Precise hole leading method for machining training plane skin

A technology for trainer aircraft and aircraft skinning, which is applied to aircraft assembly and drilling templates for workpieces, etc. It can solve problems such as poor marking accuracy, poor consistency, and benchmark deviation, so as to avoid out-of-tolerance or scrapping, and reduce labor intensity , Improve the effect of hole making efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the invention, and are not intended to limit the scope of the present invention.

[0012] The method for precise drilling of trainer skin processing includes the following steps:

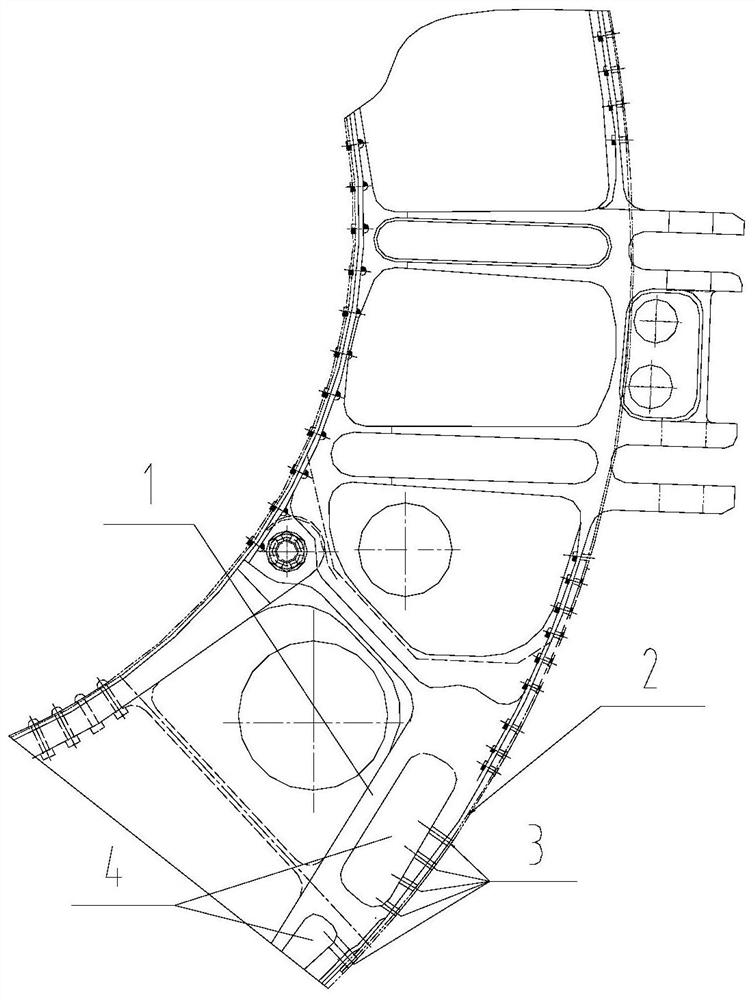

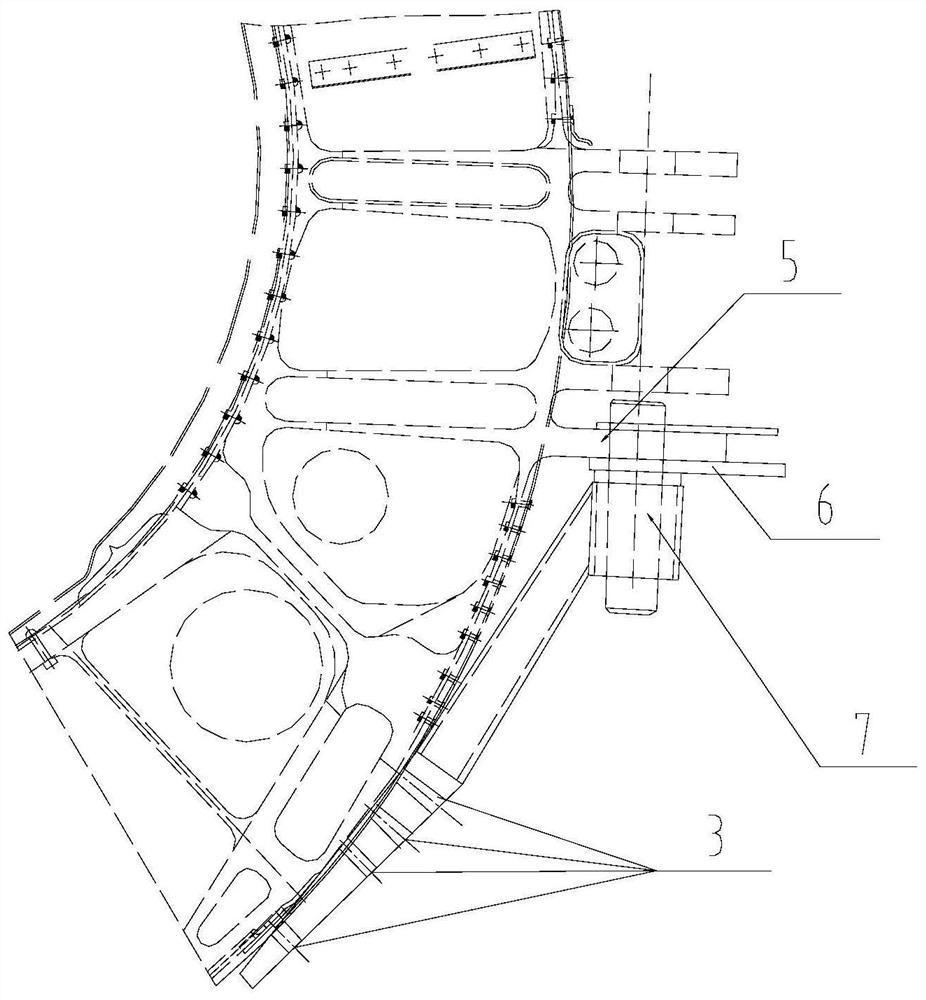

[0013] (1) First, according to the structure form of the required lead hole, select a suitable and reliable part or part of the frame plate 1 of the aircraft trainer aircraft structure as the installation point, design and manufacture the lead hole drilling template 7, and the installation position of the lead hole drilling template 7 is adjustable , the leading hole drilling template 7 is consistent with the position of the hole that needs to be led out;

[0014] (2) Assemble the aircraft skin 2 on the aircraft structure frame plate 1, install the pilot hole drilling template 7 on the aircraft structure lug hole 5 on the aircr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com