Hole making normal interpolation correction method for five-axis numerical control hole making machine tool

A technology for controlling holes and machine tools, applied in program control, computer control, general control systems, etc., can solve the problems of inaccurate normal measurement, affecting the overall efficiency of hole making, and inability to correct, and achieve the effect of improving hole making efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

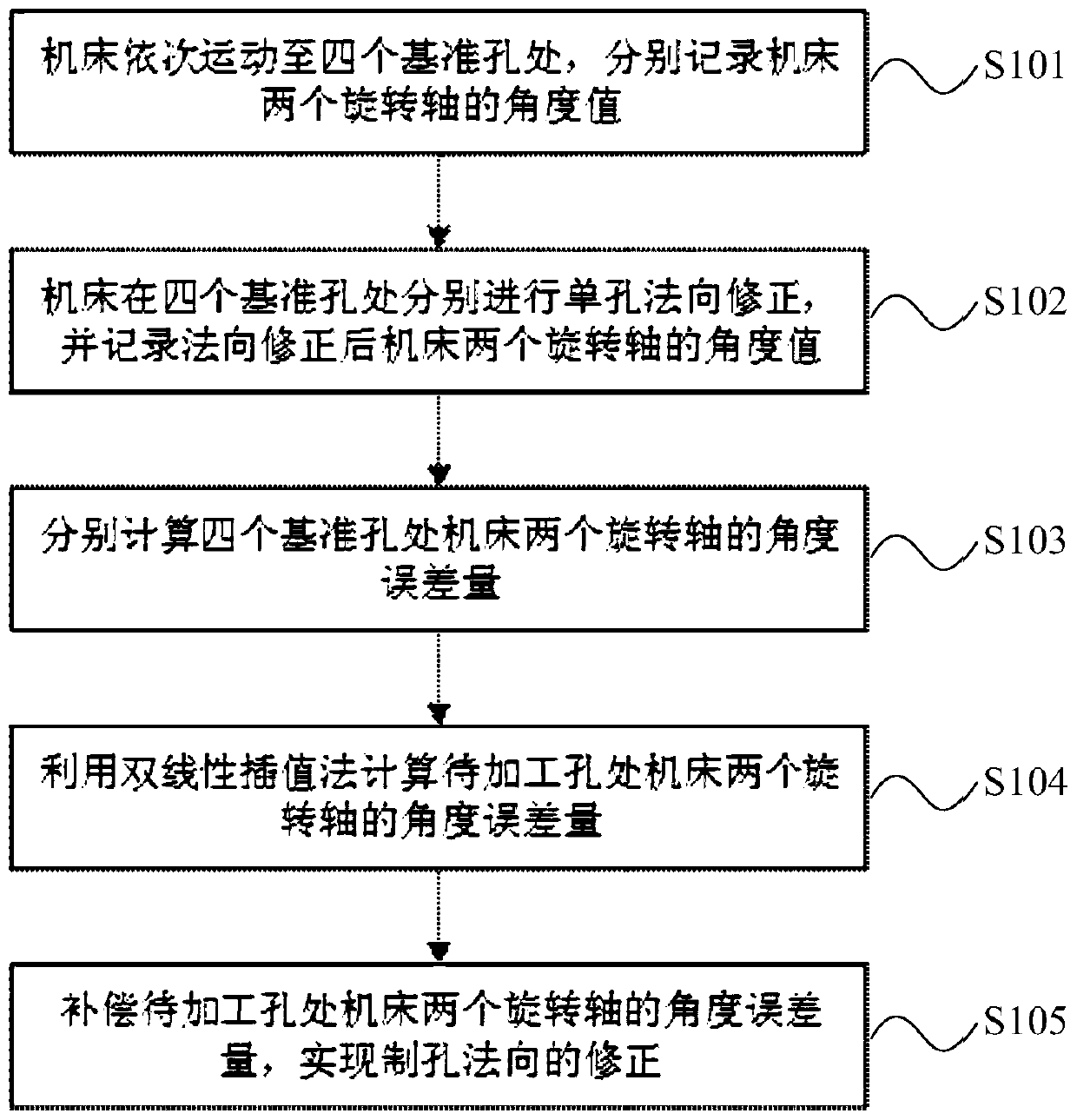

[0039] figure 1 A schematic diagram of a hole-making area for an aircraft panel, where P 1 ,P 2 ,P 3 ,P 4 are four reference holes, and P is any hole to be processed in this area. See figure 2 , which includes the following steps:

[0040] S101, the machine tool moves to P 1 ,P 2 ,P 3 ,P 4 At the four reference holes, the positions of the four reference holes are obtained from the digital model of the product to be processed, and the angle values of the two rotation axes of the machine tool (referring to the A axis and the B axis, the same below) are respectively recorded, that is, A 1 , B 1 , A 2 , B 2 , A 3 , B 3 , A 4 , B 4 ;

[0041] S102, the machine tool is at P 1 ,P 2 ,P 3 ,P 4 Correct the normal direction of the single hole at the four reference holes respectively, and record the angle value of the two rotation axes of the machine tool after the normal direction correction, that is, A′ 1 , B' 1 , A' 2 , B' 2 , A' 3 , B' 3 , A' 4 , B' 4 ;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com