Preparation method of printed circuit board and copper foil for processing

A printed circuit board and copper foil technology, which is applied in the fields of printed circuit manufacturing, printed circuit, printed circuit parts, etc., can solve the problems of endangering the health of the staff, the health of the operator, and the inability to reuse, so as to reduce the production time , avoid the infringement of toxic substances, and reduce the effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

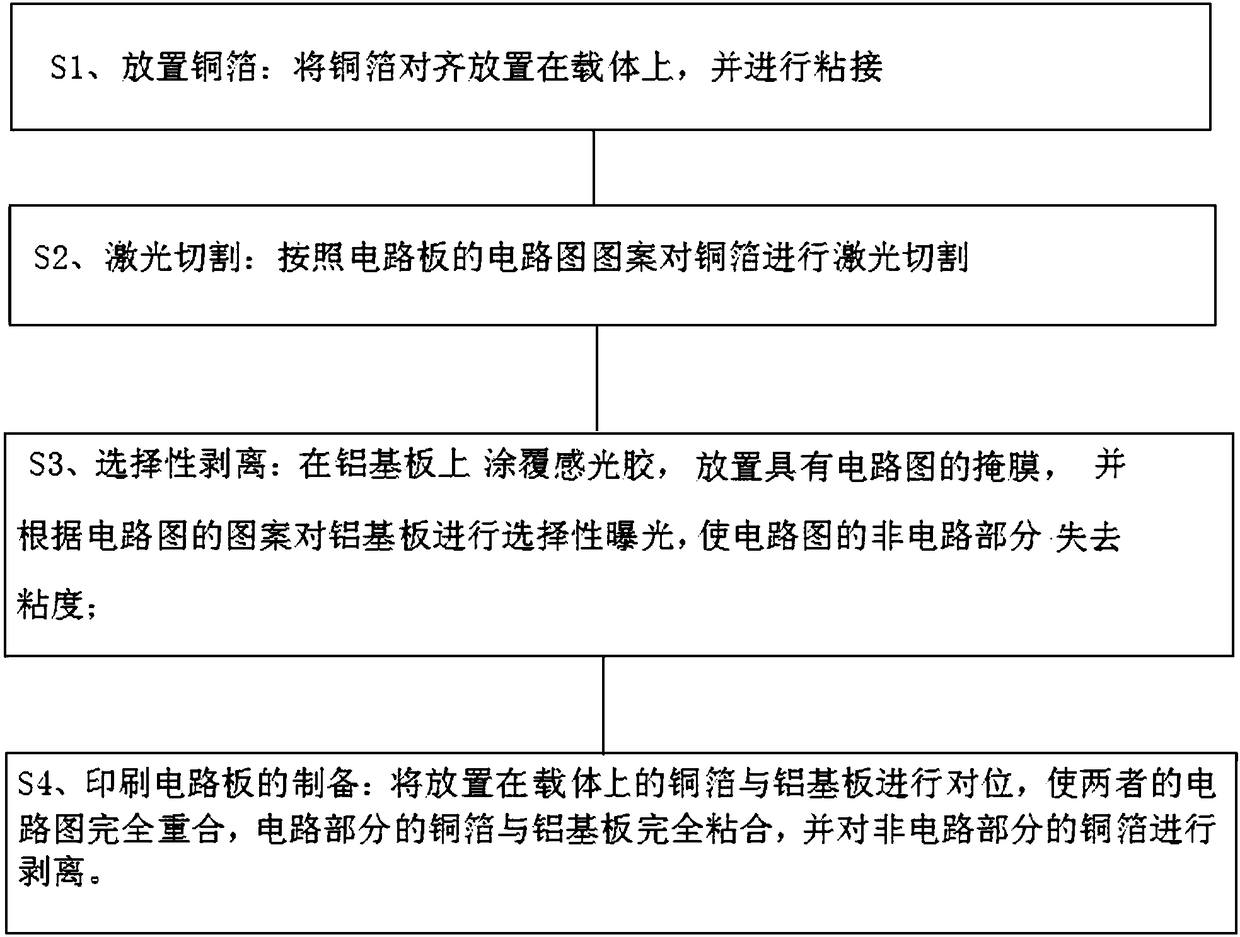

[0033] The invention provides a method for preparing a circuit board, such as figure 1 As shown, it includes the following steps:

[0034] S1. Place the copper foil: place the copper foil on the carrier and compound it with sticky substances;

[0035] S2. Laser cutting: laser cutting the copper foil according to the circuit diagram pattern of the circuit board;

[0036] S3. Selective peeling: Coating photosensitive glue on the aluminum substrate, and placing a mask with a circuit diagram, selectively exposing the aluminum substrate according to the pattern of the circuit diagram, so that the non-circuit part of the circuit diagram loses viscosity;

[0037] S4. Preparation of printed circuit board: Use the alignment device to accurately align the copper foil placed on the carrier with the aluminum substrate, so that the circuit diagrams of the two are completely overlapped, and the copper foil of the circuit part is completely bonded to the aluminum substrate, and the The cop...

specific Embodiment 1

[0046] The working principle of the present invention is further explained below in conjunction with specific embodiments:

[0047] 1. Preparation of photosensitive adhesive

[0048] Mix epoxy resin, calcium hydrogen carbonate, silicone resin, epoxy acrylic photosensitive resin, magnesium hydroxide, aluminum hydroxide, and diluent in a ratio of 50:2:0.03:60:1:10:20:20:80 After stirring and dissolving evenly, use sand mill equipment to grind to a fineness of less than 5 microns; add dihydroamine curing agent and imidazole catalyst, measure the viscosity and pack it after the viscosity is qualified.

[0049] 2. Laser cutting to obtain circuit boards

[0050] Align and place the copper foil on the carrier and bond it; in S1, the copper foil is placed on the PET substrate through an adhesive substance. Laser cut the copper foil according to the circuit diagram pattern of the circuit board; apply photosensitive glue on the aluminum substrate, place a mask with a circuit diagram, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com