Novel shaft sleeve unit

A bushing, a new type of technology, applied to the parts of boring machine/drilling machine, the drilling template for the workpiece, the measurement of positioning in the boring machine/drilling machine, etc., can solve the problems of difficult correction, affecting the shape quality, one-way clearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

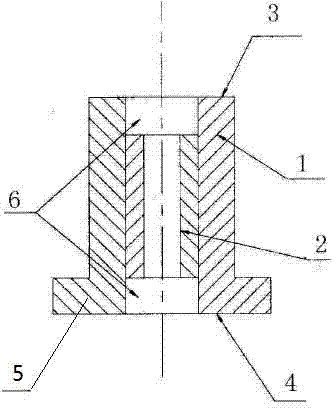

[0011] Such as figure 1 As shown, a new type of bushing, a bushing 2 is coaxially arranged in the jig shell 1, and a through hole is arranged in the bushing 2; the two ends of the jig shell 1 are respectively a small circle action surface 3 and a large circle action surface 4. An end plane 5 is provided on the large circle action surface 4, which is tangent to the corresponding circle of the small circle action surface 3. The length of the shaft sleeve 2 is less than that of the jig casing 1 , and there are drill chip storage grooves 6 at both ends of the inner circumference of the jig casing 1 .

[0012] The part to be drilled in the device is an inclined plane, and the large circular action surface 4 of the verticality-guided drilling mold coincides with the surface of the part, and the hole is processed through the guidance of the shaft sleeve 2; as shown in Figure 4, the part to be drilled is provided with a boss, and the drill The position of the hole is close to the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com