Special laser selecting area melting equipment for directly manufacturing metal orthopedics implant

A technology of laser selective melting and orthopaedic implants, which is applied in the directions of additive manufacturing, process efficiency improvement, additive processing, etc., can solve the problems of poor adaptability, medical implants cannot adapt to individualized manufacturing, and long manufacturing cycle, etc. Achieve the effect of small occupied space, compact structure and high powder utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

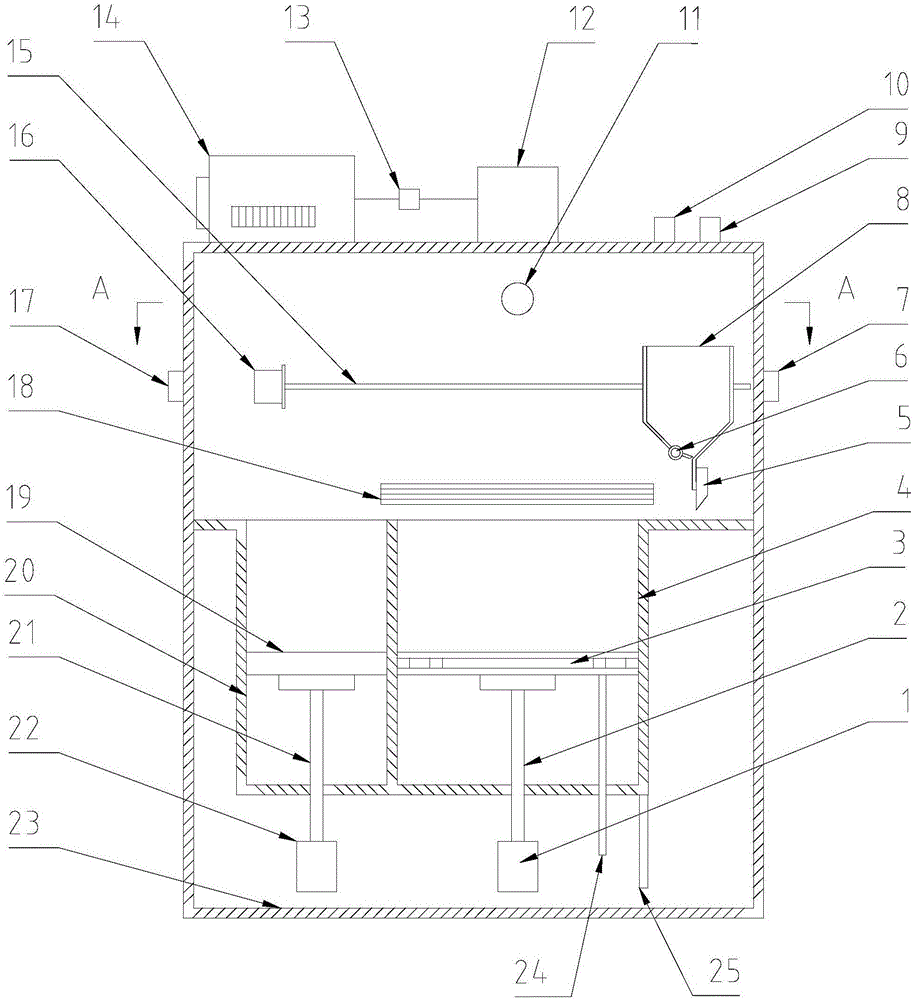

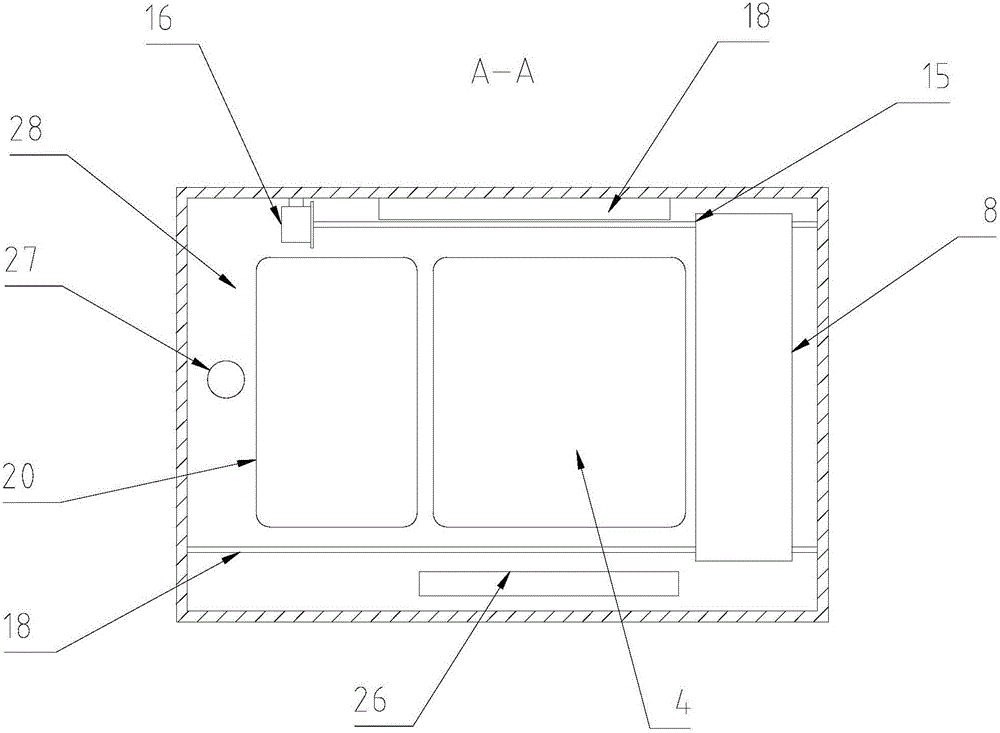

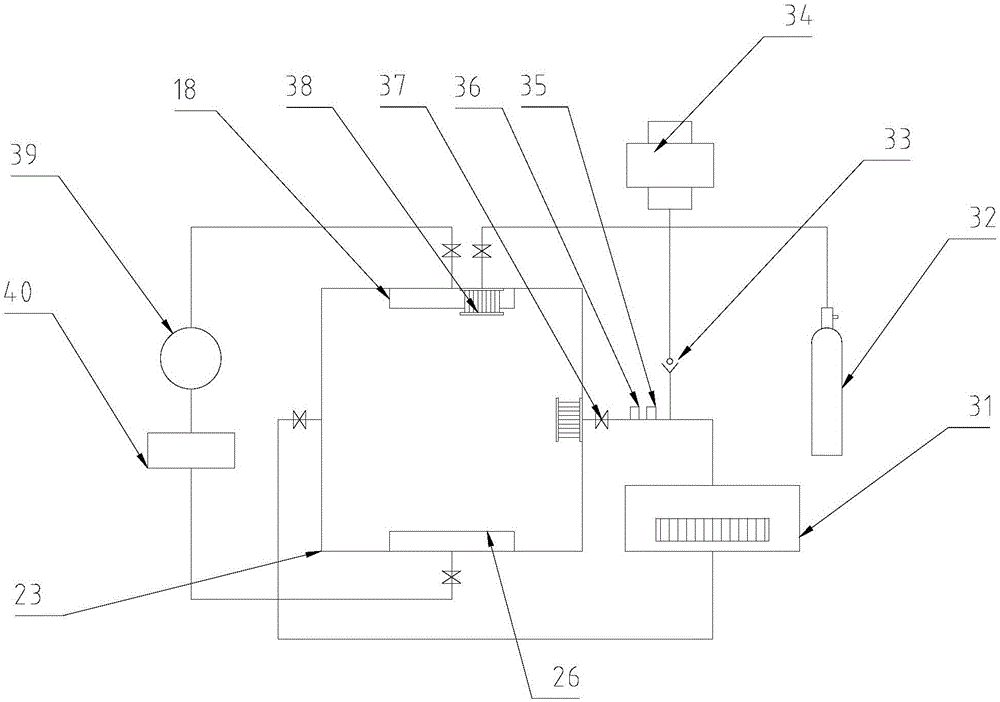

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0047] A laser selective melting dedicated device for the direct fabrication of metallic orthopedic implants such as figure 1 As shown, it includes: forming cylinder servo motor 1, forming cylinder ball screw 2, forming cylinder piston 3, forming cylinder 4, scraper 5, hopper solenoid valve 6, right vent hole 7, hopper 8, sealing chamber pressure sensor 9, sealing Cavity temperature sensor 10, argon supplementary air inlet 11, galvanometer assembly 12, collimator beam expander and field mirror 13, fiber laser 14, hopper ball screw 15, hopper drive motor 16, left air hole 17, rear feeder Air grid 18, powder recovery piston 19, powder recovery cylinder 20, powder recovery cylinder ball screw 21, powder recovery cylinder stepper motor 22, sealed cavity 23, grating reading head 24, scale grating 25.

[0048] figure 2 yes figure 1 The cross-sectional vie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com