Preparation method of high temperature resistant SiC aerogel

An aerogel, high temperature resistant technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of low yield and easy damage to the microstructure of aerogel, and achieve the effect of simplifying raw material components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

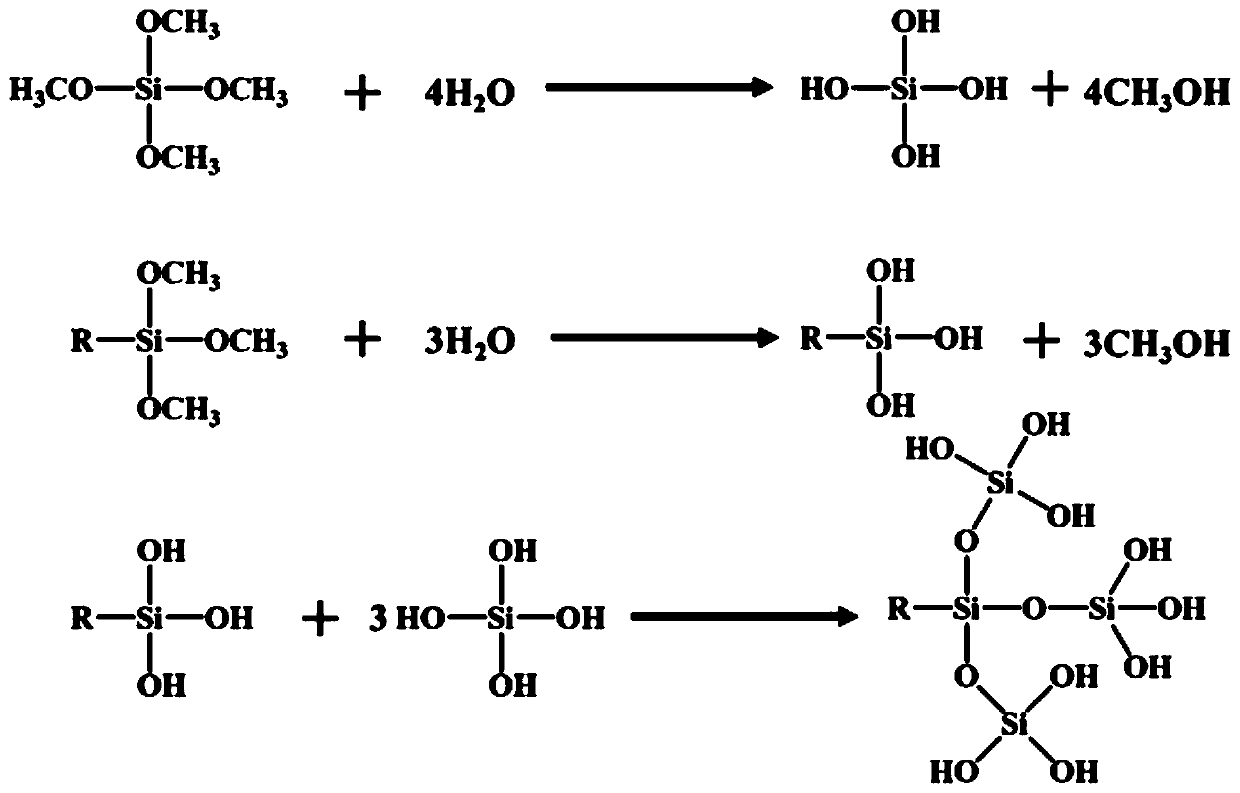

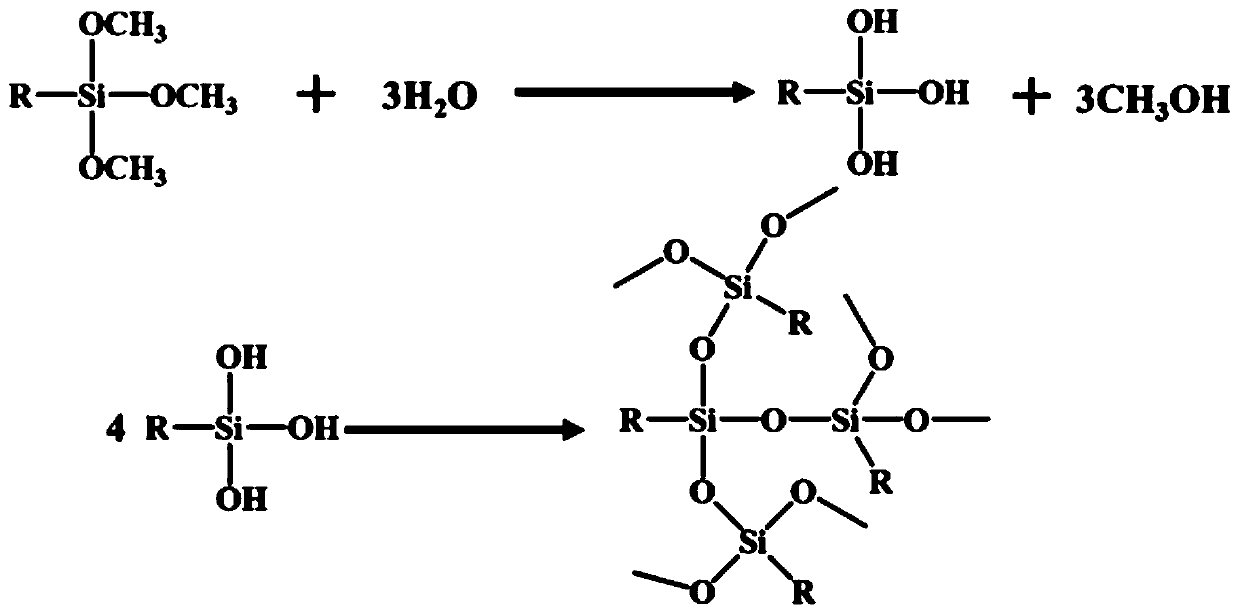

Method used

Image

Examples

specific Embodiment approach 1

[0044] Specific embodiment 1: The preparation method of high temperature resistant SiC airgel in this embodiment is carried out according to the following steps:

[0045] 1. Weigh 9.9g R 1 Si(OR 2 ) 3 And 7.6g methyl orthosilicate, after magnetic stirring for 5min, mixed solution A was obtained;

[0046] 2. Weigh 46g of ethanol, 1.8g of deionized water and 0.25g of Span-20 and mix to obtain the mixed solution B;

[0047] 3. Mix the mixed solution A and the mixed solution B, drop 0.5 mL of hydrochloric acid with a concentration of 1 mol / L and stir magnetically for 2 hours at room temperature to obtain a hydrolyzed solution;

[0048] 4. Take 25mL of hydrolyzate, drop into it 0.5mL of ammonia water with a concentration of 1mol / L, transfer it to a closed container, and place it in an oven at 50°C for 0.5h-10h to obtain a wet gel;

[0049] 5. Aging the wet gel with 25mL methanol at 50°C for 24h, then exchanging twice with 25mL ethanol and three times with 25mL n-hexane, and dry...

specific Embodiment approach 2

[0052] Specific embodiment two: the difference between this embodiment and specific embodiment one is that R described in step one 1 Si(OR 2 ) 3 , where R 2 =CH 3 or CH 2 CH 3 , R 1 = Aromatic hydrocarbons or alkanes with carbon number ≥ 6. Others are the same as the first embodiment.

specific Embodiment approach 3

[0053] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the R described in step one 1 Si(OR 2 ) 3 For phenyl trimethoxysilane. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com