Steel member assembling mould

A technology for assembling molds and steel components, applied in auxiliary devices, manufacturing tools, auxiliary welding equipment, etc., can solve problems such as high cost of construction technology, inability to build buildings, and slow construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0006] Specific embodiments: the present invention will be further described below in conjunction with accompanying drawing;

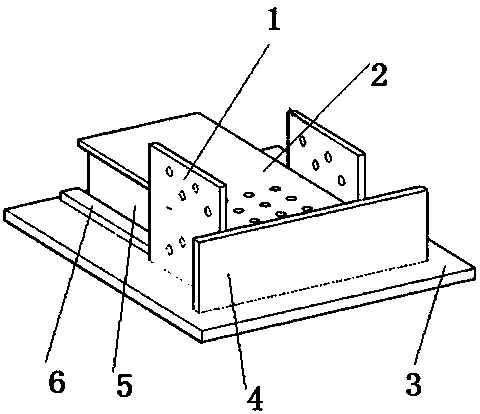

[0007] A steel component assembly mold, which consists of mold side plates, middle plates, and a mold platform, is characterized in that two support plates are arranged on the mold platform, a middle plate is arranged on the two support plates, and a backing plate is arranged on the outside of the two support plates , the outer side of the two backing plates is provided with a mold side plate; one end of the two mold side plates and the middle plate is connected to the baffle plate arranged on the front end of the mold platform; the mold side plate and the middle plate are provided with through holes. During specific implementation, the corbel is composed of a corbel wing plate and a corbel web. According to the hole and size requirements of the high-strength bolts on the steel member corbel wing plate and corbel web on the drawings, the mold side plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com