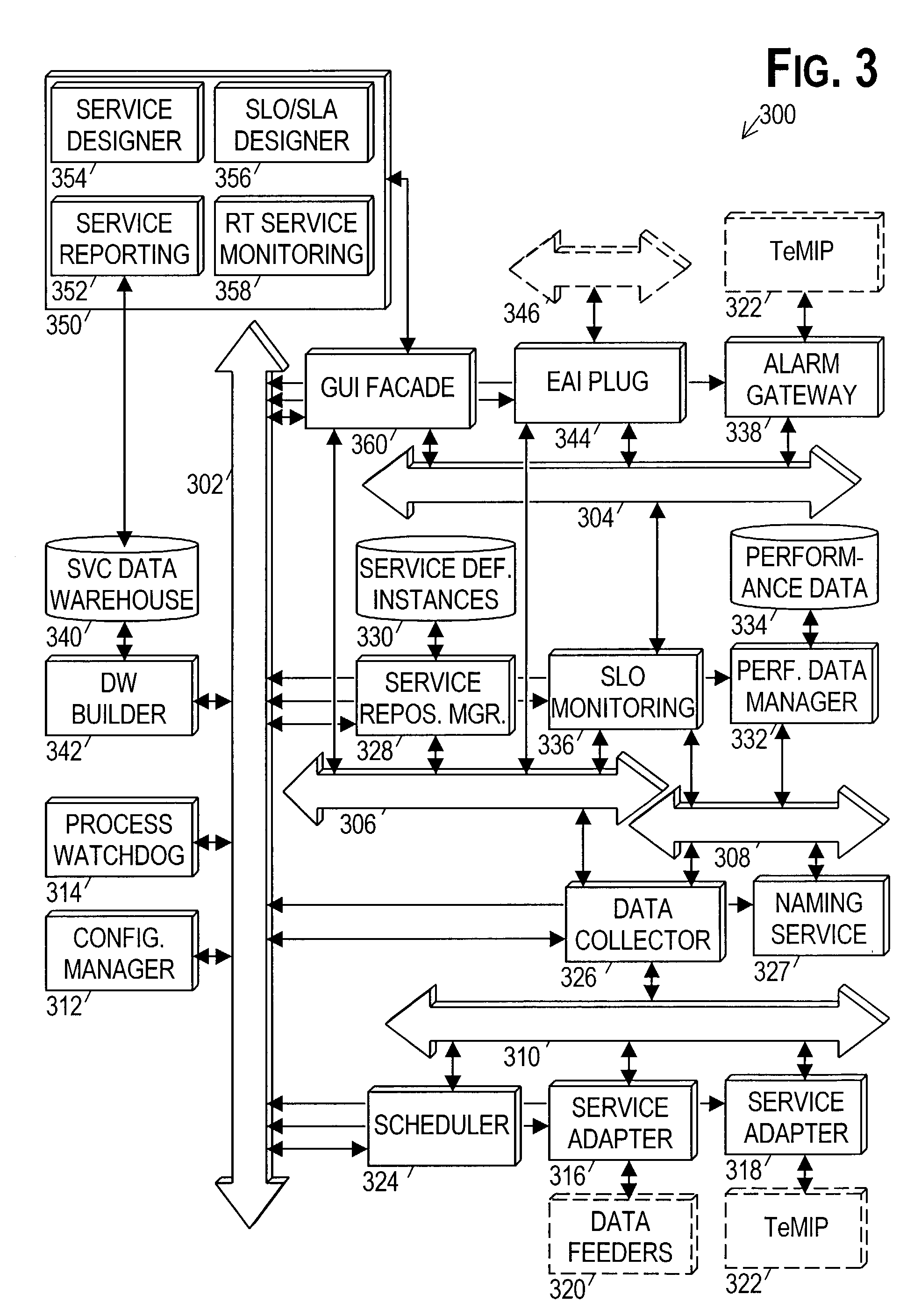

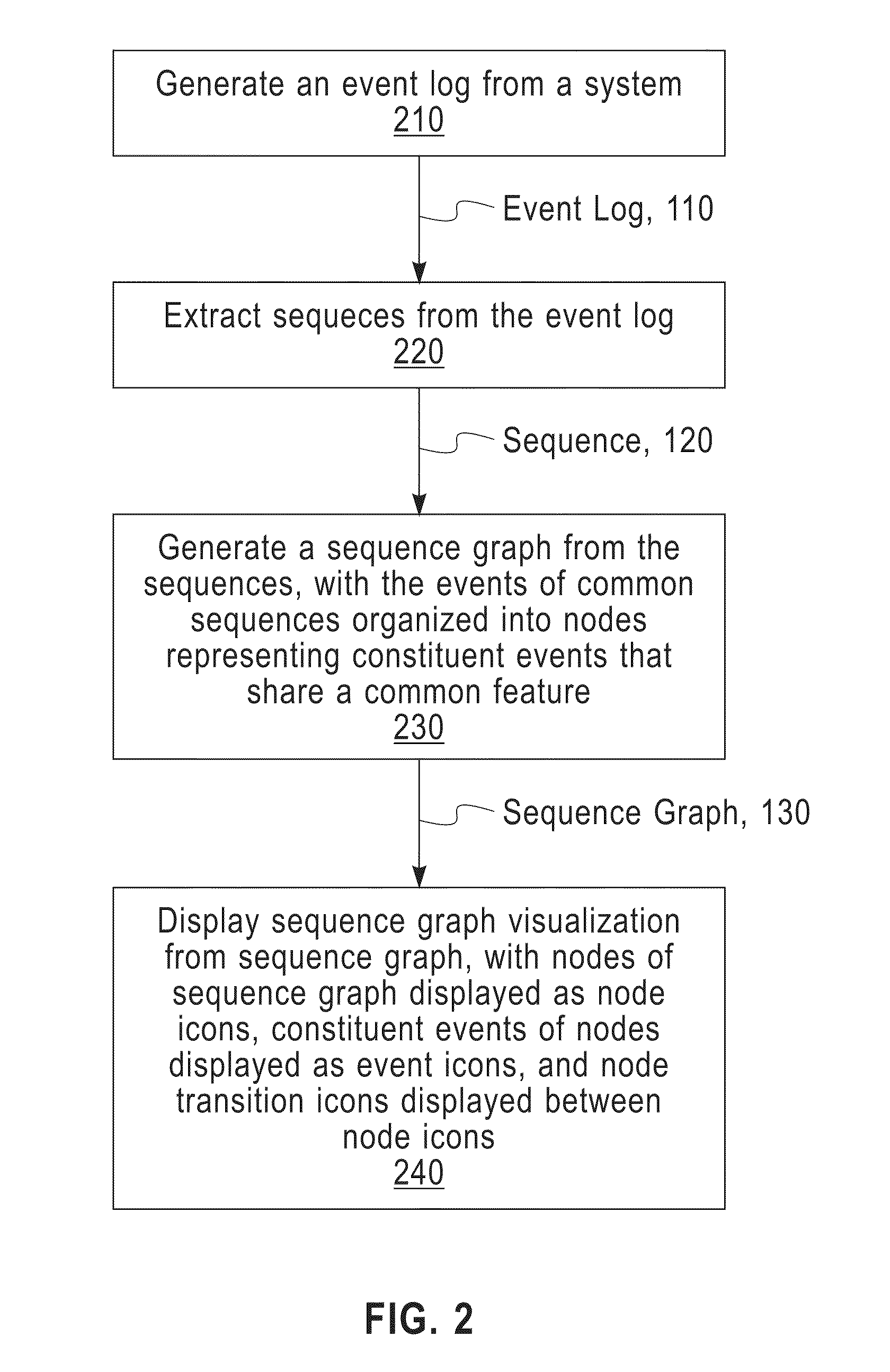

InactiveUS20030212778A1Simplifies editingSimplify creationDigital computer detailsData switching networksAlgorithmSequence diagram

An object-oriented modeling approach is used to represent telecommunication services, parameters and calculation expressions associated with the parameters. Preferably, the Unified Modeling Language ("UML") is used in this regard. Further still, UML "sequence diagrams" are used to represent the calculation expressions as a sequence of UML methods that accomplishes what is required by the expression. The use of UML to represent calculation expressions simplifies editing and creating the expressions and permits a visual representation of the expressions.

Owner:HEWLETT PACKARD DEV CO LP

Displaying a visualization of event instances and common event sequences

InactiveUS20110227925A1Drawing from basic elementsError detection/correctionSequence graphData mining

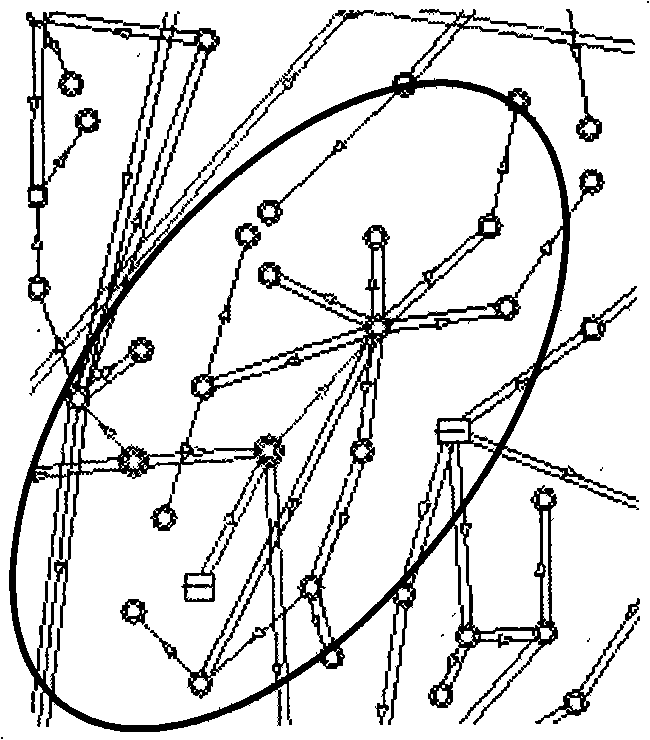

A method, system and computer readable article of manufacture for displaying visualization from an event log. According to the method, sequences are extracted from the event log. The event log is a record of a plurality of events that occurred. A sequence graph is generated from the sequences. The sequence graph includes nodes representing the events of the event log and the events of each node have a common property. A sequence graph visualization is displayed from the sequence graph. The sequence graph visualization includes (i) node icons representing the nodes of the sequence graph, (ii) node transition icons representing relationships between nodes, and (iii) an event icon for each of the one or more events of a corresponding node.

Owner:IBM CORP

Generating sequence diagrams using call trees

InactiveUS20060053414A1Simple and fast and easy to operateDirect operationError preventionFrequency-division multiplex detailsSource code fileSequence diagram

A software tool is provided to analyze static source code. Source Code files are selected to define the project work space. A class and a method in the class are selected from said selected source code files. The tool generates a Call Tree as an ordered recursive sequence of all method calls in different classes or their instances that are invoked by said selected method in said selected class. A Sequence Diagram is generated from said Call Tree. The tool remembers all updates to the Call Tree used to generate the Sequence Diagram. This information is used when a generated Sequence Diagram is impacted due to changes made to any source code file included in the project.

Owner:KYNDRYL INC

Method for systematic modeling and evaluation of application flows

InactiveUS20070150322A1Computation using non-denominational number representationNetwork connectionsSequence diagramMathematics model

A system and method for modeling and evaluating resource requirements of services is disclosed. The system and method in one aspect enable describing an application session in a software model, for example, as a sequence of events in a sequence diagram, annotating the sequence diagram with information and using the sequence diagram and the information to create a mathematical model such as a Markov model that represents the application session. Once in Markov form the service can be analyzed.

Owner:TELCORDIA TECHNOLOGIES INC

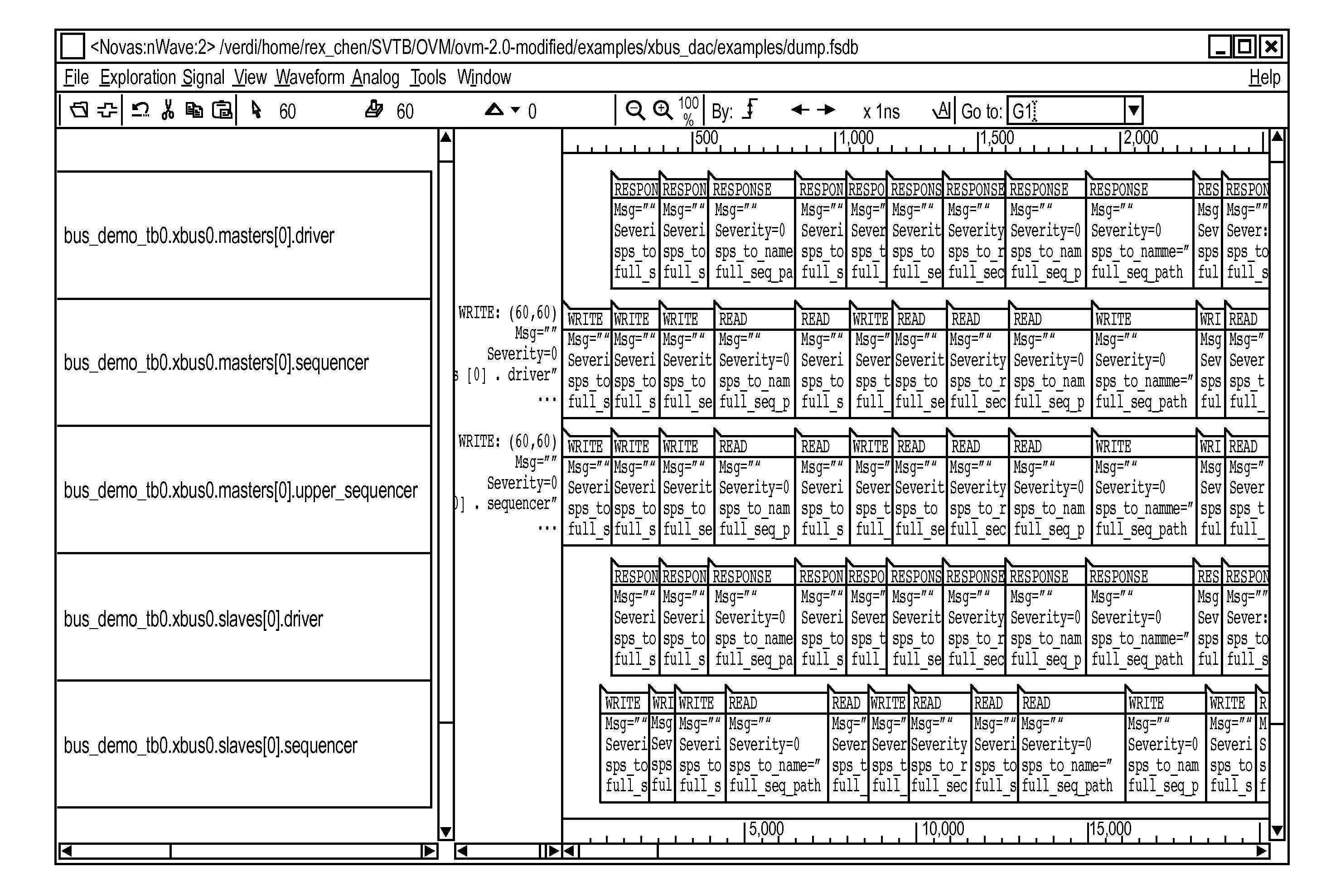

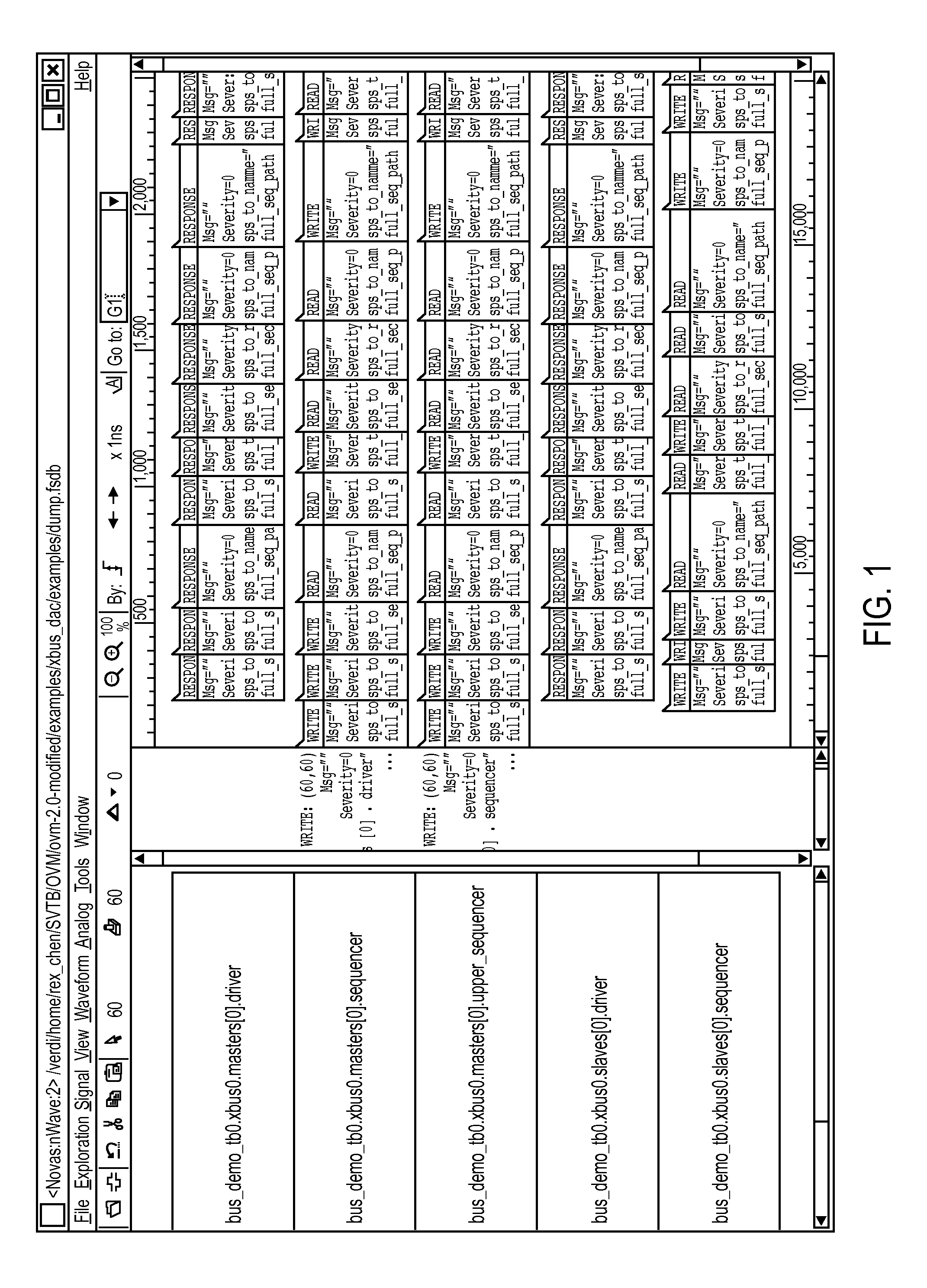

Method and apparatus for transaction recording and visualization

ActiveUS20110238397A1Simplify the viewing processError detection/correctionAnalogue computers for electric apparatusComputer hardwareSequence diagram

Methods and apparatus for recording and visualizing transactions of a test bench simulation are disclosed. Transaction-specific data generated from a test bench simulation may be displayed in a sequence diagram view to provide a view of the transactions arranged sequentially in time.

Owner:SYNOPSYS INC

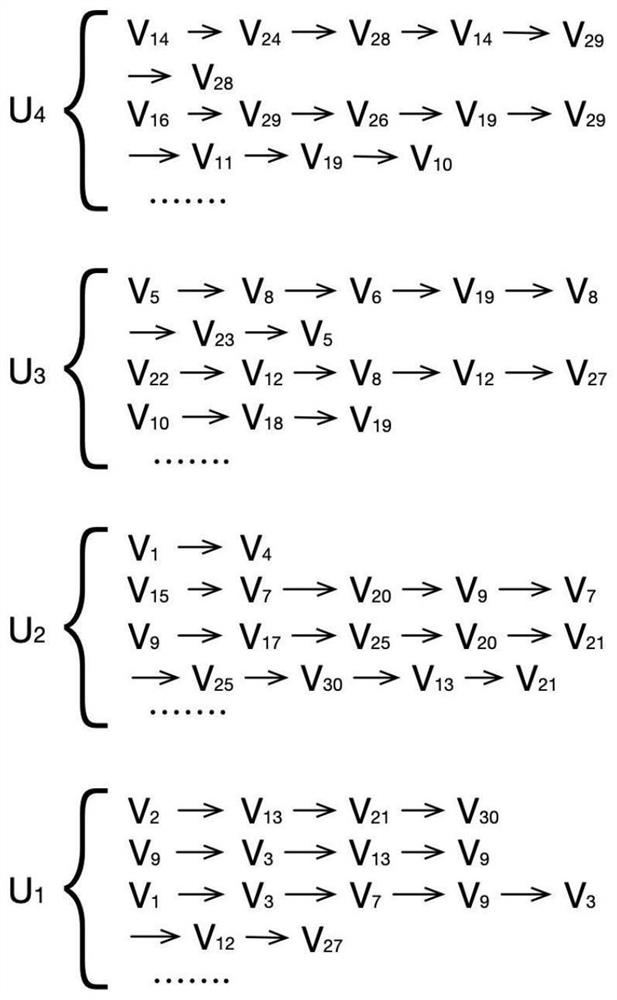

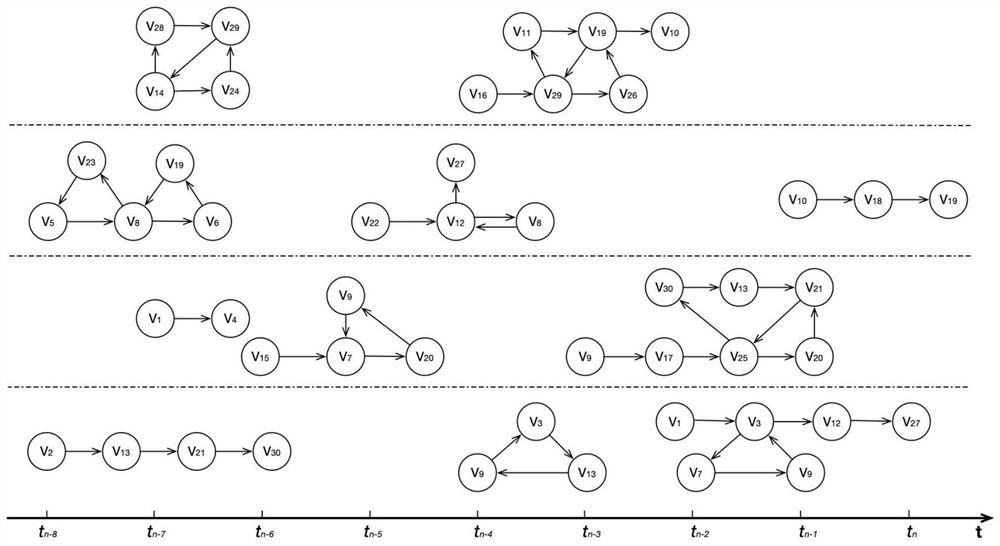

Session recommendation method based on space-time sequence diagram convolutional network

InactiveCN112035746AFully captureRelationship richBuying/selling/leasing transactionsNeural architecturesTheoretical computer scienceEngineering

The invention discloses a session recommendation method based on a space-time sequence diagram convolutional network. The method comprises the following steps: S1, modeling all session sequences intoa directed session graph; S2, constructing a global graph by taking common commodities in the session as links; S3, embedding an ARMA filter into a gated graph neural network, extracting a topologicalgraph signal which changes over time from the graph model, and obtaining a feature vector of each node involved in the session graph; S4, obtaining global preference information from historical sessions of the user by adopting an attention mechanism; S5, obtaining local preference information of the user from the last session clicked by the user, and obtaining final preference information of theuser in combination with the global preference information; S6, predicting the probability of possible occurrence of the next clicked commodity in each session, and giving a Top-K recommended commodity. According to the method, rich context relationships of clicked commodities can be captured from the global graph, global and local preferences of the user are accurately learned, the time attenuation effect of historical preferences of the user on current preferences is effectively evaluated, and accurate commodity prediction is provided.

Owner:HUNAN UNIV

Application-generic sequence diagram generator driven by a non-proprietary language

ActiveUS20060161890A1Reverse engineeringProgramme control in sequence/logic controllersGeneral purposeSequence diagram

An application-generic sequence diagram generator is driven by a non-proprietary language. According to one embodiment, a source file describes, in a non-proprietary language, a flow (e.g., a message exchange) of an application. An automatic sequence diagram generator is operable to receive as input the source file, and generate, based on such source file, a sequence diagram representing the flow described by the source file. In an exemplary embodiment, the non-proprietary language is a markup language, such as Extensible Markup Language (XML). The sequence diagram generator is general purpose (or “application-generic”), as it can generate a sequence diagram representing the flow of any application described in the source file. The application for which the source file describes the flow may be any type of application, including without limitation a computer-executable software application, a communication protocol, or any message exchange between actors.

Owner:KEYSIGHT TECH SINGAPORE (SALES) PTE LTD

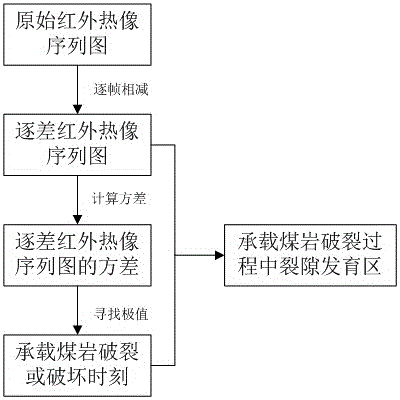

Method for monitoring and positioning crack development areas in coal and rock fracture procedures by means of infrared radiation

InactiveCN106018096APreserves infrared radiation (transient) change characteristicsEffective extraction of infrared radiation featuresMaterial strength using tensile/compressive forcesNODALSequence diagram

The invention provides a method for monitoring and positioning crack development areas in coal and rock fracture procedures by means of infrared radiation, and relates to the field of water conservation mining and rock stratum control. The method is applicable to detecting crack development laws and development locations in coal and rock fracture research procedures. The method includes determining bearing coal and rock fracture and failure time nodes by the aid of variance indexes of successive difference infrared thermal imaging sequence diagrams; extracting infrared thermal imaging diagrams at current moments according to the time nodes on the basis of the time nodes to position the crack development areas at bearing coal and rock fracture moments so as to temporally and spatially predict the crack development areas. The method has the advantages that research results can be applied to monitoring and controlling human engineering disasters such as coal (rock) burst and mine water inrush due to bearing coal and rock fracture, and the method particularly has scientific significance on enriching water conservation mining and rock stratum control theories for mines.

Owner:CHINA UNIV OF MINING & TECH

Method for implementing program, method for verifying program result, devices and system

InactiveCN101571810AEasy to debugEasy to deployMultiprogramming arrangementsSpecial data processing applicationsProgramming languageSequence diagram

The invention discloses a method for implementing a program, a method for verifying the program result, devices and a system, belonging to the field of computers. The method for implementing the program comprises the steps of obtaining instruction information from a text file of a source program; establishing a serial queue according to the instruction information; constructing a parallel sequence diagram according to the serial queue; and implementing the source program in parallel according to the parallel sequence diagram. The device for implementing the program comprises an acquisition module, an establishment module, a construction module and an implementation module. The device for verifying the program result comprises a creation module, a first setting module, a second setting module, a mapping module, a first judging module and a second judging module. The system for implementing the program comprises the device for implementing the program and the device for verifying the program result. The invention can improve the program development efficiency and facilitate scheduling and deploying the program.

Owner:TSINGHUA UNIV

Method for verifying consistency of dynamic behavior in UML model and time-sequence contract

InactiveCN101673198AGuaranteed accuracyGuaranteed reusabilitySpecific program execution arrangementsGraphicsPromela

The invention relates to a method for verifying the consistency of a dynamic behavior in a unified modeling language (UML) model and a time-sequence contract. The method is characterized by comprisingthe following steps: modeling according to the UML standard, including generating a UML state diagram and a UML sequence diagram, and then saving the metamodels of the diagrams; mapping the UML statediagram to a PROMELA code for the dynamic behavior of the model; establishing the time-sequence contract of the model to map the UML sequence diagram to an LTL temporal logical formula; utilizing a model verifying tool SPIN to verify the PROMELA code and the LTL temporal logical formula; and analyzing the returned SPIN verifying result. The technical scheme of the invention associates the unifiedmodeling language (UML) and the verifying tool together, solves the problem of model inconsistency arisen in the requirement and design stage of soft engineering and provides an effective basis for the subsequent development of model driving type software.

Owner:EAST CHINA NORMAL UNIV

Method for predicting field of view of user based on deep learning

ActiveCN108492322AReduce the impactReduce transmission delayInput/output for user-computer interactionImage enhancementViewpointsSequence diagram

The invention discloses a method for predicting the field of view of a user based on deep learning, which comprises the steps of (1) mapping a panoramic video from a spherical surface to six surfacesof a sphere inscribed cube to obtain videos corresponding to the six surfaces, respectively generating a dynamic feature sequence diagram and a saliency sequence diagram of the videos, and performingblocking and numbering; (2) judging the video content viewpoint switching intensity w according to dynamic features; (3) recording the head turning of the user by a helmet, and processing the recordedhead turning; (4) selecting a prediction network according to the size of the w value, obtaining the field of view of the user in the last n video frames by network prediction, and processing to obtain the number of a video block overlapped with the field of view; and (5) rendering the transmitting the video block obtained by prediction, and repeating the steps until the final n frames are predicted. The method disclosed by the invention reduces influences imposed on input video features by the panorama distortion, and pre-judgment grading of the video information is added at the same time, so that the field of view of the user when watching video in a VR HMD (Head Mount Display) can be predicted with high accuracy.

Owner:NANJING UNIV

System, method and computer program for generating sequence diagram

A system, method and computer program for generating a sequence diagram that specifies processing among modules included in source code. First, a source code is acquired and then analyzed to generate a log acquisition code for acquiring an execution log. Then, a program including the generated log acquisition code is executed to acquire execution log information on the execution of the program. On the basis of the acquired execution log information, automaton information on states and transitions among the states is extracted, and then the extracted automaton information is converted into sequence diagram component information on components constituting a sequence diagram. Thereafter, a sequence diagram is generated based on the converted sequence diagram component information.

Owner:IBM CORP

IMS signaling flow visual presentation system, method and server

The invention discloses an IMS signaling flow visual presentation system, an IMS signaling flow visual presentation method and a server. The system comprises a signaling processing server, wherein the signaling processing server is connected with a core switch in an IMS network; the core switch is connected with network cell equipment in the IMS network; the signaling processing server is also connected with a signaling inquiry computer; the network cell equipment of the IMS network is used to generate a signaling data message; the core switch is used to send the signaling data message generated by the network cell equipment to the signaling processing server; the signaling processing server adopts a signaling protocol stack to receive the signaling data message of the core switch, analyzes the signaling data message according to a protocol type, and stores the signaling data message in a database; and after the signaling processing server receives an inquiry request of the signaling inquiry computer, an inquiry result is extracted from the database through WEB service and is pushed to the signaling inquiry computer, and presentation is performed in a way of a signaling flow sequence diagram.

Owner:INFORMATION COMM COMPANY STATE GRID SHANDONG ELECTRIC POWER +3

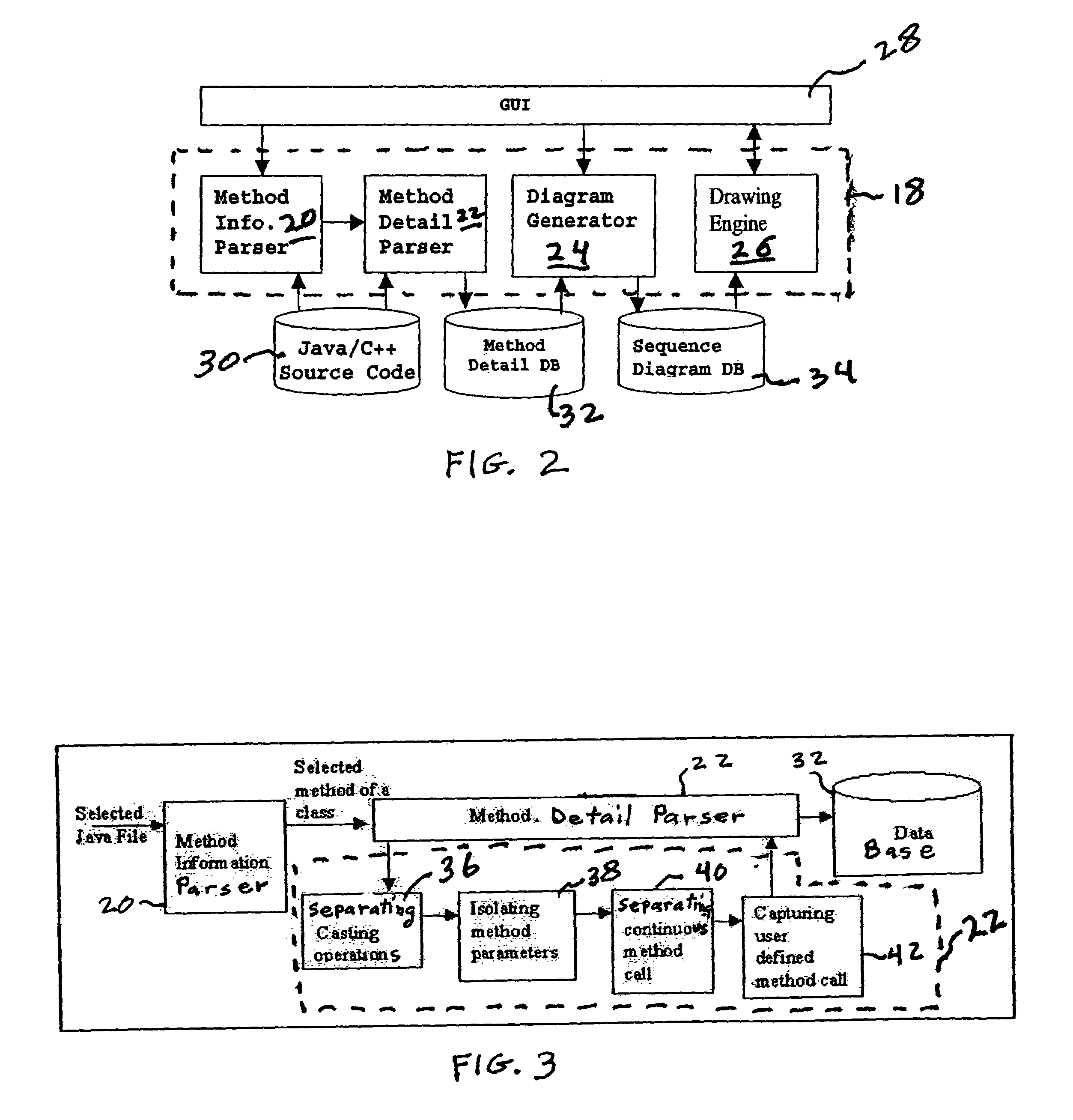

Recovery and representation of object interaction in an object oriented program

InactiveUS7426716B2Reverse engineeringSpecific program execution arrangementsSequence diagramSource code

A process and system are provided for representing object interactions, by means of a sequence diagram or the like, wherein the object interactions are recovered from source code written in Java or other object-oriented programming language. Initially, a Method Information Parser determines the respective methods declared inside the source code and extracts their names. A Method Detail Parser then extracts the method calls to other objects within a method, to resolve each complex method call into multiple lines of single method calls. Information derived from the multiple lines of single method calls is then used to generate the sequence diagram.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Extension UML-based Web application formalization modeling and verification method

InactiveCN108830085AGuaranteed designEnsure consistencyPlatform integrity maintainanceWeb applicationSoftware system

The invention discloses an extension UML-based Web application formalization modeling and verification method, which comprises the following steps: step (1), extracting functional demands of a software system to be designed, and performing demand analysis, step (2), performing UML modeling; step (3), using XML to represent the aforementioned UML2.3 model; step (4), generating formalization description; step (5), performing security attribute verification. The invention provides a feasible method for automatic conversion from the UML2.3 model to the formalization language to expand class diagram, sequence diagram and state diagram in the UML2.3 to implement protocol verification in Web application and implement automatic conversion from the UML model to pi calculation formalization language, and greatly reduces the difficulty of carrying out formalization modelling on the protocol directly; the formalization modeling verification tool is used, and the formalization verification model isrefined; the loophole of the formalization model is detected through display of the verification result and analysis of the attack path, which facilitates quick refining of the model and efficient defect detection.

Owner:TIANJIN UNIV

Coverage analysis method of foundational software platform application program interface integrated test

The invention provides a coverage analysis method of foundational software platform application program interface integrated test, which is used for evaluating the coverage level of the interfaces offoundational software application program by the foundational software platform integrated test cases and the interactive coverage level between interfaces. The method combines static analysis technology with dynamic analysis technology, firstly uses the static analysis technology to obtain the structural information of the foundational software platform integrated application system which is represented as a static interface method calling sequence diagram S-IMAD, then the dynamic analysis technology is used for obtaining interactive information between the interfaces of the foundational software platform application program, and between the interfaces of the foundational software platform application program and the interfaces of other members in the process of executing the integrated test cases which is represented as a dynamic interface method calling sequence diagram D-IMAD, and finally the coverage analysis is used for evaluating the coverage state of the interfaces of the foundational software platform application program by the integrated cases and the interactive coverage state between interfaces based on S-IMAD and D-IMAD.

Owner:BEIHANG UNIV

Method and system for processing long pulse infrared non-destructive detection sequence image

ActiveCN109060822ACancel noiseEliminate outstanding detailsImage enhancementImage analysisNon destructiveImaging processing

The invention discloses a method and system for processing a long pulse infrared non-destructive detection sequence image. The method comprises the following steps such as polynomial fitting, fast Fourier processing, pixel point processing, gray level expansion, detail enhancement, data conversion, sequence diagram processing, and defect summary. The processing method, processing device and detection system and detection method provided by the invention are very efficient in non-destructive detection and evaluation of composite materials, have the cost only a percentage of the pulse thermal loading device and high excitation energy, and is suitable for the detection of large depth defects in metal materials and composite materials. In addition, an ordinary halogen infrared lamp is as the light source, and defect details are specifically enhanced by using sequence image processing methods. The image processing method and image processing device and detection system and detection methodprovided by the invention are economical and practical.

Owner:SHANGHAI UNIV

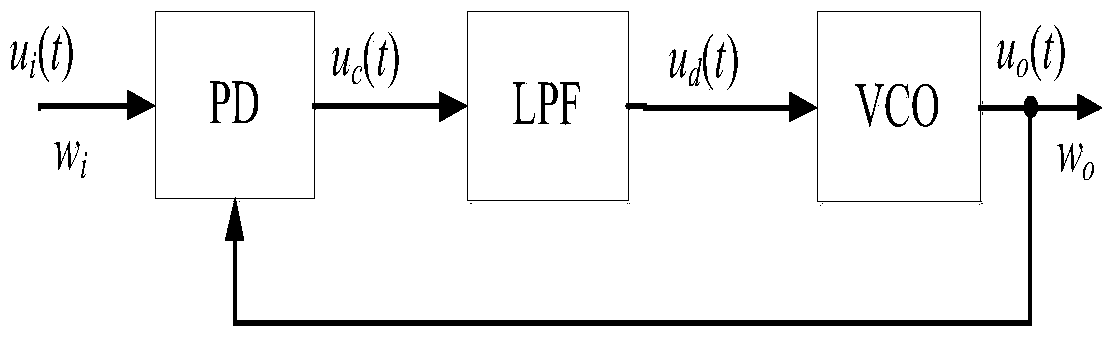

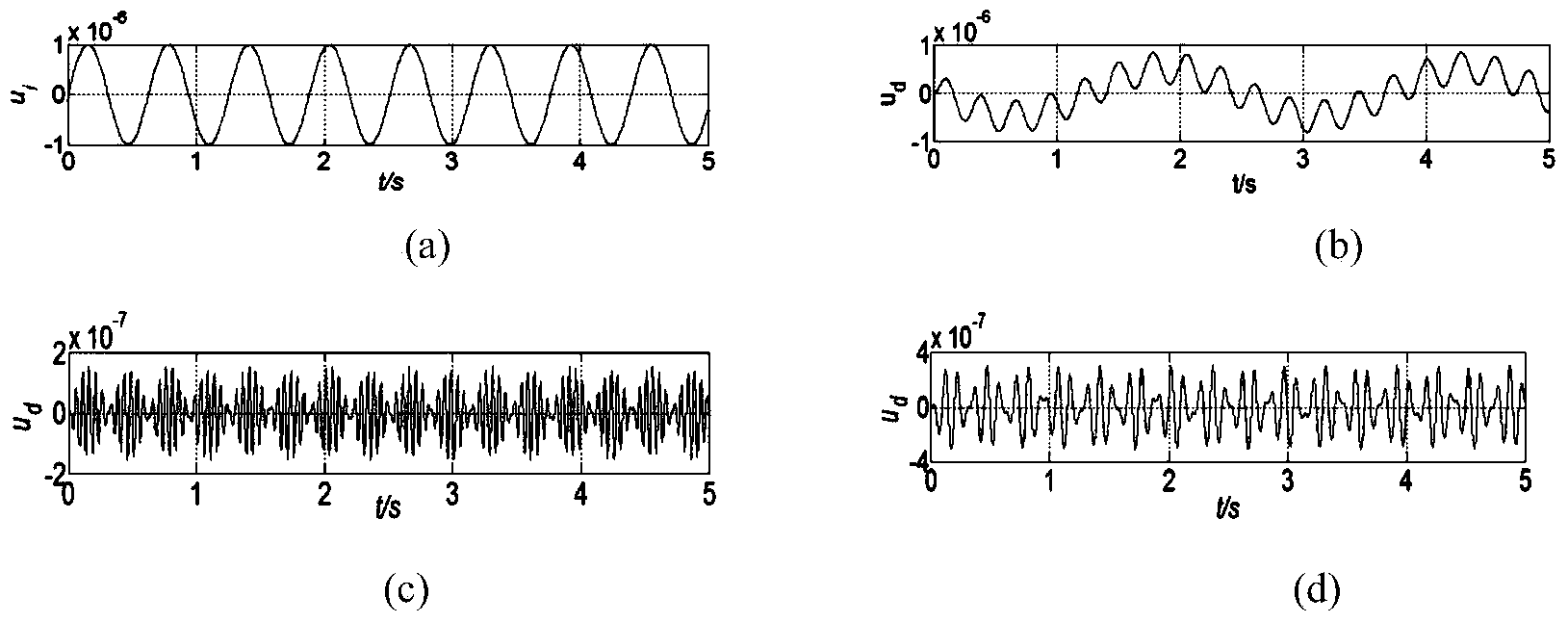

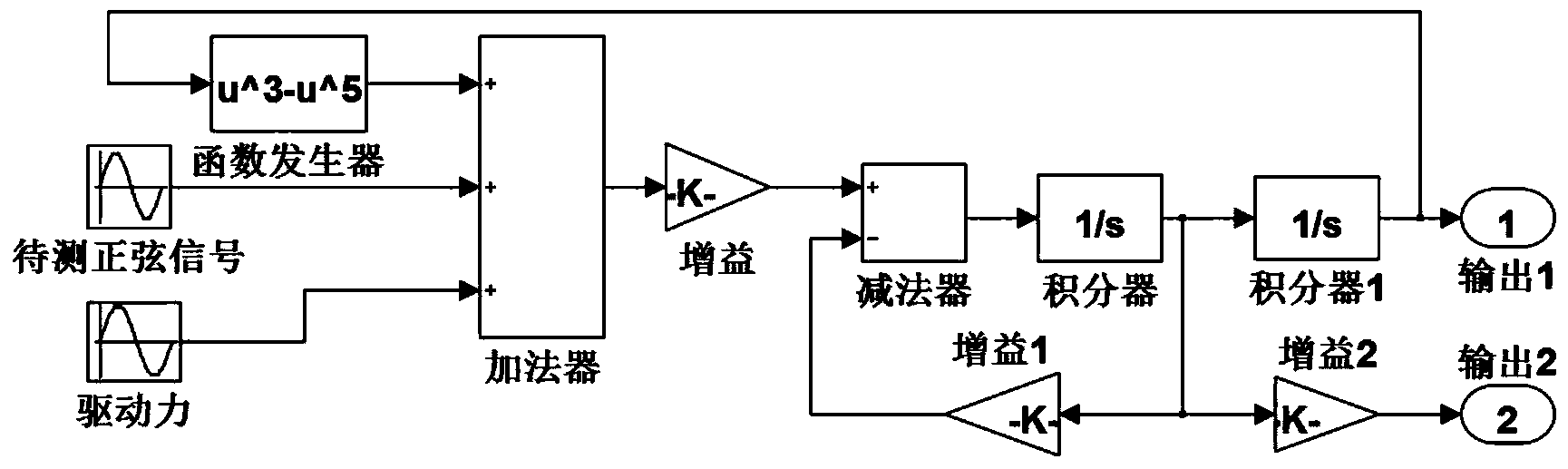

Duffing oscillator weak signal time domain detection method based on phase-locked loop

InactiveCN103913222ASave memoryShorten the timeSubsonic/sonic/ultrasonic wave measurementTime domainPhase locked loop circuit

The invention relates to a weak periodic signal detecting method based on a phase-locked loop and a Duffing oscillator, and belongs to the field of signal processing. According to the method, the phase-locked loop and the Duffing oscillator are used for setting up a combined weak signal detecting system; signal frequency is detected through the phase-locked loop to detect weak periodic signals with unknown frequency; according to the curve characters of a time history of chaotic signals, and a sequence diagram method and a phase plane diagram method are matched to serve as the criterion for detecting a system state and detecting whether the system state changes or not; a precise threshold value at which the system jumps into a periodic state from a chaotic state is obtained, and the threshold and quality for detecting the weak periodic signal are improved. Compared with a traditional method, the weak periodic signal detecting method can detect the signals with the unknown frequency, is easier to implement, saves a lot of simulation time, is of great signification in practical application and thereby has very good application prospects.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

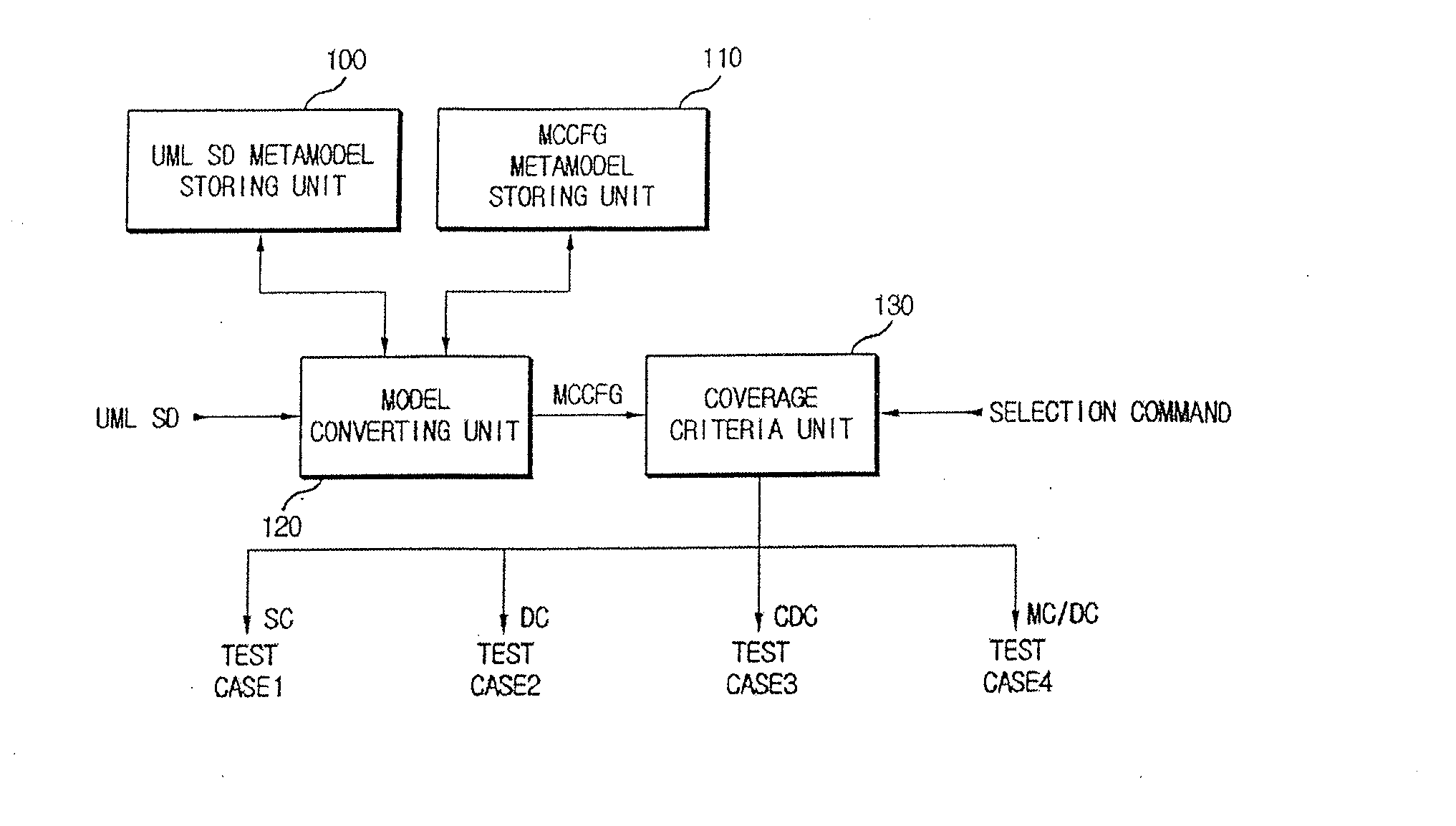

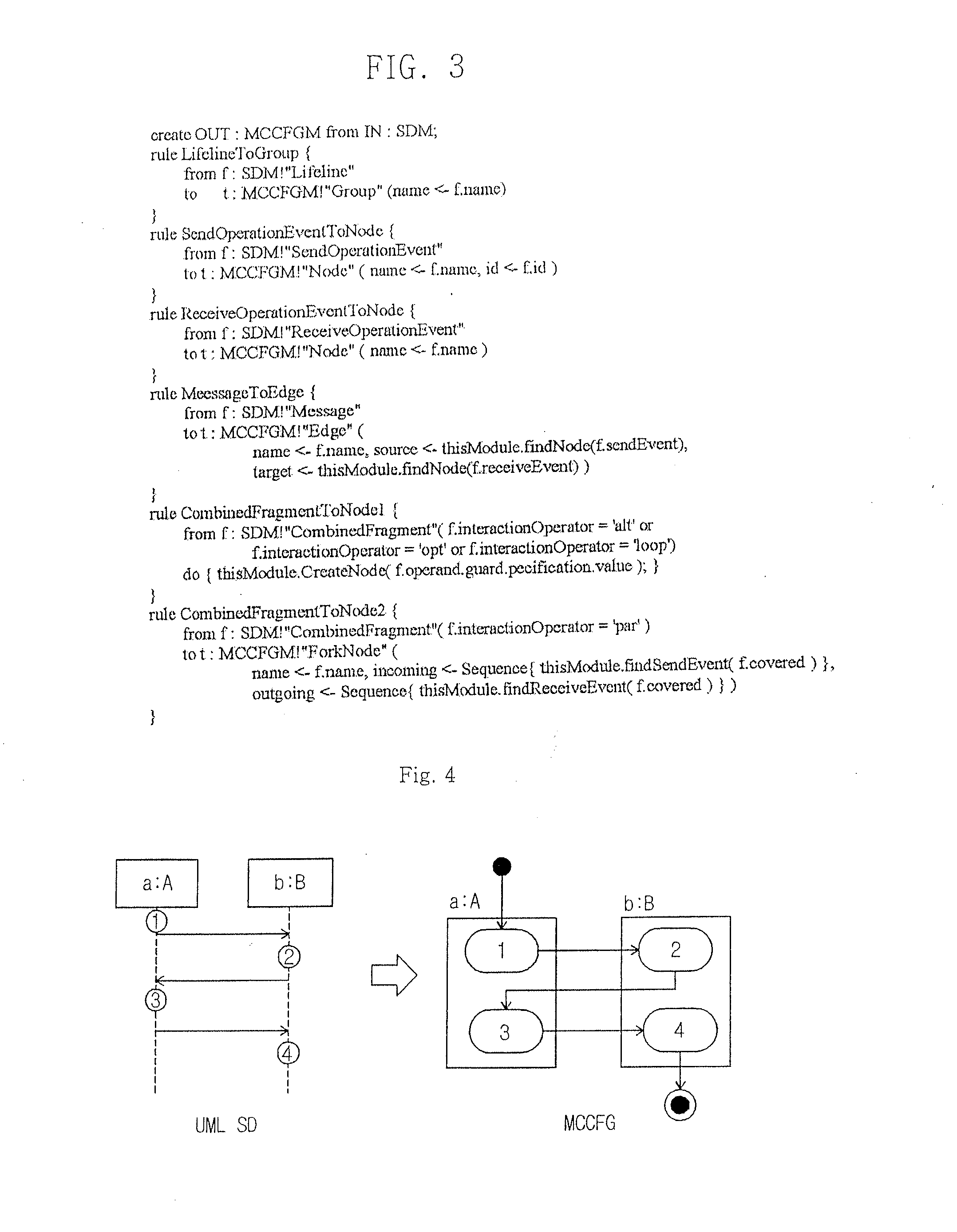

Apparatus and method of generating multi-level test case from unified modeling language sequence diagram based on multiple condition control flow graph

InactiveUS20140130006A1Software testing/debuggingSpecific program execution arrangementsSequence diagramUnit model

Disclosed herein are an apparatus and a method for generating a multi-level test case for testing software from a unified modeling language (UML) sequence diagram (SD) based on a multiple condition control flow graph (MCCFG). The apparatus includes: a UML SD metamodel storing unit storing a UML SD metamodel defined for a model to be converted therein; an MCCFG metamodel storing unit storing an MCCFG metamodel; a model converting unit model-converting the UML SD from which the test case is to be generated according to the UML SD metamodel and the MCCFG metamodel to generate the MCCFG; and a coverage criteria unit converting the MCCFG into a tree structure and then converting the tree structure into test cases according to a selection command.

Owner:DAEGU NAT UNIV OF EDUCATION IND ACADEMIC COOPERATION FOUND +1

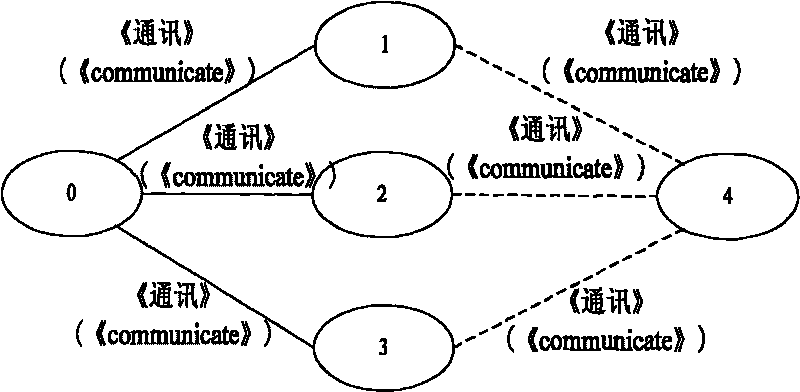

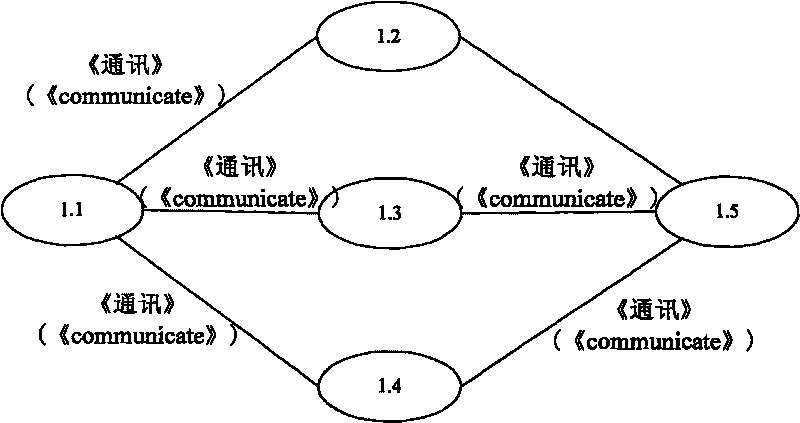

Web application model and test method based on UML use case diagram and sequence diagram

InactiveCN101702136ASoftware testing/debuggingSpecific program execution arrangementsWeb applicationDirected graph

The invention relates to a Web application model and a test method based on a UML use case diagram and a sequence diagram, which is used for establishing the Web application test model based on use case and automatically generating test scenes therefrom. The test method comprises the following steps: firstly, using a layered UML extension use case diagram is used as a Web application model from the viewpoint of an external user, wherein the model is called a use case transition model (Use Case Transition Model, UCTM); secondly, describing each use case from top to bottom by a formalized sequence diagram, and automatically transforming the sequence diagram to a restricted directed graph (RDG); thirdly, providing a constraint message coverage criterion ( CMC), and generating test cases from the RDG, wherein the test cases can meet the CMC, and the number of the test cases is reduced; and fourthly, merging the RDG from bottom to top, and traversing the RDG. The test scenes on different levels of Web application can be generated, and the provided constraint message coverage criterion (CMC) can be met.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

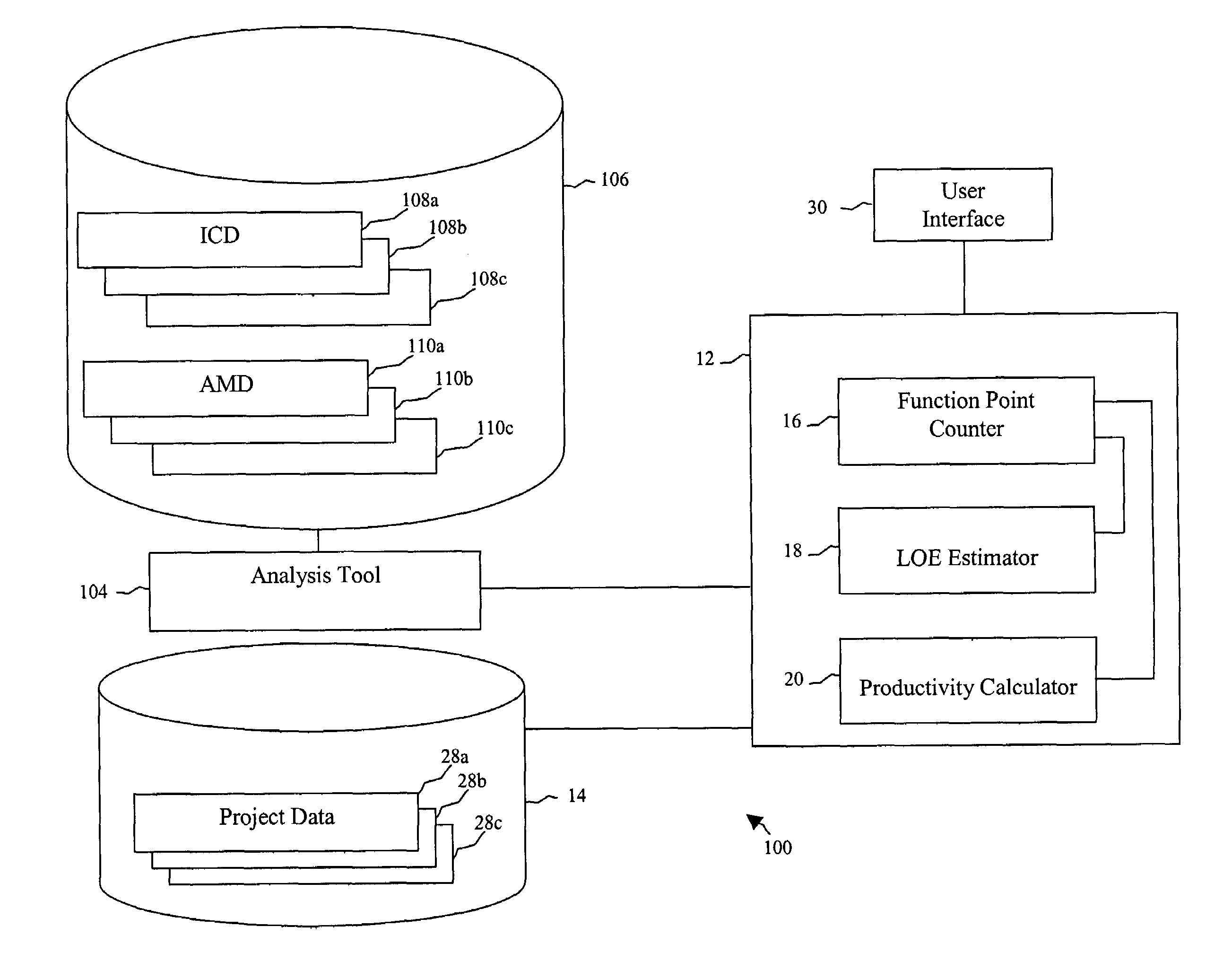

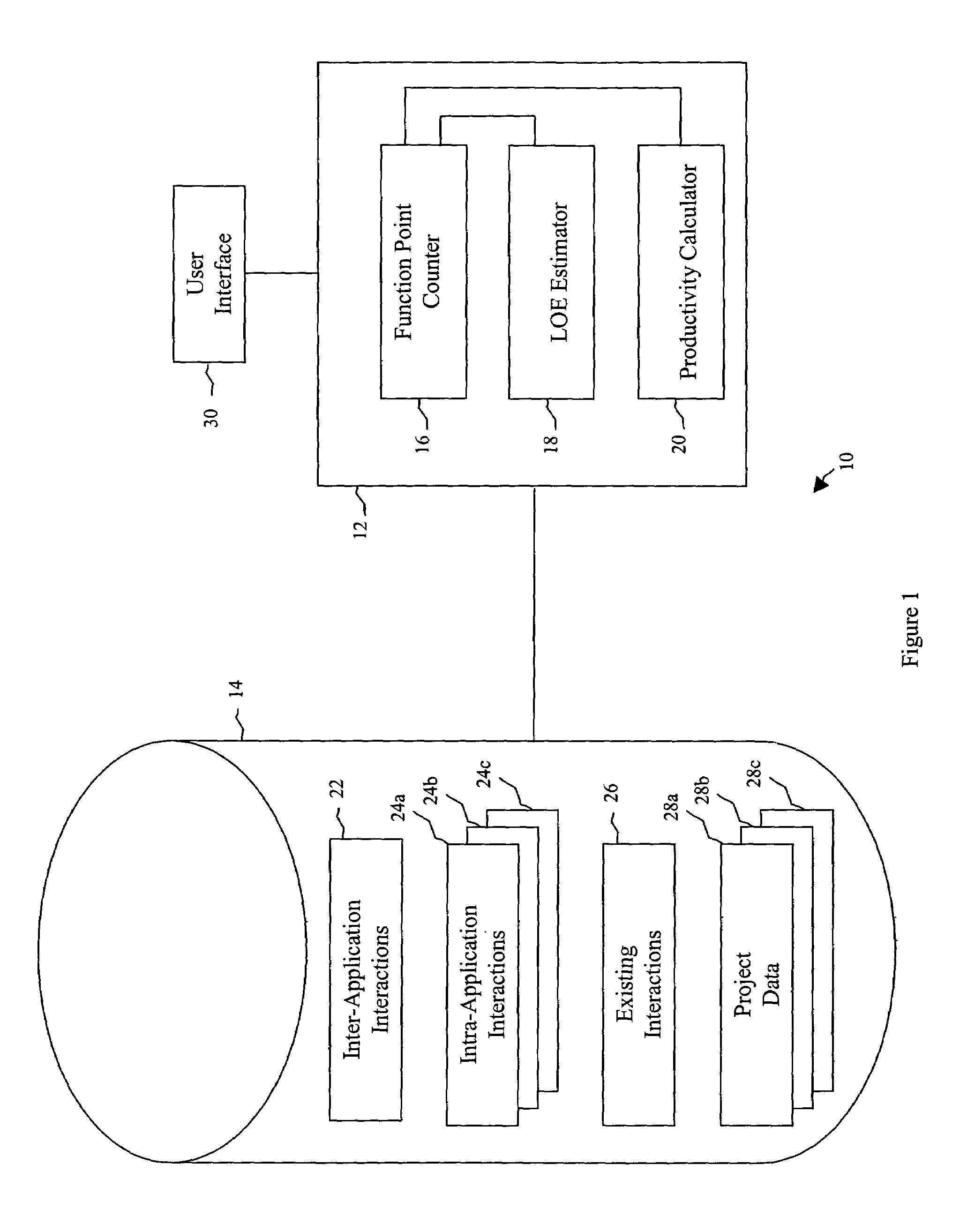

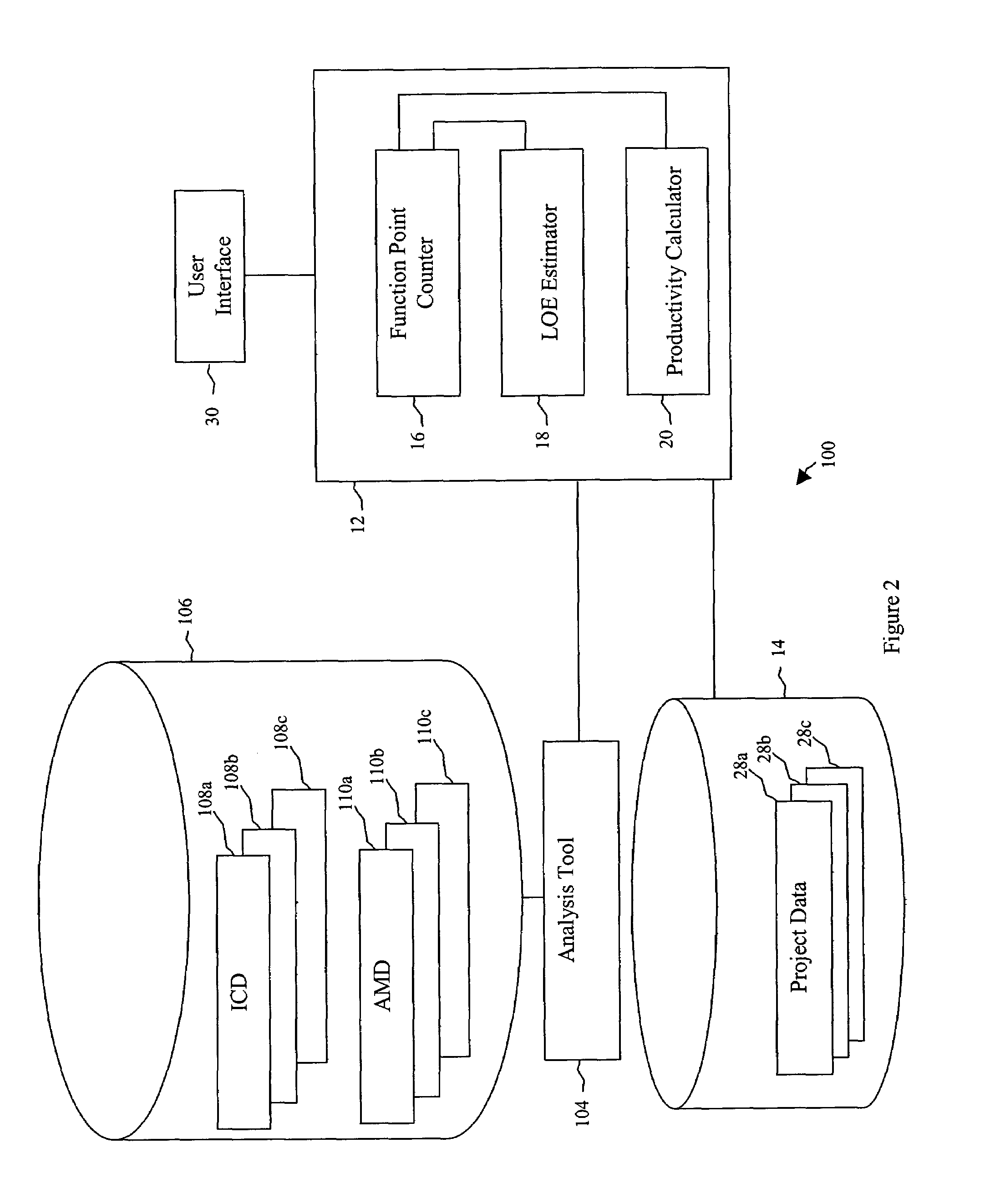

Enhanced function point analysis

InactiveUS7743369B1Easy to countError detection/correctionSpecific program execution arrangementsElectronic documentSequence diagram

A system for automatically counting function points is provided. The system includes an electronic document, an analysis component, and a user interface. The electronic document contains a sequence diagram that specifies interactions in a software application. The analysis component can analyze the interactions in the sequence diagram to identify a start point and an end point in the sequence diagram as a function point. The analysis component can also maintain a count of the function points. The user interface can promote counting one or more function points when more than one of the sequence diagrams involve data that is part of a set of data objects identified via the user interface.

Owner:T MOBILE INNOVATIONS LLC

Method for restraining power grid single-phase short circuit current

ActiveCN101267107ASmall declineEmergency protective arrangements for limiting excess voltage/currentAutotransformerSequence diagram

The present invention provides a method of inhibiting 220kV side bus single-phase short circuit current of 500kV pivotal substation. An electric grid adopting mass autotransformers makes the more 220kV side bus single-phase short circuit current of 500kV pivotal substations larger than the three-phase short circuit current, and exceeding the rated breaking ability of the circuit breaker. Considering change the autotransformer to non-autotransformer to reduce the single-phase short circuit current, reducing the grounding branch of the zero-sequence grid essentially. According to the sequence diagrams principle analyse, changing autotransformer to the non-autotransformer in 500 kV substation has a larger impact to the 220kV bus single-phase short circuit current of the 500kV pivotal substation than changing the autotransformer to the non-autotransformer in the 220 kV substation, the practical example also proves the accuracy of the theoretical analysis. The method provides technical support for the limiting the grid single-phase short circuit current, enhancing the credibility of the grid operation.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +1

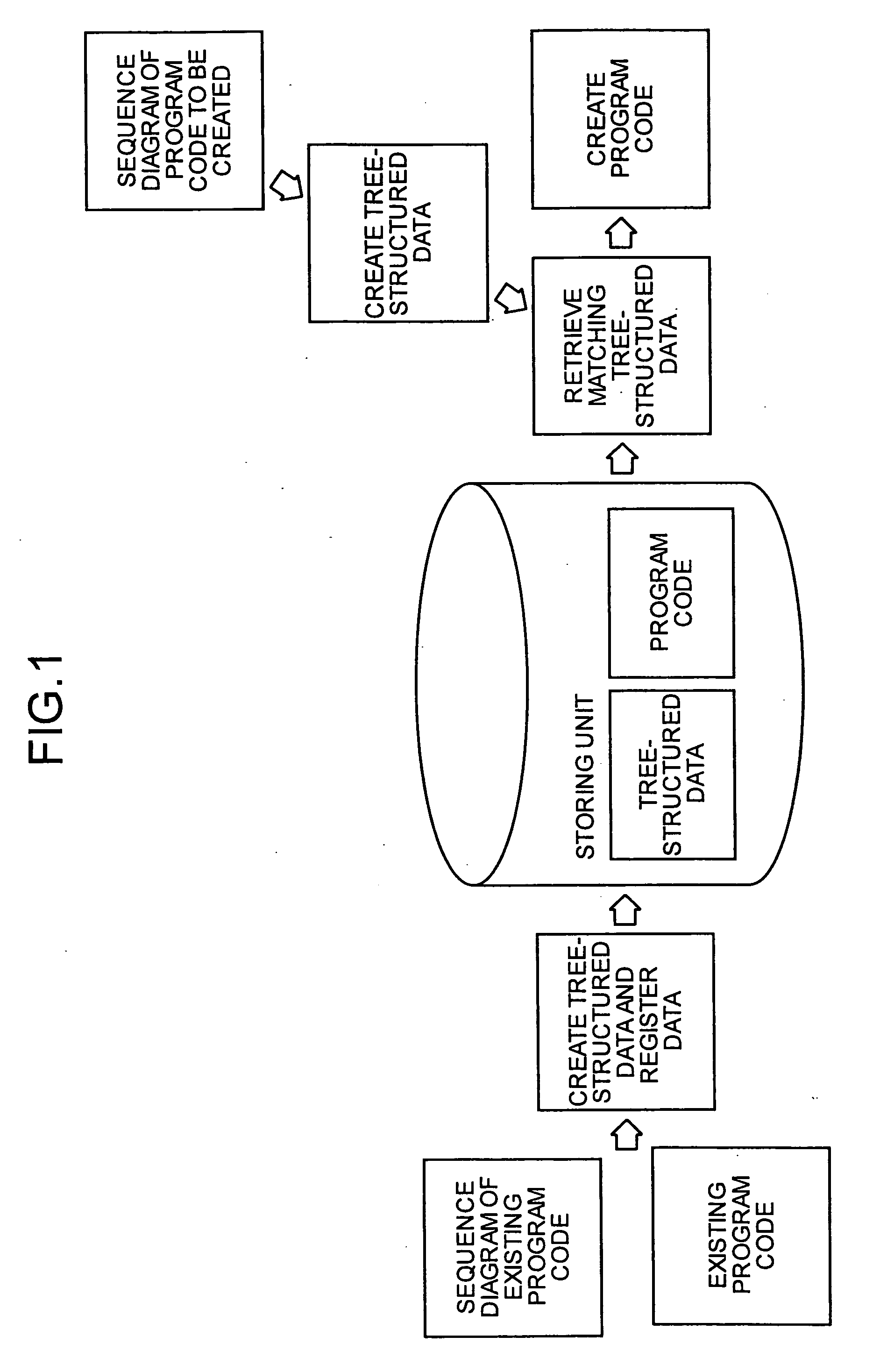

Source-code-generation supporting method and computer product

A first tree-structured data is generated based on a sequence diagram indicating a specification of a new source code to be generated. A second tree-structured data matching with the first tree-structured data is retrieved from a storing unit that stores at least an existing source code and tree-structured data corresponding to the existing source code. A source code corresponding to the second tree-structured data is acquired from the storing unit.

Owner:FUJITSU LTD

IC (integrated circuit) function verification method

InactiveCN102147829AIncrease coverageControlling Validation Vector ContentSpecial data processing applicationsValidation methodsFinite-state machine

The invention provides an IC (integrated circuit) function verification method. The method comprises the following steps: based on an interface sequence diagram reflecting external characteristics of a module to be tested and configuration information of an internal register reflecting the internal state of the module to be tested in design specifications of the module to be tested, establishing a finite-state machine model, then traversing the state of the finite-state machine model, simultaneously adding loop parameter setting to a directed circuit and a critical path more concerned by a user, thereby realizing a higher function coverage rate. The method has the ultimate goal of obtaining more function verification coverage with less verification vectors, thereby improving verification working efficiency, reducing verification cost, improving design reliability and shortening the marking time of products.

Owner:李姮乐

Generating sequence diagrams using call trees

InactiveUS20080196011A1Simple and fast and easy to operateDirect operationReverse engineeringProgram loading/initiatingSource code fileSequence diagram

A software tool is provided to analyze static source code. Source Code files are selected to define the project work space. A class and a method in the class are selected from said selected source code files. The tool generates a Call Tree as an ordered recursive sequence of all method calls in different classes or their instances that are invoked by said selected method in said selected class. A Sequence Diagram is generated from said Call Tree. The tool remembers all updates to the Call Tree used to generate the Sequence Diagram. This information is used when a generated Sequence Diagram is impacted due to changes made to any source code file included in the project.

Owner:KYNDRYL INC

Production line layout method facing manually assembled product

InactiveCN105243213AIncrease production capacityBalance loadForecastingSpecial data processing applicationsProduction lineDecomposition

A production line layout method facing a manually assembled product comprises the following steps of: 1, determining a product object, and performing basic operation decomposition on a product; 2, analyzing a context logical relationship of a basic opeation, and drawing a basic operation sequence diagram; 3, performing time study on an operating method by applying operation measurement, and determining standard operating time; 4, drawing the basic work sequence diagram according to the context logical relationship of the operation; 5, carrying out primary designing of a product production line by using a ranked positional weight method; 6, by using a simulation optimization method, performing analog simulation on the primarily designed production line and optimizing the primarily designed production line; and 7, performing reasonable layout on the production line by using an optimization result in step 6. The production line layout method has the beneficial effects that the production line can be systematic designed, the labor load of each station can be balanced, and the production capacity of the production line can be improved.

Owner:ZHEJIANG UNIV OF TECH

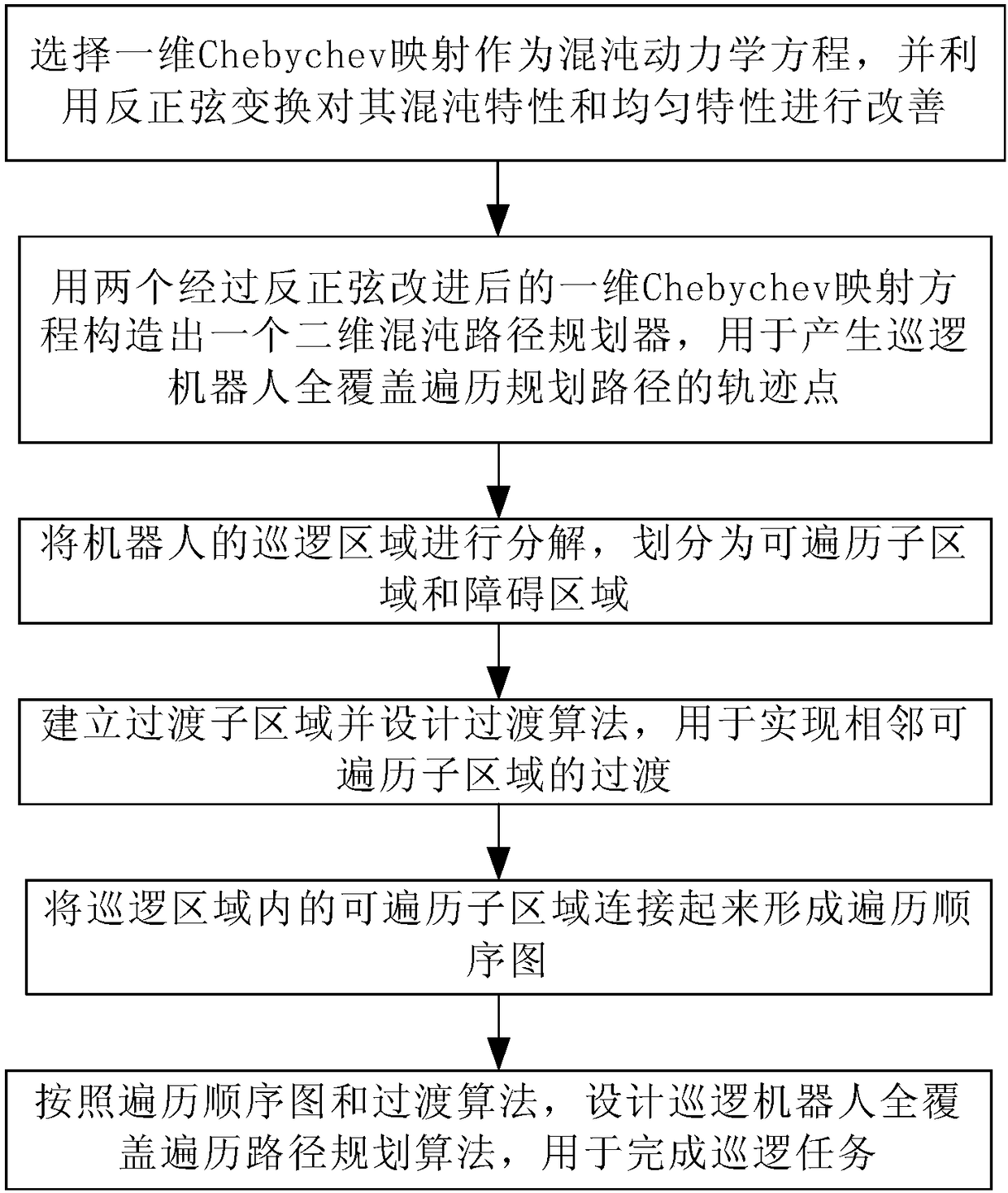

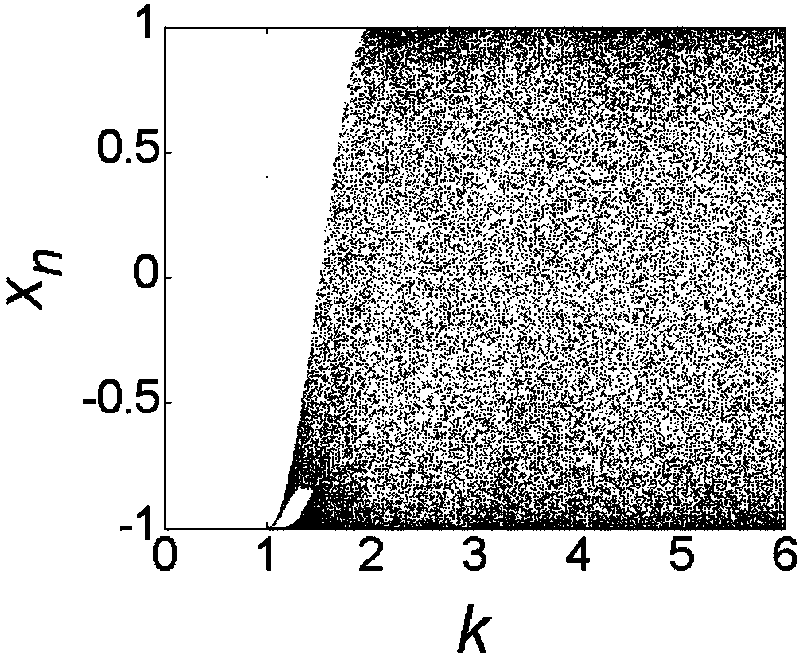

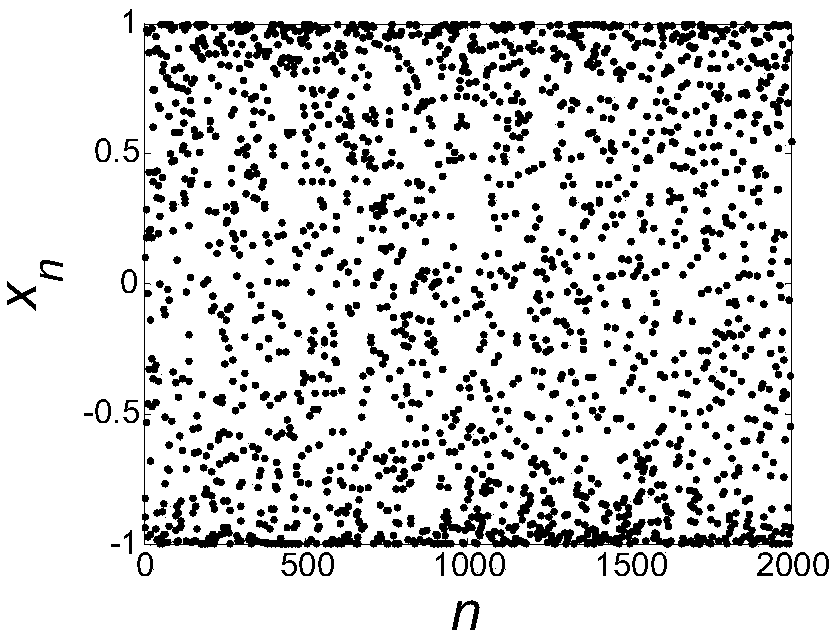

Design method of patrol robot full-coverage traversal path planning algorithm

InactiveCN108255178AIncrease coverageImprove work efficiencyPosition/course control in two dimensionsDynamic equationSequence diagram

The invention discloses a design method of a patrol robot full-coverage traversal path planning algorithm. The method includes the following steps that: a one-dimensional Chebychev mapping is selectedas a chaotic dynamic equation, and inverse sine transformation is utilized to improve the chaotic characteristic and uniform characteristic of the chaotic dynamic equation; two inverse sine-improvedone-dimensional Chebychev mapping equations are adopted to construct a two-dimensional chaotic path planner; the patrol area of a robot is decomposed into traversable sub-regions and obstacle regions;transition sub-regions re established, and a transition algorithm is designed; the traversable sub-regions in the patrol area are connected to form a traversal sequence diagram; the patrol robot full-coverage traversal path planning algorithm is designed according to the traversal sequence diagram and the transition algorithm, and the patrol robot full-coverage traversal path planning algorithm can be used for completing a patrol task. The algorithm of the invention has the advantages of simplicity, low repetition rate and high coverage rate, and can ensure the randomness and unpredictabilityof the patrol task while ensuring full coverage of the patrol area.

Owner:SHANDONG UNIV OF TECH

Teaching platform based on product assembly sequence model facing to virtual disassembly and assembly

The invention relates to a teaching platform based on a product assembly sequence model facing to virtual disassembly and assembly, which comprises a disassembly and assembly model, an input module and a comparison module, wherein the disassembly and assembly model can reflect the correct assembly sequence and disassembly sequence of parts; the input module can acquire the actual disassembly and assembly sequence input by a user; and the comparison module compares the actual disassembly and assembly sequence with the disassembly and assembly module and recognizes whether the actual disassembly and assembly sequence is correct. The construction of the disassembly and assembly model comprises the following steps of: acquiring the actual assembly sequence and disassembly sequence of the product parts, and respectively establishing an assembly sequence diagram corresponding to the assembly sequence and a disassembly sequence diagram corresponding to the disassembly sequence; respectively converting the assembly sequence diagram and the disassembly sequence diagram into computer-recognizable data structures; and forming a disassembly model from the data structures. The teaching platform has the advantages of expressing the layer relationship between the assembly sequences and inspecting the reasonableness and correctness of the disassembly sequence made by a user in a disassembly and assembly experiment.

Owner:ZHEJIANG UNIV

State machine based fault positioning method and apparatus

ActiveCN105159809AAchieve positioningHigh precisionDetecting faulty computer hardwareHardware monitoringSequence diagramTemplate match

The application discloses a state machine based fault positioning method and apparatus. The method comprises: obtaining analysis information of an operation process with a fault, wherein the analysis information comprises logs, and the logs are generated when performing operation steps in the operation process with the fault; obtaining a state machine template matched with a special character of one log according to the special character in the log; performing mode matching on the analysis information and the state machine template to obtain an operation step sequence diagram of the operation process with the fault; and finding the operation step with the fault in the operation step sequence graph according to an error log in the logs. The method is capable of realizing fault positioning in operation step level, thereby improving the precision of fault positioning.

Owner:HUAWEI CLOUD COMPUTING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com