A kind of ultra-low temperature forming device and forming method of aluminum alloy component

An aluminum alloy component, ultra-low temperature technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of poor heat preservation effect of molds, difficult to achieve low temperature, long transfer time, etc., so as to avoid splashing and avoid excessive thinning , Improve the effect of wall thickness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

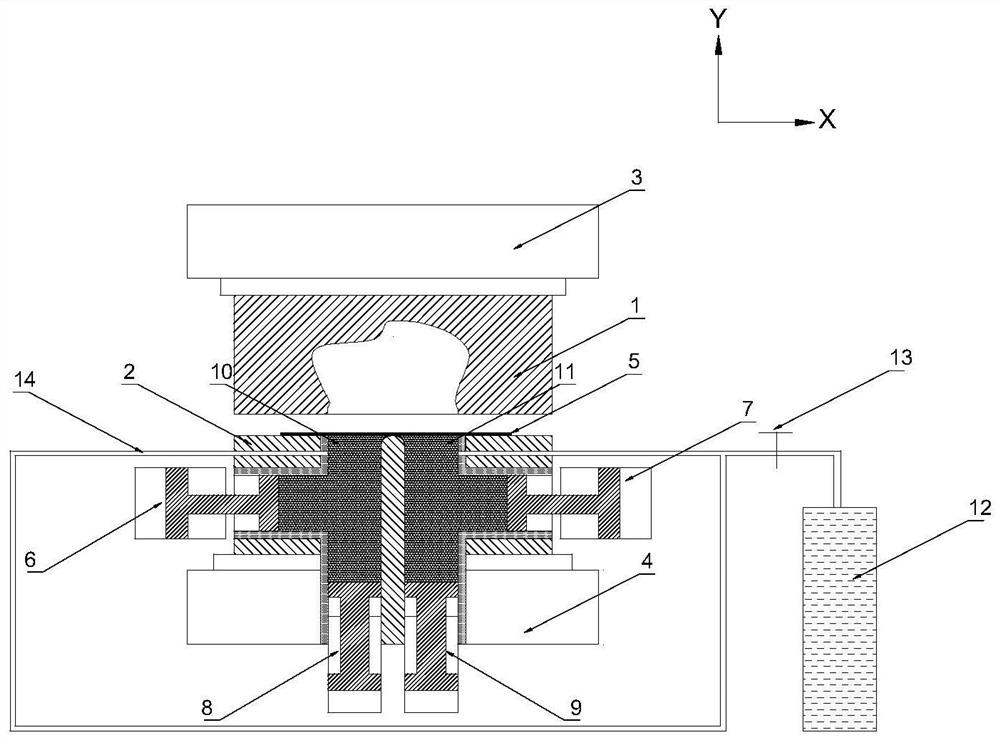

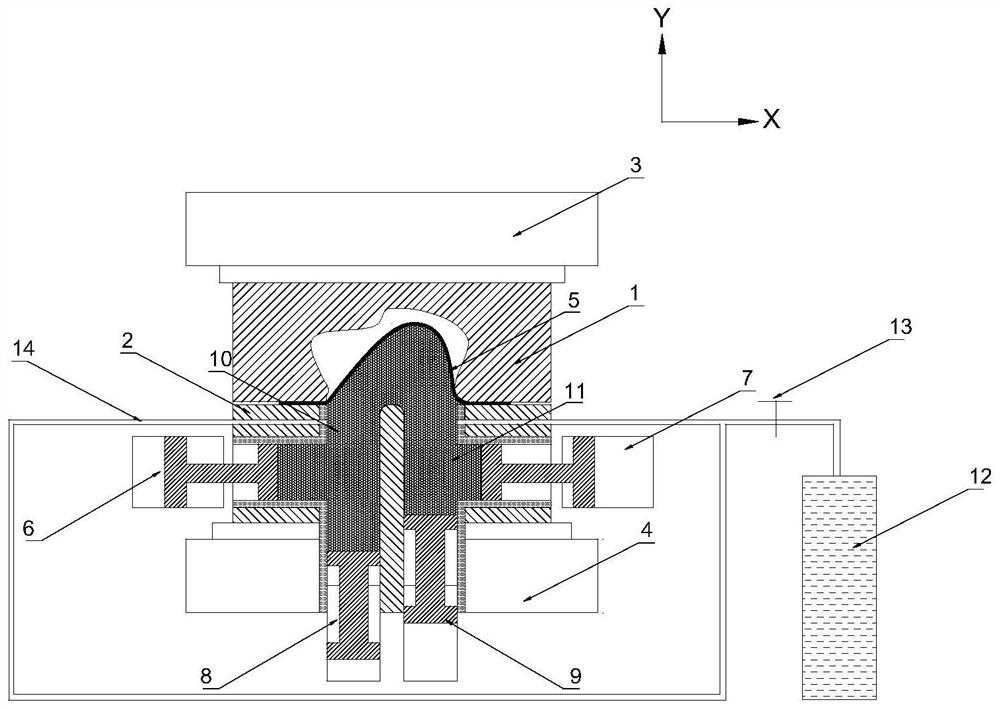

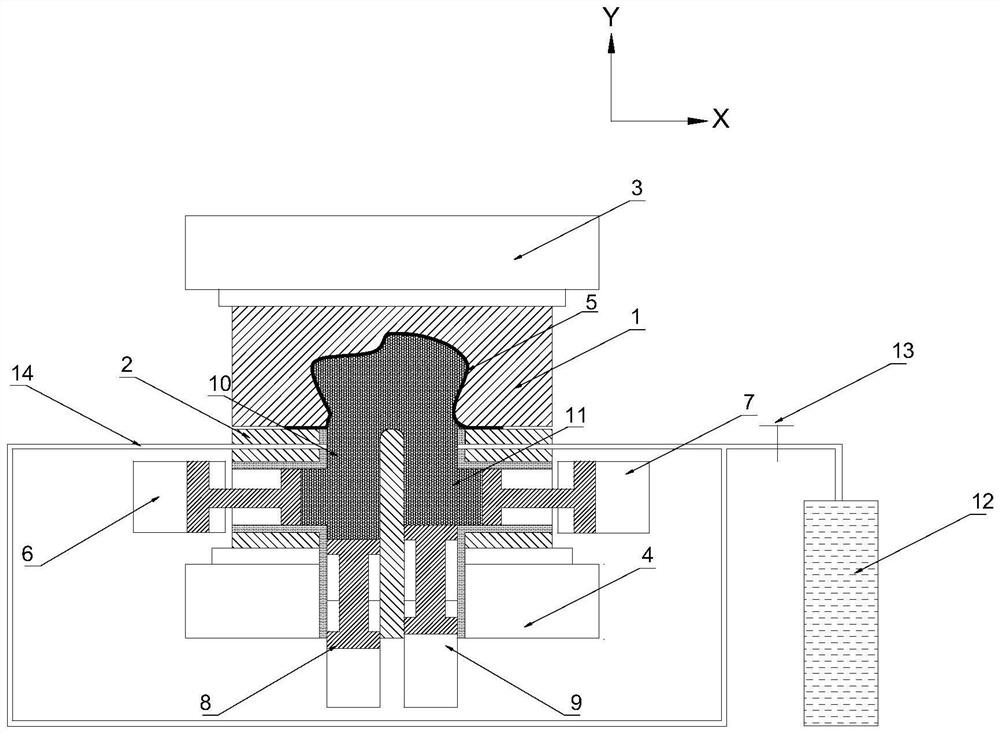

[0083] like Figure 5 and Image 6 As shown, the embodiment of the present invention provides an ultra-low temperature forming method for a 5A06 aluminum alloy complex deep cavity curved surface component, wherein the aluminum alloy slab is 1.5 mm thick, and the length, width and height of the prepared aluminum alloy forming component are 792 mm × 392 mm × 315mm, and there are deep cavity surfaces and deep drawing negative angle features, including the following steps:

[0084] Step S1: the upper mold 1 and the lower mold 2 are in the open state, and the solid particle medium is respectively injected into the first medium cavity 11 and the second medium cavity 10 until they are full;

[0085] Step S2: Passing a cooling medium into the first medium cavity 11 and the second medium cavity 10, so that the solid particle medium is cooled to a temperature of -190° C., and kept for 10 minutes, wherein the cooling medium is liquid nitrogen;

Embodiment 2

[0092] like Figure 7-9 As shown, the embodiment of the present invention provides an ultra-low temperature forming method for a 5182 aluminum alloy complex deep cavity curved surface component, wherein the aluminum alloy slab is 1.2 mm thick, and the length, width and height of the prepared aluminum alloy forming component are 1060 mm × 520 mm × 345mm, there are larger stepped surface and convex surface features, including the following steps:

[0093] Step S1: the upper mold 1 and the lower mold 2 are in the open state, and the solid particle medium is respectively injected into the first medium cavity 11 and the second medium cavity 10 until they are full;

[0094] Step S2: Pass a cooling medium into the first medium cavity 11 and the second medium cavity 10, so that the solid particle medium is cooled to a temperature of -180° C., and kept for 20 minutes, wherein the cooling medium is liquid nitrogen;

[0095] Step S3: placing the pre-cut aluminum alloy slab 5 to be forme...

Embodiment 3

[0102] like Figure 10 As shown, the embodiment of the present invention provides an ultra-low temperature forming method for a 2219 aluminum alloy complex curved surface, wherein the aluminum alloy slab is 1 mm thick, and the length, width and height of the prepared aluminum alloy forming member are 388 mm × 156 mm × 118 mm. Larger double curvature surface features, including the following steps:

[0103] Step S1: the upper mold 1 and the lower mold 2 are in the open state, and the solid particle medium is respectively injected into the first medium cavity 11 and the second medium cavity 10 until they are full;

[0104] Step S2: Passing a cooling medium into the first medium cavity 11 and the second medium cavity 10, so that the solid particle medium is cooled to a temperature of -185°C, and kept for 15 minutes, wherein the cooling medium is liquid nitrogen;

[0105] Step S3: quenching the pre-cut aluminum alloy slab 5 to be formed, the solution temperature is 525°C, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com