Tool device and method for machining large turbine blade combined partition plate

A steam turbine blade and processing method technology, which is applied in metal processing equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of difficult weld formation, increased difficulty of arc welding with electrodes, and welding bumps, and achieves the convenience of reaching the molten pool close to the level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

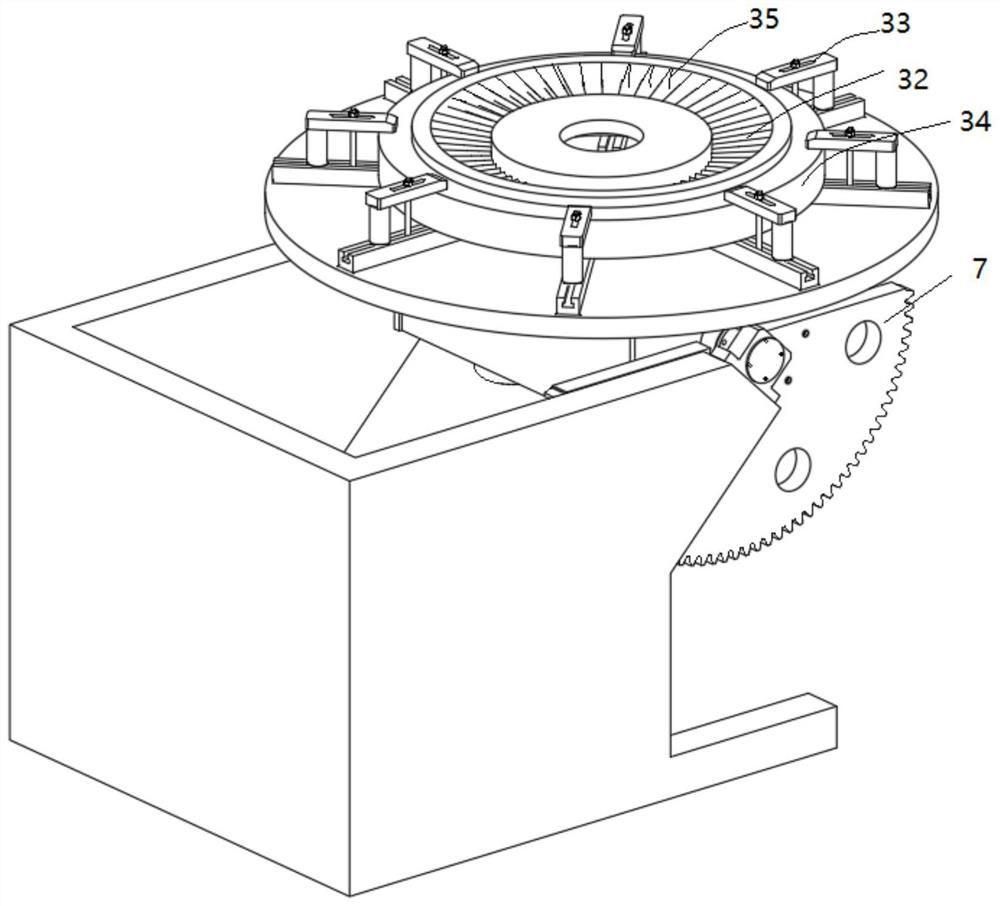

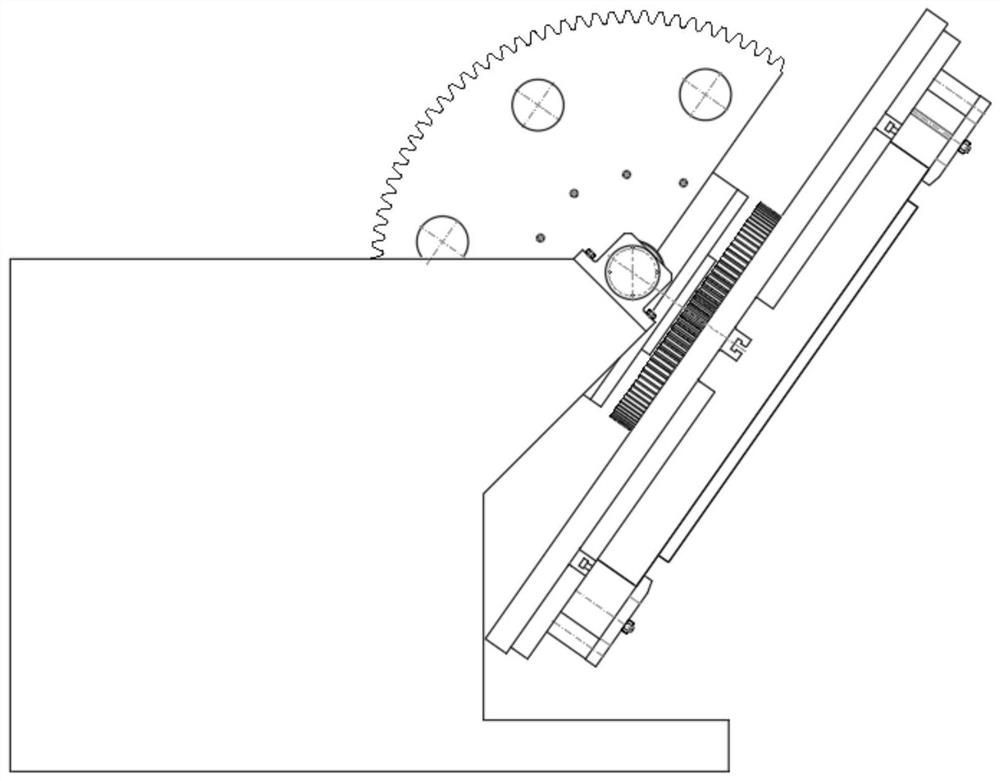

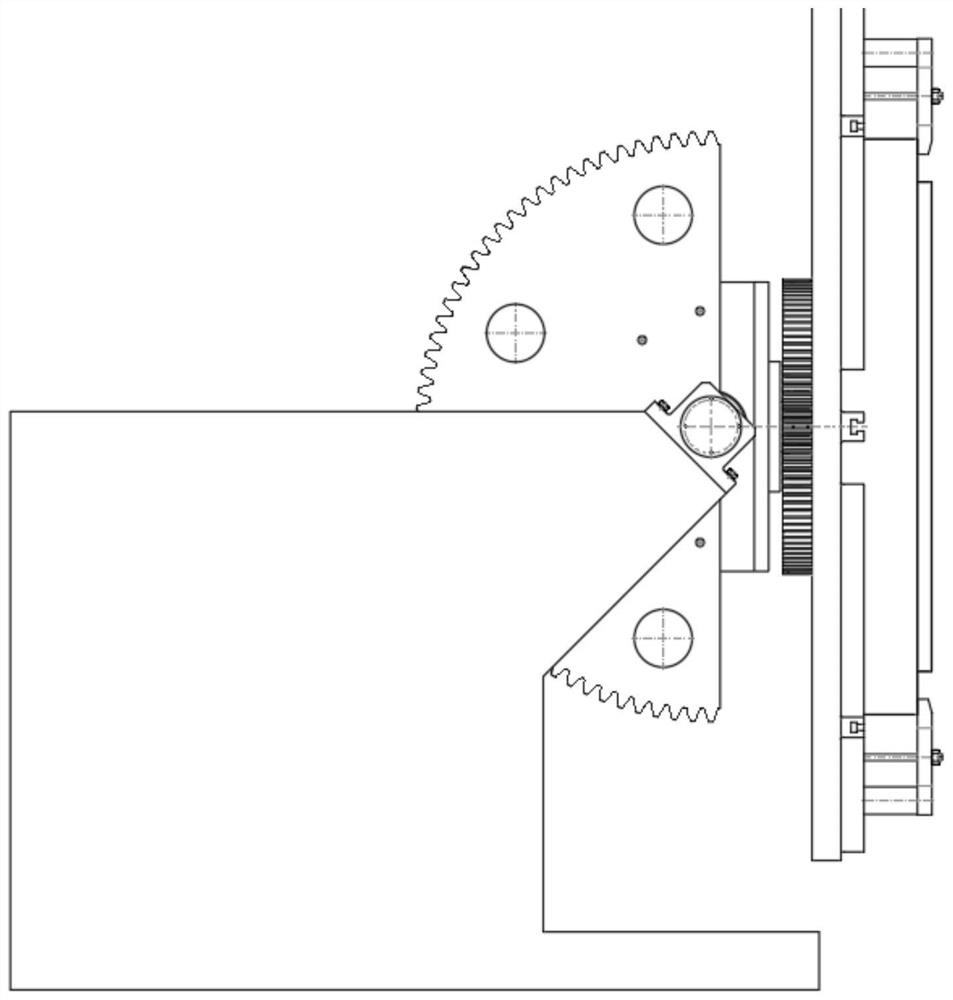

[0018] As shown in the figure, the present invention includes a base 1 and a rotating bracket 8. The inside of the base 1 is provided with a transmission motor 2. The transmission motor 2 is connected to the reducer 5 through the motor coupling 3 and the reducer coupling 4. The reducer 5. The other end is provided with a reducer gear 6. The reducer gear 6 drives the large gear 7 through meshing. The rotation range of the large gear 7 is controlled by the limit switch 9. The large gear 7 is fixed on the rotating bracket 8 by bolts. The rotating bracket 8 is equipped with a Transmission shaft 19, transmission shaft 19 is fixed with transmission bearing 15 by lock nut 14, is provided with transmission bearing spacer 16 in transmission bearing 15; Transmission shaft 19 one ends are provided with transmission gear 18, and transmission gear 18 is fixed on the turntable 10 by bolt, and turntable 10 is fixed on the transmission shaft 19 by turntable end cover 20; And rotary shaft 25, o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com