Three-coordinate galvanometer scanning laser processing head

A laser processing head and galvanometer scanning technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of lack of modularization and independent interface characteristics, difficulty in realizing complex curved surface workpieces, and difficulty in disassembly and installation. Achieve the effect of simple combined processing, compatible functions, and not easy to disassemble and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Typical implementations of the present invention will be described in detail below with the help of drawings and examples.

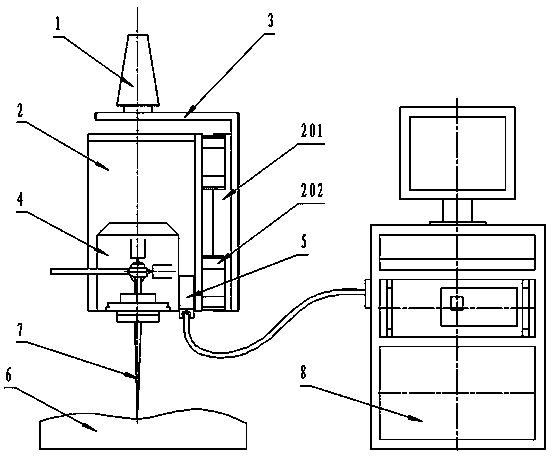

[0017] The three-coordinate galvanometer scanning laser processing head of the present invention has a structure such as figure 1 As shown, it includes: clamping mechanism 1, Z-axis moving mechanism 2, bracket 3, XY two-axis laser vibrating mirror system 4, laser displacement sensor 5 and control system 8. The Z-axis moving mechanism 2 , the XY two-axis laser vibrating mirror system 4 , and the laser displacement sensor 5 are all electrically connected to the control system 8 . The bottom of the clamping mechanism 1 is installed on the bracket 3, which is used to install the laser processing head on the multi-axis linkage CNC machine tool; the Z-axis moving mechanism 2 is also installed on the bracket 3, which is used to adjust the XY two-axis laser galvanometer system The Z-axis position, which can move up and down along the Z-axis direction; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com