Preparation method of polyacrylonitrile based three-dimensional macroporous carbon block

A polyacrylonitrile-based, three-dimensional macroporous technology is applied in the preparation/purification of carbon, chemical instruments and methods, carbon compounds, etc. Simple, efficient hole making, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

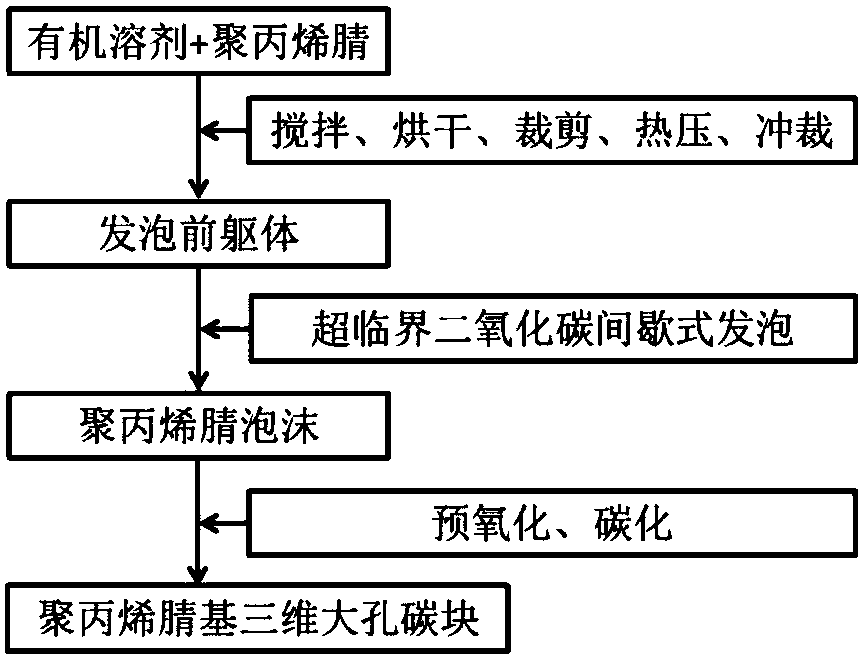

[0039] A method for preparing a polyacrylonitrile-based three-dimensional macroporous carbon block. The process includes three steps of preparing a foaming precursor, preparing a polyacrylonitrile foam, and preparing a polyacrylonitrile-based three-dimensional macroporous carbon block.

[0040] Specific steps are as follows:

[0041] (1) Preparation of foaming precursor: After adding an organic solvent and 8-12wt% polyacrylonitrile into the flask, stir at 55-75°C for 8-24 hours until the polyacrylonitrile is completely dissolved, then pour the solution into the culture In the dish, dry at 60°C for 10-16 hours, and after part of the solvent is evaporated to dryness, the mass ratio of the remaining solvent to polyacrylonitrile should be controlled within the range of 35-55wt%.

[0042] Obtain thin slices and cut them into thin slices with the same size as the cavity of the hot-pressing mold. Take 10-16 slices, heat-press at 140-160°C and 10-20Mpa for 10-20 minutes to obtain bloc...

Embodiment 1

[0052] The process of the preparation method of the polyacrylonitrile-based three-dimensional macroporous carbon block involved in this example includes three steps of preparing a foaming precursor, preparing a polyacrylonitrile foam and preparing a polyacrylonitrile-based three-dimensional macroporous carbon block:

[0053] (1) Preparation of foaming precursor: After adding dimethyl sulfoxide and 10wt% polyacrylonitrile powder into the flask, mechanically stir at 60°C for 10 hours until the polyacrylonitrile is completely dissolved, and then pour the solution into a petri dish , drying at 60°C for 12h (at this time, the mass of the remaining solvent and polyacrylonitrile is about 42wt%) to obtain thin slices and cut them into thin slices with the same size as the cavity of the hot-pressing mold. Take 12 slices and heat through 160°C , 10Mpa hot pressing for 10 minutes to obtain a block sample, and finally punch it into small pieces as a foaming precursor.

[0054] (2) Prepara...

Embodiment 2

[0058] The process of the preparation method of the polyacrylonitrile-based three-dimensional macroporous carbon block involved in this example includes three steps of preparing a foaming precursor, preparing a polyacrylonitrile foam and preparing a polyacrylonitrile-based three-dimensional macroporous carbon block:

[0059] (1) Preparation of foaming precursor: After adding dimethyl sulfoxide and 10wt% polyacrylonitrile powder into the flask, mechanically stir at 60°C for 10 hours until the polyacrylonitrile is completely dissolved, and then pour the solution into a petri dish , drying at 60°C for 12h (at this time, the mass of the remaining solvent and polyacrylonitrile is about 42wt%) to obtain thin slices and cut them into thin slices with the same size as the cavity of the hot-pressing mold. Take 12 slices and heat through 160°C , 10Mpa hot pressing for 10 minutes to obtain a block sample, and finally punch it into small pieces as a foaming precursor.

[0060] (2) Prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com